5th axis rotary table manufacturer

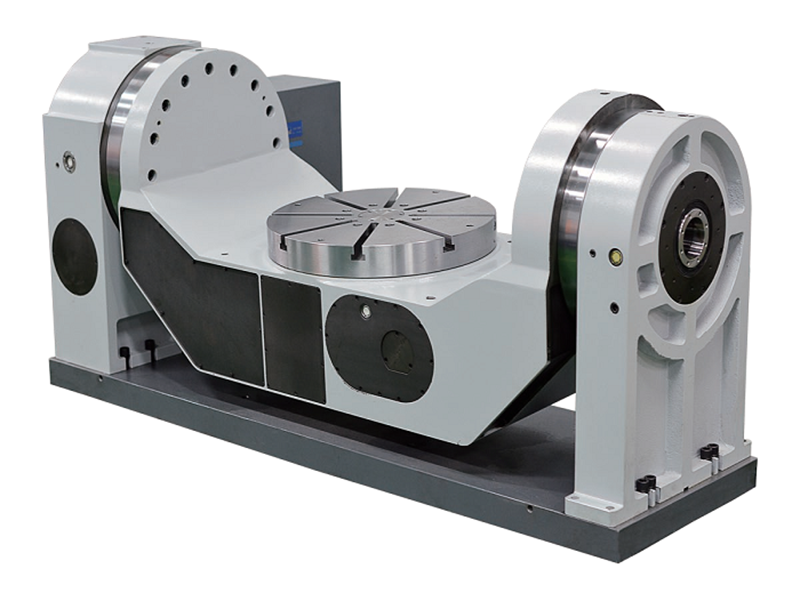

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises. ...

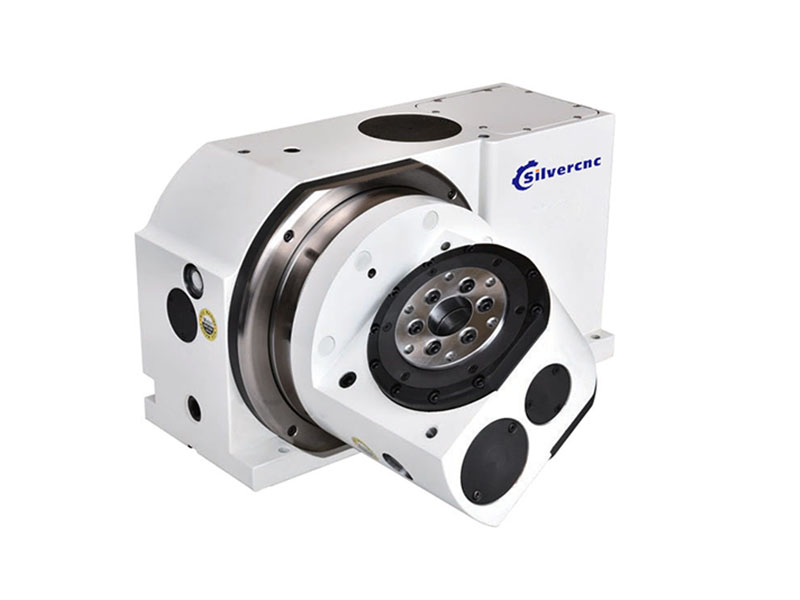

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables ...

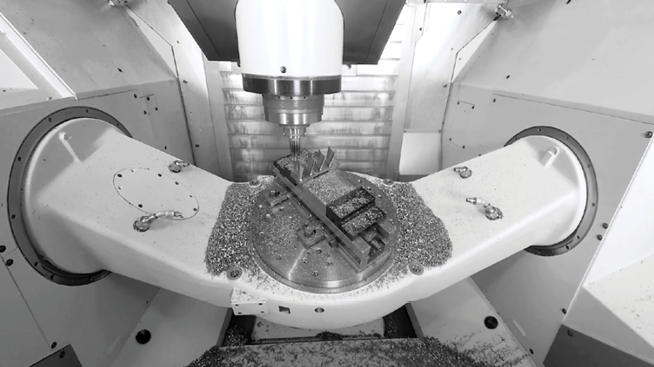

#cncmachining #cncmanufacturing #manufacturing #indianmanufacturing #machinist #metalcutting #5thaxis #5axis #cncmill #cncmachine #5axismill #machineshop #5axiscnc #rotarytable

