rotary table tailstock factory

The answer depends on the length of the piece. For short-length pieces, you can get by without a tailstock. However, a tailstock for long, slender pieces — such as a rifle barrel — a tailstock is vital to ensure accurate machining without distortion or chatter. Read more

The center of the tailstock is aligned with the center of the spindle if it comes from the factory. If the tailstock is added to a rotary table, the center height of the tailstock is matched to the center height of the rotary table. If you want to check the alignment, you would use an indicator sweep of the tailstock quill. Indicators can be mounted to either the lathe spindle or the rotary table faceplate. Tailstocks can be adjusted side to side, but if the center height is off you will either need to add shims if it is low or remove material if it is high.

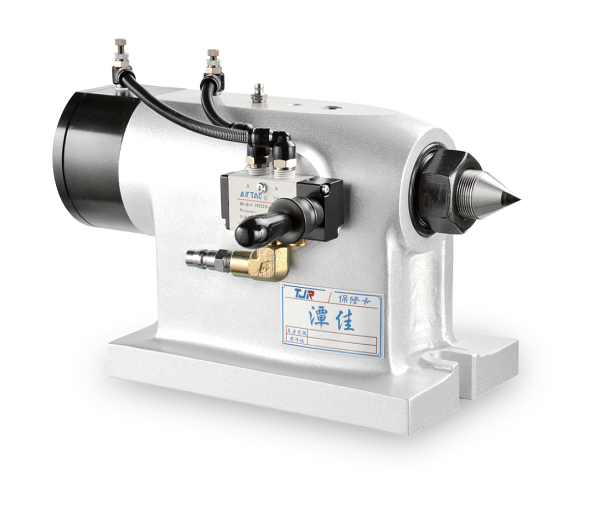

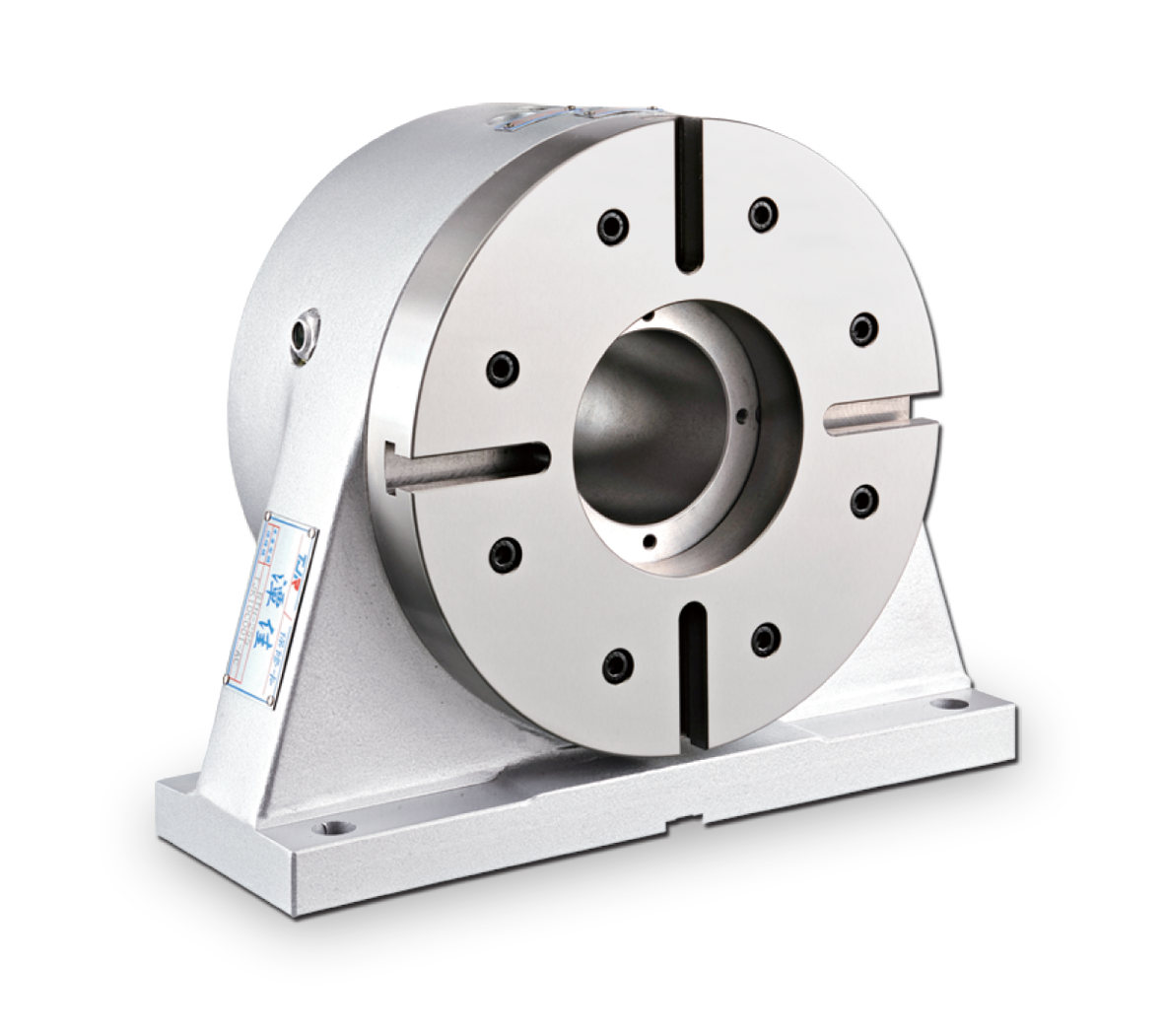

There are manual, hydraulic, pneumatic tailstocks, and there are tailstocks with built in live centers. In the case of rotary tables, you can also get a heavy duty tailstock which looks more like a another rotary table to support heavy parts.

There are dead centers and live centers. Dead centers that do not turn are almost always used on manual machine tools or rotary table tailstocks. Live centers, with built in bearings, are commonly used on CNC machines and where higher RPMs are required.

The TJ/TTJ is the most popular series of manual tailstocks that TJR offers. The TJ series is a fixed taper manual tailstock and the TTJ series offer a replaceable taper. Both series use a Morse tapered center to enable the support of a long work piece on a rotary table during the machining process. The center is easily moved forward and backward by rotating the handle on the rear of the unit.

This depends on the length of the workpiece. If you’re working with short-length pieces, a tailstock may not be necessary. However, for long, slender pieces — such a rifle barrels — it is important to have a tailstock to ensure accurate machining, avoiding distortion or chatter.

