weiss rotary table made in china

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

Successfully competing in our increasingly competitive global environment requires strategy, innovation and proven reliability from a partner that you can trust. Give us a call at 888-WEISSNA, fill out the form above, schedule a call below or simply send us an email to discuss your automation needs.

FEATURES: The TSL series horizontal and vertical rotary tables are for indexing,circular cutting,angle setting,boring,spot facing operations and similar work in conjunction with a milling machine. This type rotary table is so designed as to permit...

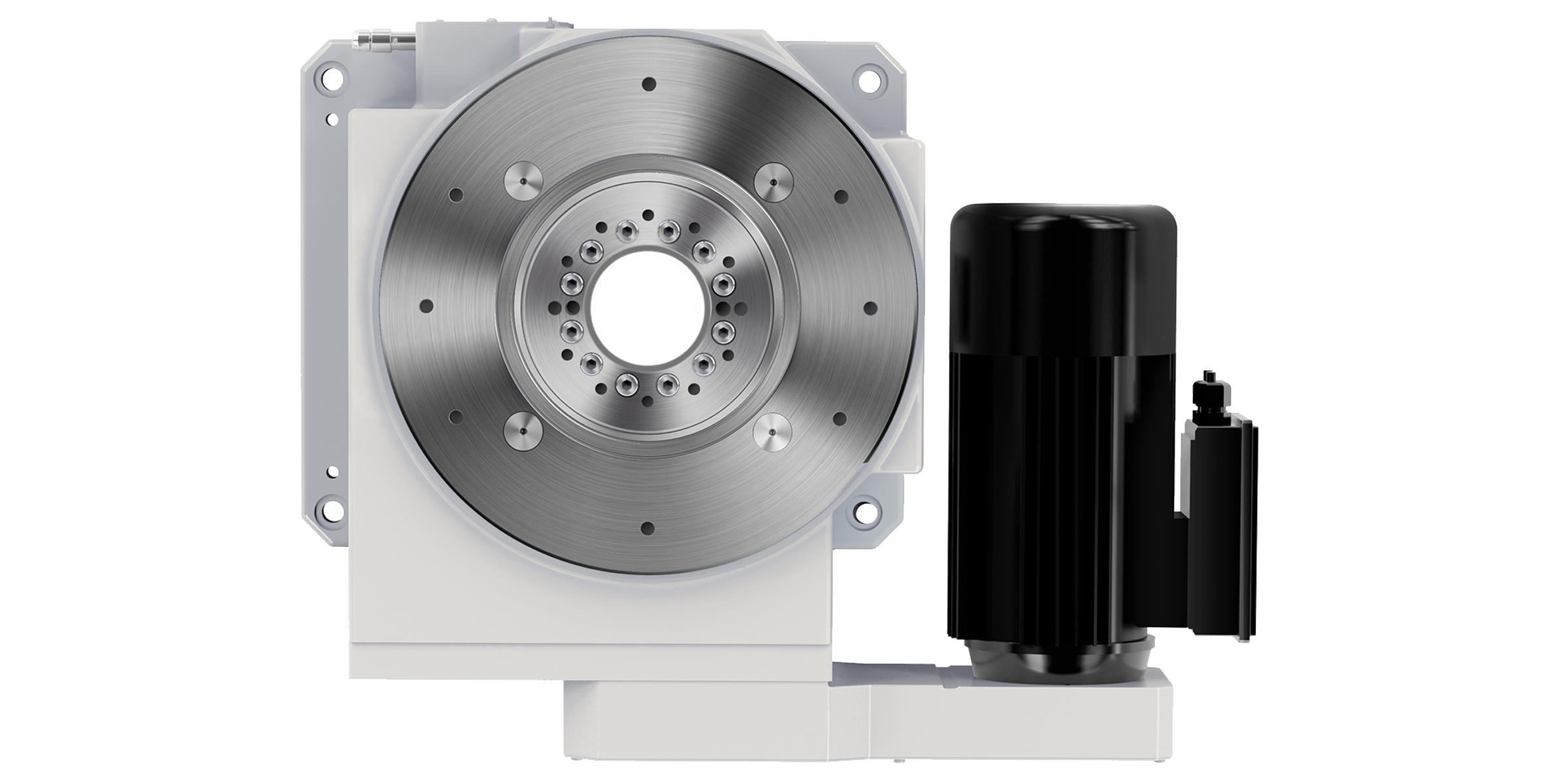

We have given the new TC range a significantly larger central opening for the 120 – 320 sizes. The cables and hoses can now be guided downwards directly through the table or through the practical side channel. We have achieved this while maintaining the same external dimensions as its predecessors – which have now been replaced by the new range.

Alongside automatic nest detection, with the new DriveCliq encoder option in connection with the EF2 rotary table control system we now also offer cam switching mechanism functionality, which permits a significant increase in the effectiveness of the overall system.

By the way: we also offer automation options for cleanroom environments. If you would like to receive information and offers relating to the Cleanline versions of our rotary tables

