2 axis trunnion rotary table manufacturer

Martin Trunnion Tables offers complete 4th axis packages for Sankyo Automation rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Sankyo Automation Rotary Table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

The FAR Series is TJR’s standard pneumatic brake tilt rotary table line comes in single arm, cradle type dual arm, extended cradle type dual arm options. The FHR Series is TJR’s standard hydraulic brake line offered in dual arm cradle type and dual arm extended cradle type tilt rotary tables

The compact tilt rotary table design with a 170mm(6.69”) face plate diameter and is ideal for smaller machining centers and smaller workpieces. Featuring full rotation and tilt capabilities, they can be integrated into your existing machine control for 5 axis operation.

The manual tilt table is designed with a full 4th axis (rotating axis) and a manual tilting axis. It is available in 255mm table diameter and is ideal for customers who need a rotating axis but only occasionally require tilting axis capabilities.

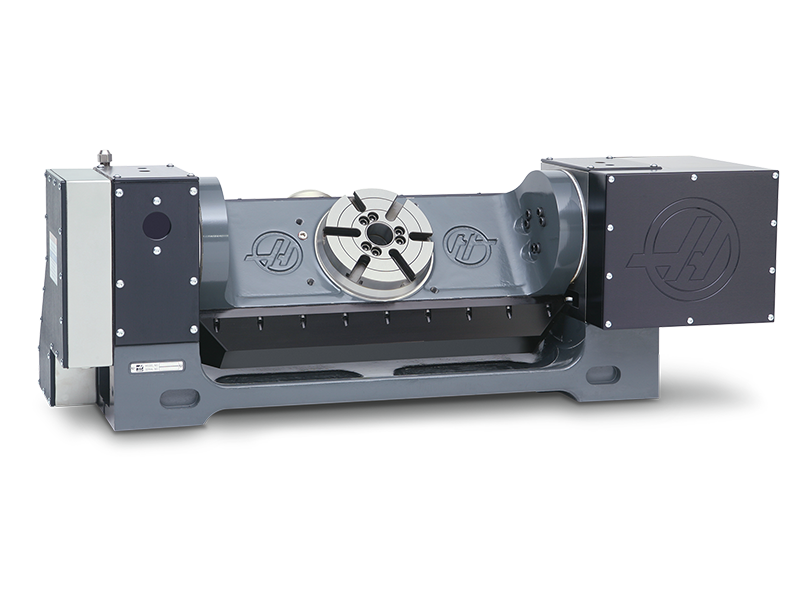

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

Methods & Equipment works with several manufacturers of rotary tables: Tsudakoma, Nikken, Yuasa and more. Give us a call or fill out the RFQ if you would like a quote on any of the high speed rotary tables, direct drive rotary table, or the new ball drive rotary table with zero backlash.

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The dual-spindle design allows two workpieces to be loaded and machined in a single setup. Scale feedback on the A (tilting) axis increases positioning accuracy and repeatability. The unit fits into VF-2 and larger VF Series machines (extended Z-axis clearance option highly recommended).

Tsudakoma TTNC-151-2 Dual Pallet 2-Axis Trunnion Style Programmable Rotary Table with Yaskawa Drive Motors - Came from Matsuura 5-Axis MC-6600VG Machine

US /Europe – US-based CNC machine tool manufacturer, Haas Automation, will use the upcoming AMB 2016 exhibition in Stuttgart to present an ‘advance sight’ of a new Y-axis CNC turning centre, as well as a prototype of a newly developed compact mill for micro-machining, and two new CNC rotary tables.

On Stand C11 in Hall 9, Haas Automation will showcase its new ST-15Y big bore, small footprint CNC turning centre. The ST-15Y provides 102 mm of Y-axis travel (±51 mm from the centerline) for off-centre milling, drilling and tapping, and comes as standard with 6000 rpm high-torque live tooling and a full C-axis for versatile four-axis capability. The machine, which will be available in Europe in Q4, offers 63.5 mm bar capacity and a maximum cutting capacity of 356 x 406mm, with a swing of 406 mm over the cross slide.

