rotary table repair in stock

CNC TOOLS provides an exchange credit for most defective items. Our exchange program provides you with savings and keep us stocked for the next time you order. A repairable unit will need to be evaluated to approve full exchange credit.

CNC TOOLS provides 12-Month Warranty to most NEW and Refurbished products unless otherwise specified. If the unit fails within the warranty period we will evaluate, repair or replace no questions asks. We stand behind our products to help customers minimize machine downtime.

CNC TOOLS provides an exchange credit for most defective items. Our exchange program provides you with savings and keep us stocked for the next time you order. A repairable unit will need to be evaluated to approve full exchange credit.

CNC TOOLS provides 12-Month Warranty to most NEW and Refurbished products unless otherwise specified. If the unit fails within the warranty period we will evaluate, repair or replace no questions asks. We stand behind our products to help customers minimize machine downtime.

We believe that our wealth of experience and our passion for quality makes Midland Engineering the best choice when it comes to the repair of your rotary table. We understand the need for a quality assured repair service with a focus on keeping downtime to a minimum.

We have experienced engineers based throughout the UK who are available to travel worldwide, we also have a premises here in Chesterfield just off of the M1 where we carry out in house repairs and refurbishments.

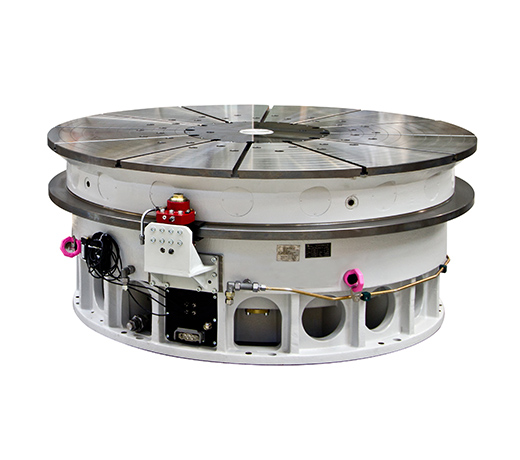

We offer quick turnaround and since all repairs and maintenance are performed locally, it reduces your down time. We diagnose, rebuild and repair each machine to restore it to optimal performance. All services are performed by knowledgeable, courteous, local Haas factory-certified service technicians to ensure that your CNC rotary table repair service is done according to manufacturer standards.

Productivity offers rotary table preventive maintenance that includes motor checks, backlash adjustments, flushing and replacement of lubricant and replacement of O-rings and seals. We also offer full service electronic repair of servo control units and cables.

Please call NDS for all of your rotary table needs, whether it may be for repairs or for new sales. We stock a wide variety of parts for the Gardner Denver 503 5-1/4″ rotary table, the 603 5-1/4″ rotary table with bottom ring gear, the 603 5-1/4″ rotary table with top ring gear, the 7-1/2″ 2003 rotary table with bottom ring gear, the 7-1/2″ 2003 rotary table with top ring gear, the 10″ 3003 rotary table, the 5-1/4″ GEFCO rotary table, the 7-1/2″ GEFCO rotary table, 7-1/2″ Mayhew table for a Failing Rig, 8-1/2″ Speedstar table, 8-1/2″ Mayhew Table for a Speedstar rig and the 8-1/2″ Midway rotary table. Portadrill, Mayhew, Failing and Midway rotary tables and parts are also available.

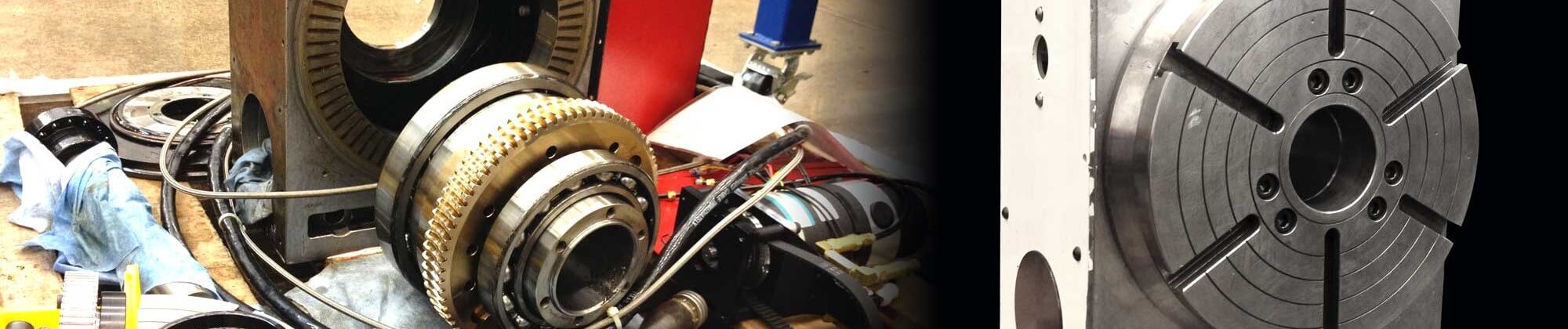

Has it suddenly stopped working and you"re panicking about downtime? Don"t worry - at CNC we can repair or deconstruct and fully rebuild your device back to its former glory.

At CNC Rotary, we offer a quick, dependable service where we will collect your table, take it back to our workshop, fix it and deliver it back to you as quickly as possible.

C). Face plate spindle damage, we had one unit that actually collapsed part of the spindle shaft. Fortunately, we were able to repair the spindle, potentially saving the customer the cost of replacing the entire face plate spindle.

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification.

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

As you"ll see below, we are the most qualified to repair your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. -Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of theses units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

Offering free over the phone and email support to all our customers, we understand the importance of avoiding downtime. Should you require an on-site visit, our dedicated service engineers have direct access to our warehouse stock of just under 1 million, ensuring minimal waiting time for a new part and installation. Our professionals are equipped to perform anything from minor repairs, to full strip downs, and mechanical rebuilds, as well as being trained in electrical support to replace cable looms to cable manufacturing.

A large number of specially selected, high-quality second user products are available through our webshop or directly from our technical sales department, providing rotary table products that have been fully rebuilt exclusively by us, to a very high...https://facebook.com/cncrotaryshop/videos/475171379666589/…

Rotary Base Table provides quick and easy height adjustment to accommodate samples of various sizes. Included are pair of T-bolts for securing Rotary Base Table to slot in base of CT3 Texture Analyzer.

And finally, a great deal of attention was devoted to the service friendliness of CNC rotary tables from pL LEHMANN in order to keep downtime as brief as possible. Thanks to sensors and electronic applications, every partner can, in an emergency, receive support directly from headquarters via teleservice. Or the customer is advised in advance to perform maintenance, depending on the usage. Real industry 4.0 / smart factory.

For products that use guide pieces to fix their body in accordance with T-slots of the mating machine, such as CNC rotary tables, tail stocks, side tables and side spindles, step guide pieces are available as well as standard guide pieces.

8613371530291

8613371530291