4 axis cnc rotary table free sample

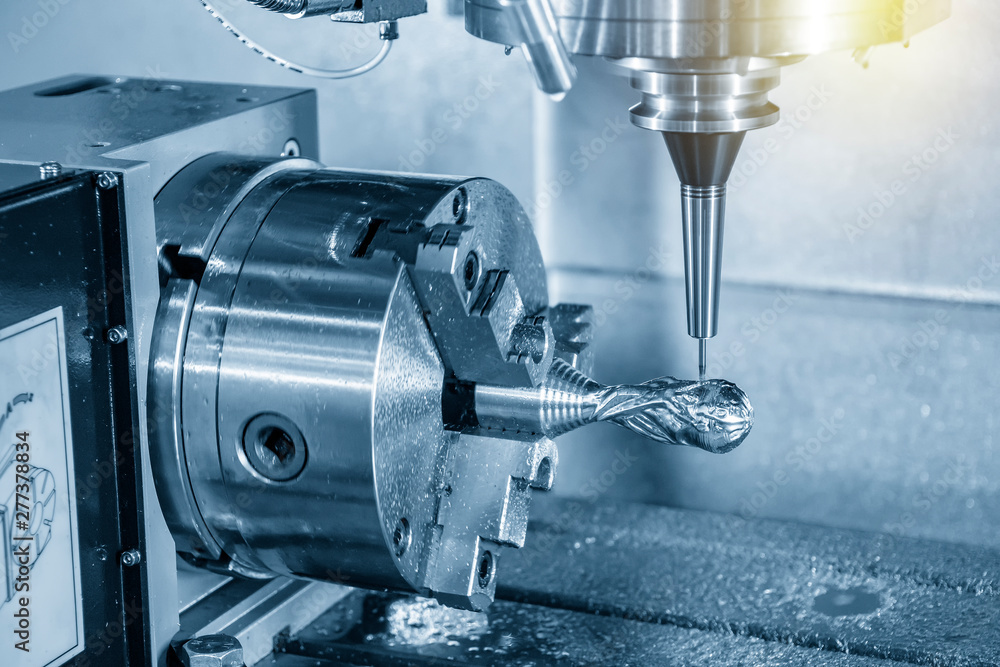

The 4-axis CNC milling machine cutting the sample parts with ball endmill tools. The 3-axis machining center attach the rotary table for cutting the sample parts.

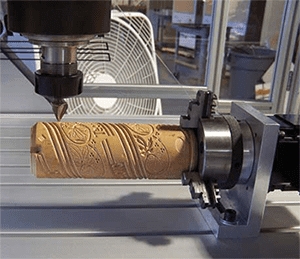

With this extension, your CNC milling machine gets the 4th axis. That allows you, for example, to mill round parts or create engravings on rounded surfaces.

This rotary axis is made to order for us by a German precision mechanic. In this price segment, this rotation axis for CNC milling machines is unrivalled in Europe!

There are many rotary tables on the market. If possible, they have to be inexpensive. You can get a lot of them! Usefulness? That is where the wheat is separated from the chaff. For example, there are many CNC turntables with the cheapest belt transmission. The disadvantages are obvious: slippage due to the belt. If not in the belt drive itself, then on the load or idle side of the belt. Perhaps useful for engraving work. For milling, however, usually not or limited in the choice of material (aluminium 3D milling not possible).

That means you can use the CNC router for 3D 360° machining in almost all materials. Even round engravings on Plexiglas are possible without any problems with this CNC accessory. That means for our CNC machine users: Round surface milling of plastic parts, wooden parts, aluminium parts or round parts made of brass, as well as engravings of all kinds.

The 4-axis CNC milling machine cutting the sample parts with ball endmill tools. The 3-axis machining center attach the rotary table for cutting the sample parts.

Tombstones correspond to Fixture Plates on a mill. There are many different shapes and sizes of Tombstones available for 4th Axes. Here’s one I’ve shown before from a big horizontal milling setup:

I was reading an article about Tombstones in the Tormach blog recently and it got me to thinking about how Tombstones on VMC’s can make a job more profitable.

