nikken 5 axis rotary table supplier

A special alloy steel worm screw with excellent shock resistance is adopted for small-size rotary tables to extend their service life and realize high cost effectiveness.

On the other hand, the extremely rigid and high-speed rotation-capable carbide worm screw is adopted for large-size rotary tables to withstand severe usage and maintain its accuracy almost permanently.

Martin Trunnion Tables and Lyndex Nikken are now offering complete 4th axis packages. Ready to be mounted into your machine tool, your Stallion Trunnion Table will already be attached to the Lyndex Nikken rotary table of your choice and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis machining. Our line of trunnion tables can be made to fit any Lyndex Nikken indexer. Multiple workholding options are also available including 5th axis, AME, Schunk, Triag, Orange Vise and more. If you have any questions, do not hesitate to reach out to one of our applications engineers! Scroll down to view package options.

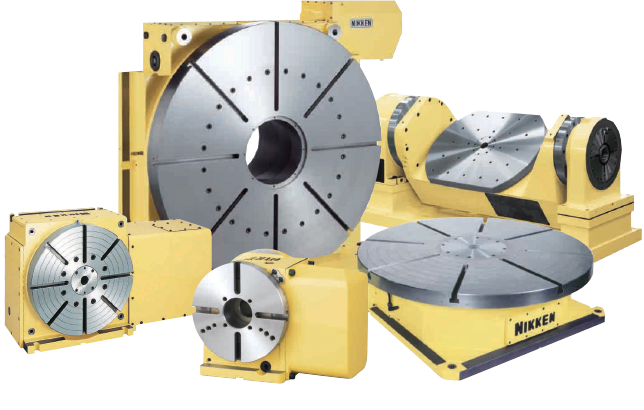

NIKKEN’s world-renowned CNC Rotary Table range provides proven performance, reliability and accuracy benefits for any application or requirement that others simply cannot hope to emulate.

With an extensive range of rotary table sizes, configurations and options available, all fully supported by our extensive global network, you can be sure to find the perfect product to meet any requirement or machine tool.

Single Axis, Twin Axis, Multi-Spindle, Standard Drive, High-Speed Drive, and Direct Drive capabilities are all available from stock. These can be configured and supplied for control directly by the CNC Machine or by integrating our exclusive Alpha 21 and EZ controllers to provide precise positioning and also full Macro B control (Macro B function – Alpha 21 only).

NIKKEN can also provide a complete and expansive range of accessories precisely engineered and customised to suit both the machine tool and the component. These options include a wide variety of chucking solutions, vices, bespoke trunnions & workpiece fixturing along with a wide range of NIKKEN manufactured rotary work supports and tailstocks to cater for all production expectations.

A pre-owned unit that is fully refurbished to a very high standard. This device is around 750mm in overall width subject to motor selection which suits a wide range of larger machine tool bed widths and an overall height of 295mm. The unit has a standard tilting range of zero to + 105 degrees. An excellent carrying capacity of 50kg through the whole tilting range and 80kg horizontally or between centres and speeds of up to 22. 2rpm in the rotary axis and 11. 1rpm in tilt dependent on motor selection. (Based on a 2,000rpm motor) Net weight of this device is around 210kg. The Nikken 5AX-200 CNC rotary tilting table without motors, can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface” (motor, switch, cable and connector requirements if you already have a “4th / 5th axis interface” in the machine) and machine interface costs (if you do not have the additional axes fitted). Rotary axis motor is mounted to the right hand side on this device and may restrict the Y axis capability in certain circumstances, the tilt axis motor is mounted in a rear facing direction on the far side of the device and should not have any bearing on traverses. This range of Nikken devices come with a carbide worm and specially treated hardened wheel, which means that backlash adjustments may be on an extended time frame to that of a device with say a bronze wormwheel. Nikken is a leading class manufacturer from Japan and in our experience build a very fine device with a very long service life.

