3 jaw chuck rotary table factory

A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy

A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy

Before assembling the jaw to its designated chuck body, the jaw"s finish machining are performed on a closed tolerance state of the art CNC machine from Japan

1. The screws securing the chuck to the plate are too long, they need to be shortened about 1/4" to keep from bottoming out in tapped blind holes in the chuck.

2. The "T" nuts holding the plate to the table are poor quality. The flange portion of the nuts are too tall so they interfere with the locking tabs on the table when you attempt to rotate the table.

3. And the worst problem is the raised area on the adapter plate which centers the chuck to the table is a sloppy fit, about .017" allowable movement.

Once you shorten the attaching bolts, machine the "T" nuts down about .100" and bore out the locating boss and re-machine it to an appropriate fit in the rotary table, it works pretty well.

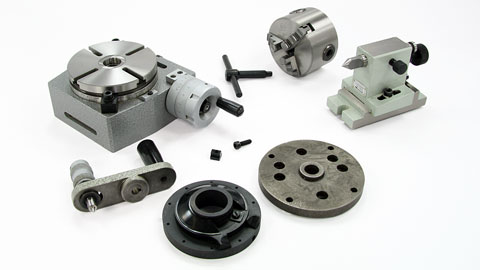

6" PRECISION 3 slot ROTARY TABLE /HORIZONTAL&VERTICALwith 6" 3-jaw self-centering chuck top&bottom reversible jaws, front mounting. All bolts and T-nuts to mount the chuck included.

Rotary mounted three-jaw manual chuck with high concentricity. For internal and external clamping of rotationally symmetrical parts. With Ø2 x 7 mm deep holes and 2 sets of pins of different lengths for elevating parts for access from all sides. Available with an SWA 39 quick-change adapter or base plate.

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available.

8613371530291

8613371530291