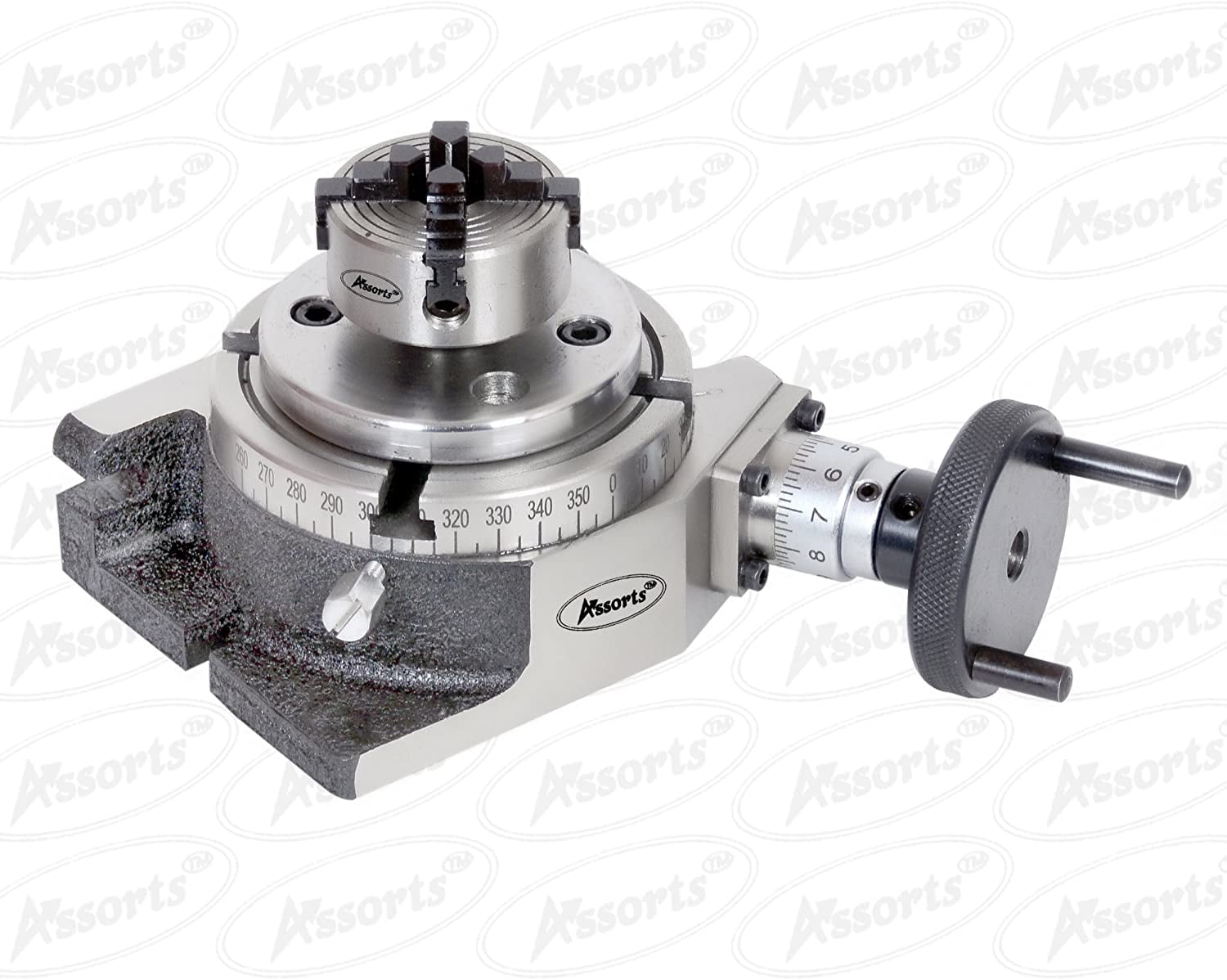

4 rotary table with chuck in stock

Before assembling the jaws to its designated chuck body, the jaws finish machining is performed on a close tolerance state of the art CNC machine from JapanThe scroll plate"s thread flank are ground on both sides to achieve tighter contact with the master jaw

Each chuck has gone through rigorous accuracy and repeatability inspection by clamping and jamming multiple random testing rods or ringsAccuracy is maintained for the entire clamping range

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Your one stop SHOP for ROTARY TABLES, SUPER SPACERS TAILSTOCKS and ACCESSORIES. Serving the American Machine Shop since 1953. AJAX INDUSTRIES, Lets PUT WORKHOLDING to WORK for Your Shop.

Ajax Industries is a leading manufacturer of Lathe Chucks & Jaws Providing our Customers with the Workholding Solutions to make Your SHOP more Productive.

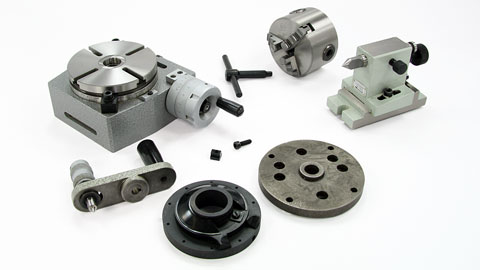

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available.

This is a modification of our 4″ Manual Rotary Table. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through-hole to which they could mount our chucks.

This version of the Sherline rotary table has a Nickel-Teflon plating on the tabletop because it was designed to be used in an everyday production environment. This gives the table a rust-resistant surface that is hard and has added lubrication qualities.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel or stepper motor. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

NOTE: You can have your manual rotary table upgraded to CNC-ready, but this is done as a factory-only replacement. You will need to ship your manual rotary table back to our factory for the conversion.

Now you can attach a 1/4″ or 3/8″ drill chuck, an older Unimat chuck with 12 x 1 mm or 14 x 1 mm threads or a 1/2-20 Sears chuck to your Sherline rotary table. The adapter screws into the 3/8-16 threaded center hole of the table.

The chuck adapter has a 15/32 through hole with 3/4-16 thread for the chuck and a 5/8-24 thread for the rotary table. The through hole allows stock to pass through the chuck and P/N 3710 4″ Rotary Table.

Rotary tables can also be equipped with a chuck for workpiece clamping fixtures. These are attached to the set-up table with a flange. Three-jaw chucks are ideal for round or regularly shaped three- and six-sided workpieces. The workpiece is always held centered, because the jaws are operated by a scroll chuck.Centered clamping

8613371530291

8613371530291