bridgeport rotary table manual supplier

Hardinge Rotary Products More Accuracy, Speed and Flexibility! The Most Flexible Quick-Change Workholding Concept on the Market… Hardinge’s A2-4 (5C) and A2-5 (16C) spindle nose designs allow quick change between collets, expanding collets, step chucks, 3-jaw chucks and face plates. Common spindle tooling can be shared between the Hardinge Rotary System(s) and a lathe. The gripping is in the spindle, closest to the spindle bearings, unlike surface-mounted adapters used on traditional rotary tables. Multiple workholding options provide alternate gripping solutions for increased precision and...

Table of Contents Hardinge has a large selection of rotary products for all ranges of production. Choose from precision and super-precision systems – single-spindle, multi-spindle and dual-axis configurations… 5C2 Gear-Driven Rotary Indexers GD5C2 single GD5C2-02 dual GD5C2-03 triple GD5C2-04 quad pages 8 - 9 • Accuracy to ±3 Arc-Sec • Repeatability to ±2 Arc-Sec • Rapid positioning speeds • Reliability • Zero backlash systems • Flexibility of workholding tooling 16C2 and 3J2 Gear-Driven Rotary Indexers GD16C2 and GD3J2 single GD16C2-02 and GD3J2-02 dual GD16C2-03 and GD3J2-03 triple pages...

Quality Manufacturing Processes Hardinge"s GD5C2 has more accuracy, more spindle clearance and more thrust & radial load. All rotary products are manufactured in Elmira, New York to strict specifications. Curved front casting and removable handle for increased spindle clearance and better tool access. ±5 arc-sec Repeatability ±25 arc-sec Accuracy .0002" Max. Runout (.005mm TIR) Robust, dual-bearing spindle for heavier radial and axial loads. 50-lb (23kg) part weight and 1000-lb (4448N) tailstock thrust per spindle is not a problem – even on a quad unit with tailstocks! 1 4 6 2 4 5 3 Small...

Productivity Features Hardinge Collet-Ready Spindles provide the most Flexible Rotary Products in the industry! Hardinge rotary systems accept many styles of standard tooling without an adapter, which is unique in the industry. You can purchase a complete system all tooled up and ready to run your parts. Rely on the spindle tooling experts for the accuracy and repeatability to get the job done. Zero-Backlash Direct-Drive Technology Hardinge offers direct-drive technology for flexible, high-speed, SUPER-PRECISION® parts positioning. Features include rapid bidirectional response, zero...

Fourth-Axis Integration GD160LP Rotary Indexer mounted in a Bridgeport® vertical machining center machining six sides of the part. Direct-Drive DD300 Rotary Table Indexer mounted in a Bridgeport® vertical machining center machining an out-of-round, elliptical part. Trunnion tailstock application for the DD100 High-Speed Direct-Drive Rotary Positioner. Spiral milling application on a Bridgeport knee mill using a 5C2 indexer and manual tailstock. 6

Interfacing to a Host Machine True 4th-Axis* via the host machine (gear-driven) Hardinge gear-driven rotary systems may be connected directly to the host machine and its CNC control. Connecting to the machine"s CNC control requires replacing the standard servo motor and cable with a servo motor and cable that is compatible with the host CNC. If the machine is not 4th-axis ready, the machine will need a 4th-axis option and servo amplifier installed. Hardinge has integrated its rotary products with Fanuc, Siemens, Heidenhain, Okuma and Milltronics. Other systems can be supported with the...

5C2 Rotary Indexers The 5C2 Rotary System is based on a long history of Hardinge 5C spindle and manual indexer designs. Over 60 years of GD5C2 GD5C2-02 GD5C2-03 GD5C2-04 Hardinge-engineered and proven mechanical elements guarantee an accurate, repeatable, reliable and flexible product. SERVO CONTROL / PROGRAMMING Servo Model Standard Servo Storage - Number of programs/steps up to 50/1000 RS-232 Interface YES Text Display multiple lines Infrared Upload/Download Baud Rate Capacity YES up to 56K SPINDLE Runout Maximum (TIR) Standard Features • Curved front casting and removable handle for...