Tombstones are par for the course on Horizontal Machine Centers, but they’re seen a lot less often on Vertical Machining Centers. Perhaps it’s because they’re just built into a lot of HMC’s at the factory whereas you have to set one up using a 4th Axis on the a VMC. The question for this article is how to get a handle on their value?

There’s an old saying that you’re not getting the most return out of your CNC Machine until you have fixtured a job up so that every square inch of the table’s accessible area is being used to make parts. Put as many parts as possible down for each setup, in other words. Relying on just a single machining vise, for example, can mean a lot of available table area is wasted versus putting two vises on the table (so you get 2 parts per setup), or two double station vises (so you get 4 parts per setup). It’s all about how many parts the machine can “chew” on for each setup. The more the merrier because your setup time divided among all the parts will invariably be less on a per part basis.

On a Tormach PCNC 1100, you get 18 inches of X and 9.5 inches of Y travel. So, that’s 171 square inches you can utilize for making parts–fit as many in as you can!

Now consider a tombstone like the one pictured above. It’s like having 4 smaller tables available. In fact the width of the tombstone is 4″and the length is 13″, so counting all 4 sides, you get 4 x 4 x 13 = 208 square inches. That’s actually 22% more area than the travels suggest would be available on the table. So, for about every 4 parts we can fit 1 part gets a free ride. That’s not bad!

In addition, we can machine 3 faces on each part. Ordinarily, that would take 3 setups which would be a lot more time consuming. Pretty cool, eh? Depending on how much additional setup time is required for this arrangement versus just using the table, we’ve probably made our job more profitable. Perhaps by quite a bit.

Suppose we had a tombstone that was a full 18″ long to match the Tormach’s travel. Yes, we might need a big fixture plate so the 4th axis and tailstock have room on the table, but that’s doable. With the same math, we’d get 4″ x 18″ x 4 sides = 288 square inches. Dang, now we’ve got 68% more available area and we’re really starting to cook with fire. 68% more parts each time we press the green button get finished.

Suppose we create our own “Tombstone” with a piece of 1″ thick cast iron. We can go 2″ if we want it to be more rigid. Now, let’s further assume it is the width of the table’s diameter, which for the 8″ 4th axis is 7.9″. We’ll mount it dead center of the axis, make it a full 18″ long, and use the two sides. Our total area is now 7.9 inches x 18 inches x 2 sides = 284 square inches. That’s almost as good as the earlier tombstone example, and gives us 66% more area.

What if we have a triangular tombstone that just fits in the inscribed circle of the table? No problem. The math says each of the 3 faces of the triangular tombstone will be 6.84 inches, so we have 6.84 x 18 x 3 = 369 sq inches. That’s 116% more area than on our table–twice as many parts per run. Winner, winner, chicken dinner!

When you look at it this way, it’s not hard to see how a 4th axis with tombstone can increase the available area for parts in each setup and make available more faces of the part to be machined.

For round parts, and for many things that go ’round, lathe tooling is where its at. After all, it’s optimized to do workholding along a rotating axis. Hence, it’s very common to mount lathe chucks on your 4th Axis:

All the same ideas that apply to which chuck to use in a lathe work for 4th Axes on mills. Years ago, I put together a chart that has been useful to me in turning work and we can refer to it here too:

“Repeatability” applies to the ease with which you can remove a part and put it right back into the chuck in exactly the same position so you can continue machining. It’s a big factor to consider, but typically isn’t as important for 4th Axis work as it is for turning. When turning, for example, you often have to swap a part end for end, or you may have to take an existing part and put it in the lathe to rework some aspect. With a 4th Axis, you will often just stick in a piece of raw material, in which case Repeatability is not a factor. Hence the ubiquity of the relatively non-repeatable 3-jaw chuck for 4th Axis work.

Turning between centers happens fairly often with a 4th Axis just because you have to make sure you’re supporting any part with significant overhang out at the end too. How much is significant? I was taught 3 or 4 diameters was about a much as you want to hang off the chuck on a lathe before you start looking for more support.

