stepper motor rotary table supplier

With four different product lines, our motor rotary tables solve a wide range of positioning tasks. They are suitable for the exact, fast and repeatable setting of angular positions.

As a turntable manufacturer, we offer advanced solutions for Industry 4.0. We offer the universally applicable Basic Line with compact precision, the High-Performance Line, which is particularly fast and precise, and our strongest product line, the Strong Line, with maximum power. The powerful turntable motor of the SG-Line precisely positions the turntable via the cross rollers, even under high mechanical loads.

In our latest product line, the "QN-Line", the turntable is not driven by a worm gear. The turntable stepper motor drives the turntable via a toothed belt drive. This enables the turntable to rotate quickly and dynamically.

Our turntables with motor are used in test laboratories, research, in mechanical engineering and automation, in the plastics processing industry or as welding turntables.

We supply our motor turntable in different sizes, suitable for small and large-format applications. As a rotary table manufacturer, we offer equal precision and performance for all sizes. The motor turntables differ in the diameter of the turntable and in the transmittable torque. The turntable motor is always arranged coaxially to the worm of the worm gear.

For example, the MDT36008-AK-S model from our BS line is a small turntable with a stepper motor and controller. This rotary table with drive has an outer diameter of 54 millimeters. The maximum output torque is 1.2 Nm. As a product in the upper size class, we offer the turntable with stepper motor MDT36012-HP. The HP-Line has a turntable diameter of 80 millimeters and a maximum torque of 3 Nm.

We offer the motorized turntables in three configurations. The complete solution includes the turntable stepper motor with integrated positioning control.

In addition, our turntables are also available without a motor. This ensures the greatest flexibility when integrating into new designs. Furthermore, the customer can fall back on drives and controls that he is familiar with.

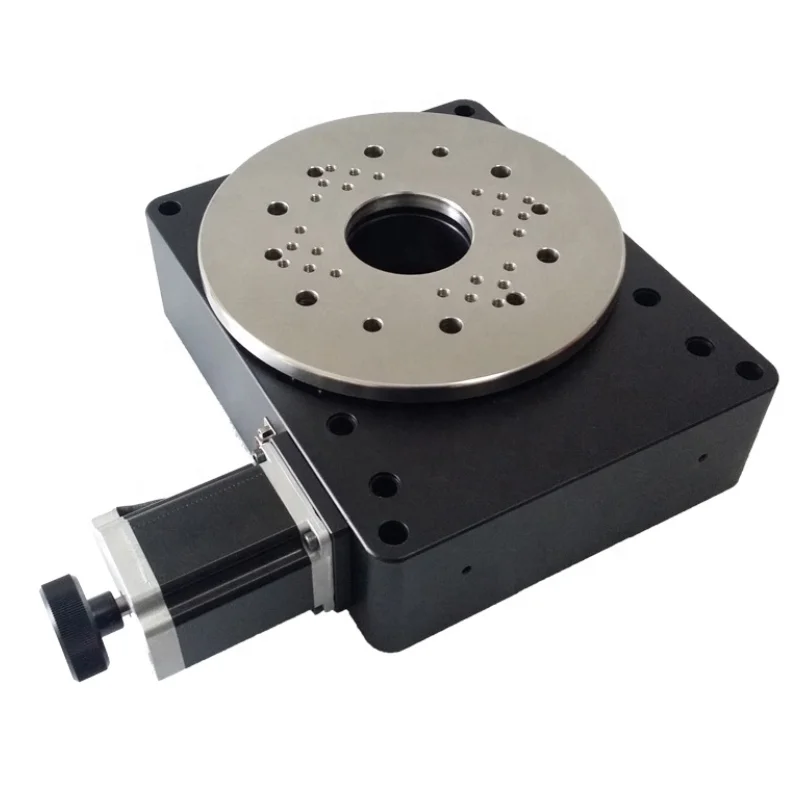

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an AlphaStep closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

AlphaStep products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.

