camco rotary table free sample

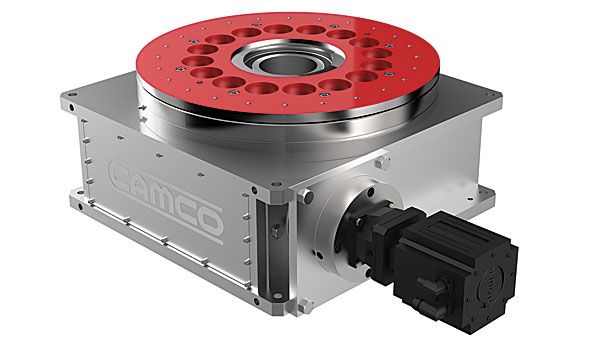

For more than 50 years, Camco global products have been the industry standard for the highest quality cam-actuated, motion control products available. Camco Indexers and Servo Drives assist with device indexing. Indexing is the starting and stopping of a device in precise intervals at precise locations. DESTACO"s Camco cam-operated rotary indexers move a wide variety of products and components with precision. Larger E-Series indexers can rotate several tons of automotive body parts in seconds while smaller Parallel and Roller Gear indexing drives accurately index pharmaceutical or electronic components in milliseconds.

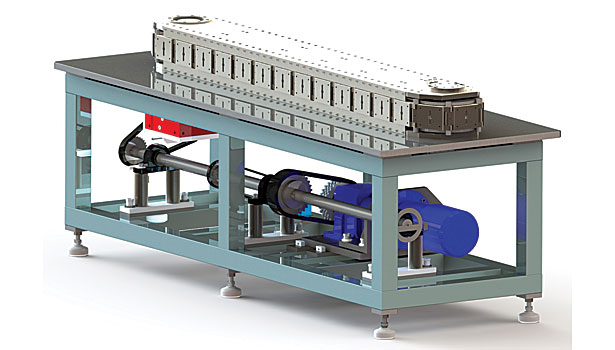

We combine rotary index tables with industrial automation systems so each task of your manufacturing process blends seamlessly into the next. For example, in the past we’ve created industrial automation systems that join rotary indexing machines with pick-and-place units for some of our clients. Contact us to see what we can do for you.

Rotary indexers are just one part of the equation when building a custom assembly cell. It’s important to remember the entire scope of the project and be cognizant that the rotary table should be able to move precise distances before stopping cleanly, with no backlash or wobbling. It needs to be balanced and capable of handling the tasks at hand.

Our automation experts have years of experience in consulting with our customers to create machines that suit their needs. We incorporate rotary tables from industry leaders like WEISS, Fibro, and Camco into our machines to create the perfect fusion of form and function. Our dedication to quality is unmatched in the world of custom machinery.

We seamlessly integrate rotary indexing tables into our automated machinery to provide you with custom solutions that work for your business. If you’re looking to take your manufacturing process to the next level, give the custom machine builders at Paramount Tool a call at (616) 582-5300 today. We’re always happy to answer any questions you may have about our rotary indexing machines or the machine building process as a whole. For a free quote, fill out our contact form and we’ll get back to you as soon as we can.

6.1. North America Automated Rotary and Indexing Table Market Size (US$ Mn) and Volume (Million Units) Analysis & Forecast, by Configuration, 2017‒2031

Camco offers a range of high performance servo positioners for light to heavy duty applications. All of the series feature large center thru-holes and zero backlash mechanisms. Larger positioners can rotate several tons of automotive body parts in seconds while smaller Parallel and Roller Gear indexing drives accurately index pharmaceutical or electronic components in milliseconds. These servo positioners feature easy integration into a multi-axis system, 60+ cycles per minute, and programmable motion profile of the servo motor to fit your desired index motion/dwell times.

Among the many indexer manufacturers, what sets Pascal’s indexing table apart is undoubtedly its brakeless design, compact size, and durability. It has an ample amount of ports lending itself well to automation.

Pascal’s MDF index table operates with a 90° index 0.5 sec. Its unique rolling gear transmission is maintenance free and can operate with high index speed and accuracy for a long time unlike traditional worm gear. Traditional worm gear undergoes abrasive wear that can lead to backlash causing machining failure and degrading index accuracy.

Pascal’s high-performance rotary unions are integrated to enable clamp sensing and actuation but also provides a footprint 20% smaller than its competitors. Ideal for indexing large workpieces in compact machining centers, you will also achieve increased production capacity. As one example, our rotary indexing table can allow a machining center to increase their production capacity from 16 robodrill units to 24 units in the same amount of space.

The MDF index table has a total of 20 ports, lending itself well to automation. 18 of those ports can be used for hydraulic and air, while 2 are for coolant. A double acting cylinder with sensing can be used instead of a single cylinder, and its rotary joint accommodates a 7MPa pressure circuit.

Pascal is confident in the quality and reliability of our rotary indexers so much so that we use them in our own factories. That is also why these indexers are utilized in the factories of major automakers around the world.

Index tables, also called indexers or rotary indexers, are designed to move parts from one stage of the assembly process to another. Index tables/indexers allow for the most efficiency possible to be achieved by an automation system. Index tables/indexers reduce labor substantially, while also increasing production rates. Dial-X Automated Equipment, Inc. has experience with all types of index tables/indexers and can help you determine your needs.