16C2 and 3J2 Rotary Indexers 16C2 and 3J2 Rotary Table Indexers Hardinge"s world-renowned collet-ready A2-5 spindle is the heart of the system. The same accuracy, precision and reliability built into the Hardinge lathe extends to a large capacity rotary indexer. A variety of standard 16C or 3J spindle tooling will mount directly in or on the spindle without the use of an adapter. Common spindle tooling can now be shared between a rotary unit and a lathe. SERVO CONTROL / PROGRAMMING Servo Model Enhanced Servo Storage - Number of programs/steps RS-232 Interface YES Text Display multiple lines...

Question 2. Oil for these appears to be critical. Am I correct that the rotating table and cast base make a "way" surface? If so how is this lubricated?

Be sure the work holding device is mounted solidly to the table, and the work is held firmly. Spring or vibration in the work can cause thin cutters to jam or shatter!

We offer Bridgeport Milling Machines that have been serviced by our TAS IRON LTD facility in Berea, Ohio. Some of the best pricing around. Your need to have your Bridgeport serviced and brought back to a good service. Send it to us, we will send it back ready to work. We have serveral in stock machines available as well as we take orders, if you want one unit or ten units, we will build them for you.

We offer crating service and free loading and packaging. Don"t take a chance on buying a used machine tool until you give us a chance. If you need glass scales installed, Table feed drives, what ever it may be, we do it here. So when your mill breaks down, send it in to get repaired, a lot of times its more cost effective.

Bridgeport milling machine. Of the brand bridgeport in the same way as an operation of the type manual just as a setting position qualified as horizontalvertical * A countryregion of manufacture : "united states" ¬

