3 jaw chuck rotary table manufacturer

A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy

A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy

Before assembling the jaw to its designated chuck body, the jaw"s finish machining are performed on a closed tolerance state of the art CNC machine from Japan

1. The screws securing the chuck to the plate are too long, they need to be shortened about 1/4" to keep from bottoming out in tapped blind holes in the chuck.

2. The "T" nuts holding the plate to the table are poor quality. The flange portion of the nuts are too tall so they interfere with the locking tabs on the table when you attempt to rotate the table.

3. And the worst problem is the raised area on the adapter plate which centers the chuck to the table is a sloppy fit, about .017" allowable movement.

Once you shorten the attaching bolts, machine the "T" nuts down about .100" and bore out the locating boss and re-machine it to an appropriate fit in the rotary table, it works pretty well.

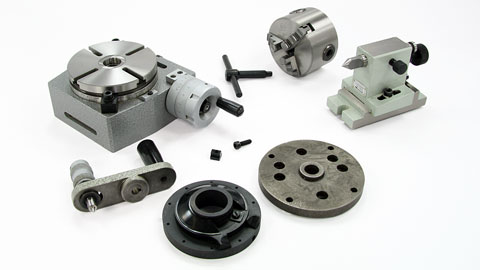

6" PRECISION 3 slot ROTARY TABLE /HORIZONTAL&VERTICALwith 6" 3-jaw self-centering chuck top&bottom reversible jaws, front mounting. All bolts and T-nuts to mount the chuck included.

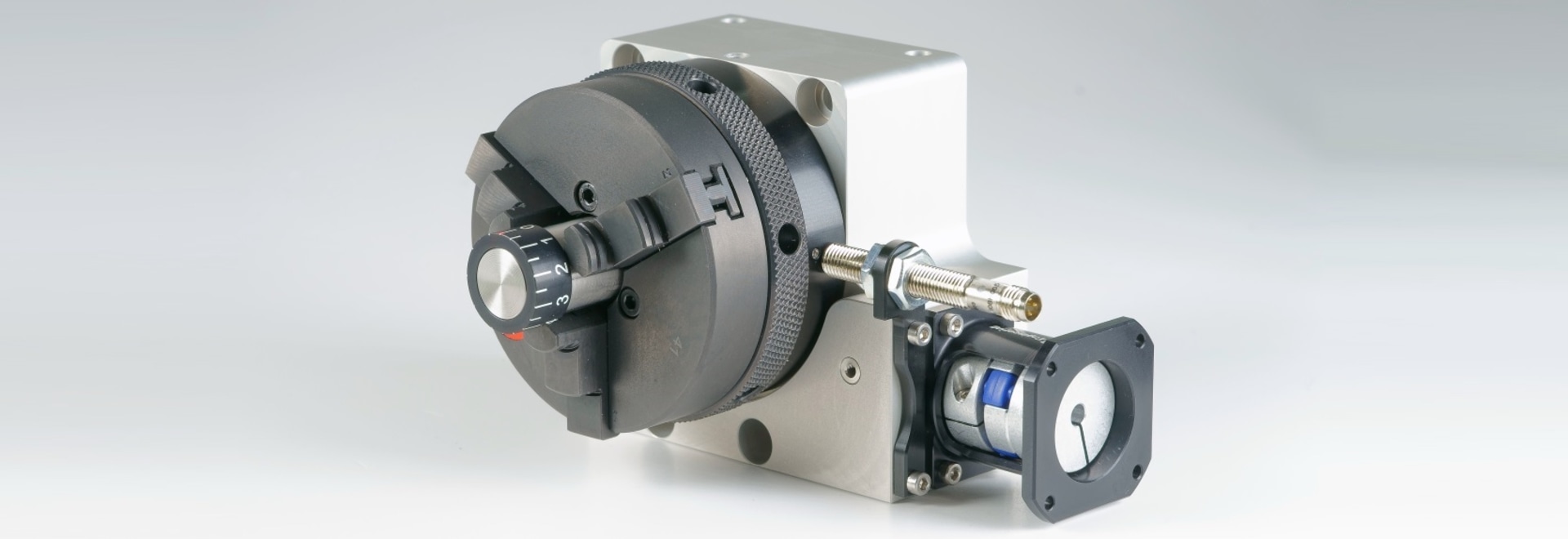

Rotary mounted three-jaw manual chuck with high concentricity. For internal and external clamping of rotationally symmetrical parts. With Ø2 x 7 mm deep holes and 2 sets of pins of different lengths for elevating parts for access from all sides. Available with an SWA 39 quick-change adapter or base plate.

Three-jaw ring chucks are mainly used for clamping cylindrical or ring parts at low clamping forces. In contrast to chucks for machining workpieces, the clamping force must be significantly lower in measuring technology, otherwise there is a risk of deformation of the components. By clamping by hand with the clamping ring, the components can be clamped exactly with the clamping force required in each case.

With interchangeable jaws, you can conveniently adapt the ring chuck to your requirements. Special jaws manufactured in-house can also be adapted. The kit version for the DuraMax rotary table is equipped with a mounted adaptation to the rotary table and also includes a reference sphere to qualifiy the rotary table.

Your one stop SHOP for ROTARY TABLES, SUPER SPACERS TAILSTOCKS and ACCESSORIES. Serving the American Machine Shop since 1953. AJAX INDUSTRIES, Lets PUT WORKHOLDING to WORK for Your Shop.

Ajax Industries is a leading manufacturer of Lathe Chucks & Jaws Providing our Customers with the Workholding Solutions to make Your SHOP more Productive.

Price is for a new Shars 8" rotary table with 3-jaw chuck, but from their ebay store (cheaper): https://www.shars.com/8-h-v-rotary-table-with-8-3-jaw-chuck

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available.

The chuck is a specialized clamp-type used to hold objects with radial symmetry like drills or perforators. By fixing chuck for rotary table on the front part of your rotary tools, you will be able to fix various tools and parts such as screws, nuts, drills, and cutters. Having a chuck in your toolkit will allow you to finish your jobs quickly thanks to its versatility and practicality.

chuck for rotary table can also be used to fix a workpiece. This small tool facilitates the transition between different activities, like going from drilling to screwing. Furthermore, you can also use it as a rotating element in drawn glass manufacturing. Some chucks are composed of retractable keys, which give you more freedom in your work and improved performance.

You will find various types of wholesale chuck for rotary table in our online collection. The jawed chucks are one of the popular types, and they often have three jaws. They are ideal for gripping circular or hexagonal cross-sections. The four-jawed chucks are also available, and they are generally suitable for gripping square or octagonal material.

We also have other modern types of chuck for rotary table. For example, the collet chuck is perfect for small-sized bar stocks, and you can operate it by hand or by power. Another modern type is the magnetic chuck, which is perfect for holding ferromagnetic workpieces. Without forgetting to mention the vacuum chucks that you can use to hold non-ferrous materials such as plastic, aluminum, and stone.

8613371530291

8613371530291