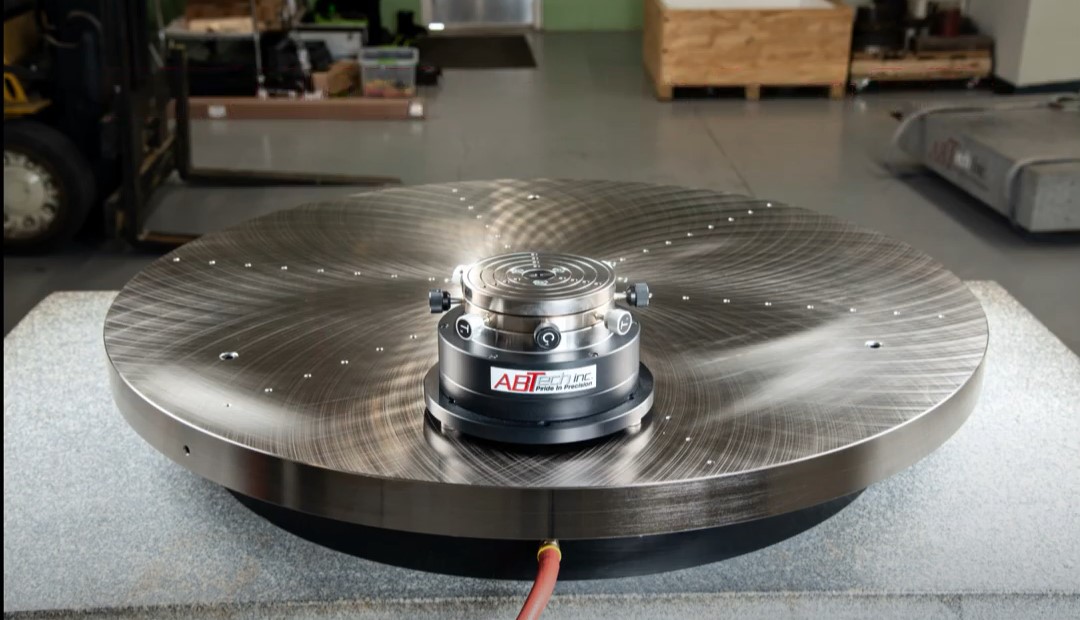

air bearing rotary table manufacturer

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

ABTech’s standard line of high precision, air-bearing rotary tables (AT Series) and heavy-duty rotary tables (HDRT Series) are ideal for low-speed TIR measurements, optical inspection, precision assembly, or light machining and grinding where radial and axial accuracies down to 2.0 µ” are required. These are available with tilt and center worktables, precision fixtures, 3-jaw chucks, vacuum feed through the center, and motor drives. They are manufactured with 440CSS and hardened to 58 – 60 RC, making these rotary tables the most robust available.

The A-688 direct drive rotary table with air bearings provides extremely high resolution and geometric performance. The angular resolution of this high precision air bearing spindle is 0.0015µrad (0.00003 arcsec), and flatness and eccentricity are specified better than 175nm and 300nm, respectively. This is made possible by high resolution, absolute measuring feedback encoders, and low-cogging frameless and slotless torque motors. The A-688 rotary table can be used in any orientation. Air bearing spindles guarantee a virtually unlimited service life with no wear, and zero required maintenance. As with all PI air bearings tables, the A-688 spindle is clean room compatible and requires no lubrication.

PI uses EtherCat based, high performance motion controllers ideally suited for closed-loop control of the rotation tables. Advanced algorithms are available to deal with changing load conditions and to suppress external disturbances.

Rotation tables with air bearings are used when rotary motion with the highest accuracy, smoothness, and geometric performance is required. Due to the lack of friction, these high precision rotation bearings and direct-drive motorized rotary tables can achieve angular resolution in the sub-microradian range. PI’s air bearing design and manufacturing group provides hundreds of man years of design experience along with the manufacturing and test equipment to produce high quality rotary tables with the tightest tolerances.

Rotary air bearings (air bearing spindles) are friction free, and all of PI’s motorized air bearing rotation stages employ closed-loop, non-contact 3-phase direct-drive torque motors, and optical high-resolution rotary encoders for ultra-reliable maintenance-free operation with basically unlimited service life.

Absolute angle-measuring feedback sensors are available to provide closed-loop control with single digit microradian bi-directional repeatability. Direct-drive rotary air bearing tables also provide better eccentricity, flatness, and minimized wobble compared to rotary stages based on mechanical bearings. The friction-free design allows for high angular velocity without vibrations and noise.