Rotary indexing table use is widespread in automated assembly machinery and selecting the proper mechanism is essential for both maximizing performance and minimizing the cost of this critical component. This how-to-guide will explore two common devices that can be used for rotary indexing and give advice for proper selection. These two popular devices are cam indexing drives and servo rotary tables.

Cam indexers are a ubiquitous mechanism that have been used for rotary tables for many decades. They are a great fit for applications that will always index the same angle and that require high-precision positioning at a very reasonable cost. A cam indexer uses a mechanical cam to provide the motion control to position the load. A mathematical motion curve is machined onto the cam that provides extremely smooth and repeatable motion.

A cam indexer has two main modes of operation. One mode is referred to as “Cycle-on-Demand”. This indicates that the camshaft will be cycled one revolution at a time to advance the output one position at a time. This is typically achieved by using an inexpensive camshaft sensor package to detect camshaft position and a VFD to stop and start the motor. The camshaft dwell period offers a wide window for the camshaft to stop without affecting the position of the output. To cycle the indexer, a PLC gives a command to the VFD to accelerate the drive motor to a preset speed, the cam rotates one revolution indexing the output, a sensor sends an in-position signal to the PLC, and the PLC signals the VFD to stop the camshaft during the cam dwell position. The table will be in the dwell position for however long is necessary to complete the work at each station. The dwell time can range from a fraction of a second to several minutes or hours depending on the application. This combination allows very accurate positioning with an inexpensive drive system.

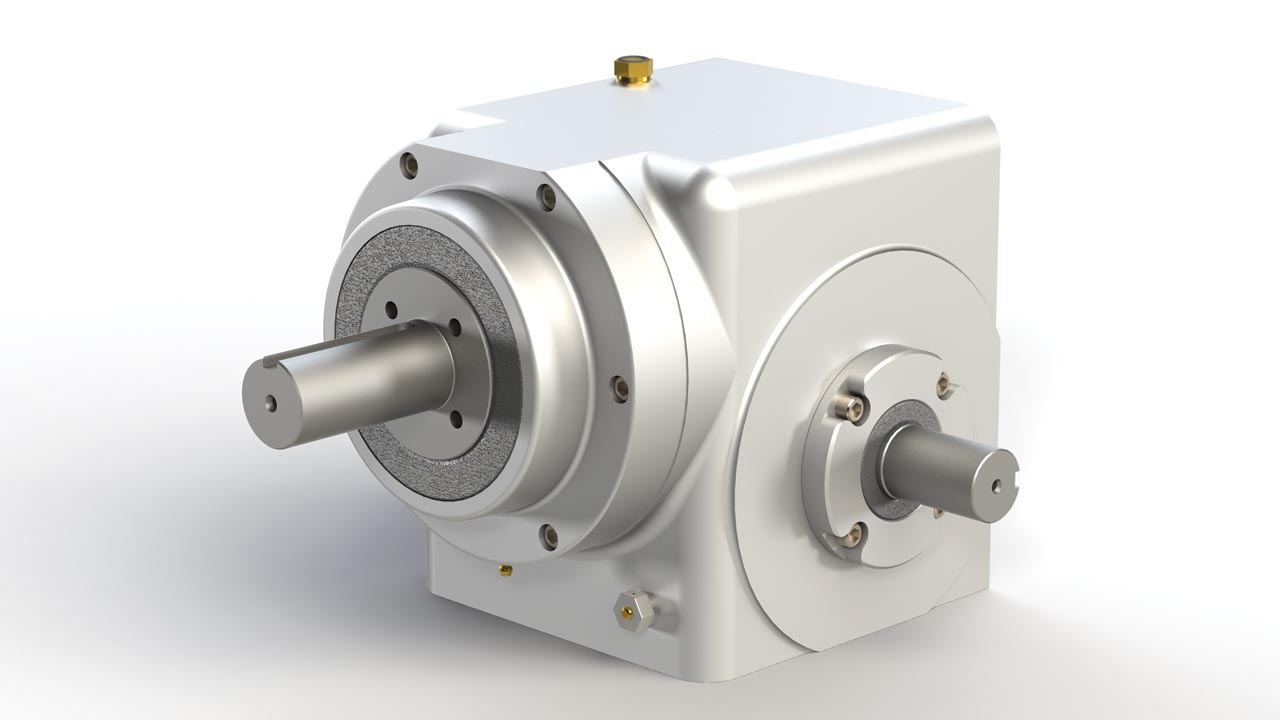

A fully programmable servo rotary table is another common option. There are two specific cases where a servo rotary table is advantageous. The first is when a flexible motion pattern is required. An example is two different products being run on one machine that each require different indexing patterns. The other situation that suits a servo indexer is when extremely fast positioning is required followed by a long dwell period. A cycle-on-demand cam indexer is limited by the need to accelerate the camshaft up to speed during the dwell period before output motion is started. There are practical limitations to how fast the camshaft can be accelerated so there will be a delay before motion is started. With a servo rotary table, the output rotates as soon as the servomotor starts moving. A practical example would be a load being indexed 90 degrees in 0.25 seconds. This is not difficult for a continuous cam indexer or a zero-backlash servo indexer, but a cycle-on-demand cam indexer may struggle with that motion. For quick servo indexing applications, a preloaded gear reducer with zero-backlash is critical to achieving smooth indexing motions with minimal settling time. A zero-backlash RollerDrive mechanism would be an optimal choice to achieve accurate positioning with great dynamic response.

For either style of indexer, application information including moment of inertia, indexing angle, indexing time, and dwell time is required. A reputable manufacture should then be able to properly size the rotary table for the application.

