nikken 5 axis rotary table free sample

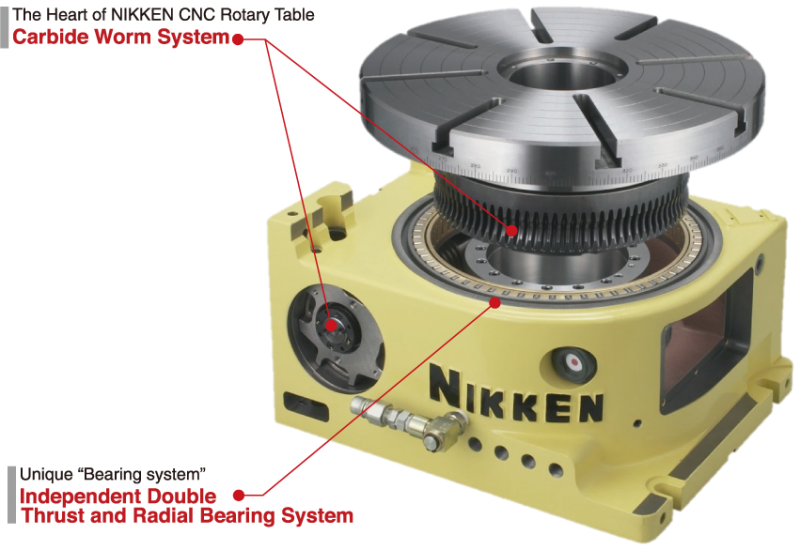

The largest B type model from Nikken with motor mounted to the rear, with higher gear ratio over earlier models increases speed over the vertically mounted motor version type CNC-400V. This unit also has a hydraulic clamping system. The unit has a 130mm spindle nose location with a location depth of 12mm with 105mm directly through the table and a has a centre height of 230mm in the vertical position. This device in the first instance is a vertical mount only device with options for a side mount motor, version which can be found under product code CNC-400V. An excellent carrying capacity of 250kg vertically unsupported and 500kg between centres with a standard tailstock with rotation speeds up to 22. 2rpm dependent on motor selection. (example given is with a 2000rpm motor)Net weight of this device is around 280kgThe Nikken CNC-401B rotary table is offered without motor and can be prepared to suit any interface at additional cost (see our interface listings for details and costs for “external interface”) (motor, switch, cable and connector requirements if you already have a “4th axis interface” in the machine) and machine interface costs (if you do not have the additional axis fitted). Motor is mounted to the rear via the right hand side on this device and is designed to avoid restriction to the Y axis capability and with a large bore available should you want to machine long bar components that need to be mounted through the centre. Please remember however, that being a back mount device the centre bore is restricted to passing through only the depth of the casting (240mm)This range of Nikken devices have Tungsten carbide worm shafts and hardened wheels which can mean less backlash adjustment required over a conventional brass/bronze standard gear.

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. - Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of these units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines.

VH65 - After years of installing and also repairing the many various manufactures rotary tables we sold, we learned what different designs worked and didn"t work in the machines. The second rotary head Fadal designed was the VH65. The VH65 stands for Vertical or Horizontal mount and 6.5" diameter faceplate.

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

You will receive an estimate of repair 5-10 days (depending on workload) after receiving rotary unit. Repairs take an average of 10 to 30 working days after receiving approval. Evaluation charge of $500.00 will apply if you do not get it done.

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification. We warranty our complete Rebuilds for 1 year.

As you can see we are the most qualified to tune-up or rebuild your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications. Simply call Toll Free 1-800-342-3475 for any questions.

NIKKEN"s ‘Green Button Machining’ concept promotes the benefits of how NIKKEN solutions can ultimately contribute to increased machine uptime. Tool life can be fundamentally improved to negate ‘red button’ operation, with the machine being stopped for tool changeover or tool breakages and the consequential additional set-up times. Thus, reducing energy consumption, providing greater efficiency and a surge in sustainability.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

• Please refer to page 29 for tailstocks and table accessories details. • Left hand mounted motor table(L type) is available; please contact us for more information.

“We’re a family business that’s evolved tremendously,” says Van Gardner, vice president of sales and marketing at GCG Industries. Much of the Fort Wayne, Indiana, job shop’s evolution has occurred in the past four years, after it purchased an Okuma CNC vertical machining center (VMC) with a rotary table to add five-axis machining capabilities. Since then, the shop has experienced cascading successes, which it attributes to this machine, along with specific machine components and additional equipment, such as new tooling, quick-change workholding devices and on-machine part and tool probes, that have helped it maximize its five-axis capabilities.

