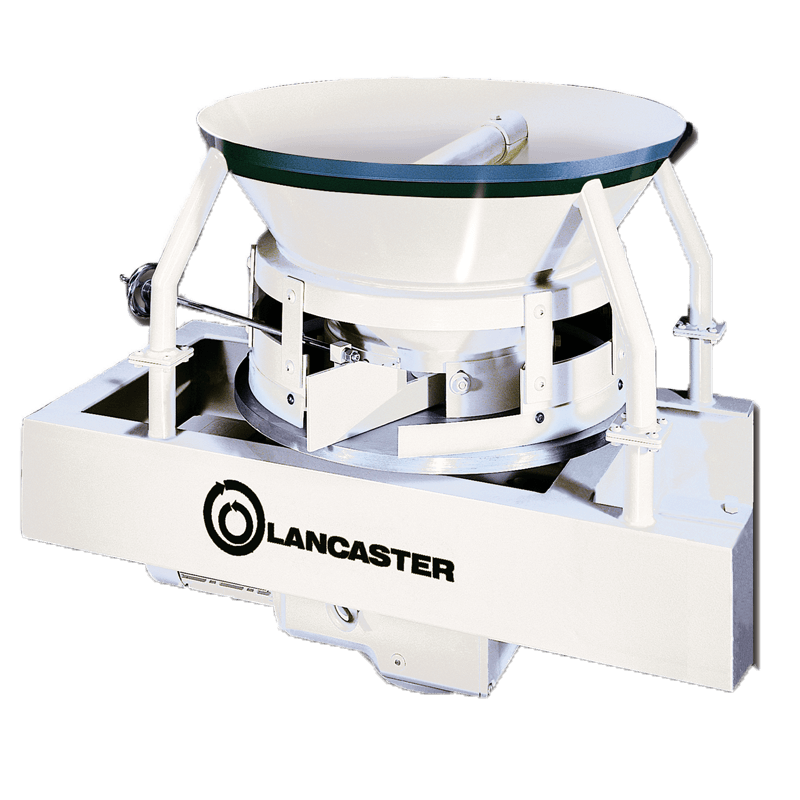

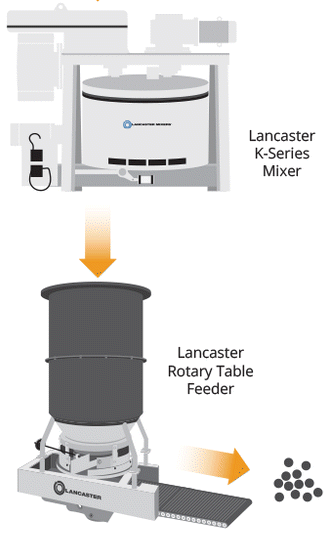

rotary table feeder quotation

Components of a Rotary FeederThe rotor shaft is a component found at the center of the electric motor. It produces a torque force, or motion, that causes movement of the material through the rotary feeder.Housing is the metal shell that contains and protects the electrical components of the rotary feeder. It forms the shape of the rotary feeder.

A rotary feeder works by separating pressure differences while allowing the passage of material into the processing system. To best illustrate how a rotary feeder works, it is best to imagine how a revolving door works. It permits the passage of material through while maintaining the difference of pressure in the building against the outside pressure.

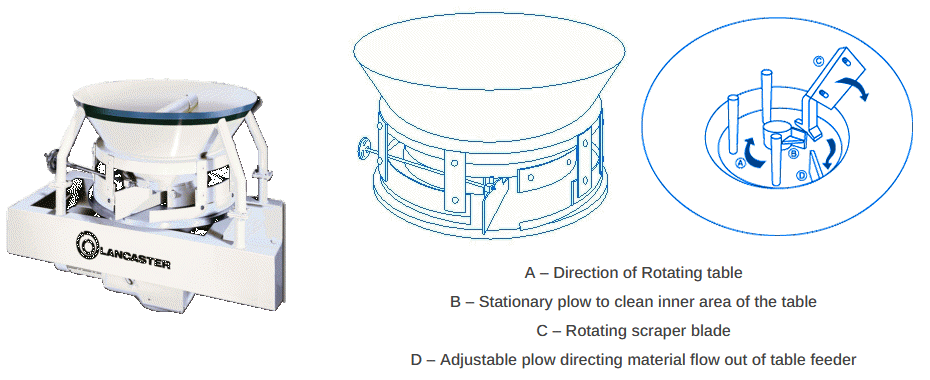

Commonly known as ARFs, these feeders have varied speeds. They usually follow the direction of material flow and make use of a rotating member and the articulable gate to control the flow volume of material. There is also what is called drum rotation. This regulates and prevents the backflow of material and reduces overloading, product distraction, formation of fine dust, and ensures a uniform flow of material.

These feeders are usually set to feed material in a pneumatic conveying line. Rotation of the valve, coupled with the leakages between the rotor and the stator, cause gas from the conveying line to go upstream and be emitted.