With industry witnessing a marked trend for micro-machining applications, Haas will also shine the spotlight on a prototype of its new CM-1 compact mill, which is designed as a high-accuracy solution for high-volume production and prototyping of small, high-precision 2D and 3D parts such as those found in the communications, medical and dental industries. Small enough to fit into most freight elevators, the CM-1 features 300 x 254 x 300 mm travels, a 508 x 254mm T-slot table, a 30,000 rpm ISO20 taper spindle and a 20-pocket automatic tool changer. Maximum cutting feeds are 12.7 m/min, with rapids to 19.2 m/min for reduced cycle times.

Another new rotary on display at AMB will be the Haas TR200Y, a dual-axis trunnion rotary table that puts 5-axis capabilities well within reach of the average job shop. The TR200Y is designed to mount in the Y direction (front to back on the table) of a mid-size VMC. At less than 686 mm wide and only 508 mm deep, the TR200Y easily fits on one end of the machine’s table, leaving the remaining space free for additional fixtures or vices. The TR200Y has a 200 mm T-slot platter, and will swing parts up to 206 mm diameter, Haas says.

There will be two TR200Y units on display, one as a separate unit and another fitted to a Haas VM-2 vertical mould making machine. This will be joined at the show by a cross-section of CNC machines from the existing Haas portfolio, including a UMC-750SS Super Speed 5-axis universal machining centre, a VF-3YT/50 VMC with 50-taper spindle and a VM-2 vertical mould making machine.

The TR160Y dual-axis trunnion rotary table puts 5-axis capabilities well within reach of the average job shop, and its compact size provides greater mounting flexibility.

Five-axis machining is becoming more common today as a means to reduce set-up time and increase accuracy for complex parts. But investing in a 5-axis machine tool can be prohibitively expensive, especially for smaller shops. The TR160Y dual-axis trunnion rotary table from Haas Automation (Oxnard, CA) puts 5-axis capabilities well within reach of the average job shop, and its compact size provides greater mounting flexibility.

The TR160Y is designed to mount in the Y direction (front to back on the table) of a mid-size vertical machining center. At less than 25 in wide and only 20 in deep, the TR160Y easily fits on one end of the machine’s table, freeing up the remainder for additional fixtures or vises. The TR160Y has a 160 mm T-slot platter, and will swing parts up to 7.5 in diameter. The maximum platter capacity is 80 lb. The trunnion provides ±120 deg of tilt and 360 deg of rotation for full simultaneous 5-axis motion, or to position parts to almost any angle for machining. Yet, like all Haas rotary tables, it can easily be removed when not needed.

Powerful brushless servomotors provide 150 ft-lb of spindle torque on both axes of the TR160Y. Brake torque is 300 ft-lb and 100 ft-lb respectively, and speeds are 130 deg/sec on the rotary axis and 100 deg/sec on the tilt axis. The trunnion’s precision-ground platter of heat-treated 4140 alloy steel has six standard 5/8 in T-slots equally spaced at 60 deg for easy fixturing. Three servo-control configurations are available, making the TR160Y easy to interface to almost any machine.

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

Turn Your Vertical Machining Center into a 5-Axis Production Machine. Designed specifically for Vertical Machining Centers, KME CNC’s 5-axis platters are built right into a precision rigid meehanite cast iron trunnion frame and table.

Standard models come with 1, 2, or 3 independent 5-axis platters on the trunnion table, giving your VMC full-range production capability. Just like the 5-axis tombstones, KME CNC’s trunnions are able to completely integrate with control systems, so you do not need to program the control box.

Payment must be made via WIRE TRANSFER or ACH only.Final payment information will be provided in a separate invoice within 24 hours following the auction. Payment must be received in full within 48 hours of receipt of invoice.

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

Requires a Haas mill with 4th- and 5th-axis drives, and NGC software version 100.20.000.1110 or later, for true 4th- and 5th-axis operation. Not available for stand-alone operation.

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

Add serious 4- and 5-axis capability on your machine with a plug-and-play connection to your Haas VF-6 through VF-14 VMC. Get industry-leading performance with this heavy-duty design that’s made in the USA.

Dynamic Work Offsets (DWO) and Tool Centre Point Control (TCPC) are software features in the Haas control. These make setting up 4- and 5-axis jobs as easy as setting up a 3-axis machine. They allow an operator to place the part and fixture anywhere on the machine’s table or platter, regardless of the location that was programmed in the CAM system. DWO and TCPC determine the difference between the centres-of-rotation programmed in the CAM system and the centres-of-rotation within the machine and apply the appropriate offsets.

8613371530291

8613371530291