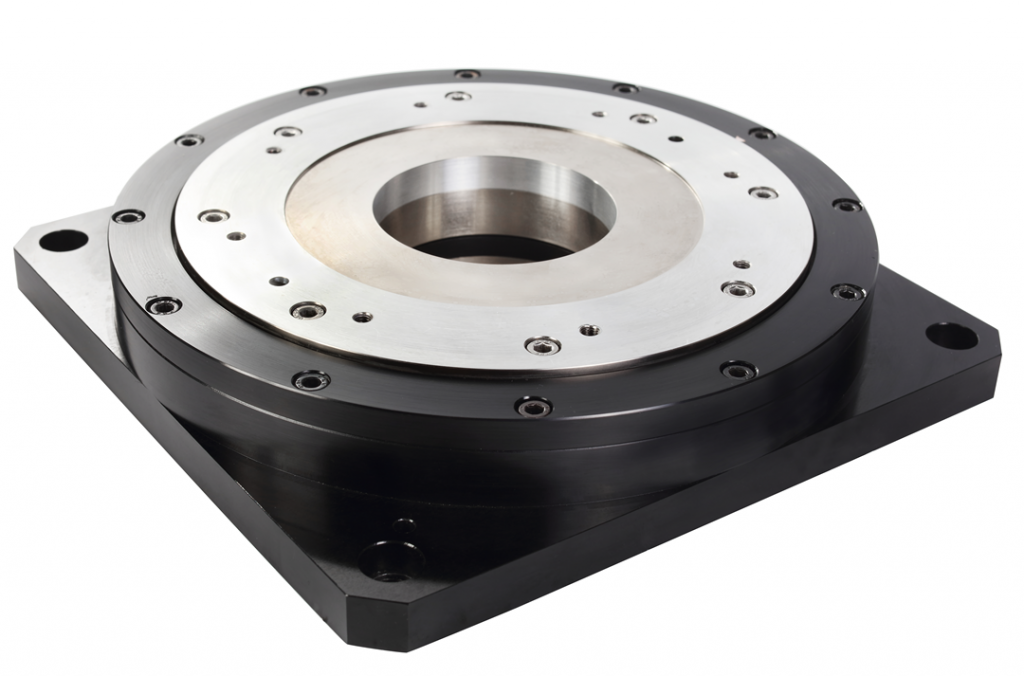

direct drive rotary table in stock

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

The requirements for rotary positioning are diverse. For high-precision, dynamic positioning, ITK offers the FRS200 rotary table with direct drive and many advantages for the user.

The extremely flat FRS200 stands out among the rotary tables because it meets very high requirements for axial runout, concentricity, repeatability and overall height. With an overall height of only 28 mm, a diameter of 200 mm and an accuracy of less than 10 µm, it is among the absolute top class on the market. The rotary table also benefits from a large central hollow shaft with a diameter of 50 mm for feeding through cables, connectors, spindles, vacuum, etc., which significantly increases the degree of integration on the application side. The integrated measuring system with reference marks allows the recurring and very precise location of a dedicated position within the 360° motion sequence at any time with repeat accuracies of ± 1 arcsec. Very good axial and radial run-out characteristics as well as a high positioning accuracy enable the very precise movements. ITK"s in-house developed controls are optimally matched to the FRS200 and are an essential part of the mechatronic assembly to exploit the full performance potential. The patented technology also ensures good heat dissipation.

The FRS200 rotary table is intended for applications in the optical industry for measuring and bonding lenses, in measuring machines of all kinds, wire bonding machines or in the semiconductor industry in inspection systems for testing wafers.

There is no mechanical reduction mechanism such as a worm system in a rotary table with a DD motor. DD (Direct Drive) motor is built in the rotary table to drive directly. The compact two-axis direct drive rotary table enables rapid acceleration/deceleration and high-speed rotation. Its biggest advantage is the super high speed up to 2000 rpm. Thus, it can work as a mill/turn component. As a result of the lack of a mechanical reduction mechanism, the driving torque of the rotary table is not strong. It is necessary to choose an application for the rotary table with a DD motor.