Collets are really nice for turning work (hence the ubiquity of the old Hardinge Lathes and their 5C collet system). They get high marks on just about every aspect. It’s no coincidence that the original Haas 4th Axis had a 5C indexer:

I never would have guessed it, but Geof on CNCZone says the following 4-axis mill set up was able to machine these aluminum bars to length, ensure the faces were square, and drill and tap a hole faster than he could do it in a lathe. You can imagine each of those 4 parts being a 5C spin indexer and suddenly you fit quite a few more parts on your 4th Axis.

I’ve written at more length on Stallion’s Trunnion fixtures in another post. They’re very slick, but you need to make sure they solve the problem you need solved for your 4th Axis. In particular, the access to the part is going to be limited to the access you can get form a vise. As such, you’d be looking to use a Vise on your 4th Axis largely because it is super easy, familiar, and to gain access to 3 sides of the work rather than just the top in a single setup.

Note that on a big Horizontal Mill tombstone, you may mount multiple vises on 4 sides of the tombstone and even more than one on each side. That creates a lot of capacity!

Workholding and Fixturing are always an art that it pays to learn well. I’m always on the lookup for clever setups and fixtures and you should be too. The 4th Axis opens whole new avenues for fixturing and setup.

This video includes a demonstration of plane working and a display of four-axis rotary machining. The flat-working is taken in our workshop when we test the machine before delivery. The job is a relief of a lamp. Rotary processing is carried by the customer when he made his first operation in their plant after receiving the cnc. Here is the demo, please enjoy it!

For your reference, we"d like to share a customer case with you here. They bought the exact woodworking 4x8 4 axis cnc router EA-1325SVR from us. The customer just started his new project – Queen Anne style furniture; we guide them through everything from programming to the CNC operation. When he finished his first queen leg sample under our guidance, he sent us the review below. If you have an interest, please click here to read the whole story.

• For the convenience of operation, we abandoned the removable design and adopted the built-in rotary table construction. This way, you no longer need to disassemble and frequently assemble the rotary.

• The rotary headstock is a three-jaw chuck driven by an individual NEMA34 stepper motor with worm gear. The tailstock is a thimble-type fixture. It is capable of clamping a 300mmD x 2000mmL workpiece at maximum.

• The flatbed of the 4x8 4 axis cnc router for woodworking is a PVC vacuum suction table with several T-slots embedded. The clamping method can be vac-sorb or clamps.

• At the front and left side of the flat table, we have installed a total of 5 pieces of Pneumatic Material Alignment Pop-ups. This design dramatically shortens the clamping time of the wood sheets and in return, improves productivity.

It is a cnc router for general woodworking applications engineered to make door panels, Cabinetry, Exhibits and Fixtures, furniture, woodworking projects, complex 3-dimensional leg curve patterns, table or chair legs, cabriole, sculptures, 3d art, interior decoration, curved parallelogram shapes, signs, and more.

A: We shall answer in two parts: three-axis machining and four-axis machining. For the three-axis working, you can use ArtCAM or Aspire software. In terms of the four-axis mill, the software is PowerMILL. EagleTec CNC would like to provide detailed tutorials of ArtCAM and PowerMILL to you if we work together. They are practical guides for beginners with instructions step by step. And here is a demo for your reference:

A: The 4 axis wood cnc machine would come with accessories and extra parts like collets, spanner set, leveling machine feet, clamps, transmission belts, dust hood, fuses, on/off button, emergency stop button, and limit sensor.

A: Its weight is 1450KGS, and the package dimension would be 3200x2200x1900mm. We need to use a forklift to get it off the truck and get it into the building for such a machine.

A: Correct, the model EA-1325SVR did come with the 4-axis simultaneous rotary axis. And the rotary has a permanent location which is on the right side of the machine.

