rotary table conveyor quotation

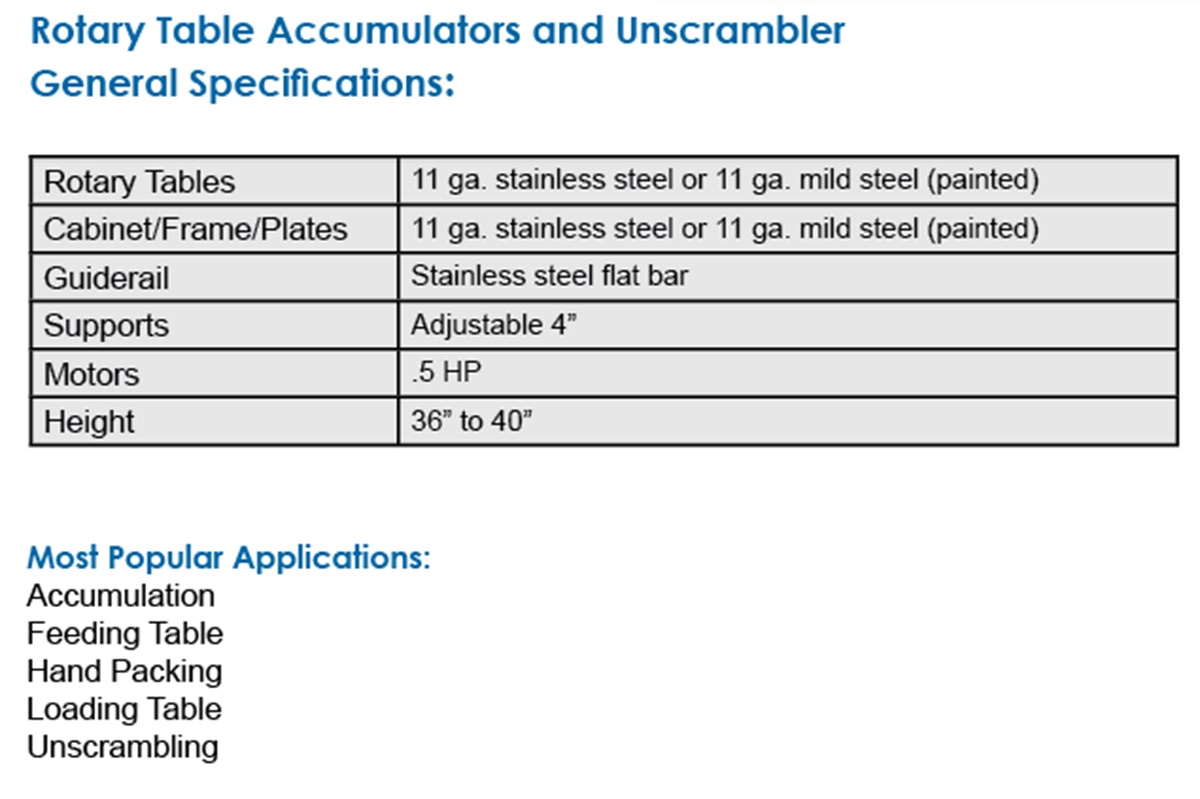

One of the earliest designs for accumulation or unscrambling is the rotary table. Both configurations can handle multiple container sizes and materials. The rotary design is flexible and effective. Standard (non-custom) diameters are 36", 48" and 60”. Top discs are stainless steel with machined backer plates for trueness. Accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. Infeed and discharge conveyors are recommended to be designed with a close interface for smooth transfers. A smooth edge bowl top is available for hand packing applications.

Our SNEED-PACK Rotary Accumulation Tables can be used at the end of production lines, as an infeed to a conveyor, and as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Rotary accumulation tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

Please be advised that the pricing DOES NOT include freight. Due to the many variables including final destination and conveyor dimensions it is not possible to include freight on website orders for this product.

... turning table is equipped with motorized roller conveyors. It is used in conveying systems for changing the direction of the package units, without difference in the forward front. In addition, it is ...

The turntable roller conveyor is used for rotating a pallet to any desired angle. The transport direction of the pallet remains the same. Its modular ...

... duty turntable featuring a 1912 gravity roller top and concave transition sections (2 included) that can be used in a pass thru conveyor line. The transition section can be reconfigured to make 90° turns ...

The cumulative rotary table is an auxiliary device for the accumulation of packs before group packaging or other tasks. The storage disk made of stainless material, which allows the use of the table ...

Rotary tables are ideal for maintaining continuous material flows. If workpieces need to be buffered, stored, staggered or separated between work steps, they can be ...

Turntables with built-on slat conveyors permit 90° rotation changes for conveying systems with standing paper rolls.The slat conveyor is mounted on a stable slewing ring bearing with ...

Rotary accumulation tables are a small footprint conveyor solution designed for accumulating and unscrambling products at various points during the conveying or packing processes. An efficient process to balance production rates, a buffer space accumulates product allowing production to continue while downstream product is temporarily stopped. This accumulation solution is also ideal for end of the production lines accumulation needs with limited floorspace. Rotary accumulation tables are often used in conjunction with bulk round, flat-bottom products to be off-loaded in a single-file line.

Variable Frequency Drive (VFD) speed control sets the optimum table rotation speed. Nercon’s rotary accumulation table is designed to handle extremes with ease reducing wear and tear on the motor that can otherwise lead to early motor burnout. Temporarily off-loading product flow due to inconsistent speeds between processes maintains production schedule and decreases downtime.

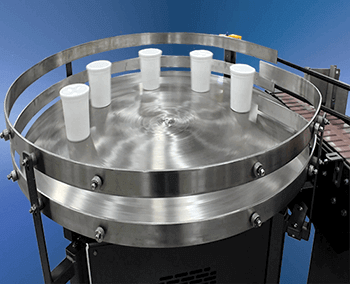

Height adjustable to integrate seamlessly into current production lines, the adjustable supports also allow for leveling on uneven floors to keep the rotary accumulation table stable.