Applications of rotary air bearing spindles / motorized direct-drive rotary tables include indexing, metrology, optical lens testing, bio-medical engineering, runout measurements of machined parts, and fiber optics.

PI’s high-performance closed loop servo motor controllers are available to precisely control position, acceleration and velocity, with advanced algorithms. Fully integrated multi-axis motion systems with linear air bearing stages and combinations with gantry systems are also available from PI’s air bearing division.

Air Bearing Rotary Tables, Table Top and Work Load are Supported on Air Bearings whose Freedom from Friction Contributes to Extremely High Positional Accuracy

An Interlocking Switch is used when Motors are Incorporated to Prevent the Table Top from Moving when the Air Supply is Turned Off. When the Air Supply is Turned Off, the Table Top Sits Firmly on our Cast Base with an Extremely High Accuracy of Parallelism Between the Base and Table Top

Rotary tables specifically developed for use in Metrology applications. CMM tables, inspection tables, assembly tables. Range of sizes 100mm thru 5,000mm. Larger on request.

Air bearing rotary tables, when rotating, the table top and work load are supported on air bearings whose freedom from friction contributes to the extremely high positional accuracy. High precision needle roller bearing maintains radial accuracy.

Supplied with each table. On/off Switch controls the compressed air supply to the table. Interlocking ensures that the motor drive can only operate if the air supply is on. When air supply is off, table sits firmly on the base casting with extremely high accuracy of parallelism between the top surface and the underside of the base.

They come with worktable diameters from 424 in. (100605 mm) with radial and axial accuracies from 0.000,0010.000,010 in. (0.0250.25 µm). Several models have load carrying capacities up to 1,000 lbs, and larger, heavy duty models can be supplied with air float centering assist or air/ball bearings. These heavy duty tables offer load capacities to 5,000 lbs and diameters to 60 in. (1,524 mm).

The modular design allows the rotary air bearing tables to be used in a variety of measurement and motion applications. They can be used with the company"s line of options and accessories.

X-ray inspection systems are inhigh demand. Known for their ability to identify anomalies, they have become crucial to ensuring quality and proper operation across a wide range of applications. These inspection systems function using specialized software to analyze the X-ray images. And, getting an accurate image relies on one deceptively simple tool: precisionrotary tables.

At their most basic, the precision rotary table consists of a motor or drive assembly and a spindle. For accurate data collection, the determining factor is the spindle. There are innumerable contact spindles on the market today, and while orifice bearing options are available as well, New Way® is here with the facts. Learn why Porous Media™ Air Spindles are the best choice for you.

Conventional roller bearings have many downsides in a rotary table. Uneven bearings can cause unpredictable movement and vibration, reducing precision. They also wear over time, compounding performance loss. Air bearings eliminate these inconsistencies. Using a stiff cushion of air, these bearingsremove frictionand provide a wide array of benefits, including:

Even among other air bearings, New Way is special. To understand why, the first step is understanding the two main groups that constitute broader category of air bearings:

Porous media, utilizing the natural permeability of porous carbon. Millions of sub-micron holes inherent to the material enable the even distribution of air across the bearing surface.

The key differentiator between orifice and porous media is how the air is distributed. OurTechnical Report 1covers this topic in detail, but the most important point concerns the pressure gradient created by the bearing. With orifice bearings, you have spikes and dips in pressure, while porous media produces a smooth, consistent air film. This allows for even pressure distribution, providing better support.

One of the major concerns when considering an orifice-based bearing design is the response to sudden pressure loss. For orifice bearings, this type of crash can be catastrophic, often resulting in hard, metal-to-metal contact which damages both the bearing surface and the stator surface. These scenarios become particularly problematic as precision rotary tables have become more widely adopted. Any failure in the rotary table means downtime for repair, costing you both time and money for new parts.

Conversely, porous media naturally acts as a restrictor for the air supply, creating a consistent, nanometer-thin air cushion with an unmatched combination ofdamping and stiffness. Even in a worse case scenario where a crash is unavoidable, the soft carbon face (at a compression strength of 91 MPa) means the carbon will absorb the blow, protecting your guide surface and other components which might be difficult or costly to replace.

Air bearings also offer massive improvements for precision. Manufacturing imperfections in ball bearings, coupled with the wear induced on multiple rotating surfaces, causesasynchronous and synchronous errors, impacting precision and creating hysteresis error. By suspending the rotor on a frictionless five micron-thick layer of air,synchronous error is standardized and asynchronous error is almost entirely eliminated. Additionally, because an air-bearing-based system doesn’t need to contend with unequal pressure loadings or theinternal momentumand inertia inherent to a ball-bearing-based system, porous-media-based rotary tables boast nano-scale accuracy.

