hirschmann rotary table supplier

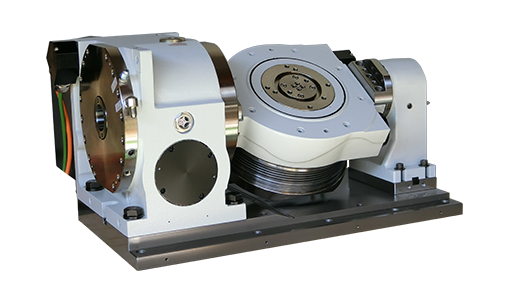

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

Cost and time pressure in part machining on EDM are new challenges for industry and trade. The key to success can be found in set-up times – where efficiency can increase productivity. For more than 40 years we develop and manufacture rotary indexing tables with coordinated reference and clamping systems. With them you can optimize machine running times and improve economics.

With decades of experience and perfected engineering we are leading manufacturer of rotary indexing tables, a-axes, rotating and indexing spindles together with total clamping technology for EDM technology. Due to high vertical range of manufacturing the customers approach only to one contact person and receive the guarantee that all components are not only assembled but made by Carl Hirschmann. Even for products which are in use for decades the company still offers suitable parts.

Rotary indexing tables combined with wire and sinking EDM offer completely new application possibilities. In wire and sinking EDM processes shapes can be realized far beyond the capabilities of turning, grinding or milling. In an erosive grinding process today microtechnology structures can be realized that seemed to be unthinkable even not long ago.

With our new and further innovations, constructions with zero and small series, test runs and prototypes we already opened a multitude of the nearly endless opportunities. In our high-precise rotary indexing tables, rotary tables and rotary axes are decades of experience and the know-how of special requirements of spark erosion, HSC and laser technology.

Project oriented research and development, in-house testing on our own benches and a high level of vertical integration are all available from Carl Hirschmann out of one source.

:quality(90)/images.vogel.de/vogelonline/bdb/1072500/1072570/original.jpg)

ISO 9001:2008 certified custom manufacturer of rod ends & spherical bearings, axial shafts, seals, submersible rotary axes & tables for EDM, workholding fixtures, robotic integration, dielectric fluids & grinding fluids. Rod ends & bearings are available in relubricatable or maintenance free versions & in metric sizes ranging from 2mm to 50mm & from 5/16 in. to 3/4 in, & in free-cutting steel, tempered steel, galvanized steel, chromalized steel & stainless steel. Other products include threaded bolts, metalworking fluids, work holding pallet systems for CNC machining, pallet systems for EDM, robotic loading devices, CNC rotary submersible axes, C axes & tool-changers for the machine tool industry. Serves various industries including aerospace, agricultural machinery, bakery machines, driving machinery, engine building, filling machine, hydraulic cylinders, machine tools, pneumatic cylinders, printing machines & welding machines. Meets DIN ISO 122404 & Cetop standards.

Sample Applications Sinking EDM • Undercuts • Tooth systems • Perforations Wire EDM • Curved shapes • Spirals Uniaxial rotary indexing tables Multi-axial rotary indexing tables Rotary indexing tables with hollow axle Rotating and indexing spindles Customized special solutions If requested, all rotary indexing tables can be equipped with a precise clamping system. Common characteristics • Complex shapes • Completely sealed (IP68) for use in dielectric fluid • Maintenance-free, patented EDM power transmission for wire EDM • Maintenance-free AC drive • Applicable on any EDM, laser oder HSC...

Rotary Indexing Table Goes Digital - for digital control during manufacturing process Functions: • Measuring and reporting of temperature and humidity inside the axis. • Readable using an app via Bluetooth on tablet or smartphone. • Data is transmitted, can be read out, evaluated and corresponding statistics on minimum-maximum-average-standard deviations can be generated • Values can also be read directly from LED display on the rotary table without any technical devices • Configuration of limit values for monitoring with visual and acoustic alarm function Advantages: • Increase of humidity...