Global provider of vibratory feeders and other custom part feeding solutions, specializing in automated equipment that orients bulk parts by means of vibration and centrifugal feed systems, built to customers specifications. Products include custom tooled vibratory bowls, inlines, escapements, bulk hoppers, gravity tracks, sound enclosures, tables, base plates, PLC packages, IV sensors and cameras. Also offer custom centrifugal feeders, conveyors and bulk prefeeders. These feed systems use both mechanical tooling as well as vision or profile sensor integration. Systems are managed by either simple bowl and track level sensor monitoring to full PLC Logic with or without Ethernet capabilities. Engineering services from proof of principle to Solid Works modeling. Documentation/FAT approval via live streaming available. Serving the following industries: medical, medical devices, pharmaceutical, injection molding, packaging, labeling, aerospace, defense/munitions, electronics, cosmetics, fasteners, irrigation, automotive, and hardware.

ABA manufactures both in-feed and out-feed rotary tables to help streamline automated filling lines. The implementation of a rotary table improves speed and output and eliminates the need for constant operator interaction with loading and unloading of containers. All of our rotary tables are constructed from an aluminum frame with a plated circular feed table or are optionally available with stainless steel frame and parts.

Infeed tables allow operators to pre-load large quantities of containers which are then automatically fed onto the conveyor. Rotary infeed tables increase speed, efficiency, and output and give operators the time they need to attend to other aspects of the fill cycle.

Out-feed tables collate containers at the end of the fill cycle, eliminating the need for an operator to receive each filled container as it comes off the conveyor. Our out-feed tables are outfitted with a stainless steel packaging table topped with UHMW plastic for easy removal of filled containers. The end results are faster and more consistent production levels.

For more information on our rotary tables or to work with us to design something that will be the most efficient for your fill line, please contact one of our representatives today.

Located at the entrance of a conveyor belt, or directly to the machine that has to feed, performs the function of “station of accumulation and distribution”. The products can be loaded manually or by conveyor belt. The adjustable deflectors allow you to sort and align products to the food evenly and without interruption the machine that receives them. Positioned at the exhaust of a conveyor belt or in the output of a packaging machine, filling machine, labeling etc., Performs the collection and accumulation of products function. The rotary tables are equipped with a speed variator to adapt to the various needs. The rotating disc may be provided in a slippery plastic material or stainless steel.

Planar ServoRingrotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives.Low maintenance and high throughput characteristics of the Planar ServoRing stage yields the lowest total cost of ownership.

Compact package and Superior designof the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working height. Angular contact bearings are used to maximize performance with respect to wobble, moment stiffness and friction. ULTRATHIN ServoRing stage has large clear center aperture that can be used for air or wire line feed-through or beam delivery.

Accurate Positioningis assured with contactless encoder.The motor and rotary encoders are directly coupled to eliminate coupling backlash. The low inertia and zero backlash make Planar ServoRing the ideal solution for applications requiring frequent directional changes.

For medium to large parts, the VH-11 rotary table has an 11" (280mm) diameter platter with a 6.75" center height. A 10" or 12" chuck or fixture can easily be bolted to the table using the six precision T-slots. Its large 4" through-hole can be used for bar feeding and special fixture-locating requirements. The spindle and worm have two bearings for front and back support. As always, the worm wheel is helically cut and throated for greater surface contact between the wheel and worm. There is an optional 10" or 12" manual 3-Jaw chuck and adapter plate available as well as a manual or pneumatic tailstock with matching center height.