DESTACO’s CAMCO cam-operated rotary indexers move a wide variety of products and components with precision. A larger indexer can rotate several tons of automotive body parts in seconds, while smaller parallel and roller gear indexing drives accurately index pharmaceutical or electronic components in milliseconds. Preloaded for no backlash, they have the capacity for handling high loads and speeds with smooth motion and controlled acceleration and deceleration for repeatable, accurate positioning. They require little or no maintenance and have known power requirements and displacement-time relationship.

The industry’s first scalable indexing solutions, CAMCO MDE and HDE Series mechanical and servo-based indexers, are built for precision positioning and long-term endurance applications. The HDE1200S is a freely-programmable servo-based index drive, while the HDE1200M is a mechanical indexer using an AC induction motor drive package. The open base mounting frame can be scaled in both width and height to fit existing and new assembly line requirements. The MDE is a high-performance rotary indexer with an industry leading torque rating. These cost-effective rotary index drives have high dynamic payload capacity while still maintaining a fast indexing speed, flexible mounting options and easily replaceable cam followers.

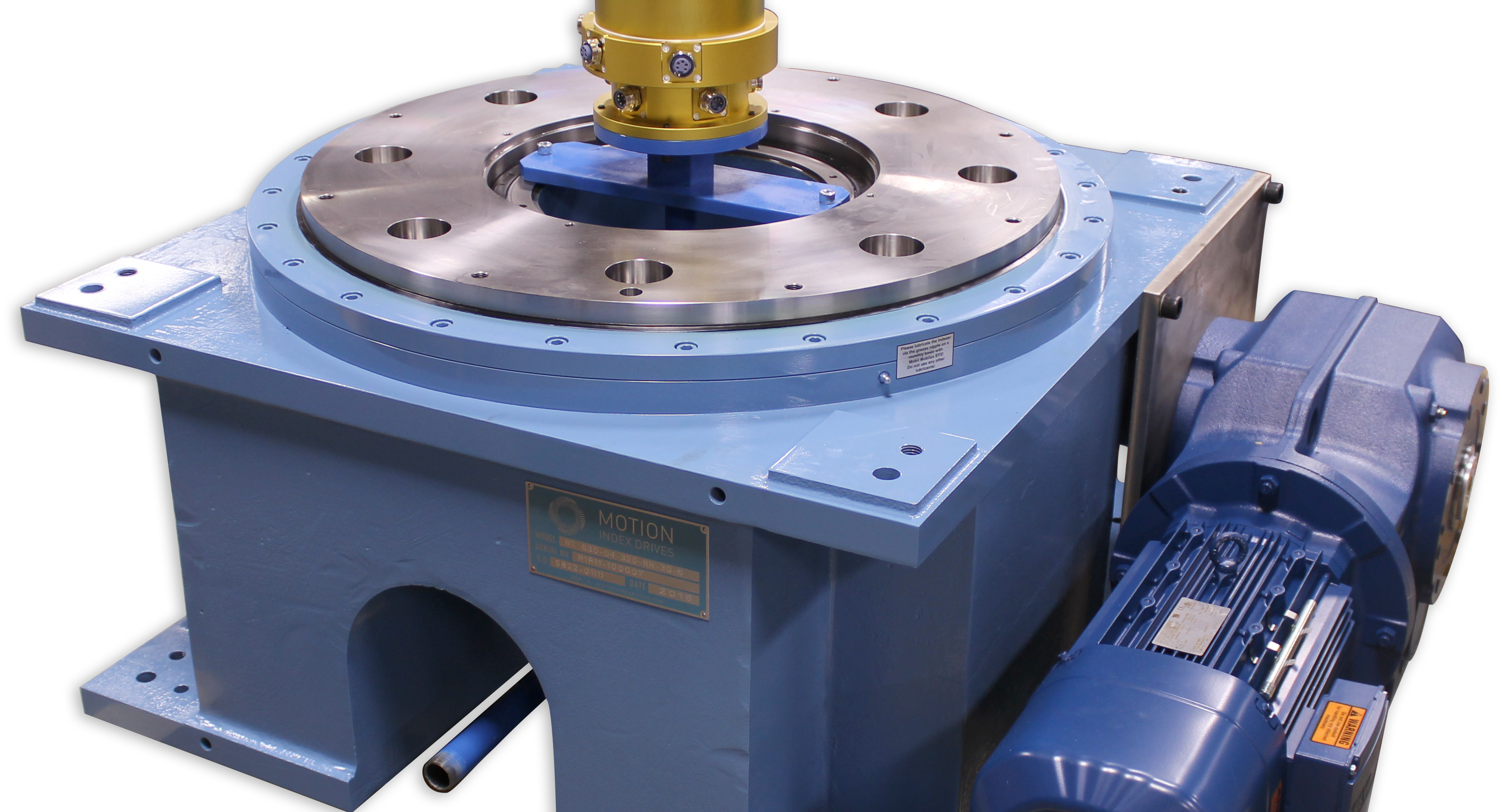

The CAMCO E-Series is ideal for heavy-duty rotary dial applications. These models feature durable welded steel housing, precision cam with preloaded cam followers for maximum accuracy and preloaded center-rib design for smooth acceleration and deceleration with precision positioning. This design includes a large output mounting surface that’s supported by a 4-point contact bearing that provides superior thrust and moment capacity. The large center thru-hole accommodates stationary center post, electrical wiring, and air or hydraulic lines. This complete motorized drive package with reducer and AC inverter drive is suitable to most applications.