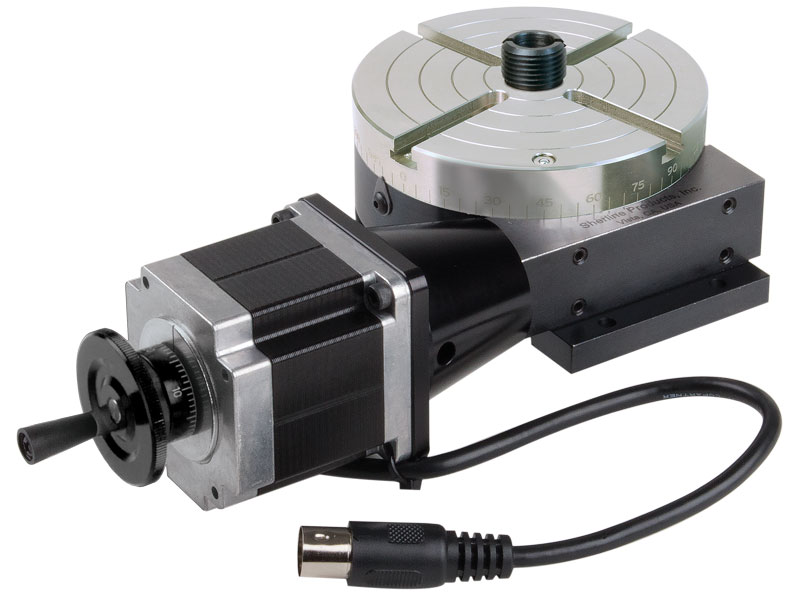

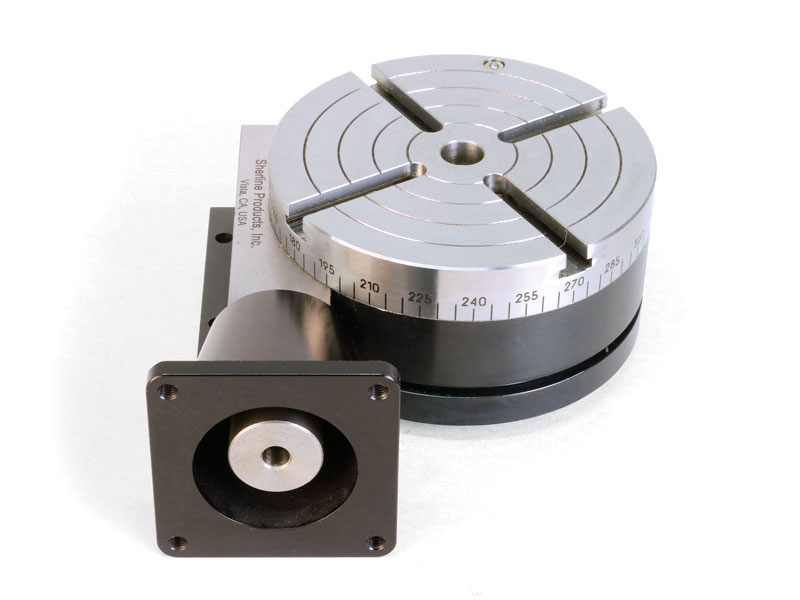

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. The 8730 rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external 8760 driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a 3700-CNC rotary table and a 67127 stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

NOTE: We are stating the following weight limits for our rotary tables for continual use. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

Hollow rotary table, installation size 60, 85, 130, disc device can withstand large inertia, the integration design presents a cross roller bearing angle and rotary table with high rigidity, the whole group of collocation of stepping motor and drive.

Rotary tables are used for precision metal work. They are usually made of a solid base that can be attached to another bracket. The table is a disk that rotates freely or with the help of a spiral (hand crank).

The rotary table is a disk-shaped metalworking device that enables precise positioning of the workpiece. It allows the metalworker to cut or drill the workpiece at precise intervals vertically or horizontally around a fixed axis. The turntable can be controlled both manually and digitally by computer. Some types of rotary tables are designed to be used with indexers or separators for special operations. A rotary table used with one of these positioning plates is often called a dividing or indexing head.

The Rotary tables is usually a sturdy base that can be attached to a separate stand or table. This device is basically a rotating disc that holds the workpiece in place while cutting or drilling. The disk portion of the rotary table can be freely rotated or rotated for indexing operations by means of an attached control lever known as a worm wheel. Tables used in precision operations are usually turned with a duplex type helical wheel to compensate for clearance. Rotary tables used in automated metalworking processes are connected to a digitally controlled computer.

Rotary tables are mostly used in a flat position with the table axis vertical. Sometimes they are installed with the shaft pointing horizontally so that the suppository can be used to support the free end of the workpiece. When this device is attached to the secondary table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutter. In this configuration, the axes of the rotary table, secondary table and cutter are coaxial to facilitate concentric cutting operations. This configuration also allows the secondary table to be moved to drill evenly spaced holes in the workpiece.

Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed” against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

The MOR-215-70 motorized rotation stage uses the precision ground and hardened worm gear with self-compensating preload and precision crossed roller bearings. The precision ground worm gear produces consistent driving torque to the rotating carriage. The crossed roller bearings with high rotation accuracy are capable of bearing loads in every direction.

This motorized rotation stage is equipped with a hardware origin and allows for continuous rotation of 360°. The central aperture is 70mm. A hall effect sensor (as the zero position) is built in the rotation stage, so the top plate can"t move in a negative direction to pass over the zero position.

02 series motion controller can be used to control motorized stage with NEMA23 stepper motor. We have 220V and 110V power supply options for each motion controller. The USB line can be used to connect the motion controller to laptop. Please click following links to get more information.

8613371530291

8613371530291