If the tailstock comes from the factory, the center is aligned with the center of the spindle. However, if the tailstock was added to a rotary table, the center height of the tailstock matches the center height of the rotary table. To check tailstock alignment, use an indicator sweep of the tailstock quill. Mount indicators to either the lathe spindle or the rotary table faceplate. You can adjust tailstocks from side to side, but to adjust center height, shims will need to be added if it is low or material removed if it is high.

There are several different types of tailstocks, including manual, hydraulic, pneumatic tailstocks, as well as tailstocks with built in live centers. For rotary tables, you can also get a heavy duty tailstock that resembles another rotary table to support heavy parts.

There are are two types of centers commonly used in tailstocks: live centers and dead centers. Live centers are built with bearings and are often used on CNC machines, which require higher RPMs. Dead centers do not turn and are most often used with manual machines or rotary table tailstocks.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new rotary table tailstock or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement rotary table tailstock, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new rotary table tailstock are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

The adjustable right angle tailstock supports the end of long stock held in the rotary table when it is in the vertical position. This allows you to accurately rotate a part between centers for milling or drilling operations.

Because of “tolerance buildup” in the various parts used to place the rotary table in the 90° position, it is not possible to build a tailstock that would come out exactly on center each time. By using a split base design with slightly oversize holes, the height of the tailstock center is adjustable slightly. Once set to exactly match your rotary table/right angle attachment combination, it should not need to be readjusted. It will work with both the Right-Angle Attachment and the Tilting Angle Table in the 90° position.

8613371530291

8613371530291