Mr. Gardner says five-axis machining has enabled GCG to take on more complex and diverse work that other smaller, local shops do not have the ability to produce. The shop can complete jobs in fewer setups and achieve tighter-feature, true-position tolerances. Its sales have increased, and it has added more machines. In fact, the shop now has seven VMCs with five-axis capabilities. This provides a solid foundation for potentially adding automation (via a pallet system or robotics) in the future, with the hope of increasing the annual sales growth even more than what the shop has been realizing since adding that first five-axis machine in 2014.

That said, there were lessons to be learned as the shop decided to pursue five-axis machining and as it gained experience its machines. Mr. Gardner shared some of these lessons during my recent visit to this Midwest shop.

Mr. Gardner’s father Terry founded GCG Industries 30 years ago. The now has 13,000 square feet in two buildings with plans to expand another 3,500 square feet. Included among its 37 employees are Terry’s wife Tammy, who handles accounting, his son Justin, who heads up the quality requirements and his daughter Brooke, who oversees customer service. The shop focuses on short runs (50-75 pieces) of small parts (a three-inch cube would be considered a large part, depending on the material) for accounts in a range of industries, including medical, aerospace, agriculture and RV. Typical materials machined include aluminum, 17-4 stainless steel and Inconel.

GCG never went down the road of Swiss-types. However, its sole medical customer at that time prompted the shop to get five-axis capabilities. GCG had done three-axis work for the company, and it brought the shop a part that required five-axis machining. Mr. Gardner says it would have been virtually impossible to make this part on a three-axis machine because it required tight feature-to-feature tolerances that a three-axis machine more than likely could not hold due to the multiple setups it would have needed. GCG made the investment in its first machine with five-axis capabilities, and it turned out to be just the solution the shop needed. “It’s harder to find a shop to do this type of complex work than it is to find one that performs more conventional three-axis machining,” Mr. Gardner says. “We’re trying to secure our future that way.”

There are a variety of five-axis machine configurations on the market. At the recommendation of its distributor, Gosiger (Dayton, Ohio), GCG went with an Okuma Genos M560-V VMC and a Lyndex-Nikken 5AX201 rotary table to provide the fourth and fifth axes of rotation. The shop already had some machines from Okuma (Charlotte, North Carolina), and the familiarity played a role in the decision. “It made sense to keep going down that path,” Mr. Gardner says.

In the four years since the first purchase, GCG has acquired six additional machines with five-axis capabilities. It added the last four in less than a year’s span. Mr. Gardner says there are clear benefits to standardizing in such a way. All of the shop’s employees know how to run all of the machines. The risk of error is reduced because they only need to know one type of machine, and they have become familiar with it. Using the same type of machine has the added benefit of enabling operators to run the same part programs on any of the machines.

According to Mr. Gardner, the table-on-table application has several benefits for GCG over a true five-axis machine. For one, he says it gives the shop “a lot more bang for our buck,” as it is a more affordable solution than a dedicated five-axis machine. Because the shop specializes in small parts, the machine can fit the rotary table along with two vises and a tool probe on the main table. In some cases, five sides of a part can be machined using the rotary table and then the part can be flipped and loaded in a vise to complete machining of the sixth side. Also, given its specialization, the shop never needs to take the rotary tables out of the machines to make room for large parts on the table. Mr. Gardner says the Lyndex-Nikken rotary tables are also beneficial in that their clamping system is hydraulically actuated instead of being actuated with compressed air, meaning they offer higher holding force and rigidity during cuts.

This solution also gives the shop the ability to do full five-axis contour machining as well as five-axis positioning. Mr. Gardner says that one of the most important factors in choosing the Okuma machine was that its control enabled full, simultaneous five-axis contouring. Although it mostly uses the machines for “3+2” five-axis positioning, the shop wanted the flexibility to be able to do full five-axis machining as well. “It made sense to spend a little more to have the ability to do that,” he says. While virtually all the current work that GCG does only requires five-axis positioning, it has run full-five-axis tool paths on some of its jobs, and it does open the possibility to pursue more of that contouring work in the future.

Because GCG mostly does five-axis positioning, Mr. Gardner says the transition has been easy for the shop in terms of much of the programming. It does the programming for its five-axis parts offline using Mastercam, the same CAD/CAM system it uses for three-axis machining. He says that the shop approaches part programming either by essentially stringing together the three-axis programs for each side or by using more complex programming techniques, like programming off of the centerline of rotation to account for the different positions in which a part might be tilted.

