2 axis trunnion rotary table brands

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

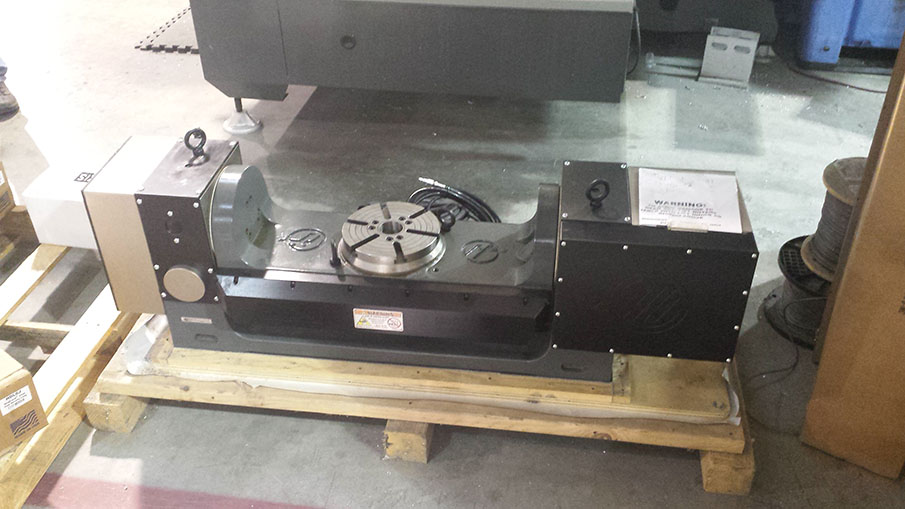

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

Methods & Equipment works with several manufacturers of rotary tables: Tsudakoma, Nikken, Yuasa and more. Give us a call or fill out the RFQ if you would like a quote on any of the high speed rotary tables, direct drive rotary table, or the new ball drive rotary table with zero backlash.

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

Whether your CNC control has AC or DC drives, uses Fanuc, Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build your rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we also supply the parts you need; such as amplifiers, drives, cables and connectors. If your application does not require simultaneous 4th axis cutting, we offer an easy-to-program, single-axis control box that can be M-function interfaced to your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

The TN4 Trunnion Table is a very compact yet rigid device offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller bearings. It is engineered and built here in California with all aluminum and stainless steel construction. This 2-Axis Trunnion is primary designed for machining applications and can be purchased as part of a complete 5 axis mill or as a retrofit to one of our existing 3 axis cnc mills. Both rotary axes are sealed to allow for operation with liquid coolant. Homing Switches are integrated into each axis to provide a repeatable reference point.

This trunnion table can also be used for non-machining applications such as dispensing and 2-Axis rotary positioning for sensor calibration. Call use today to discuss your custom application!

If you would like to discuss your 5-Axis CNC Mill application with us please give us a call and we will be happy to help you determine which of our Small 5-axis CNC Mill is best for you.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

US /Europe – US-based CNC machine tool manufacturer, Haas Automation, will use the upcoming AMB 2016 exhibition in Stuttgart to present an ‘advance sight’ of a new Y-axis CNC turning centre, as well as a prototype of a newly developed compact mill for micro-machining, and two new CNC rotary tables.

On Stand C11 in Hall 9, Haas Automation will showcase its new ST-15Y big bore, small footprint CNC turning centre. The ST-15Y provides 102 mm of Y-axis travel (±51 mm from the centerline) for off-centre milling, drilling and tapping, and comes as standard with 6000 rpm high-torque live tooling and a full C-axis for versatile four-axis capability. The machine, which will be available in Europe in Q4, offers 63.5 mm bar capacity and a maximum cutting capacity of 356 x 406mm, with a swing of 406 mm over the cross slide.

With industry witnessing a marked trend for micro-machining applications, Haas will also shine the spotlight on a prototype of its new CM-1 compact mill, which is designed as a high-accuracy solution for high-volume production and prototyping of small, high-precision 2D and 3D parts such as those found in the communications, medical and dental industries. Small enough to fit into most freight elevators, the CM-1 features 300 x 254 x 300 mm travels, a 508 x 254mm T-slot table, a 30,000 rpm ISO20 taper spindle and a 20-pocket automatic tool changer. Maximum cutting feeds are 12.7 m/min, with rapids to 19.2 m/min for reduced cycle times.

Another new rotary on display at AMB will be the Haas TR200Y, a dual-axis trunnion rotary table that puts 5-axis capabilities well within reach of the average job shop. The TR200Y is designed to mount in the Y direction (front to back on the table) of a mid-size VMC. At less than 686 mm wide and only 508 mm deep, the TR200Y easily fits on one end of the machine’s table, leaving the remaining space free for additional fixtures or vices. The TR200Y has a 200 mm T-slot platter, and will swing parts up to 206 mm diameter, Haas says.

There will be two TR200Y units on display, one as a separate unit and another fitted to a Haas VM-2 vertical mould making machine. This will be joined at the show by a cross-section of CNC machines from the existing Haas portfolio, including a UMC-750SS Super Speed 5-axis universal machining centre, a VF-3YT/50 VMC with 50-taper spindle and a VM-2 vertical mould making machine.

KME CNC Rigid Cast Iron Trunnion Tables are one of the leaders in the industry for accuracy, surface finishes and repeatability. Allowing you to speed up your cycle times, these tables are ideal for high volume production applications. Powerful and compact trunnion design ensures smooth operation over the entire travel range.

