autocam rotary table factory

The Cam can extend the development and application limitlessly , Our customer relies mainly on machine tools manufacturers in initial stage. We research and develop and produce " the automatic tool changer unit " in the first. Begin to sell 60 growth to sell 600 per month per month, and we cultivate the achievement that have today in this field. But we are not complacent , because the world is flat. Our challenge of accepting all the time, and it is the competition rule even more that not to advance is to go back. We must be inevitable to more high-tech level development. The industry of Taiwan should move ahead simultaneously and can just face the challenge in the world. We will have already invested the cam will be developed " Rotary Table" in 2006.

This is a brand-new application technology, and NO.1 of Taiwan, develop with the world in step. We offer a large amount of manpower and materials to make perfectly during the course of testing. and exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. Because the “Tilting rotary table” B/C axle actual achievement experience that has 2007~2009 two years, let the perfect product line be extended and practical.

Tools , Cutters , Moulds And Dies , Jigs , Fixtures , Nc Tools For Machining Center , Modular Tooling System , Vises , Universal Vise , Standard Tools For Milling Machine , Mill Chucks , Accessories For Machining Center , Index Drives , Rotary Tables , Horizontal , Rotary Tables , Vertical And Horizontal , Cnc Rotary Table , Vises , 3-directional Multi-functional Type , Vises , Hydraulic Type , Vises , Multi-function Type , Vises , For Use In Horizontal And Vertical Positions , Vises , Synchronously Bi-clamping , Super Dividers , Sine Plates , Toolholders For Cnc Machines , Machinery Parts And Components