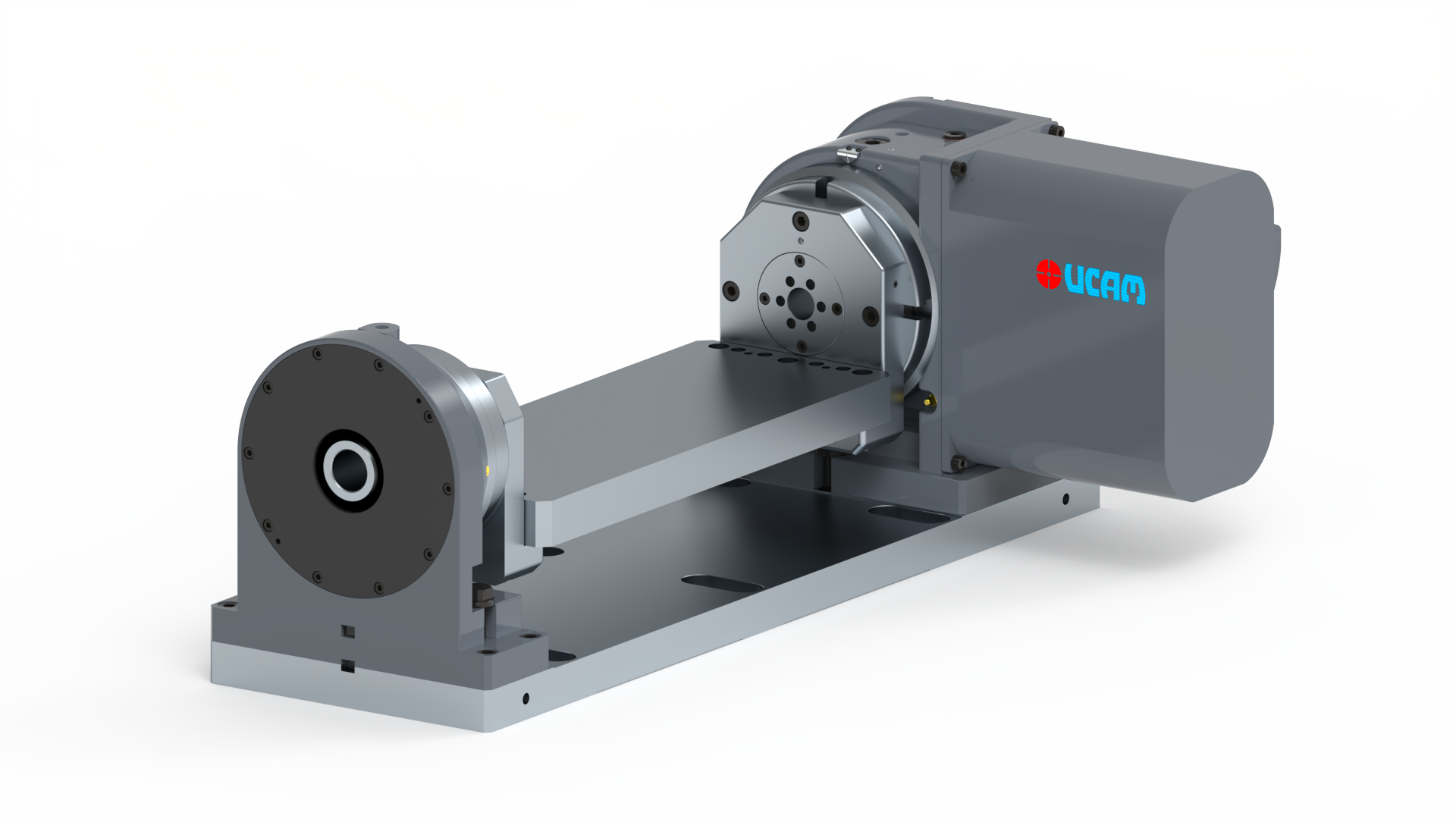

About UCAM: We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others.