The trunnion table is a rotary table designed to provide two additional axes to the 3-axis machine tools and increase the positioning accuracy. It is a very compact yet rigid accessory for modern CNC machining centers.

The trunnion table is designed to provide additional 2 axes to the 3-axis machine tools and increase the positional accuracy, which is a very compact yet rigid accessory for modern CNC machining centers. A trunnion type indexer is typically made from heavy-duty cast iron, providing maximum rigidity and quick rotation that is free of backlash. It is available for accurate machining operations like milling and drilling, which is suitable for medium to large applications.

Similar to 4th axis indexers, which is added onto the vertical machining center, in general, the tilting axes of trunnion tables upgrades the capability of cutting multiple sides of the intricate part simultaneously, the positional accuracy, the repeatability, and also productivity with a full 360° rotation. It usually comes with work-holding devices like machine vises, chucks, sub-plates, and also spacers. As for the power source and control system of this work holding device, there are manual, pneumatic, hydraulic and also computerized types in the market.

Trunnion tables rotational axes for various CNC machining centers enhance the productivity and surface properties of the intricate machining applications. These features make them highly sought-after accessories for machinining in aerospace, shipbuilding, automotive industry and more.

Different from the integrated 5 axis machining center, adding the high-performance rotary positioning technology, the trunnion rotary table can achieve the 5-axis machining operations with less cost and simple installation, expanding the available work of the general 3-axis machine tools. The structure is considered as the “3+2 axes machining”.

The trunnion platter upgrades the machining center by adding the rotational axes, or tilting axes, to the original three linear axes, which are known as the X-axis, Y-axis, and Z-axis. The X-axis on a machining center is the linear direction where the column travels along, which is typically the left-to-right direction in a VMC. The Y-axis is aligned with the path the workpiece moves along from front to back. The Z-axis is typically aligned with the main axis of the machine tool; it is vertical in a VMC.

A trunnion-type model offers the rotational axes around the X-axis and the Z-axis, achieving the 3+2 machining technology and high-end accuracy and productivity of CNC machines. However, before adding one to your machine tool, you should check if the CNC system of the 3-axis machine can accommodate the controlling of simultaneous 4- or 5-axis machining operations.

On the other hand, the 5-axis machines that have integrated tables or rotary work holding tools are also advantageous to ensure simultaneous 5-axis machining with a simpler setup. Although the acquisition cost of 5-axis CNC machining centers is much higher than adding an external accesory, they still have their advantages.

For example, the 5-axis machine allows cutting tools that have standard lengths, reducing the costs relative to tool turnover and insert replacement, increasing the feed speed. Also, the high accuracy of the 5-axis machining operations results in fewer scraps as well as less waste. The easier setup can reduce the time and effort of the user and human interference of the complex process.

In the turning or milling machine, whether the spindle with the cutting tools is locked or not, the rotating trunnion table is used to turn the symmetrically round parts under a predetermined high speed. The workpieces are mostly large aerospace, energy industry components, or other medium to heavy-duty applications. Some CNC machines that leveraged the two rotational axes at once, which adds tilting movement to spin, can let the tools get further closer to the surfaces of the parts. It offers a stable plane for heavy workpieces to rest.

The open working area translates the power to a large range of movement for the trunnion table, providing fully 360° rotation. The wider the range of the rotational movement, the easier it is to operate the jobs, permitting much more high performance and rapid turning or milling of intricate contours. To provide high speed and high turning force during mill-turn operations, the trunnion rotary table used in the mill-turn machines will require drives that supply higher torque such as a 4,000-Nm torque drive to complete the tasks.

For starters, since it provides exceptional rigidity and flexibility for the machining center with the extra rotary motion, the machines can allow shorter and more hard cutters, which are produced with aggressive parameters.

These tooling options can upgrade the surface finishes, tool life and also reduce the cycle time. As for the trunnion table itself, it typically has heavily ribbed cast iron construction, making it durable and rigid to bear the vibrations and repeated operations in long-term use.

When it comes to the simple setups and installation, trunnion type models in the metalworking environment are designed to be flexible, which can be simply bolted onto a wide range of CNC machinery, allowing the user to cut on multiple sides of the parts for mid-range productions. The fast setups and ease of operations for precise 5-axis turning, milling, drilling and other machining tasks provide the solution to significantly upgrade the productivity of the shop in a short time.

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Going from 3-axis machining to 4-axis and 5-axis machining can be intimidating. This short video shows how easy it is to transition from basic 3-axis milling to full 5-axis design and production.

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

To ensure indexing accuracy, we cut the worm gear while it’s attached to the spindle, rather than assembling the finished worm gear to the spindle, as other manufacturers do. Each assembled spindle is trammed-in on a CNC gear hobber to a maximum 2-micron runout, and then the worm gear is precision cut. This guarantees the utmost concentricity between the large-diameter ball bearings and the worm gear, ensuring many years of smooth, extremely accurate, and bind-free operation.

As stated earlier, using 3+2 CNC machining can help reduce costs and cycle times. If you’re just using a 3-axis machine without any rotary tables or trunnions, you’ll need to flip, turn or rotate the part to work on it from all sides. Every time you do this, you’ll need to stop the spindle of the machine. This can be a huge headache if you have to move a piece five, six or even seven times. 3+2 machining can help eliminate this problem.

Vertical machines usually only use three axes. However, you can still use 3+2 machining on an existing machine. The benefit to using a 5-axis machine is being able to process five sides of a workpiece at one time. All in all, 3+2 machining can have a hugely positive impact on your business by cutting down on time to machine a part of workpiece.

8613371530291

8613371530291