GCG realized that it needed more than just the ability to move parts in five axes. Beyond the rotary tables, the machines are equipped with several other features and additional technologies that have helped the shop get the most out of its machines and grow its business. These include:

Touch-trigger probing. GCG bought its first M560-V with Renishaw touch-trigger probing, but the first job it ran on the machine (which lasted for almost two years) did not require it. Due to this experience, the shop opted not to include the probing equipment on its second machine. However, when it started running jobs with castings, the shop saw the value of the probing equipment. “If you’re trying to put a hole in the center of another hole that’s already there, you can probe the casting, set the work fixture offsets and go at it that way,” Mr. Gardner says. It proved to be so useful for oddly shaped and irregular castings that the shop purchased probing equipment on all its subsequent M560-Vs and had it field-installed on the second machine.

The shop also uses the probing equipment for alignments and to square the machine, which increases repeatability and enables tighter tolerances. For example, it might probe the rotary table after a rotating move to ensure that the table is in the proper position. An alert will be sent if it is found to be out of position. Probing also helps speed setups because it can locate the actual position of a part or fixture on the machine, then automatically adjust the coordinate system in the control to match that location.

Specialized workholding. On the rotary tables, the shop uses a range of workholding devices, including Kurt Dovelock vises. The Dovelock vises, which can also be used in the standard Kurt vises installed on the table, grip on a small dovetail feature machined into the bottom of the workpiece blank. This provides ample clamping force, but also provides the tool with a good amount of access to fives sides of the part to minimize the chance of the tool or spindle colliding with any fixturing elements. Both workholding solutions have high clamping forces to keep workpieces rigid as they are machined on each side. Mr. Gardner adds that the shop is exploring the idea of creating its own workholding devices.

High-pressure coolant. When GCG made the investment in five-axis technology, it also decided to make an investment in high-pressure coolant. This helps improve chip evacuation and enables operators to push tools harder and faster. Mr. Gardner says that the coolant could benefit three-axis machines as much as it does five-axis machines, but the shop was not ready to spend the money for it until it purchased the VMCs and rotary tables.

The five-axis machines also use a different type of coolant than the one used on the shop’s three-axis machines. According to Mr. Gardner, the new product, Trim MicroSol 585XT from Master Fluid Solutions, is cleaner. “It’s not as gummy and it doesn’t stick to the walls,” he says. “Therefore, there’s nothing for the chips to stick to it and they just fall where they need to go.” He adds that the new coolant lasts a little longer and has improved tool life. However, he also notes that it can be difficult for customers to approve new coolants once they have committed to one.

GCG’s five-axis capabilities mean that it is taking on different work, making more complex parts that require higher precision and quality than its previous parts. Some of GCG’s customers are taking advantage of the new capabilities, causing a shift in the shop’s portfolio.

Even though many of the parts GCG makes on these machines theoretically could be made with just three-axis capabilities, quality concerns and increased setup and cycle times often make this impractical. While five-axis machining has the potential reduce cycle times and increase profitability for parts that only require three-axis machining, there often is not open time on the machines with five-axis capabilities to move jobs around like this. “That’s kind of painful,” Mr. Gardner admits.

Despite these issues, Mr. Gardner says the addition of five-axis capabilities is behind the shop’s growth. He estimates that business has grown between 8 and 10 percent each year since GCG got its first M560-V four years ago. The shop also invites customers in to see its five-axis machining capabilities, using the technology as a sales tool to generate additional business.

The new CNC-PLUS series (CNC260P and CNC302P) offer unique features in terms of performance, reliability and precision for any application or requirement. Already the previous generations of this series have always been used on a wide range of vertical machining centres, thus enabling a fourth axis with minimal effort. With a completely redesigned and updated clamping system and a new design that takes better advantage of the standard pneumatic supply, numerous applications and requirements can be met and machined without the need for an additional hydraulic power unit.

The latest generation of the braking system can provide a clamping torque of up to 1550 Nm maximised by pneumatics – that is 2.4 times stronger than the previous models CNC260 or CNC302 (1430 Nm are achieved with an air supply of 5 bar, with a typical workshop supply of 6 bar even 1550 Nm are possible)! Both 4-axis rotary tables can be mounted vertically or horizontally to adapt to any application and significantly improve both the capacity and performance of your machining centre!

8613371530291

8613371530291