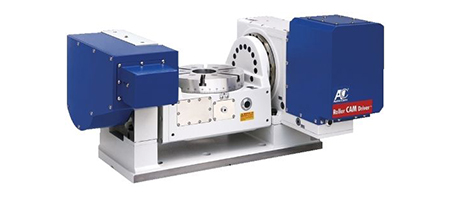

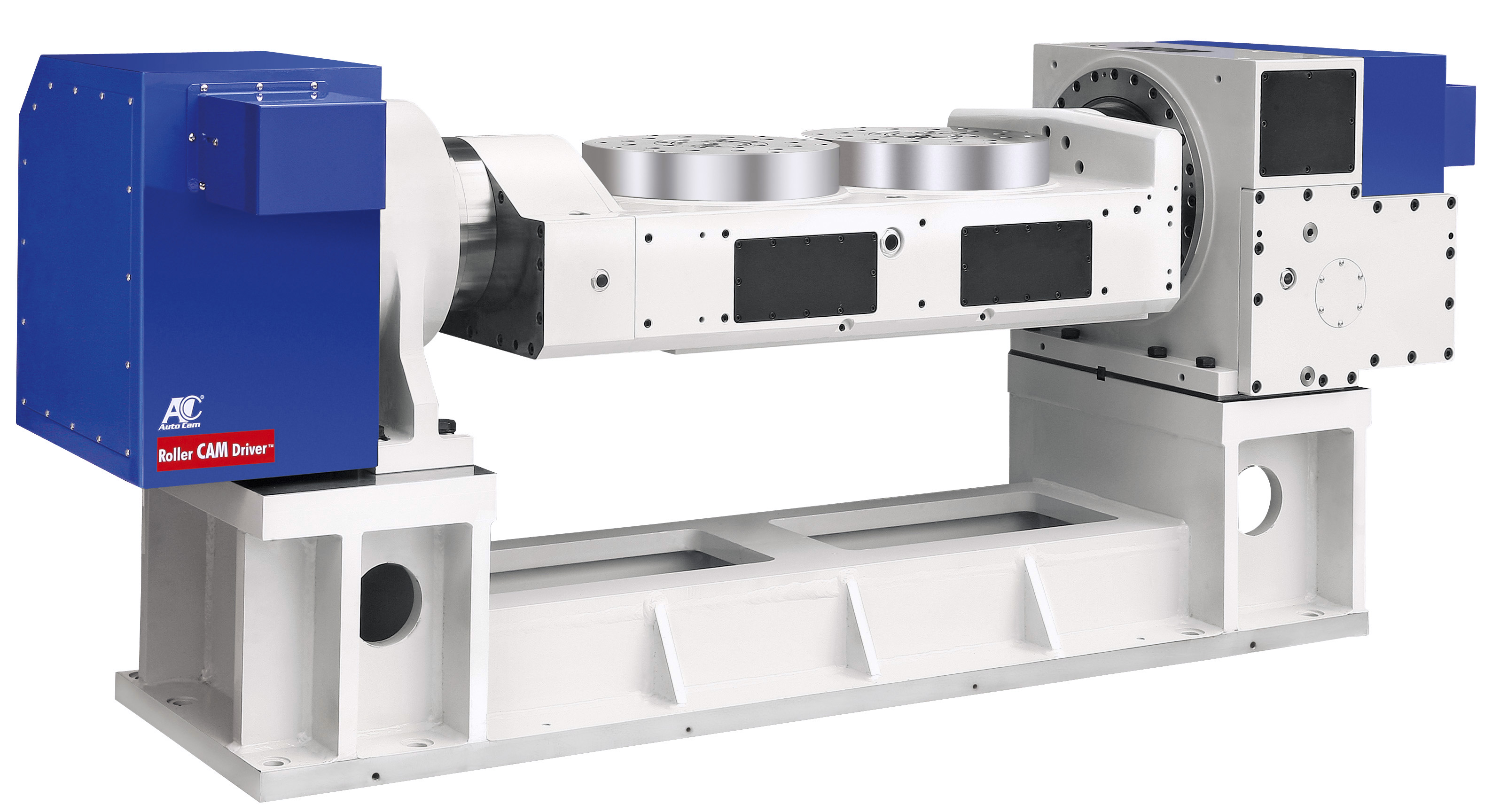

Double the machining speed! AutoCam presents the new Multi-spindle Roller Cam Driver tilting rotary table. The rotations are driven by only one servo unit, furthermore the accuracy and working ability as good as tradition one rotation models. It can carry the production volume and precision at the same time.

AutoCam adhere to three ideas of " Insistence, Innovation, Growing ". It’s our duty to carry technology first of the world, and improve our competition advantage to create with customer"s cooperative opportunity.

Our customers rely mainly on machine tools manufacturers in initial stage. We researched and developed and produced " the automatic tool changer unit " at first. Beginning to sell 60 growth to sell 600 per month per month, and we cultivate the achievement that have today in this field. We have invested " Rotary Table" in 2006.

We exhibit the practical “Tilting rotary table”(B/C ATS160B) products on TIMTOS (Taipei International Machine Tools Show) for the first time in 2007, and exhibited the “Rotary table” and “Tilting rotary table” of the whole series on TIMTOS in 2009. We extend for the future with the development orbit of history, and management idea and industry future is it go down to writing of us.

Year by years, metal-cutting technology steps forward to an higher level. The application of machine tool becomes more diversity. We want it faster, cheaper, and better! AutoCam, provides key accessories for machining tool as 4/5 axis NC Rotary table and Automatic Tool Changer. To meet the marketing demand, we spend years of time, to improve our product every day. To satisfy todays’ production capacity, multi-axis metal working, we focus on the target market such as automobile industry, aerospace technology, medical application and also energy solution. AutoCam is established in 1995. Auto is for “automated production”; Cam for “Roller Cam”. All products made by AutoCam are designed by different kind of cam. In 1998, we announced the first one cam-type sync-unclamping ATC. By 2004, Roller Cam Driver series launched; It becomes an AutoCam flagship product for years till today. “What we want is when engineers push the Cycle-Start button, they feel the difference.”

After adding four-axis or five axis rotary table on the machine tool, multi axis machining can be realized, which can improve the machining efficiency and yield. With the improvement of manufacturing automation in China, the demand for rotary table increases significantly.

Now, I will introduce the situation of several rotary table brands in China. We will divide them into four categories: Europe andAmerica, Japan, Taiwan and Chinese brands.