The CAMCO ring drive offers easy-to-integrate automation that fits into a wide array of operations. Minimize machine footprint by mounting equipment inside the through-hole of the CAMCO Ring Drive. Tool the ring drive by attaching fixtures directly to the dial ring, eliminating the need for an additional dial plate. Popular applications for this model include print/decorating machines, rotary automatic assembly and assembly systems that require a large number of tooling stations.

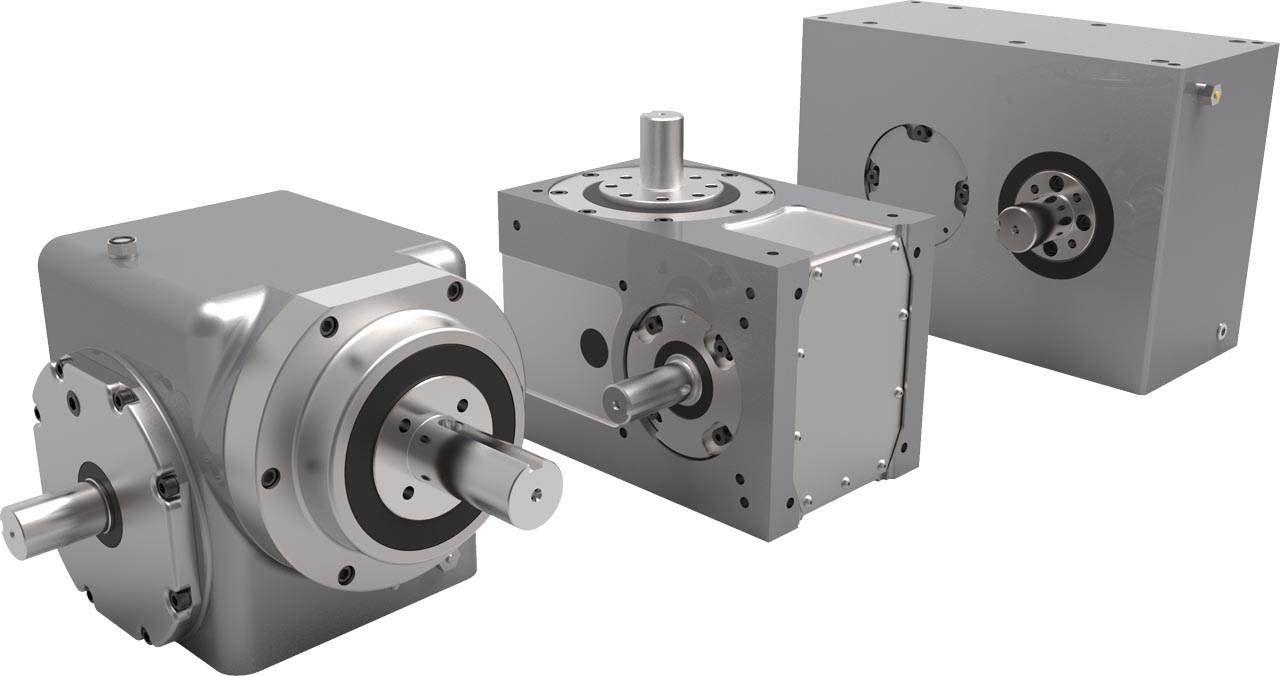

These CAMCO drives are robust, versatile units suitable for many applications, available with a flange (RGD) or shaft (RGS) output, and all six surfaces are machined for universal mounting. The optional center thru-hole in the flange version facilitates passage of electrical wiring, pneumatic lines or mechanical linkages. This series features short camshaft motion periods, due to oversized cam design, and is well suited for continuous running applications or for special motion requirements such as oscillating motions.