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

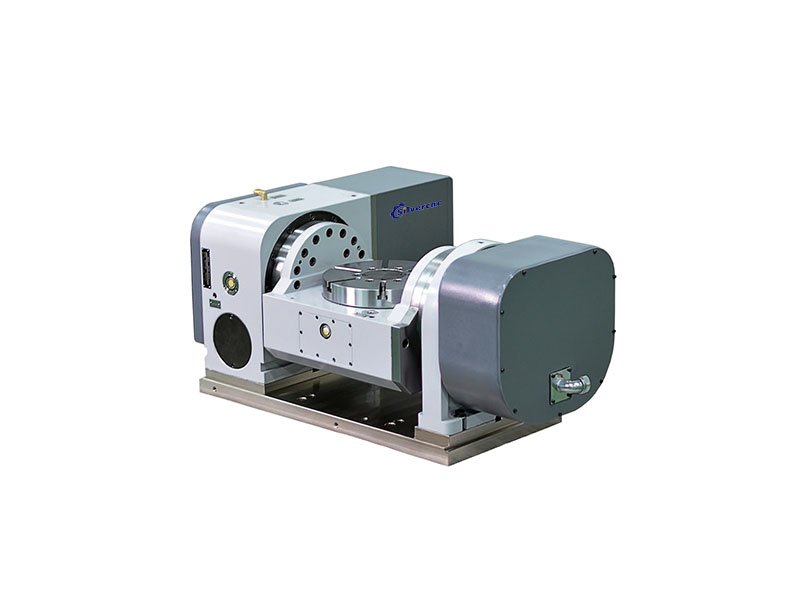

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

5 axis rotary tables allow you to work with an additional dimension. In addition to the two rotary motions, these indexing tables have an extra swinging axis allowing it to tip as well as turn.

5th Axis CNC Rotary Tables are perfect for larger manufacturers. They offer unmatched levels of versatility, precision and efficiency. Here at 1MTA, we are able to supply a 5 axis indexing table to suit your budget or project size. We also offer a bespoke, custom solution to your project which you can learn more about here.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

Because the tilting axis normally needs to bear a heavy load, a robust transmission mechanism for the tilting axis should be employed to improve the wear resistance and precision of the tilting axis. Thus, we can provide roller gear cam, alloy steel worm gear, or Japanese- made worm & worm gear (wear life is 2.6 times longer than aluminum bronze PBC3.) as the transmission mechanism of the tilting axis.

Tsudakoma has been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

Stop building custom adapters and subplates for every new job that comes into the shop. With the patented RockLock system job changeover becomes simple and repeatable, saving you time and money.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

A 5th axis rotary table is a precision positioning device that is widely utilized in the 3-axis vertical machining center, which turns the original machine tool to a 5-axis CNC machine. The simple installation and seamless interface make the 5th axis rotary table fit numerous 4-axis and 5-axis applications.

A 5th axis rotary table is a precision positioning device that is widely utilized in the 3-axis vertical machining center, which turns the original machine tool to a 5-axis CNC machine. With the rigid cast frame and the ideal torque capacity, the small accessory is flexible in use and supports the various machining operations of the vertical machining center effectively. The simple installation and seamless interface make the 5th axis rotary table fit numerous 4-axis and 5-axis applications.

5th axis rotary table, like the basic level of the rotary table, is designed for accurately locating the work pieces in metal machining operations under rapid and high performance rotation. All kinds of rotary tables are popular to be employed in various metalworking equipment, larger tables and machines in order to perform accurate drilling, milling, boring, or adding other unique features on the metal parts at extremely precise intervals. The tooling operations are smoothly performed around the vertical or horizontal axes. To provide more flexible options of use and also even more precise positioning for machining, there are additional plates like index plates or dividing plates can be mounted on for more applications.

With the rise of modern CNC machines and 5-axis machining productions, there are more and more tailed 5th axis rotary tables or tilt tables manufactured to act as the additional axes, assisting the various cutting tools to remove the materials from the surface of work pieces, especially the place that is hard for the tools to reach. In a 3-axis machine, there are only X, Y and Z axes, which are the linear axes to perform the precision machining. The A, B, C axis in 4-axis or 5-axis machining centers are the additional, rotational working axis which are 180° work around the X, Y, Z axis correspondingly. By employing a 5th axis rotary table, the CNC machining center can add 2 rotational directions to not only increase the versatility of the machines but ensure more ideal accuracy in multiple face cutting.