A high torque motor drives the direct drive rotary table directly. There is no backlash or abrasion generated during rotation because it is not driven by worms and gears. Typically, these rotary tables are used in applications requiring high accelerations and decelerations, such as blade machining. For high-speed drilling centers with very important indexing times, a two-axis direct drive rotary table is an excellent choice.

Tsudakoma has developed the new RDS series direct-drive rotary tables. This series utilizes Tsudakoma’s proprietary direct-drive motor system, enabling the rotary table to achieve high speed and acceleration with no backlash.

The RDS-200 model is a compact single-axis, 150-rpm, direct-drive rotary table with indexing accuracy of ±10 arc seconds and a strong pneumatic braking system. Various options such as rotary joints, chucks, tailstocks, support spindles and faceplates are available. The RDS-200 can be effortlessly integrated with machine tools that have FANUC or Mitsubishi controls. Integration with other controls will be available soon.

This series also features a slim low profile build that makes it suitable for mass production and high-speed indexing operations in the automotive, medical and computer/electronic manufacturing industries. The combination of these innovative technologies makes Tsudakoma rotary tables the most reliable and productive in the industry.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

Rusach International & Innovative Rotary Table Solutions are a leading worldwide supplier of small to medium sized compact CNC rotary tables, standard and application oriented designs, high accuracy, compact rotary tables. Thru bore rotary tables, horizontal rotary tables, vertical rotary tables, combination/convertible H-V rotary tables, multi spindle rotary tables, 2-axis tilting rotary tables, direct drive rigid and flexible rotary tables. Production style rotary tables to fit any machine.

Innovative Rotary Table Solutions has a full line of accessories like tail stocks, magnetic plates, rotary supports, steady rests, rotating tail stock supports and controllers, all designed to fit your application. Contact Rusach International today with your application.

An accuracy specification of ± 3 arcseconds with repeatability of ± 2 arcseconds for this direct-drive rotary indexing table is verified using precision laser measurement.

The advantages of applying fourth-axis machining capability to the shop floor are self evident, especially when high accuracy, ±3 arcsec and ±2 arcsec repeatability class are called for. The question becomes what type of rotary tables should be under consideration? This article makes the case for direct-drive rotary technology as applied to high accuracy rotary tables.

A direct-drive rotary table consists of housing, bearings, an encoder, and a spindle that uses a high-energy, rare-earth permanent magnet DC torque motor rotor wrapped around itself—sometimes referred to as an integral spindle motor. The encoder is mounted directly to the spindle to provide position feedback.

Play or “slop” is virtually eliminated in a direct-drive system because one potential source for such compliance—indirect gear drives—is not used in a direct-drive system. Therefore, no compliant couplings exist between the motor and the load.

Also, since there are no gears between the motor and the load, there is no backlash. Accordingly, the servo gain (stiffness) can be high without any concern regarding servo instability. And since there is no backlash, bidirectional movement can be made without the need to compensate for backlash error.

Positioning speed is limited only by the torque available to accelerate the inertia from the load (work-piece) to be positioned. Very high accelerations and positioning speeds are achievable on models of these rotary table types. These high accelerations/decelerations are the same as seen with DC linear motors that are used as axis drives on some machine tools.

The only losses that will create heat are in motor losses and bearing losses. However, brushless permanent-magnet DC torque motors are typically run 90 percent (or more) efficient. The direct-drive rotary system used on these rotary tables was designed with a predictable continuous duty cycle at a certain torque output.

For all practical purposes, a table will not be used in this manner, so intermediate-duty cycles that use much more torque than the continuous rating up to the peak torque available can be used without much concern. If cooling liquid is required for loads generated by off-center drilling or other rigorous duty cycles, you simply connect a standard coolant line to the housing, using the existing machine’s coolant supply.