A: You will get a perfect solution that gets both toolpath programming and machine operation involved from us. EagleTec CNC not only sells cnc machines but also guides you step by step to put your device into production. Below is an operation demo for your reference. Technical support is also a crucial part of the product value. About this, please refer to our testimonials.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

Sometimes when using a CNC router to make cuts it is necessary to change out tooling. With a single tool spindle this operation can take valuable production time and introduces another point in the production process for human error to be introduced.

The PHANTOM CNC SYSTEM-ATC CNC machine reduces production time by automatically changing cutters between tool paths, thus eliminating the need for the CNC operator to change and zero tools individually. The ATC feature allows our router to do the full job, even when different tooling is required to make different types of cuts. Signs and complex 3D carvings are a good example of this. A machine equipped with an ATC can perform operations normally done on other pieces of equipment, eliminating the need for additional machines in the shop.

Sometimes when using a CNC router to make cuts it is necessary to change out tooling. With a single tool spindle this operation can take valuable production time and introduces another point in the production process for human error to be introduced.

The PHANTOM CNC SYSTEM-ATC CNC machine reduces production time by automatically changing cutters between tool paths, thus eliminating the need for the CNC operator to change and zero tools individually. The ATC feature allows our router to do the full job, even when different tooling is required to make different types of cuts. Signs and complex 3D carvings are a good example of this. A machine equipped with an ATC can perform operations normally done on other pieces of equipment, eliminating the need for additional machines in the shop.

Vacuum tables are common in cnc routers. Besides its firm holding, a vacuum table can also flatten boards and make closed shaped cut-outs more easily without obstructions like clamps in the way of the toolpath.

The vacuum table surface is made from Phenol Resin Panels ( Bakelite ) instead of Hard PVC Boards for better strength and wear resistance. This will provide a longer lifespan in a tough shop environment. The vacuum table can be control with 4 independent gate valves.

PHANTOM CNC SYSTEMS T ATC CNC uses a 1.5M helical tooth rack and pinion system. This allows for smooth high speed, high precision and low noise operation. We use PMI 25 Linear guides with flange sliders on all axis.

The Spindle alone is 22 lbs. After it has been assembled the Z Axis section weighs more than 200 lbs. We use a high precision and high speed ball screw system with a Delta 750 watt drive and brake motor to move the Z axis.

The Z Axis mounting plate is made anodized aviation aluminum. The spindle is fixed on the high-quality aviation aluminum T6061/6063 plate. The Z-axis uses a TBI High-Precision Ball-screw. The ball screw connects to the Nema 34 motor with a disc coupler that protects the ball screw in case of crashes.

We use a stand alone control system that is completely separate of a PC controller. This allows full control of the CNC without worry of Windows updates or controller software updates that could slow down your business.

CNC Routers adopt advanced open-architecture CNC controllers, with built-in high-performance industry computers, LCD screens, and combining with servo axis, spindle, and MPG axis, built-in PLC ( Programmable Logic Controller ) and USB interface, Compact Flash Card reading device.

The roller pressure is distributed on both sides of the spindle, which can effectively prevent the material from moving on the table when processing small materials or materials that are not easily suctioned or clamped. Rollers provide 600lbs of downward pressure.

ATC CNC router has an automatic tool change function including carousel tool change type and linear tool change type. According to the processing requirements, automatic tool change can be realized without manual participation, which further improves the machining efficiency. To know ATC CNC router machine price information, you can leave a message through our website or directly call us. To learn more about our ATC CNC Router, browse our range below:

ATC 4th Rotary device: Rotary could be added on the side of the machine table or put it on the machine table, depends on your using habit. You can choose the proper rotary"s diameter and length according to your materials. It"s mainly be used for processing some round or square materials.

Rotary on Table: 4-Axis rotary table assembly comes complete with a 3-jaw chuck, tailstock, and guide track for easy tailstock movement and center alignment. The addition of 4-axis rotary table assembly adds greater functionality to the machine"s capabilities allowing for 4-axis cutting in both 2D and 3D carving and indexing functions.