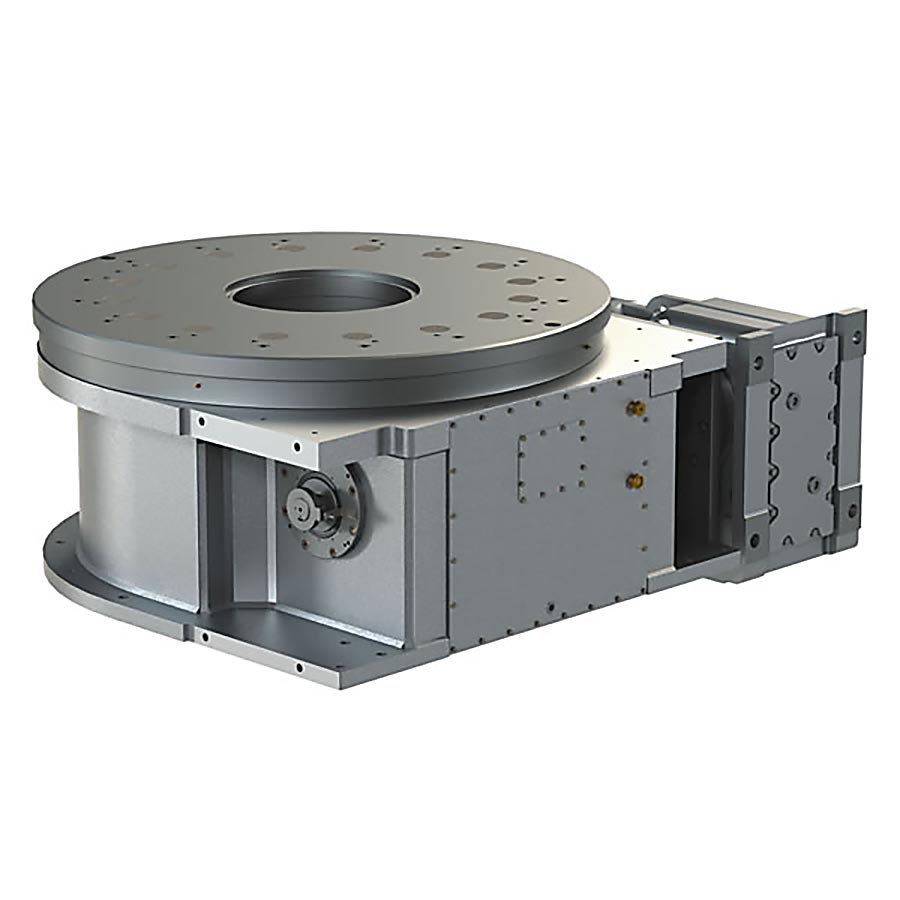

The CAMCO RDM Series index drive is ideal for rotary dial applications and feature a large output mounting surface supported by 4-point contact bearing that offers superior thrust and moment capacity. This series of index drives also offer a low-profile design, large center thru hole and optional output overload clutch.

The CAMCO RA Series indexer is ideal for dial applications or actuation-type applications such as driving a linkage or in-line conveyor. These models feature a fixed center distance between input and output, a hardened ground barrel cam and a compact design that requires minimum use of floor space. They also feature preloaded center-rib design with modified-sine motion that provides smooth acceleration and deceleration with precision positioning.

These CAMCO drives have a robust, flexible design with superior load capabilities. These models feature short camshaft motion periods, due to oversized roller gear cam design, and are well suited for continuous running applications or for special motion requirements such as oscillating motions. This series also offers universal mounting, including a horizontal mounting option ideal for trunion applications. Additionally, they are designed with optional stationary center post with thru-hole to provide mounting for upper tool plates.

Camco P Series drives are ideal for high-speed applications or for actuation-type applications such as driving a linkage or a conveyor. These models feature hardened and ground conjugate cams, yoke-mounted, preloaded cam followers that are non-reversing for high capacity and speed, and preloaded tapered roller bearings for rigidity and backlash-free operation. This design allows for whole or fractional stops, oscillating and complex custom motions. Long transfer distances are achieved with simple linkages.

For more information on Rotary Indexers from DESTACO (CAMCO, Robohand), as well as how Power Motion can help, please contact us. We have locations in St. Louis, Kansas City and Little Rock, providing distributor and automation solutions services for Missouri, Kansas, Arkansas, Nebraska, Southern Illinois, Southern and Western Iowa, Northern Louisiana, Eastern Oklahoma and Northeast Texas. Not all products available in all areas.

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HT Ring Table Series are designed to propose new solutions for fixed or flexible positioning of heavy loads, thanks to the high performance of the cross-roller bearing.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product ...

... with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute ...

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

Numerous advantages are offered by indexing tables. No matter whatever is the transfer velocity or the load is, the motion is very smooth and progressive. Robust and accurate MCPI cam shaft movement design ...

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

The TS Series is manufactured by SOPAP Automation. It is a rotary indexing table, that is constructed mainly for plates of a large diameter. Features of the TS includes continuous or ...

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or water; SAT rotary ...

... distributed on the turntable (or total weight)(*) – the maximum total load refers to the forces on the turntable. This does not mean that the indexing table will be able to rotate this ...

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

Introduction A. Engineering B. RDM Index DrivesC. RD and Intermittor Index DrivesD. Roller Gear Index Drives E. Parallel Index Drives F. Right Angle Index DrivesG. Heavy Duty E-Series Index DrivesH. Overload Clutches I. Parts Handlers I-2 RPP Cambot® Rotary Parts Handlers I-15 HD-LPP Heavy Duty Linear Parts Handlers I-27 MR-LPP Mid-Range Linear Parts Handlers I-39 WBD Walking Beam Drives J. Precision Link Conveyors K. Servo-Mechanical Drives L. AccessoriesM. Torq/Gard Overload ClutchesN. Custom Applications

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 1 Quality Policy

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-52002 Introduction

Formed by the merger of Commercial Cam capital equipment, IMC is unique in its abilityCo. and Ferguson Machine Co., IMC offers to manufacture a full range of motion controlthe widest range of products in the industry. products under the Ferguson and CamcoWith over 100 years of experience and brands.significant investments in personnel and

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 3 Introduction

IMC Headquarters European Headquarters Industrial Motion Control, LLC European Headquarters 1444 South Wolf Road Ferguson Co. SA Wheeling, IL 60090 USA 33 Parc Industriel Tel: 847-459-5200 B-1440 Braine-le-Château Fax: 847-465-3042 Belgium E-Mail: mktg@camcoindex.com Tel: +32 (0)2 367-1311 www.camcoindex.com Fax: +32 (0)2 366-1891 sales@Ferguson.be IMC Michigan 550 Forest Avenue Camco UK Ltd. Unit #14 432 Perth Avenue Plymouth, MI 48170 Slough Trading Estates Tel: 734-459-8080 Slough, Berkshire SL1 4TS Fax: 734-459-8110 United Kingdom Tel: +44 (0)1753-786-100 Fax: +44 (0)1753-786-101