New Way Air Bearings products have shown extensive increasedreliabilityover their contact and orifice bearing counterparts. Because rotary tables and spindles built on porous media have no dynamic parts in contact with one another, friction is eliminated, resulting in a product that is longer-lasting, while also providing superior performance.

Servo-Drive Rotary Stagesare New Way’s all-encompassing solution for your high-tolerance precision rotary needs. Combining air spindles with a slotless, brushless motor and a precision rotary encoder capable of 1.1-arcsecond precision, the Servo-Driven Rotary Stage offers 1,184,000 counts/rev.

T-Series Air Spindlesprovide our highest levels of resolution, ideal for precision rotary table operations. Available in several standard sizes in both round and square stator configurations, the T-series spindle provides frictionless rotary motion with the tightest tolerance, reducing radial and axial error motion down to 0.1 µM.

Thrust Bushingscan be utilized as a precision rotary table by floating the table on top of the thrust face. Thrust bushings are available in a range of standard sizes for different rotary applications.

For precision rotary tables requiring less precision, we offer a unique combination of ourFlat Round BearingsandAir Bushings. By placing the flat bearings in a ring configuration with the air bushing as the center “spindle,” a precision rotary table can be created.

Whether it’s for an X-ray system inspecting a life-saving medical device or a CNC setup for machining critical electronic parts, New Way has the solutions to create a precision rotary table to meet your requirements.

Discover the power of porous media’s increased precision and reliability in your operations. To learn more about how air bearings are changing industries,download our eBook! And, as always,contact us anytimeto discuss how our products can benefit your custom application!

PI is a leading manufacturer of precision motion control and automation systems, hexapod 6-axis parallel robotic stages, air bearing motion systems, Gantry Systems, 3D printing, laser machining, and piezoelectric nano-positioning solutions. Applications include photonics, semiconductor technology, medical engineering, assembly, inspection, materials handling, and bio-nanotechnology. PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagneti

Schaumburg, IL – PI (Physik Instrumente), a leader in precision motion control solutions, will show its latest rotary air bearing stage series at this year’s LAM/LME (Laser Additive Manufacturing / Laser’s for Manufacturing Event) show on March 27/8 in the Schaumburg Convention Center. PI’s new A-635/A-637 PIglide lowprofile precision rotary tableshave no rolling or sliding elements and deliver frictionless, non-contact motion, resulting in negligible reversal error, better wobble, eccentricity and velocity stability – ideal prerequisites for high-end industrial applications such as inspection, metrology, calibration, and scanning, including cleanroom environments.

The PIglide RL direct-drive high performance rotation stages offer superior accuracy, flatness, and wobble performance. Featuring 3-phase, low-cogging slotless torque motors with velocity to 500rpm and optical encoders, these stages provide outstanding performance such as 0.0015µrad resolution ±2µrad bidirectional repeatability and absolute accuracy of ±6µrad (with error compensation and ACS motion controller). Geometric performance is also excellent with 50nm flatness, ±50nm radial runout and 1µrad wobble. Available in 2 motion platform diameter sizes of 200 or 300mm, various options can be combined to create a solution ideal for point-to-point indexing or constant velocity scanning. These rotary positioners have a virtually unlimited life, there are no parts that wear or require maintenance.

PI designs and manufactures all air bearing products in the USA. PI’s engineering team has more than 200 man years of air bearing design experience. In addition to customized systems for OEMs, PI offers a substantial standard product line of air bearing stages that includes motorized and non-motorized, linear, rotary, spherical, X/XY, voice coil, compact, and large scale systems, as a complement to the existing comprehensive range of piezo nano positioning stages, traditional motorized positioners and hexapod 6-axis parallel positioning systems. The addition of air bearing technology puts PI in the unique position to cover the whole motion range from finger-tip sized nano-positioners to large scale stages with long travel ranges, through a plethora of different drives and guiding systems that can be tailored to meet the needs of an OEM or customer.

PI is a leading manufacturer of air bearing stages, piezoelectric solutions, precision motion control equipment, and hexapod parallel-kinematics for semiconductor applications, photonics, bio-nano-technology and medical engineering. PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagnetic drives for 4 decades. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. The PI group employs more than 1,000 people worldwide in 15 subsidiaries and R&D / engineering centers on 3 continents.

The ABRT series precision rotary tables from Jena Tec utilise robust high precision roller axial bearings with an air bearing in the horizontal axis for smooth, precise rotary motion. The air bearing principle offers a compact overall height of only 100mm with a cost effective bearing solution and high geometric accuracy. A hollow shaft design means that centralised services for pnuematic or hydraulic clamping can be provided easily. Units can be supplied in either manual or CNC format with a standard range of torque motors offered.