Nikken 5AX-120 120mm Diameter Rotary Tilting CNC Table fully refurbished without motors or control. Requires motor and cables to suit target machine. All our tables are refurbished using Manufacturers specified parts only, we do NOT use inferior products. Nikken is a leading class manufacturer from Japan and in our experience build a very fine device with a very long service life. Nikken products sold by CNCROTARY. COM carry a standard one year parts and labour warranty.

At Lyndex-Nikken, they have made it their mission to provide the two things their customers need most: advanced technology and the innovation to keep it moving forward. That"s why, in addition to manufacturing the best machine tool accessories available on the market, they offer unmatched customer service and engineering support to their customers worldwide.

Their product line includes the world"s number one most durable, precise, and rigid CNC 4- and 5-axis rotary tables, the latest technology of static and live tools for lathes and turning centers, and the broadest range of high-precision AngleHeads and toolholders.

Every Lyndex-Nikken product is made in Japan, and expertly engineered to meet—and even exceed—your strict manufacturing demands. Through the power of the THINC control, their products seamlessly integrate with Okuma machining centers, allowing you to reduce cycle times and achieve maximum efficiency.

You can see their rotary tables, live tools, and toolholders on demonstration on Okuma machining centers at the Partners in THINC facility in Charlotte, NC.

Incorporated in 1989, Nikken Kosakusho Europe Limited is a subsidiary of Nikken Kosakusho Works Limited Japan. Its principle activities are the import, distribution and supply of the entire Nikken product range, which encompasses CNC Rotary Tables, NC Tooling Systems and Measuring Devices including Elbo Controlli Tool Presetters.

Nikken Works Limited, in Japan, annually produces some 500,000 tool holders, 3500 rotary tables and 250,000 reamers. It employs a global workforce in excess of 550 and has earned, and maintains, a reputation for producing quality products and demonstrating total commitment to its clients.

Nikken Kosakusho Europe Limited"s headquarters, workshops, sales offices and European distribution centre are based in Rotherham, South Yorkshire. This facility also plays host to numerous invited guests on a regular basis for seminars, presentations and cutting demonstrations on the in-house machining facility.

Nikken Kosakusho Works Ltd. is a manufacturer of Tool Holders and attachments for machine tools, we have been market leaders in various industries, i.e. Aerospace, Automotive, and Ultra Precision Machining ever since the company was created in 1958.

The word NIKKEN translates into "Everyday Study and Research" a principle adopted by all our staff in their daily pursuit of excellence in their work.

Nikken"s Osaka-Daito manufacturing facility opened during 2004. All product production and worldwide distribution are now handled from one extensive site.

By swapping its previous live toolholders for Mimatic models from Lyndex-Nikken, this manufacturer improved accuracy and rigidity in a critical drilling operation for a life-saving emergency rescue tool.

This shop refused to accept the notion that large, complex parts necessarily require multiple, time-consuming setups. Rotary tables from Lyndex-Nikken have saved time and expanded capabilities to the point where the shop can take on new work and bring previously outsourced jobs back in-house.

Integrating Lyndex-Nikken rotary tables into three-axis Mori Seiki VMCs provided this shop with five-axis capability at a fraction of the cost of a new five-axis machine.

A complete series of live tools for Nakamura Tome CNC lathes are now available from Lyndex-Nikken. Designed for precision and rigidity, these tools improve milling, drilling and tapping capabilities in turning operations, the company says.

Lyndex-Nikken’s shrink fit toolholders are designed for optimum accuracy, rigidity and balance. The solid construction minimizes unbalance variations when changing cutting tools, the company says.

The 5AX-200II CNC rotary table from Lyndex-Nikken is said to perform with high accuracy and fast rotating and tilting speeds. The company’s patented carbide worm system ensures wear resistance, rigidity and the rapid speeds of this rotary table. The carbide worm system uses a carbide worm screw and ion nitrided worm wheel rather than a conventional bronze or bronze-alloy actuation mechanism.

Mounted in a horizontal or vertical plane, rotary tables can be used to add fourth and fifth axis capability to conventional three-axis CNC machining centers. This rotary table manufacturer has developed an actuation mechanism that, according to the company, significantly increases the useful life of its rotary tables.