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-52004 Introduction

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 5 Introduction

A Foreword Cam-actuated motion control is a specialized recommend are Clyde H. Moon’s “Cam Design business. In a 4 to 5-year university curriculum for Manual for Engineers, Designers, and Draftsmen”, mechanical engineering, most students spend only published by Emerson Electric Co., Harold A. a few weeks studying cams and their related Rothbart’s book, “Cam Design Handbook” published mechanisms. In addition to continuing academic by McGraw-Hill and Robert L. Norton’s book “Cam research, many advances in cam technology have Design and Manufacturing Handbook” published by been made by companies and employees involved Industrial Press. Mr. Moon’s book is available in Adobe in the commercial application of these products. Acrobat® PDF format on the IMC web site and can be This engineering section provides the basic concepts easily downloaded at www.camcoindex.com. necessary for machine designers to wisely choose the best cam solutions for their application. We would like to thank all of the IMC employees and IMC manufacturer representatives that have There are some good publications available to the contributed to our extensive cam knowledge base general public for those seeking a more in-depth and helped collect the information presented in this understanding of the subject. Three that we can catalog.

Introduction Industrial Motion Control, LLC is a joint-venture As divisions of larger, Fortune 500 companies, company formed in 2001 between Ferguson Machine both Ferguson and Camco were able to invest in Co. and Commercial Cam Co., also known as Camco. substantial amounts of equipment and facilities while developing a diverse line of products that include Ferguson has been in continuous operation since index drives, custom cams, parts handlers, 1930, with European operations established in 1961. precision-link conveyors and servo-motor Camco was established in 1939, first manufacturing drive systems. the copper coils required for the then-emerging residential and commercial air-conditioning and Today, as IMC, Ferguson and Camco are the world’s refrigeration industries. Camco needed cam- largest producer of cam-actuated index drives, utilizing actuated machinery to produce these products and state-of-the-art production equipment to provide the eventually the business focused on the commercial- highest quality cam-actuated and servo motor- ization of cam-operated machinery, index drives actuated motion control products available. and custom cams.

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-2 Engineering

What is Indexing? AIndexing can be linear or rotary. As defined by IMC, indexing is the process of starting and stopping in preciseintervals at precise locations.

Why Cam-Actuated Index Drives?The advantages of cam-controlled motion are obvious rigidity, settling time (the time to dampen anyand effectively demonstrated in everyday life by the vibrations) in dwell is short or virtually non-existent —camshaft found in automobile engines. No other very important for many applications requiring atechnology can provide comparable speed, combination of speed and precise positioning.precision, repeatability, load capability andreliability. Through careful design of the cam profile, velocity and acceleration are also controlled throughout the index-Cam-driven mechanisms require little or no ing cycle, minimizing vibration and providing a known,maintenance and are capable of moving, with repeatable displacement-time relationship.precision, a wide variety of products and components.For example – larger E-Series Index Drives rotate In summary, cam-operated indexing systems have theseveral tons of automotive body parts in seconds – following features and benefits:and smaller P-Series and RG-Series index drives ◆ Controlled Acceleration and Decelerationsaccurately index pharmaceutical componentsand electronic components in milliseconds. The ◆ Repeatable, Accurate Positioningmechanical technology typically requires no ◆ High Load Capacitymaintenance, other than routine checks for proper ◆ High Speed Capabilitylubrication. Rolling pre-loaded contact between the ◆ Smooth Motioncams and cam followers minimize wear and thermalinefficiencies. This preloading technique is also used ◆ Quick Settling Time in the Dwell Positionon the input and output bearings of the index drive, ◆ Low Maintenance, Superior Lifeachieving the most rigid, accurate and efficient ◆ Known Displacement-Time Relationshipmechanical actuator possible. With this inherent ◆ Known Power Requirement

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-3 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-4 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-5 Engineering

Model Code Designation Camco Model Code Designation Ferguson Model Code Designation Number of Stops Model Index Period

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-6 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-7 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-8 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-9 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-10 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-11 Engineering

.09 x 1.3 x (3088 + 15 + 31) x 1 Camshaft RPM = 8 x .375 2 β 270 Nc = = = 120 RPM = 326 in.-lbs. 6 x t2 x M 6 x .375 x 1 This is a type 1 unit, therefore M = 1. Output Torque For type 2 or 3, M = 2, M = 3. To = Ti + Tf + Tw = 326 + 226 + 0 = 552 in.-lbs. From the Right Angle Series indexer catalog section, an R225 reducer with a 15:1 reduction ratio is chosen. C, K i and Kf Horsepower Values for C, Ki and Kf can be calculated or found in the table on page A-19. Tc x Nc 118 x 120 Hp = = = 0.30 Hp C = 1.0, Ki = 0.16, Kf = 0.29 63,025 x E 63,025 x .75 Due to component compatibility and horsepower requirements, a one horsepower motor is chosen for this application.

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-12 Engineering

Servo-Mechanical ExampleCamco-Ferguson software can also be used to sizeservo-driven indexers such as the Flex-i-Dex andIndexers with constant-lead cams. The followingillustrations show input and output data for a typicalservo-driven application.

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-13 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-14 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-15 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-16 Engineering

Inertia Tables AMultiply radius of gyration squared (k2) by weight to get weight moment of inertia for torque demand calculation.

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-17 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-18 Engineering

Ki Kf Tables & Moon Factor Tables (Cv and Ca) AValues listed are for type 1 units, multiply values by 2 for type 2 units. For motions with constant velocity,multiply K factor by the adjustment factor listed below.