We specializes in manufacturing single & double column vertical lathe China, both in CNC and conventional type, milling function with C axis indexing table, product range from 1000mm to 16000mm and already exported over 30 countries.

We also produce Boring machine, Gantry Milling Machine, Floor type Boring Mills, Table Type Boring Mills, CNC Vertical lathe, Vertical Turning and Milling Center, China Vertical lathe, and custom machine.

Slewing bearing are used for applications of cranes, radar, excavators, solar tracer, ladle turret, wind power, wiring unit, stacker and reclaim, and other heavy duty rotary devices.

Rotary indexing ring with very large middle opening, extremely flat design and a high level of parts accuracy.The ring-shaped design allows extra free...

Rotary indexing ring with very large central opening, highly flat design and a high level of parts accuracy.The ring-shaped design allows extra free d...

Manufacturers Of SR/SK Indexing Machine BasesIndexing machine bases in various standard sizes, individually adjustable height with special designs ava...

Rotary indexing ring with a large central opening, extremely flat design and a high level of parts accuracy.The ring-shaped design allows extra free d...

Durable Cr Heavy Duty Rotary Indexing RingsWEISS UK can offer you Flat heavy-duty rings with a large central opening. A real powerhouse. Freely progra...

Rotary indexing ring with very large central opening, extremely flat design and a high level of parts accuracy.The ring-shaped design allows more free...