The ABRT series precision rotary tables from Kuroda Jena Tec utilise robust high precision roller axial bearings with an air bearing in the horizontal axis for smooth, precise rotary motion. The air bearing principle offers a compact overall height of only 100mm with a cost effective bearing solution and high geometric accuracy. A hollow shaft design means that centralised services for pnuematic or hydraulic clamping can be provided easily. Units can be supplied in either manual or CNC format with a standard range of torque motors offered.

PI Nelson Air has developed an extensive catalog of rotary air bearings and air bearing tables for diverse applications such as optical grinding, roundness checking, disk drive inspection, semiconductor processing, torque testing, and many others. In addition to offering a line of standard air bearing tables, we can provide individually customized bearings for each application. When you call us with your rotary bearing application, we will quickly adapt one of our many existing designs to fit the exact requirements.

PI’s A-630 series of low-profile rotary tables was recently extended by the new A-634 rotary stage with 150mm table diameter and the A-638 model with 350mm diameter. These high precision, high speed direct drive rotary tables are only 60mm tall and provide high speed to 3000 degrees/second. For transmitted light applications, the A-688 model with a large aperture is available.

As all of PI’s direct drive air bearing rotary tables, the A-688 high precision stage is also equipped with absolute measuring feedback encoders for closed loop position control. They provide resolution to 0.0015µrad (0.00003 arcsec), and flatness and eccentricity as low as 175nm and 300nm, respectively.

The rotary tables use low-cogging frameless and slotless torque motors to enable this excellent geometric performance. Different designs allow use in horizontal, vertical or any orientation. Air bearings guarantee a virtually unlimited service life with no wear, and zero required maintenance. As with all other PI linear air bearings and stages, the rotary tables are clean room compatible and requires no lubrication. For transmissive light applications, the A-688 direct drive rotary table with large aperture is available.

The highest motion performance is achieved with PI’s A-800 series of EtherCat-based, high precision motion controllers, ideally suited for closed-loop control of the rotation tables. Advanced algorithms are available to deal with changing load conditions and to suppress external disturbances.

Air-bearings have no mechanical elements such as rollers or slides, and deliver frictionless, non-contact motion, resulting in negligible reversal error, better flatness, and minimal wobble and eccentricity. All these are ideal prerequisites for applications such as inspection and metrology, calibration, and scanning of high-end parts (i.e., infrared and precision optics, turbine blades, shafts and bearings) in industries like aerospace, aircraft, automotive, semiconductors, and photonics.

PI is a privately held company that designs and manufactures world-class precision motion and automation systems including air bearings, hexapods and piezo drives at locations in North America, Europe, and Asia. The company was founded 5 decades ago and today employs more than 1300 people worldwide. PI’s customers are leaders in high-tech industries and research institutes in fields such as photonics, life-sciences, semiconductors, and aerospace.

The design of the ABRS series direct-drive rotary stage has been optimized to minimize stage height. The low profile of the stage reduces the effective working height of the system, minimizing "stack-up" related errors. In addition to the low overall height, the ABRS series provides a clear aperture that can be used for product feed-through, laser beam delivery, cable clearance or application-specific requirements.

The ABRS design features large air-bearing surfaces for high stiffness and load capacity, producing not only excellent axial and radial error motions but outstanding tilt error motion, as well. The resultant face error motion is significantly better than other rotary air-bearing tables and spindles, greatly benefiting applications requiring exceptional planar performance.

AB Series Air Bearing Spin Tables Rotary tables with high accuracy motion for assembly, test and inspection The AB Series tables utilise air lubricated hydrostatic bearings designed to provide very high radial and axial stiffness. This type of bearing offers significant advantages over conventional rolling element bearings permitting operation with minimal drag vibration and mechanical noise. The design principle of these bearings ensure axial laminar flow between shaft and housing compared with conventional orifice entry arrangements thereby ensuring exceptionally good motion geometry. From 200mm to 600mm diameter rotary spin tables with high geometric performance for assembly, test, inspection and metrology applications. High grade stabilised cast iron base and rotary platen, ensure rigidity and precision. Precision hydrostatic bearings designed to provide very high radial and axial stiffness. This type of bearing offers significant advantages over conventional rolling element bearings permitting operation with minimal drag vibration and mechanical noise. ROTARY PRECISION INSTRUMENTS UK LTD The Maltings Industrial Estate, Brassmill Lane, Bath, England, BA1 3JL sales@rpiuk.com www.rpiuk.com

8613371530291

8613371530291