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-19 Engineering

IMC intentionally chooses to state the Maximum Error and repeatable to 1 arc second. The indexer will make as the indexer’s worst possible accuracy. While some 3 to 6 complete turns of its output and accuracy index drive manufacturers use the average as their measurements are recorded. The accuracy is the stated accuracy and decline to state the repeatability, mean between the maximum and minimum error. IMC takes a more conservative approach. The repeatability is one-half the difference between the maximum and minimum error. Measurement Method The output angular error of an index drive is measured Upon request, IMC can provide special accuracy using a laser collimator mounted to a precision rotary reports for a particular indexer. table. The laser collimator is accurate to 2 arc seconds

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-20 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-21 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-22 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-23 Engineering

A Input Considerations All load calculations are based on a constant velocity torque changes to negative torque (input shafts input (camshaft speed) during the index. If there are typically see both positive and negative torque in an any speed variations on the input shaft, these varia- indexing application). Pulleys should be maximized to tions are amplified on the output shaft (velocities are the largest diameter that can fit on the camshaft. accelerated and accelerations become jerk). It is very Adjustable tensioning idler pulleys are highly recom- important to have a controlled motor speed and a mended. If you have any questions regarding input reducer ratio sufficient to dampen any input speed speed control, please contact your local IMC sales variations. If input belts are used, they must be tight- representative or IMC application engineer. ened to prevent any slip or belt jumping when positive

IMC Online The IMC website, www.camcoindex.com, features useful tools for those responsible for specifying, apply- ing and servicing Camco and Ferguson products. These include: ◆ 2-D and 3-D CAD drawings in a variety of formats ◆ General and Product-specific Service Manuals ◆ Product Catalogs ◆ Contact information for local sales representatives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-24 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 A-25 Engineering

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200A-26FeaturesThe RDM Series Index Drive is ideal forrotary dial applications with featuresincluding:◆ Large Output Mounting Surface supported by 4-point contact bearing offering superior thrust and moment capacity◆ Large Center Thru Hole

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-2 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 B-3 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-4 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 B-5 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-6 RDM Index Drives

Ø4.62 (OPTIONAL) RISER PACKAGE FOR USE 12.75 MAX WITH REDUCER Ø6.62 MOUNTING C AND OPTIONAL MOTOR 3.12 (NOT REQUIRED IF REDUCER OVERHANGS TABLE)

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 B-7 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-8 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 B-9 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-10 RDM Index Drives

6.63 3 16.50 (OPTIONAL) RISER PACKAGE FOR USE WITH REDUCER 145TC MOTOR MTG. "D". (NOT ADAPTOR REQUIRED IF REDUCER OVERHANGS TABLE.)

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 B-11 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-12 RDM Index Drives

(ø8.50) 15.500 (3.00) 3 HP. MOTOR 180 V.DC.,1800RPM, TEFC B (OPTIONAL) RISER MAY BE USED WITH MTG. "C" TO PROVIDE REDUCER CLEARANCE (19.75) WITH TABLE.

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 B-13 RDM Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200B-14FeaturesIMC Roller Dial Index Drives offer superior load capabilitiesmaking them ideal for medium to high torque applications.Other features include:◆ Short camshaft motion periods, due to oversized roller gear cam design, are well suited for continuous running applications or for special motion requirements such as oscillating motions.◆ Universal mounting including a horizontal mounting ideal for trunion applications.◆ Option Center Thru-Hole facilitates passage of electrical wiring, pneumatic lines or mechanical linkages.◆ Optional Stationary Center Post with Thru Hole provides mounting for upper tool plate.The RD and Intemittor Series Index Drives have a robust, flexibledesign with features ideal for continuous-running applications andapplications requiring complex motions. RD Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-2 RD Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 C-3 RD Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-4 RD Index Drives

Optional Accessories◆ 1 hp AC Drive Package with Inverter Duty Motor and ø1.38 THRU Inverter Drive (up to 60 cpm) [change] STATIONARY CENTER POST ø2.376◆ 7350C Reducer (ratios from 5:1 to 60:1) with 1 hp (CAMCO WILL ALTER TO CUSTOMER SPECIFICATIONS) AC or DC Motor◆ Output Overload Clutch model 7.8D 7.80 OR 18D OVERLOAD CLUCH – Available Settings (in-lbs): 1400, 1700, 2600, 3200, 4200, 5000, 7200, 10,000 DIAL◆ Output Overload Clutch model 18D TOOLING PLATE – Available Settings (in-lbs): 5000, 7000, 7800, 21.00

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 C-5 RD Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-6 RD Index Drives

Optional Accessories◆ 2 hp AC Drive Package with Inverter Duty Motor and ø4.376 Inverter Drive (up to 60 cpm) ø3.00 THRU◆ 7400C Reducer (Ratios from 5:1 to 60:1) with Motor STATIONARY CENTER POST (CAMCO WILL ALTER TO Adapter and Coupling CUSTOMER SPECIFICATIONS)◆ Output Overload Clutch model 31D 31D OVERLOAD CLUTCH – Available Settings (in-lbs): 8500, 13,000, 20,000, 31,000 DIAL TOOLING◆ Center Thru Hole (4.75 in. Diameter) PLATE 27.06◆ Stationary Center Post◆ Dual Cam and Limit Switch◆ Electric Clutch-Brake◆ Air Clutch-Brake CYCLE CAM◆ 350IOC or 400IOC Input OLC AND LIMIT SWITCH◆ Left Hand Cam◆ Relief in Dwell for shot-pin applications 1301RD MOUNTED ACCESSORIES RISER BLOCKS◆ Universal Mounting Capability All dimensions are subject to change. For actual dimensions, please request the current drawing from IMC.◆ Custom Dial Plate