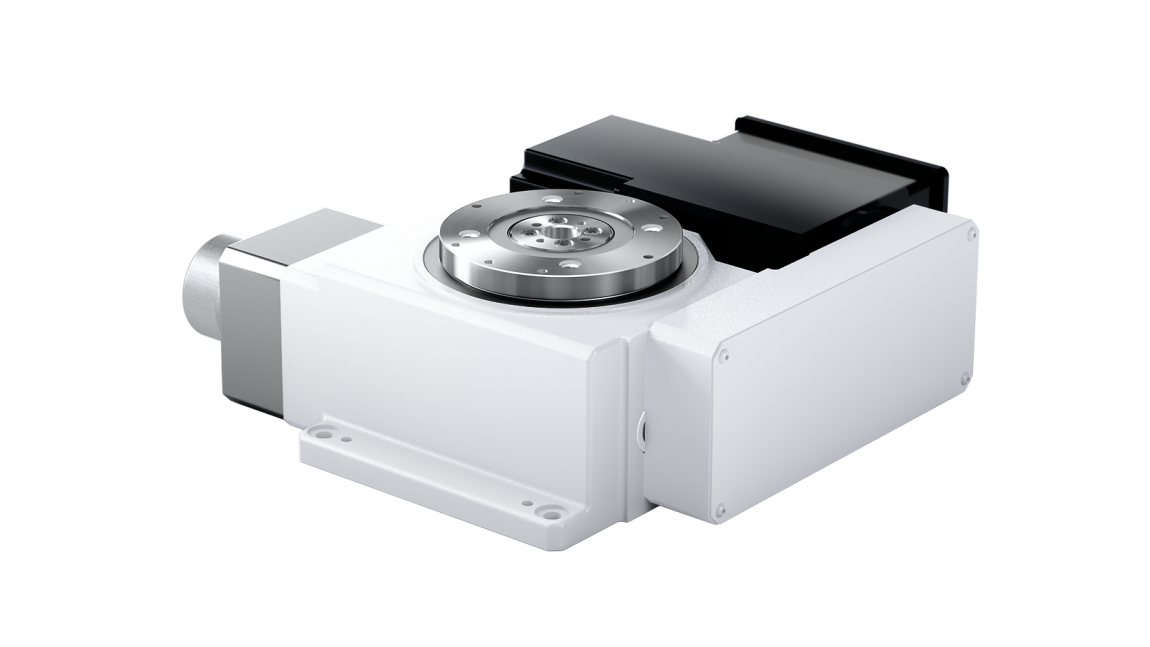

One of the most robust and reliable rotary indexing tables available worldwide. Your preferred partner in the field of automation technology. Extremel...

One of the most robust and reliable rotary indexing tables available worldwide. Your preferred partner in the field of automation technology. Extremel...

One of the most robust and reliable rotary indexing tables available worldwide. Your preferred partner in the field of automation technology. Extremel...

One of the most robust and reliable rotary indexing tables available worldwide. Your preferred partner in the field of automation technology. Extremel...

Compact HP Pick & Place ModuleWEISS UK is the UK leader in HP Pick & Place Modules. The HP pick & place modules work with two linear axes, so they hav...

One of the most robust and reliable rotary indexing tables available worldwide. Your preferred partner in the field of automation technology. Extremel...

ST Torque Rotating Unit SuppliersWe are a highly reputable company supplying ST Torque Rotating Units throughout the UK. The ST torque rotating unit, ...

One of the most reliable and robust rotary indexing tables available worldwide. Your preferred partner in the field of automation technology. Extremel...

Easy To Operate EF3 Rotary Indexing Table ControllerWe are one of the leading suppliers of EF3 Rotary Indexing Table Controller in the UK. The control...

One of the most reliable and robust rotary indexing tables available worldwide. Your desired partner in the field of automation technology. Extremely ...

EF3 Rotary Indexing Table Controller UK SupplierWe are one of the leading suppliers of EF3 Rotary Indexing Table Controller in the UK. The control of ...

W.A.S. 2 Weiss Application Software SpecialistsWEISS are the market-leading experts in W.A.S. 2 WEISS Application Software in the UK. The W.A.S. WEISS...

TS004E Control Card To Operate A Rotary Indexing TableWe are the reliable suppliers of TS Control Card in the UK. The TS004E control card is the easie...

Compact HG Linear Motor AxesWEISS are the top supplier of HG Linear Motor Axes in the UK. The aluminium profile-based HG linear motor axes can be used...

Boasting a 1300 mm footprint, the TO1300 suddenly makes larger scale applications possible that previously seemed out of reach− as current direct-drive tables are relatively small and limited to a diameter of 750 mm. Additionally the TO1300’s high-tech drive operates predominantly without mechanics or gearboxes.

With over ten years of expertise in the field of direct drive torque motors, WEISS often designs and develops out of the logical response to changing market requirements and customer demand. This was the case with the TO1300 as a client’s concrete custom requirements stipulated a high mass inertia of 160 kgm2 and a large index increment of 45° with fast cycles−namely an index time of 0.21 seconds with a dwell time of 0.29 seconds.

For challenging tasks of this nature, a mechanical heavy duty table is typically the logical choice. Due to their gearing ratio, however, these tables don’t fare well in service life calculations for use at such high speeds as the needle bearings simply suffer from too much wear.