Taiwan: TJR, Detron and GSA are the main brands, as well as DEX, Autocam and HW. These rotary tables are not only configured on Chinese brand machine tools, but also sold to end customers. Their precision is not high and their service life is not long, but they can meet the requirements when machining parts with low precision. Some users will consider these brands when their budget is limited. Among these brands, TJR has the best sales volume, with an annual sales volume of more than 10000 sets, because they have the most complete distribution network, complete models and cheap prices.Most importantl

China: there are many locally four-axis brands in China, such as Gutia,Silvercnc, Blue tech, CP and Deshu. The product quality of these brands is comparable to that of Taiwan. Due to more favorable prices and fast delivery, they have occupied the market of most Taiwan brands. The four axis of Chinese brands mainly adopt roller cam structure or harmonic structure. The wear resistance of roller cam is better than that of worm gear, with long service life and good accuracy retention. The price of harmonic reducer rotary table is low, which is suitable for 3C industry. These two structures meet the needs of the market and have been recognized by customers.

KME CNC has introduced the NDX135-RF, a completely wireless CNC rotary table. Users can operate up to four of these units with a single standard KME control system. The indexer is easily set in place and the battery is easy to change.

Engineered to meet complex machining needs, KME"s rotary tables can easily integrate with a vertical machining center (VMC). They can turn VMCs from 3rd axis into 4th, or 4th into a 5th by simply mounting the rotary table onto any pallet. The compact units feature a rigid build, a solid Meehanite cast body frame and a high torque capacity of 250 ft-lbs. Featuring a compact size, these rotary tables may be used in numerous applications and are designed to be simple plug & play.

"Rotary tables offer the perfect solution for machining multiple sides of a part in a single set-up, or for machining many parts on a multi-sided fixture. But handling very large or very small parts can prove challenging without the correct size rotary," said a Haas spokesperson.

The HRT1000 and HRT100 rotary tables from Haas Automation, Inc., cover both ends of the size spectrum, providing high-precision 4-axis positioning and simultaneous 4-axis motion for extra-large and extra-small parts.

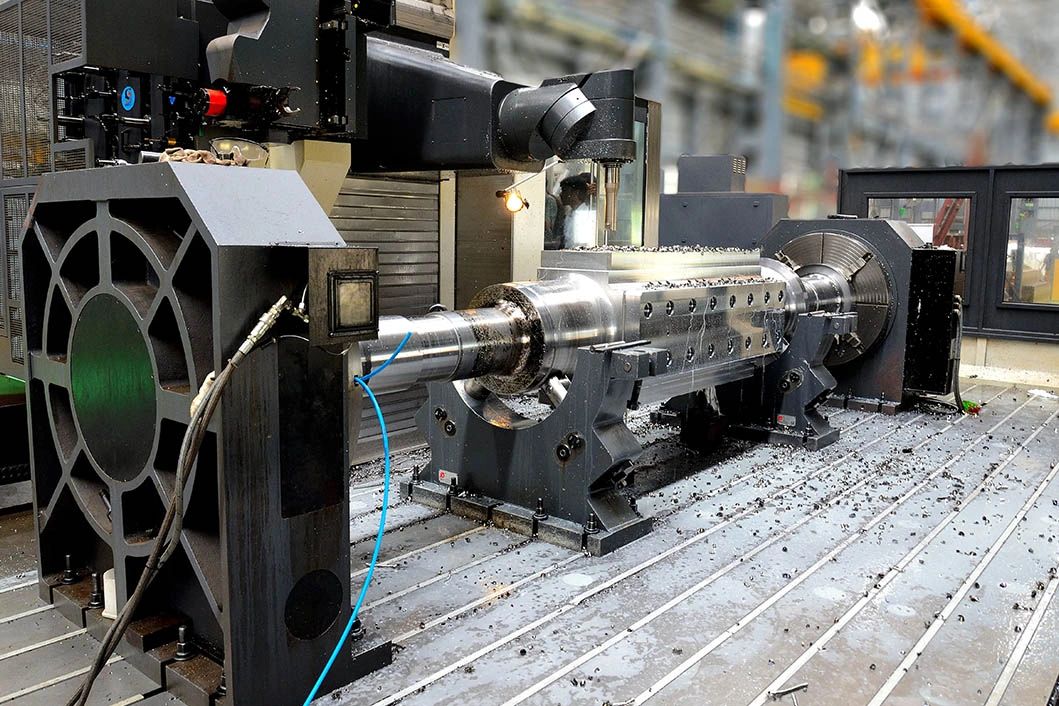

Whether machining large shafts for windmills, rethreading drill pipe or machining blowout preventers, the extra-large Haas HRT1000 rotary table is designed to handle the big jobs. "With its massive platter, generous torque and large through-hole, this extra-large rotary table will easily handle even the biggest 4-axis jobs in your shop," said the spokesperson.