Full Length 4-Axis rotary table assembly comes complete with a 3-jaw chuck, tailstock, and guide track for easy tailstock movement and center alignment. The addition of 4-axis rotary table assembly adds greater functionality to the machine"s capabilities allowing for 4-axis cutting in both 2D and 3D carving and indexing functions. (PHANTOM CNC SYSTEM rotary size has 0-3”, 0-4”, 0-6”, 0-7.9”, diameter rotary axis for your choice).

Furniture industry: various types of doors, windows, cabinets, shelves, tables, chairs, sofas, couches, stools, benches, beds, desks, night stands, bunks, cupboard, tea boards Decoration industry: door frames, handrails, building columns, pillars, table legs, chair legs, photo frames, mirror frames, screens, lights, holiday decorations.

TheRT4 4th Axis Rotary Table is a compact CNC rotary table offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller Bearings. It is engineered and built here in California with all aluminum and stainless steel construction.A rotary seal allows for operation with liquid coolant and an integrated Homing Switch provides a repeatable reference point. A number of different workholding accessories are available such as 3 and 4 jaw chucks, 5C collet chucks and two jaw chuck(see below accessories tab). This CNC 4th Axis can be purchased separately at anytime and is plug and play ready with any of MDA Precision’s CNC Milling machines.

If you would like to discuss your Rotary application with us please give us a call and we will be happy to help you determine which of our Rotary applications is best for you.

2022 best desktop CNC router with 2x3 4th axis rotary table is an entry level CNC machine kit designed for for craftsman, home shop, hobby, small business, advertising, woodworking, arts, gifts, crafts, sign making, and mold making.

STG6090 desktop CNC router kit is an entry level CNC router machine with 2x3 rotary table for hobbyists, small business, home business, small shop, home shop and craftsman. The rotary 4th axis CNC router table adopts whole cast iron machine bed, cast aluminum gantry with dustproof system, under impact resistance beam more stronger with higher machining precision. The 4th roatry axis CNC router machine adopts high quality ball screw and high accuracy segmentation to achieve the final high precision machining result. It adopts high precision all steel linear guide rail to ensure the machine frame more stability and durability. The desktop CNC router kit adopts high power driver system and stepper motor to drive the machine to run smoothly with higher efficiency. The spindle motor adopt high-speed water frequency conversion brushless motors from domestic famous manufacturer, not only can cut vigorously, but also can carve with higher precision. NCStudio, DSP, and Mach3 CNC controllers are optional with high stability and high efficiency for the desktop CNC router kits, they are easy to learn and use. It has good software compatibility, it is compatible with the Artcam, Type3, Ucancam, JDPaint and other CAD/CAM softwares for 2D/3D routing. The desktop CNC router is equipped with a 4th axis rotary table for 3D carving. It is also known as 4th axis CNC router, rotary axis CNC router, desktop CNC machine, benchtop CNC router, benchtop CNC machine, tabletop CNC machine, tabletop CNC router.

The 4th axis CNC router kit adopts Mach3 or advanced DSP numerical control system and large liquid crystal display brings out much convenient operation and simpler maintenance.

2. The machine adopts water-cooling spindle, suitable for all kinds material (wood, aluminum, copper, stone, plastic and foam ). The water cooling spindle adopts water cycle to cooling the spindle, so the cooling effect is very good, almost no noise and long life time.

4. Guide rail: Taiwan Hiwin square rails (the world famous rail and guide manufacturer), self-lubricating sliding block. This will ensure equal force in all directions and accuracy and strength of the 4th axis CNC router table.

The 4th axis desktop CNC router machine has a wide range of 2D/3D applications for small business, small shop, home business, home shop and craftsman:

The 4th axis desktop CNC router can be used for wood, stone, plastic, acrylic, double color boards, PVC, ABS, aluminum composite panels and other soft metals, etc.

Yes, in order to give you a suitable entry level CNC kit, please tell me the max working area, materials for processing and the thickness for the materials to be cut. Then an affordable CNC router machine will be recommended to fit your requirements.

Our MOQ is 1 set CNC router kit. We could send the machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price for you.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

8613371530291

8613371530291