For the Wichita, Kansas, division of aircraft manufacturer Boeing, one aspect of effective high speed machining is finding the right balance. The division machines aluminum at speeds ranging from 15,000 to 40,000 rpm. To cut at these high speeds as effectively as possible, Boeing uses both pre-balanced and balanceable toolholders.

Providing you the best range of Nikken 5AX-130 150 mm 5th Axis Compact Rotary Table, Nikken 5AX-100 410 Nm 5th Axis Compact Rotary Table and Nikken 5AX-100 205 Nm 5th Axis Compact Rotary Table with effective & timely delivery.

Features :MAX Thrust Load applicable on the Table :- 5880 Tilting Angle =0 Degree, L=65mm F=2940N Tilting Angle =0 Degree L1=0mm F1=100mm L2=3460N F2=159N Tilting Angle =90 Degree 98 Tilting Angle =90 Degree

Incorporated in 1989, Nikken Kosakusho Europe Limited is a subsidiary of Nikken Kosakusho Works Limited Japan. Its principle activities are the import, distribution and supply of the entire Nikken product range, which encompasses CNC Rotary Tables, NC Tooling Systems and Measuring Devices including Elbo Controlli Tool Presetters.

Nikken Works Limited, in Japan, annually produces some 500,000 tool holders, 3500 rotary tables and 250,000 reamers. It employs a global workforce in excess of 550 and has earned, and maintains, a reputation for producing quality products and demonstrating total commitment to its clients.

Nikken Kosakusho Europe Limited"s headquarters, workshops, sales offices and European distribution centre are based in Rotherham, South Yorkshire. This facility also plays host to numerous invited guests on a regular basis for seminars, presentations and cutting demonstrations on the in-house machining facility.

Nikken Kosakusho Works Ltd. is a manufacturer of Tool Holders and attachments for machine tools, we have been market leaders in various industries, i.e. Aerospace, Automotive, and Ultra Precision Machining ever since the company was created in 1958.

The word NIKKEN translates into "Everyday Study and Research" a principle adopted by all our staff in their daily pursuit of excellence in their work.

Nikken"s Osaka-Daito manufacturing facility opened during 2004. All product production and worldwide distribution are now handled from one extensive site.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

The new CNC-PLUS series (CNC260P and CNC302P) offer unique features in terms of performance, reliability and precision for any application or requirement. Already the previous generations of this series have always been used on a wide range of vertical machining centres, thus enabling a fourth axis with minimal effort. With a completely redesigned and updated clamping system and a new design that takes better advantage of the standard pneumatic supply, numerous applications and requirements can be met and machined without the need for an additional hydraulic power unit.

The latest generation of the braking system can provide a clamping torque of up to 1550 Nm maximised by pneumatics – that is 2.4 times stronger than the previous models CNC260 or CNC302 (1430 Nm are achieved with an air supply of 5 bar, with a typical workshop supply of 6 bar even 1550 Nm are possible)! Both 4-axis rotary tables can be mounted vertically or horizontally to adapt to any application and significantly improve both the capacity and performance of your machining centre!

The 5AX-200II CNC Rotary Table from Lyndex-Nikken performs with high accuracy and with the fastest rotating and tilting speeds in the industry while providing exceptional brake torque.

llowing for the machining of five sides of a workpiece, the 5AX-200II is ideal for medical 5-axis work. It features a drop trunion and clamping torque of 588/490Nm. The faceplate diameter of this rotary table is 200mm and maximum work load is 176lbs. It offers secure gripping capability for unprecedented accuracy. Various options are available to meet workholding, fixturing and chucking requirements.

The proven tightening technology of Nikken"s Ultra-LockT Milling Chuck is applied to be the brake of the tilting axis of this 5-axis rotary table. This virtually eliminates vibration at any tilting angle, and provides the rigidity necessary to perform heavy-duty operations including face milling and heavy drilling.

Nikken"s Rotary Tables can be supplied in single and multiple spindle versions, with several options for motor mounting position, including right side, left side, back and top.

8613371530291

8613371530291