The HRT1000 rotary table is one of three extra-large rotary tables from Haas. It features a massive 1,000 mm (39.37") T-slot platter, with a 17.50" (445 mm) through-hole to handle large shafts and fixtures. The HRT1000 provides 2,000 ft-lbs. (2,711 Nm) of cutting torque for simultaneous 4-axis machining, and offers 14,000 ft-lbs. (18,981 Nm) of brake torque to accommodate large parts and heavy off-center milling and drilling. The platter has eight standard 5/8" (16 mm) T-slots arranged radially at 45° increments.

At the other end of the scale, the ultra-compact HRT100 rotary table is designed to provide high-speed, accurate positioning and full 4-axis motion for machining small parts, such as those found in the medical, dental and electronics industries. Designed to complement the diminutive Haas CM-1 Compact Mill, the unit"s small size and lightweight make it a suitable 4-axis solution for even the smallest machining centers.

The HRT100 provides 35 ft-lbs. (47 Nm) of cutting torque, and the 100 mm (3.94") platter indexes at 300 deg/sec for short cycle times. The platter has multiple bolt-hole patterns for flexible fixture mounting, and the table provides 26 ft-lbs. (35 Nm) of brake torque to handle off-center milling and drilling.

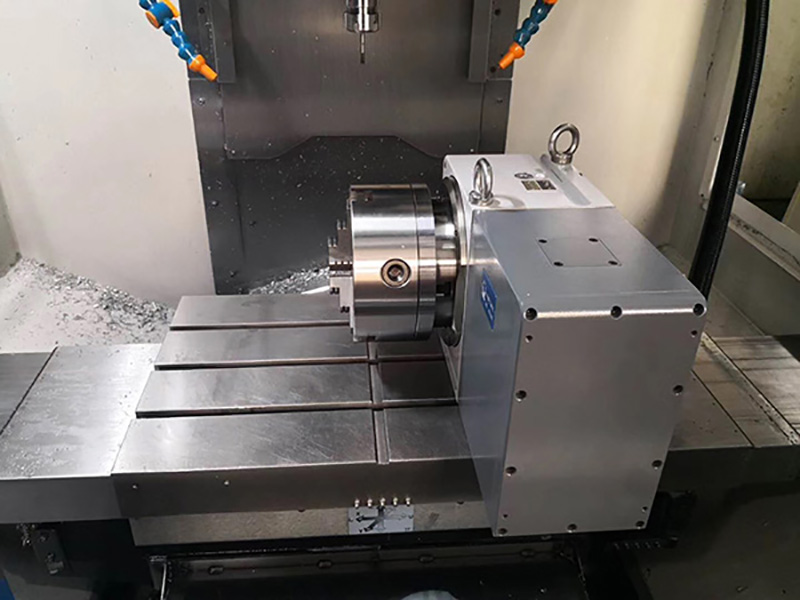

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Methods Machine Tools Inc. has introduced the KIWA-Japan Triple H40 horizontal machining center with a column traverse structure. The machine can support flexible mounting of various fixtures and rotary tables based on the application. The stationary table design enables long workpieces to be...

Methods Machine Tools Inc. has introduced the Feeler HV-1100V vertical machining center. It features a dedicated trunnion, 4+1 axis configuration, and a 13.8-in. rotary table. The trunnion—Autocam with roller cam technology—offers a 16- by 14-in. work envelope. The tilting A axis has a full...