Another advantage of direct-drive rotary tables is that if a position move is made with the intent of cutting while stationary, it may not be necessary to clamp the spindle. If the cutting forces to be applied are within the torque available from the motor, the servo will hold position with plenty of stiffness to permit the cut, since there is negligible compliance in the direct-drive system.

This is a different approach from traditional geared systems that use a servomotor at the end of a power transmission linkage. With the direct-drive system, after the cut, since no clamp was applied, there is no time delay to wait for the clamp to release, so movement to the next programmed position will be faster.

The CNC machining centers available on the market today generally have fast axis travels as machine builders have attempted to reduce the time a machine is not in the cut and to increase the amount of material removed. If the machine axes travels are faster than the positioning speeds available from the rotary unit, the machine will often be waiting for the unit to position.

The faster a rotary unit can move from one position to another, the less time the machine is waiting to cut and the faster the cycle time. Hardinge’s fourth-axis direct-drive rotary system is capable of indexing speeds as high as 4,200 degrees per second. Faster direct-drive rotary technology provides speeds that will take advantage of the faster axis travels, but it also offers the ability to do complex bidirectional machining at rates faster than can typically be done on geared systems.

These rotary systems are available for use not only on Bridgeport, but also for most other brands of machining centers. It is designed to take advantage of “look-ahead” programming when integrated on machines with that capability.

irect-drive rotary technology may not be the answer for all applications, of course, but when it fits the application, it will produce outstanding results and will enable the user to stay on the cutting edge of productivity. Its high-precision positioning and repeatability has opened the door to jobs that were previously out of reach, or jobs that were lost to competitors who could simply get the job done faster.

NIKKEN’s world-renowned CNC Rotary Table range provides proven performance, reliability and accuracy benefits for any application or requirement that others simply cannot hope to emulate.

With an extensive range of rotary table sizes, configurations and options available, all fully supported by our extensive global network, you can be sure to find the perfect product to meet any requirement or machine tool.

Single Axis, Twin Axis, Multi-Spindle, Standard Drive, High-Speed Drive, and Direct Drive capabilities are all available from stock. These can be configured and supplied for control directly by the CNC Machine or by integrating our exclusive Alpha 21 and EZ controllers to provide precise positioning and also full Macro B control (Macro B function – Alpha 21 only).

NIKKEN can also provide a complete and expansive range of accessories precisely engineered and customised to suit both the machine tool and the component. These options include a wide variety of chucking solutions, vices, bespoke trunnions & workpiece fixturing along with a wide range of NIKKEN manufactured rotary work supports and tailstocks to cater for all production expectations.

Ensure that your servo drive can handle the Nominal- and Peakcurrent of the Motor. An adjustment of the Speed and DC Bus Voltage can be done after consultation. The nominal data in this datasheet are based on an ambient/coolant temperature of 20°C.

The global Direct Drive Rotary Tables market size is projected to reach multi million by 2028, in comparision to 2021, at unexpected CAGR during 2022-2028 (Ask for Sample Report).

The Direct Drive Rotary Tables has several applications, including: Machine Tool,Cnc Rotary Conveyor,Milling Machine,Machine Center,Others. Based on types these are segmented in External Rotation Direct Drive Turntable,Internal Rotation Direct Drive Turntable. The market for Direct Drive Rotary Tables is highly competitive. There are a number of major market players in the market, including Hiwin Technologies Corp.,Rototrans,NIKKEN KOSAKUSHO WORKS, LTD,IntelLiDrives,PI USA,MASTED ASSEMBLY,SOLPOWER Machine Electronics Corp,Yukiwa Seiko Inc.,MMK Matsumoto Corporation. The report provides an expansive market geographical regions analysis by covering areas like North America: United States, Canada, Europe: GermanyFrance, U.K., Italy, Russia,Asia-Pacific: China, Japan, South, India, Australia, China, Indonesia, Thailand, Malaysia, Latin America:Mexico, Brazil, Argentina, Colombia, Middle East & Africa:Turkey, Saudi, Arabia, UAE, Korea.