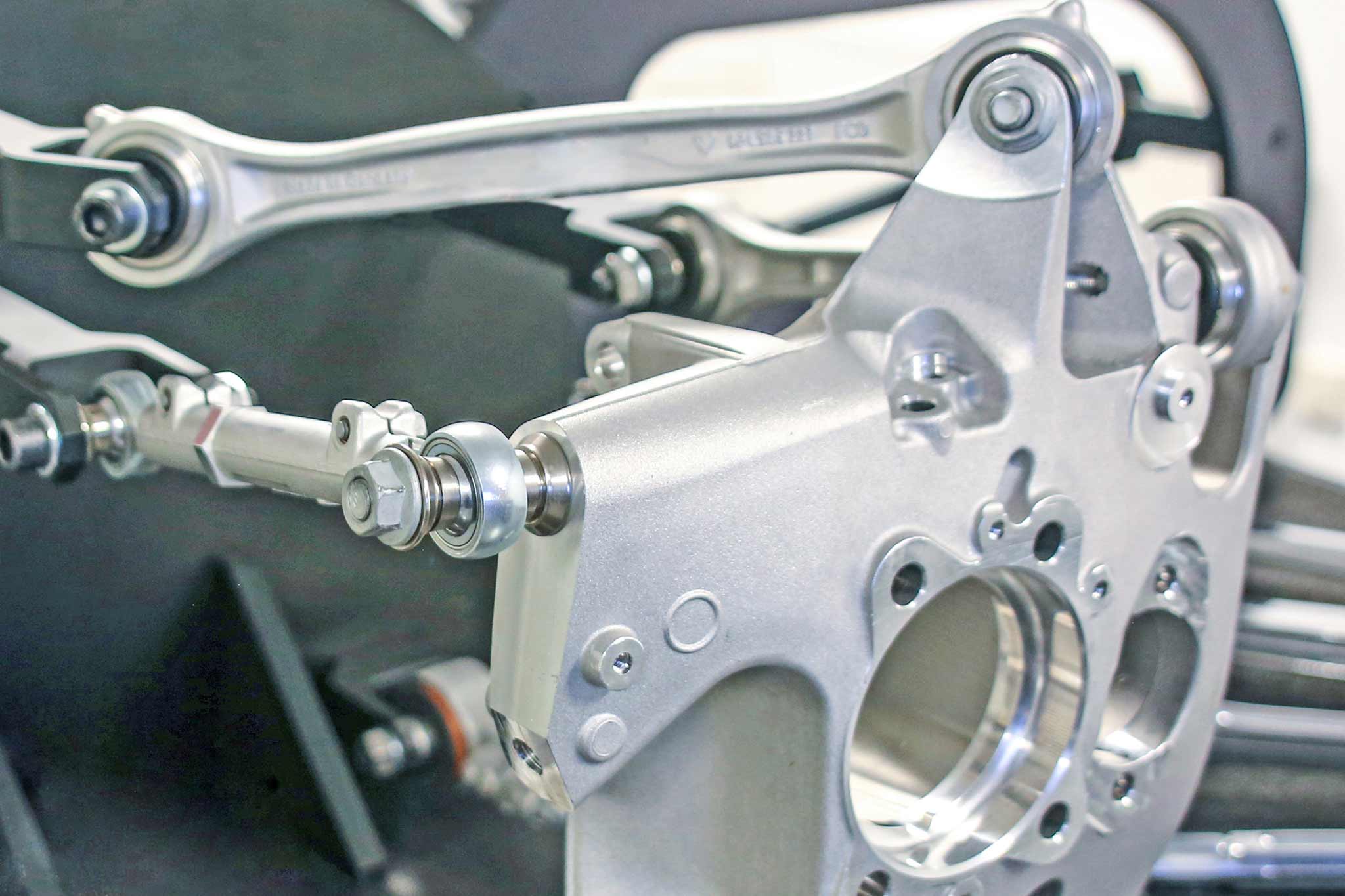

Uni-axial Rotary Indexing Tables At Carl Hirschmann all parts are homemade with high technical know-how and are assembled professionally to complete units consisting of rotary indexing table, palletizing and clamping system. With uniaxial rotary tables a vertical and horizontal machining with best positioning accuracy, concentricity and axial run-out accuracy is possible. If requested uniaxial rotary indexing tables can be delivered also with SK or HSK tapers. Two-axial Rotary Indexing Tables Our two-axial rotary indexing tables stand for highest precision, accuracy and continuity. The...