, 0iMF, 10.4″ LCD, Manual Guide I, AICCII 200/Block, 6000RPM Spindle with Chiller, 2-Speed ZF Gear Box, 25HP, 30 Tools ATC, CT-50 (no BBT), Full Enclosed, CTS Prep 1000PSI with Rotary Union, Coolant Gun, 3-Color Light, Oil Skimmer, Chip Flush, 8 M-Codes, Auto Power Off, 2 Y Axis Augers, Chain Chip Conveyor

NBP-1300A#50 (Box Ways), 0iMF, 10.4″ LCD, Manual Guide I, AICCII 200/Block, 6000RPM Spindle with Chiller, 2-Speed ZF Gear Box, 25HP, 30 Tools ATC, CT-50 (no BBT), Full Enclosed, CTS 1000PSI Prep with Rotary Union, Coolant Gun, 3-Color Light, Oil Skimmer, Chip Flush, 8 M-Codes, Auto Power Off, 2 Y Axis Augers, Chain Chip Conveyor

0iMF, 10.4″ LCD, Manual Guide I, AICCII, DDS 12000rpm w/ sp. motor: αiIT8/12000 (7.5/11/15 kw) and Spindle Oil Cooler, CAT40 Dual Contact, MPG, Heat Exchanger, Working Light, Front Door w/ Interlock, 30T Arm Type ATC System, Chain Type Chip Conveyor w/o bucket (discharge 1050mm), Chip Augers beside Y Axis, CTS Interface Prep. (incl. Electrical Wiring, Rotary Union / 500 psi) + Top Roof, Chip Flushing System w/ Coolant Gun, Oil Skimmer, 8M Function, Auto Power Off, Z Axis Travel Extends to 560mm.

U-250 4 + 1 Axis, 0iMF, 15000RPM DDS with Spindler Chiller, 20HP, 26 Tools ATC, BBT-30, Full Enclosed with Top Cover, CTS 1000PSI Prep with Rotary Union, Autocam Rotary Type Table (include Hydraulic Interface 2 – in/out ports), Coolant Gun, 3-Color Light, Oil Skimmer, Chip Flushing, Heat Exchanger, Work Light in Electrical Cabinet, Chain type Chip Conveyor with Bucket, Air Condition of Electric Cabinet, CE Modification, Auto Door + Light Safety Sensor, Manual Lubrication Systems for Ballscrew and Linear Guide Way, Auto Power Off

U-250 4 + 1 Axis, 0iMF, 15000RPM DDS with Spindle Chiller, 20HP, 26 Tools ATC, BBT-30, Full Enclosed with Top Cover, CTS 1000PSI Prep with Rotary Union, Autocam Rotary Type Table (include Hydraulic Interface 2 – in/out ports), Coolant Gun, Air Gun, 3-Color Light, Oil Skimmer, Chip Flushing, Heat Exchanger, Work Light in Electrical Cabinet, Chain type Chip Conveyor

U-600P-5AX, TNC640, 15.1″ LCD, 15000RPM DDS with Spindle Chiller, 23HP, 30 Tools ATC, CAT-40 (Big Plus), CTS 435Prep PSI with Rotary Union, Machine Thermal Compensation, Grease Lubrication, Chip Flush, XYZAC Heidenhain Linear Scales, Air Conditioner, Coolant Gun, Oil Skimmer, Auto Power off, 8 M Codes, Heidehain Work Measure TS460 + SE660, KKH250 Calibration Spheer, Kinematics, 220V/60Hz Transformer, Chain Type Chip Conveyor

U-800-5AX, TNC640, 15.1″ LCD, 12000RPM Spindle with Chiller, 50HP, 32 Tools ATC, HSK-63A, CTS 1000PSI Prep With Rotary Union, Machine Thermal Compensation, Grease Lubrication, Chip Flush, XYZ Schneeberger Ways with Linear Scales, AC Scales, Air Conditioner, Coolant Gun, Oil Skimmer, Auto Power off, 8 M Codes, Core Cooled Ballscrews XYZ, Dynamic Collision Monitor, Heidehain Work Measure TS460 + SE660, KKH250 Calibration Spheer, Kinematics, Blum Laser Tool Measure, 220V/60Hz Transformer, Chain Type Chip Conveyor

8613371530291

8613371530291