Key Benefits for Industry Participants & StakeholdersThis Direct Drive Rotary Tables research report gathers the current position and the future prospects of the global market along with various market segments and analytical components.

Through a broad and profound analysis of the global and territorial markets, the Direct Drive Rotary Tables market report has generated different aspects to resolve obstacles and combat the competitive environment.

This Direct Drive Rotary Tables research report provides an expansive market analysis of the desired sector by wrapping areas like growth drivers, trends persisting in the endeavor, regulatory framework prevalent in the sector as well as a comprehensive SWOT analysis.

Sections in Direct Drive Rotary Tables Market Report:Section 1 mainly consists of an overview and an introduction of the Direct Drive Rotary Tables company focusing on the important figures and statistics of the market.

Section 2 comprises numerous marketing methodologies, sales generation, consistency key factors, and the overall growth of the Direct Drive Rotary Tables company.

Section 3 chiefly covers the analysis of the effect of the impact of the Direct Drive Rotary Tables industry on the development and growth factors of the market across the globe.

Section 4 primarily gives pointers on the current and future prospects of the Direct Drive Rotary Tables company along with their culture and regional growth.

Section 7 enlists the benefits of the Direct Drive Rotary Tables company, by providing a full overview of the feasible company verdicts which include SWOT analysis, product profiles, and corporate growth.

Section 10 is the final section of the Direct Drive Rotary Tables market report that summarizes and gives a full stop to all arguments and wrong interpretations by providing the right outcomes to the reader end.

The Direct Drive Rotary Tables research report covers all topics of the company including marketing methodologies, analysis of the growth and performance, and interaction with real-time consumers.

It contains all the components of numerous market ideas, prototypes, product profiles, trends, and figures a user needs to evaluate the growth of the Direct Drive Rotary Tables company.

Another significant subject of this market report is the necessity to grade and evaluate the effectiveness of the Direct Drive Rotary Tables company in the global development of the firm.

In addition to this Direct Drive Rotary Tables research study, it aids in business marketing, business analysis, and overall performance with respect to the competitive field.

The Covid-19 Pandemic has hyped up the reality and has drastically affected the financial and developmental criteria of the Direct Drive Rotary Tables market. These features have shattered the core sustaining pillars of modern world economies. Even to the current date, the economic shock and impact arising from the Covid-19 pandemic are still being weighed. Data information and statistics of the Direct Drive Rotary Tables report remained in flux, and government policies fluctuate to extremes, as the killer virus swept through nations, affecting production, disrupting supply chains, and unsettling the financial markets. The report produced by the Direct Drive Rotary Tables company mainly focuses on and comprises several actions and plans devised by the company to make up for the loss and upskill their profits.

This Direct Drive Rotary Tables study highlights that there is a paradigm shift in the market regarding regional competitive advantages and the competitive environment of comparatively larger companies. The Direct Drive Rotary Tables research report is an extensive study that focuses on overall consumption patterns, development trends, sales figures, and economical crises in key countries of the Direct Drive Rotary Tables market. This report focuses on the well-recognized suppliers of the industry, market components, competition, and macro environment. A complete market investigation is carried out taking into account various factors, from the viability and business cycle of a particular country to the specific microeconomic impact of the market.

Reasons to Purchase the Direct Drive Rotary Tables Market ReportThe market research includes historical and forecasts market data, demand, application details, pricing history, and company shares of the Direct Drive Rotary Tables market by geography.

The research report also mentions the new innovations, profound inventions, latest developments, marketing strategies, and branding techniques, present in the Direct Drive Rotary Tables market.

The opportunities and threats that are ought to arise in the future for the key market players have also been emphasized in the Direct Drive Rotary Tables research report publication.

This Direct Drive Rotary Tables report additionally states import/export consumption, supply and demand figures, demographics, revenue, and gross margins alongside the features of different methodologies to upskill the company’s development.

8613371530291

8613371530291