Turntables are also ideal for hand packing stations or feeding / loading tables. Quality stainless steel components are easy to clean and result in a low maintenance, durable piece of equipment. Simply install a Rotary Accumulation Conveyor Table between your infeed and discharge conveyor to cost effectively manage your product throughput.

American Conveyor Group, Inc. has experts standing by to answer all your questions and to solve all your material handling problems, and to make sure you are getting the best solution for your needs.

Rotary accumulation tables or unscrambling tables are designed to support a variety of conveyor system requirements. Designed for a small footprint these accumulation tables are often used with round containers such as bottles to accumulate bulk or unscramble bulk products so that they can be discharged in a single file line. An efficient process to balance production rates, a buffer space accumulates product allowing production to continue while downstream product is temporarily stopped.

Rotary accumulation tables are also ideal for hand-packing stations or feeding and loading tables. Quality stainless steel components are easy to clean and result in a low-maintenance, durable piece of conveyor equipment. Simply install a rotary table between your infeed and discharge conveyor to cost-effectively manage your product throughput.

Accumulation Rotary Table.Rotary tables, also referred to asaccumulation tablesor unscrambling tables, are designed to support a variety of conveyor system requirements. They are often used with round containers, such as bottles, to accumulate or unscramble bulk, so that they can be discharged in a single file line.

A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward.

Positioned at the entrance of a conveyor belt, or directly at the machine to be powered, it performs the function of “Storage and distribution station”. The products can be loaded manually or by conveyor belt. The adjustable deviators allow you to sort and align the products so as to feed the machine that receives them uniformly and without interruption. Positioned at the unloading of a conveyor belt or at the outlet of a packaging machine, filler, labeller, etc., it performs the function of collecting and accumulating products. The rotating tables are equipped with a variable speed drive to adapt to various needs. The rotating disk can be supplied in slippery plastic or stainless steel.

It is positioned at the entrance of a conveyor belt, or directly at the machine to be fed, the rotating table with sides acts as an “accumulation and distribution station”.

It performs the function of collecting and accumulating products. The rotating tables are equipped with a variable speed drive to adapt to various needs.

Select a categoryBakeryBlendersDepositorsMixersBowlsOvensBerry EquipmentBeverage EquipmentBlowersBoilersBreweryChocolate/CandyCleaning EquipmentCoffee EquipmentConveyorsAccumulation TableAuger/Screw ConveyorBelt ConveyorBeltsBucket ElevatorFood-Grade ConveyorIncline ConveyorIndexing ConveyorRoller ConveyorVibratory and Shaker ConveyorsWire ConveyorDairyElectricalControl PanelsTransformersEnrobing & CoatingFarm EquipmentSilosFillersAuger FillersNetweigh FillersVolumetric FillersFiltersFruit and Vegetable EquipmentFryers, Skillets and CookersGeneral EquipmentCompressorsDust CollectorsForkliftsPumpsVacuumsGeneral FacilityAir Conditioning and RefrigerationLightingPallet RackingGeneratorsGrindersHeat ExchangersHoppersKettlesLab EquipmentMeat EquipmentBowl CuttersDicers / SlicersSausage FillerSmokersMetal DetectorsPackagingAdhesive MelterBag SealersBox SealersCap SealerCartonersCase PackerCup/Tray SealersDate CodersFlow WrappersHFFSL-Bar SealersLabellersBagBottleCanPalletizer / DepalletizerPouch FillersShrink WrapperThermoformerVFFSPartsBearingsDrivesElectric Motors5 HP & Under50 Hp & OverOver 5 HPGearboxesValvesPharmaceuticalProcessingBulk-Feed ProcessorCentrifugesDryersHomogenizersIQFSiftersTumblersProduct HandlingBin, Buggy & Tote DumpersBins, IBCs, TotesBuggiesRestaurantScalesBench ScalesCheckweighersLinear ScalesMultihead ScalesSeeds/GrainsTablesTanks2,001+ Gallons201-500 Gallons50 Gallons & Under501-2,000 Gallons51-200 GallonsDairy TanksJacketed TanksSS TanksUncategorized

This machine operates to feed half-stack pallets into the depalletizer. Using an operator interface the pallets can be adjusted to the correct level, to propel the bottles onto the feed table. A photoeye automates the pusher and conveyor for each round of bottles.

These high quality accumulation tables are composed from the same aircraft grade aluminum and stainless steel used in our popular line of labeling machines.

Parts are completed with a durable stainless steel coating. Standard tables are powered by an independent, variable speed DC motor that pushes the conveyor chain slightly faster than our labelers. Each table is controlled by an independent on/off push button.

The Rotary Product Table is the perfect solution for both your product infeed as well as collection needs. It is comprised of the same steel and stainless steel used in our popular line of labeling machines. The frame is completed with a enduring stainless steel coating.

The Rotary Product Table is powered by a 1/8 hp variable speed DC motor. A separate on/off control button allows it to be compeltely independent from the other machines. This makes it a highly versatile addition to any product line.

Rotary Work Tables were designed to accept product flow from discharging belt or other general material handling systems. The rotary table or some times called spinning table is a robust design, which is engineered to take demanding punishment from an industrial environment. The rotary table is the key component in designing a flexible work cell for jobs requiring manual inspection, degating, assembly or packing. In typical applications, the product is conveyed on to a the table to allow multiple operators can efficiently handle tasks or allows multiple products (sub-assemblies) to be conveyed from multiple machines to one location and have one operator handle multiple tasks without added effort or ergonomic strain.

8613371530291

8613371530291