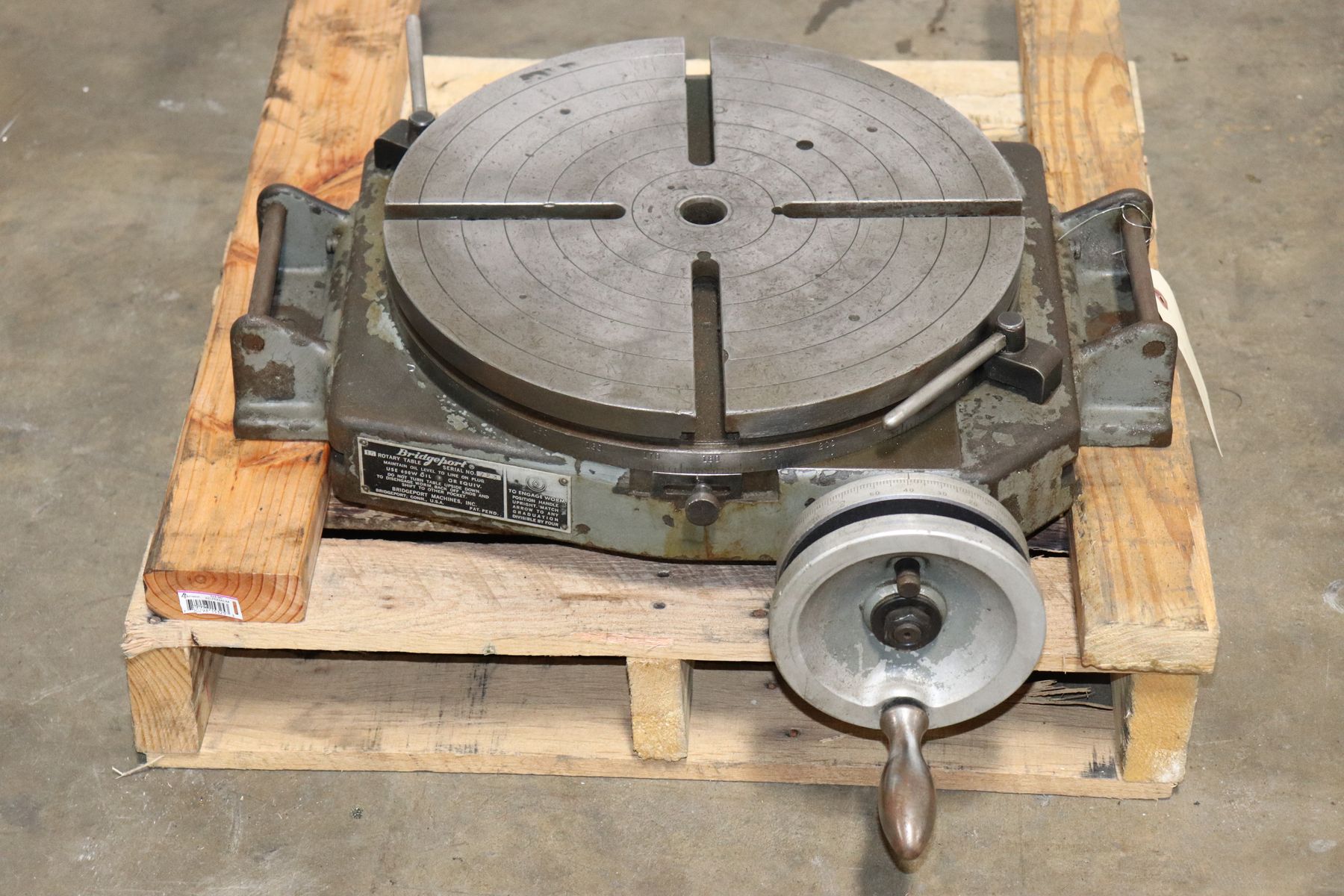

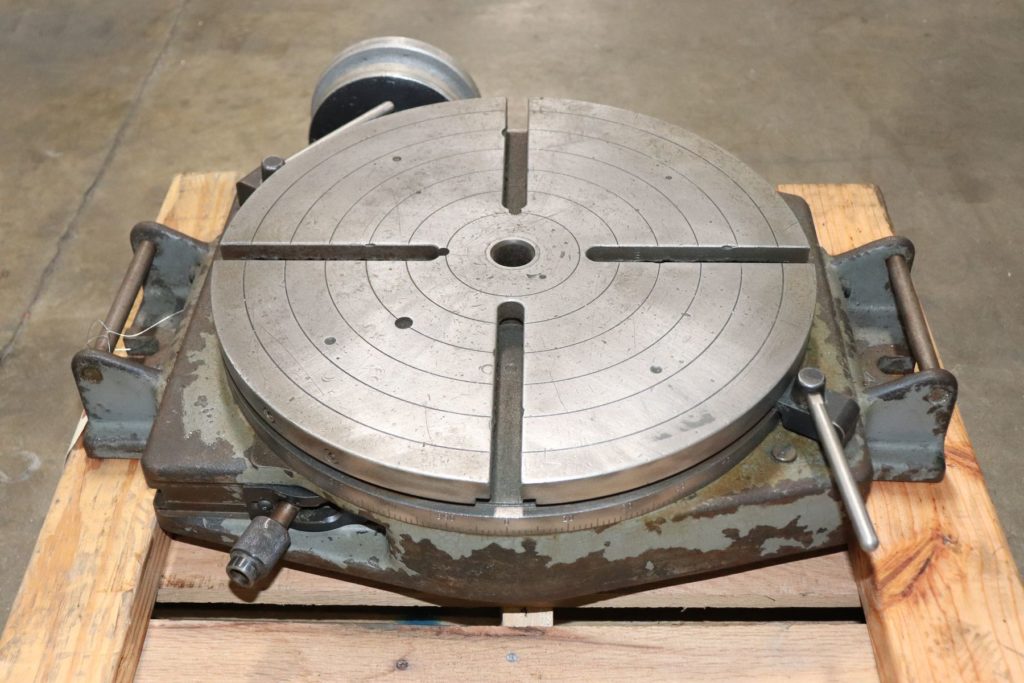

Bridgeport machine co15. Of the brand bridgeport machine co in the same way as a model 15" rotating table | A manufacturer specified as bridgeport machine co just as an operation : manual | This article are a custom bundle | Used....

TJR MTHR(s)-255 is a 255mm diameter CNC rotary table with manual tilting function for customers with specific fixture angles to machine at, or minimal tilt axis requirements and can stop the machine and manually adjust the tilting angle. Comes with a high capacity hydraulic braking system, priced without motor and can be prepared to suit any interface at additional cost. (See our interface listings for details and costs for external interface (motor, switch, cable and connector requirements if you already have a 4th axis interface in the machine) and machine interface costs (if you do not have the additional axis fitted).

8613371530291

8613371530291