The correct alternative is a direct drive; which inspired the development of the TO1300. With a direct drive, only one bearing is under load which is virtually free of backlash. The table is low-wear and easily capable of delivering the desired dynamic performance requirements.

Unique to the TO1300 is that customers can customize it to their individual requirements. For example; they can make a modular selection between bearings, encoder and motor, and thereby alter the following table characteristics:

A specialist in automation, WEISS also offers many sizes for the TO series direct-drive rotary indexing tables; ranging from small to very large. Optimal solutions for specific application challenges can be achieved from the series wide range of options. Each TO model is also available in a version with a cleanroom certificate.

Corporate Profile: An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Only two years after WEISS opened its Campus at Chakan, near Pune, the specialist for rotary indexing tables, linear transfer systems and handling solutions has expanded its on-site expertise with a Solution Factory, localised the assembly of its rotary indexing tables and established a Global Sourcing Centre.

In 2020, a year determined by the Corona pandemic, WEISS GmbH from Buchen, Germany, took an important step and opened its Campus in Pune, India. After only two years, WEISS Automation Solutions India Pvt Ltd has now established a Solution Factory, where components and subsystems that meet the needs of the local market will be designed and realised. The automation solutions satisfy the requirements of customers and sectors in the APAC region as well as users in China. For the record, Pune in India is one of the four global facilities of WEISS designated as a Lead Factory, the other three being located in Buchen – Germany, Cleveland – USA and Shanghai – China.

At the opening ceremony held in mid-October 2022, Uwe Weiss, CEO of parent company WEISS, and Sanjeebit Choudhury, Vice President Asia Pacific and CEO of WEISS India, welcomed numerous guests of honour. The list included Ms Achim Fabig, General Consul of the Federal Republic of Germany, Ms Silja Weiss, Ingo Nenninger, Group CFO, WEISS GmbH, and Rajesh Nath, Managing Director, VDMA India Office, and members of the trade media.

WEISS has more than 55 years of experience in automation systems especially in rotary indexing tables. These were first designed to meet the requirements of the automotive industry but nowadays are installed in automation systems to a broad range of industries such as communication, life science, electronics, and consumer goods. The local experts collaborate closely with their colleagues in Buchen (Germany) in order to ensure the high quality standards of WEISS. In addition, they support customers in engineering as well as in commissioning of the WEISS components and solutions. In the long run WEISS plans to establish an academy for both employees and customers. The overall strategy is to connect experts in the field of automation from different industries to open a knowledge exchange platform not only for India but for the whole APAC region. To Sanjeebit Choudhury it is especially important to share the organisation’s knowledge to increase customer centricity and improve the company’s performance for customers.

To keep delivery times as short as possible for the rotary indexing tables, which have proven their value for decades, selected product types and sizes will be assembled in India in the future. Furthermore, the recently opened Solution Factory widens WEISS India’s expertise and makes it a full range supplier in automation. The components and solutions designed and made in India will meet the expectations not only of customers from India but from a broader market region. As WEISS has decades of experience in setting up automated assembly processes, it is also a reliable partner for both – beginners in the field of automation as well as advanced companies dealing with optimisation issues and digitisation. Offering CAD data and simulation models facilitates construction of whole automation systems and virtual commissioning.

Later in the evening, a panel discussion was held at a city venue on the theme ‘Global Meets Local – Design to Value’. The panellists included Uwe Weiss, CEO, WEISS Group; KV Suresh, Country Head & President, ZF India; Harsha Kadam, MD & CEO Schaeffler India; Preshit Murudkar, MD & CEO, COMAU India Pvt Ltd; and Hemant Watve, MD, Wilo Mather & Platt Pumps Pvt Ltd. Moderated by Rajesh Nath, Managing Director, VDMA India Office, the discussion centred around how Affordable Automation is the key to Make in India.

8613371530291

8613371530291