Hollow Axes With our precise uniaxial and two-axial rotary indexing tables with hollow axle the workpiece can be machined up to its center. Wire EDM is possible also for small workpieces. Customized solutions Due to our high manufacturing depth it is guaranteed to our customers that all components are made and not only assembled by Carl Hirschmann. We are pleased to meet individual customer requirements. Please contact us directly to find the perfect product for your demand. Carl Hirschmann - System provider with more than 4 0 years of experience For more than 40 years Carl Hirschmann...

HEILBRONN KARLSRUHE A81 A8 STUTTGART Carl Hirschmann GmbH Kirchentannenstraße 9 78737 Fluorn-Winzeln Germany Carl Hirschmann, Hirschmann, Inc. Inc. 165 East Commerce Drive Ste 104 Ste 104 Schaumburg, IL 60173 Schaumburg, IL 60173, USA USA Carl Hirschmann Hirschmann Room C528, Block 180, South Chang Jiang Road Bao Shan District, Shanghai P. R. CHINA 200433 T +86 139 16 13 58 45 E info@carlhirschmann.com.cn E info@carlhirschmann.cn

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Hirschmann Engineering USA, Inc. is offering the Stainless Steel Hollow Clamper µ-PrisFix H1.5000 for use in a variety of EDM applications. This new product provides quick and accurate clamping of work pieces mounted to the new Hollow Pallet µ-PrisFixH1.5005. The H1.5000 clamper is pneumatically opened using 6 bar compressed air and closed via spring pressure. Also incorporated in this workholder, are Hirschmann’s patented µ-PrisFix reference system clamping accuracies of ≤ 0.002 mm. The H1.5000 mounts directly to the center of Hirschmann’s hollow rotary submersible tables or fixtures designed for an array of uses, including micro drilling. With a height of just 35 mm, it is suitable for applications requiring machining operations within 75 mm of the hollow pallet.

From spherical rod end bearings, rotary tables, clamping systems, axial shaft seals, oelheld UK can supply the full Hirschmann range which offers excellent workholding systems at competitive prices for EDM processes. Read on for system details or get in touch with our technical team on 01745 814 777 to discuss your requirements.

System 5000 - Workholding solution for conventional EDM and milling / electrode manufacture applications. Ease of manufacture and precision are the key to successful, profitable use of EDM machines and the Hirschmann System 5000 offers both with a repeatability of 0.002mm across its whole range. Electrodes are transferred from milling to grinding then used in EDM without the need for continuous checking of datums.