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 C-7 RD Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-8 RD Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 C-9 Intermittor Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-10 Intermittor Drives

Optional Accessories◆ 1 or 1.5 hp AC Drive Package with Inverter Duty Motor ø5.00 and Inverter Drive (up to 60 cpm) STATIONARY CENTER POST◆ 1.5 hp DC motor ø3.500 .50 1.25 THRU U DIAL◆ R4 Reducer (Ratios from 5:1 to 60:1) TOOLING PLATE◆ Output Overload Clutch model RT8D or RT8DF – Available Adjustable Settings (in-lbs): 4000-9500, 6000-15,500◆ Center Thru Hole (1.25 in. Diameter) CYCLE CAM &◆ Stationary Center Post LIMIT SWITCH

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 C-11 Intermittor Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-12 Intermittor Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 C-13 RD & Intermittor Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200C-14FeaturesIMC Roller Gear Index Drives are robust, versatileunits suitable for a wide variety of applications.Roller Gear Index Drives include:◆ Available with a Flange or Shaft Output.◆ All six surfaces are machined for universal mounting.◆ Optional Center Thru-Hole in Flange version facilitates passage of electrical wiring, pneumatic lines or mechanical linkages.◆ Short camshaft motion periods, due to oversized cam design, are well suited for continuous running applications or for special motion requirements such as oscillating motions.Roller Gear Index Drives are available in 14 modelsto meet a wide variety of speed, load and spacerequirements. Roller Gear Index Drives

Technical Specifications Output Load Capacity – loads carried during index Accuracy ±90 arcsec / ±.0013" at 3" Radius RGD RGS Repeatability ±45 arcsec / ±.0007" at 3" Radius Radial 1107 lbs 374 lbs Thrust/Axial 791 lbs 492 lbs Moment 762 in-lbs 736 in-lbs Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200D-2 Roller Gear Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 D-3 Roller Gear Index Drives

Technical Specifications Output Load Capacity – loads carried during index Accuracy ±73 arcsec / ±.0011" at 3" Radius RGD RGS Repeatability ±37 arcsec / ±.0007" at 3" Radius Radial 1775 lbs 689 lbs Thrust/Axial 925 lbs 545 lbs Moment 1572 in-lbs 1438 in-lbs Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200D-4 Roller Gear Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 D-5 Roller Gear Index Drives

70RGD/RGS Indexer Capacities Stops Index Motion B10 Capacity RGD Internal RGS Internal Model* (S) Period (β) at 50 RPM (in-lb) Inertia (lb-in2) Inertia (lb-in2) 270 ms 585 7 8 70RG(D/S)2H20-270 2 180 ms 562 7 8 70RG(D/S)2H18-180 270 ms 720 7 8 70RG(D/S)3H20-270 3 180 ms 753 7 8 70RG(D/S)3H20-180 270 ms 821 9 10 70RG(D/S)4H20-270 4 180 msc.15 942 9 10 70RG(D/S)4H20-180 120 msc.33 1107 10 10 70RG(D/S)4H18-120 270 ms 1406 9 10 70RG(D/S)6H24-270 180 ms 1583 9 10 70RG(D/S)6H24-180 6 120 ms 1768 9 10 70RG(D/S)6H24-120 90 msc.33 2110 9 10 70RG(D/S)6H24-90 270 ms 853 9 10 70RG(D/S)8H20-270 180 ms 949 9 10 70RG(D/S)8H20-180 8 120 ms 1027 9 10 70RG(D/S)8H20-120 90 ms 1063 9 10 70RG(D/S)8H20-90 270 ms 470 10 10 70RG(D/S)12H14-270 180 ms 528 10 10 70RG(D/S)12H14-180 12 120 ms 564 10 10 70RG(D/S)12H14-120 90 ms 584 10 10 70RG(D/S)12H14-90 24 180 ms 635 10 10 70RG(D/S)24H14-180 II * Specify “D” for Dial (Flange) Output or “S” for Shaft Output. Other Motions (stops and index periods) available. Contact your lMC sales representative for more information. Technical Specifications Output Load Capacity – loads carried during index Accuracy ±50 arcsec / ±.0008" at 3" Radius RGD RGS Repeatability ±25 arcsec / ±.0003" at 3" Radius Radial 2833 lbs 1019 lbs Thrust/Axial 2224 lbs 802 lbs Moment 3626 in-lbs 2808 in-lbs Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200D-6 Roller Gear Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 D-7 Roller Gear Index Drives

Technical Specifications Output Load Capacity – loads carried during index Accuracy ±45 arcsec / ±.0007" at 3" Radius RGD RGS Repeatability ±24 arcsec / ±.0004" at 3" Radius Radial 4790 lbs 2162 lbs Thrust/Axial 3470 lbs 1246 lbs Moment 7544 in-lbs 4853 in-lbs Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200D-8 Roller Gear Index Drives

Industrial Motion Control, L.L.C. • www.camcoindex.com • (847) 459-5200 D-9 Roller Gear Index Drives

Technical Specifications Output Load Capacity – loads carried during

8613371530291

8613371530291