The Index Designs VH-11 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

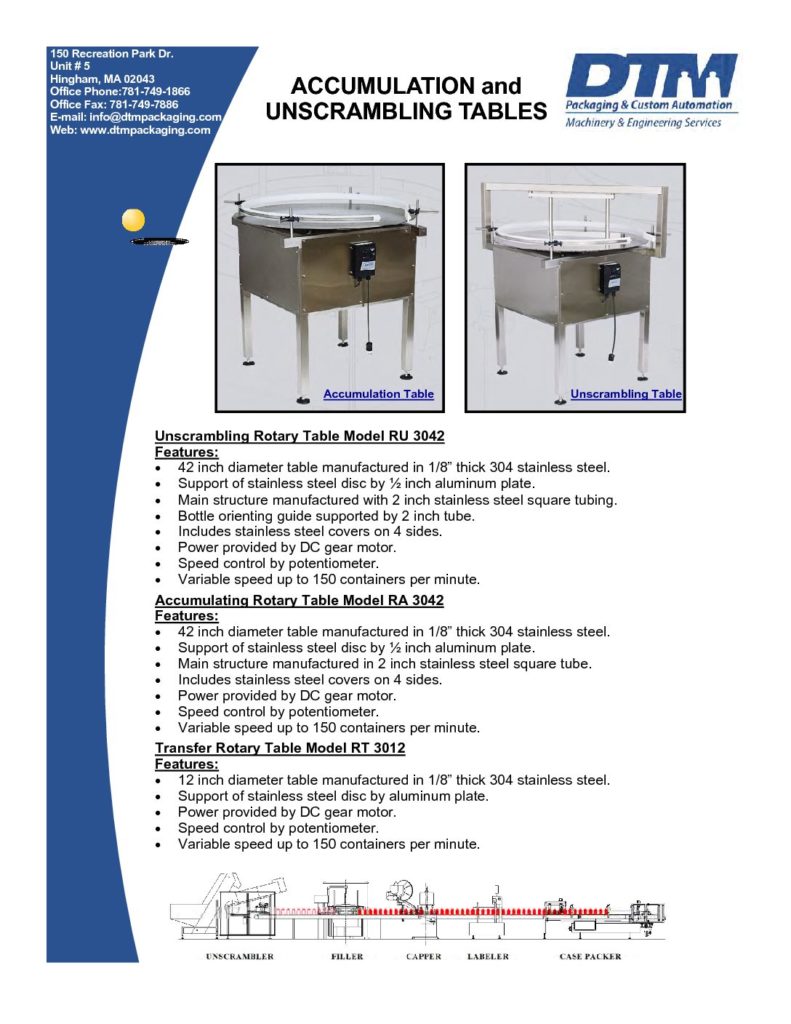

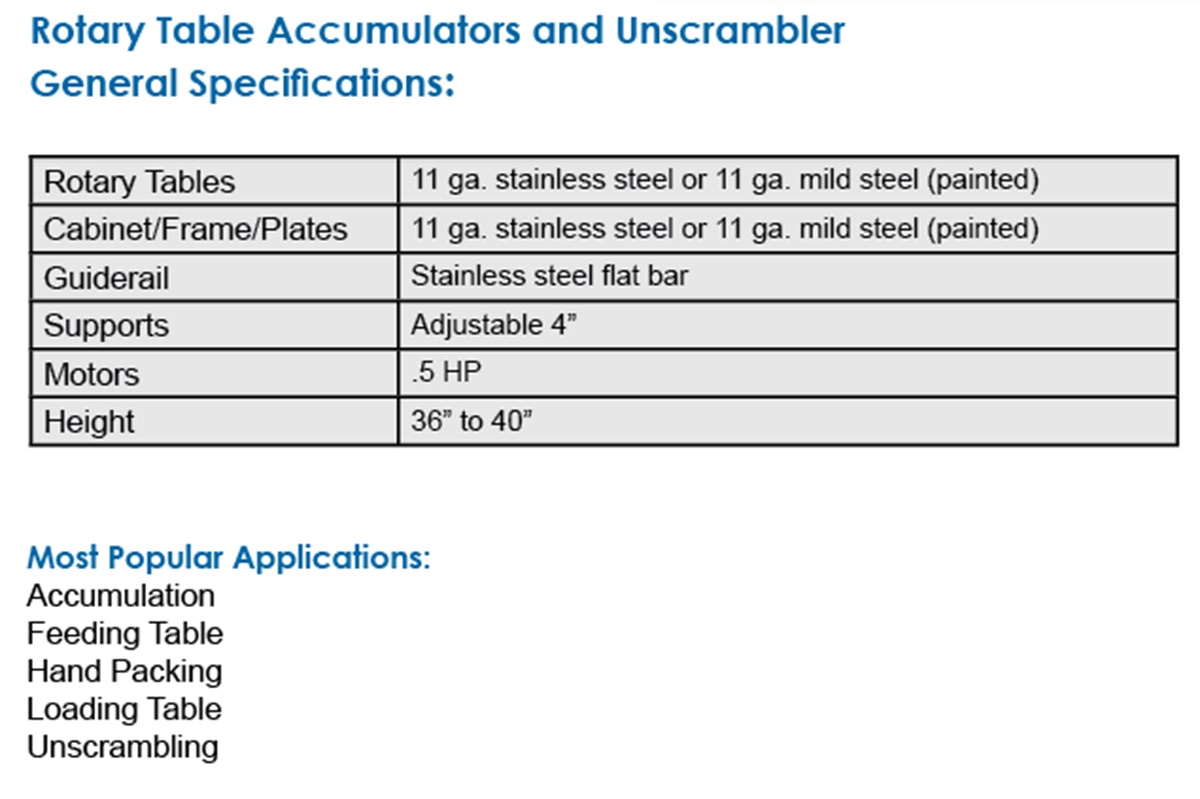

One of the earliest designs for accumulation or unscrambling is the rotary table. Both configurations can handle multiple container sizes and materials. The rotary design is flexible and effective. Standard (non-custom) diameters are 36", 48" and 60”. Top discs are stainless steel with machined backer plates for trueness. Accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. Infeed and discharge conveyors are recommended to be designed with a close interface for smooth transfers. A smooth edge bowl top is available for hand packing applications.

Spaceguard manufacture a wide range of product accumulation tables ideal for use within pack houses along with many other end of line or filling processes.

Rotary tables are usually positioned near the out feed of a process line or packing line which gives packing operatives additional time to pack or inspect. Accumulation tables are also used on bottle lines to load and unload filling lines.

We manufacture our rotary tables using grade 304 stainless steel with food grade options for the top including nylon. We also offer a number of customisation options and add ons including product guides and sweeper arms. With vast experience of packing solutions Spaceguard is the ideal conveyor and workstation provider.

8613371530291

8613371530291