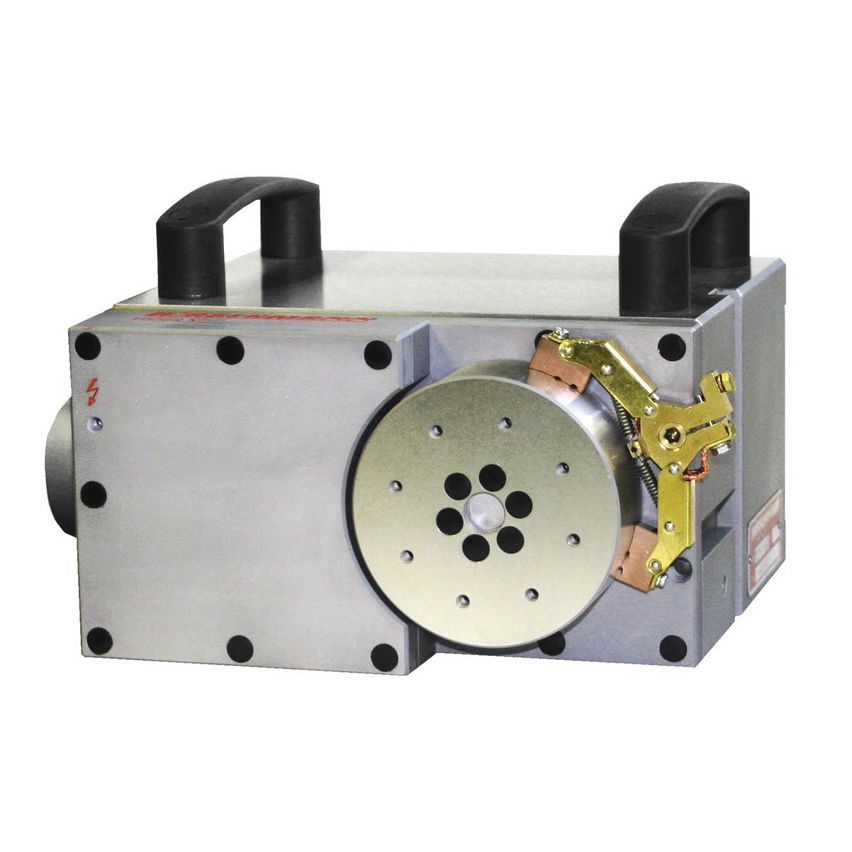

Submersible Rotary Spindles - For EDM Turn & Burn / indexing and EDM Turning applications. Carl Hirschmann have been producing rotary spindles for EDM for more than 40 years. A variety of specifications are available depending on workpiece size and application.

Rotary Spindles for Special Applications - The use of Polycrystalline diamond (PCD) as a material for the production of cutting tools in constantly increasing. The complex geometries required for this type of cutting tool can present great difficulties for standard production techniques which wire erosion processes can overcome. The addition of a high specification systems such as the Carl Hirschmann servo controlled A Axis which is suitable for use in submerged environments can quickly and effectively give a standard wire EDM machine PCD capabilities.

Anyway, to answer your questions, I looked up the Hirschmann table you referenced and it looks to me like it"s a spinner and indexer, not a turn while burn table.

Hirschmann must have a similar provision to integrate their turn while burn capable tables to whatever machines they are going to be run on...I don"t think you can just buy one and bolt it to a machine without the interface kit to mate it to the control.

Turn while burn requires that the controller governs the rotary motion; this is because the rate of rotation has to be driven by the spark gap conditions in conjunction with the axis motion of the rest of the machine whether it"s X or Y or U or V.

It was faked by tilting the wire to an angle other than the thread helix angle with the U axis, then driving a fine pitch helix with B and X (B is the rotary axis on my machine).

You can imagine just how many passes that would take (a LOT), and you will always have a 0.005" radius at the junction of each flank and the root, which may or may not be acceptable depending on the application.

Their innovative rotary indexing tables with coordinated reference and clamping systems optimize machine runtime and increase profitability. As a complete supplier, they develop specific solutions exactly according to your ideas. In addition, you can choose from a comprehensive standard range of suitable components.

They supply everything out of one source: from design, development and production to assembly in the metal-cutting machine. With decades of experience and sophisticated engineering, Carl Hirschmann is the leading manufacturer of rotary indexing tables, A-axes as well as rotating and indexing spindles including clamping systems for EDM technology or for EDM machines.

Do you have a new product or news release that should be included here for Carl Hirschmann, Inc.? We"d love to include it! Send your content to our editorial team.

Hirschmann Engineering USA now has a self-centering vise for use in its System 9000 zero point reference system. This vise allows a cost effective and universal method to quickly clamp different types of workpieces for five-sided machining.

8613371530291

8613371530291