As mentioned, many shops achieve 5-axis CNC machining by mounting the 5th axis rotary table, which is much more cost-efficient than purchasing a new machine. The easy plug-and-play rotary table is easy to set up as the 4th or 5th axis, permitting a wide variety of complex, high performance machining. The great rigidity of the rotary table permits heavy load. However, the 5th axis rotary table takes considerable space of the 3-axis vertical machining center at the same time. As a result, the work surface is, in the arrangement, more suitable for relatively small parts, which refer to pieces that are smaller than 30 cm or less. On top of that, the operator needs to make sure the control system of the machining center is available for 5-axis operations.

Upgrading the machining center by installing the 5th axis table eliminates the extra finishing jobs performed in other machines or manual adjustments. This is especially beneficial for large volume production. The 5th axis rotary table allows the vertical machining center to create sophisticated and complex contours and add multiple features at desired angles. The arrangement of adding this rotary table to upgrade the machining center is suitable for blade, helical grooves machining and other applications required to create complex features or require critical inspection, like the productions of aerospace, automotive parts and scientific equipment.

The 5th axis rotary table mounted on the vertical machining center provides great rigidity to ensure stable operations. With simple set up, the rotary table can save the cycle time and remove the need of secondary operations. The basic structure of a 5th axis rotary table consists of the disc table where the work pieces are firmly hold and secured, the rigid bearing which can support the forces and loads during the operations, the solid base or bed used for attaching the 5th axis rotary table to the 3-axis machining center or other component, and last but not least, the motor and the

The core of the 5th axis rotary table is the worm gearing meshing with the steel worm that is submerged in the lubricants. The bearings and the worm gears which typically have large diameters have ideal concentricity to ensure the smoothness, durability as well as utmost accuracy. The high performance tooling is performed on the surface provided by the table disc, where the work pieces are stably clamped. Under the guide of the CNC power system and the electric motor, the table disc can position the metal parts at exact intervals. The clamping element, which is the chuck with inner or outer jaws, grips the work pieces firmly to eliminate any movement that will affect the machining. When the work pieces are relatively wider, longer, the operator can choose a chuck with outer jaws to hold them. For more flexible or critical applications, the operator can add dividing plates which can be installed on this table disc.

The worm gear and high precise rotation is driven by the programmed signals from the computer numerical control system. CNC power system ensures the simultaneous 4-axis or 5-axis motion, and the servo control is simple to fully set up. With the software and sequential instructions sent by the CNC system, the machining operations are more reliable and efficient, removing the need and cost of human supervision. The dimension as well as the type of electric motors can determine the actual router accuracy and also the efficiency of the 5th axis table.

NIKKEN’s world-renowned CNC Rotary Table range provides proven performance, reliability and accuracy benefits for any application or requirement that others simply cannot hope to emulate.

With an extensive range of rotary table sizes, configurations and options available, all fully supported by our extensive global network, you can be sure to find the perfect product to meet any requirement or machine tool.

Single Axis, Twin Axis, Multi-Spindle, Standard Drive, High-Speed Drive, and Direct Drive capabilities are all available from stock. These can be configured and supplied for control directly by the CNC Machine or by integrating our exclusive Alpha 21 and EZ controllers to provide precise positioning and also full Macro B control (Macro B function – Alpha 21 only).

NIKKEN can also provide a complete and expansive range of accessories precisely engineered and customised to suit both the machine tool and the component. These options include a wide variety of chucking solutions, vices, bespoke trunnions & workpiece fixturing along with a wide range of NIKKEN manufactured rotary work supports and tailstocks to cater for all production expectations.

TJR’s standard tilt rotary tables offer several options for turning your traditional 3 axis milling machine into a 5 axis machine for a portion of the cost of a new full 5 axis machine.

The FAR-Series pneumatic brake tilt rotary table line and is offered in multiple sizes and configurations and is available in single arm or dual arm type.

The FHR-Series is a dual arm, hydraulic brake tilt rotary table line offered in multiple sizes and configurations. This series has (3) independent braking systems, and max tilting angle +/- 110 degrees.

The FAR and FHR Series standard tilt rotary tables are capable of being fully integrated into your current machine control so you can utilize as a full rotating and tilting axis for true 5 axis work. It is also capable of being used as a full 4th and 5th axis connecting to TJR’s DAC (Dual Axis Controller) in the event that you need to utilize the unit on multiple machine tools. All are manufactured with large-diameter radial-axial preloaded bearing system for high rigidity that can perform light or heavy cutting.

8613371530291

8613371530291