bridgeport rotary table manual made in china

FEATURES • 15” M80 Color LCD, Touch Screen Control with USB • Coolant Chip Flush System • 12,000 RPM Greased Direct Coupled Spindle with Chiller • CT40 Spindle (BT opt) • Dual Contact Big-Plus® Spindle • Hand-held Manual Pulse Generator • On board (2) SD Card Slots • Fully Interlocked Machine Guarding • NAVI Mill Shop Floor Programming • Manual Chip Wash Gun • 4th Axis Pre-wiring • ECO Friendly Centralized Grease Lubrication • Three Color Stack Light • One Year Machine Warranty Parts and Labor • Three Year Control Warranty Parts and Labor • Program and Data Protect Key • Prep for 1000 PSI...

MILL SPECIFICATIONS FOR M80 SERIEs Controls • 3-Dimensional Tool Radius Compensation (tools vertical-direction compensation) • Absolute/Incremental Command • Alarm Guidance • Automatic Backup (setup by parameter) • Automatic Support Functions • Automatic Tool Length Measurement • Manual Tool Length Measurement • Tool Life Management 200 Sets (M80) • Workpiece Position Measurement • Axis Detachment • Circular Interpolation (center/radius designation) • Cutting Feed Override • Cylindrical Interpolation • Data Protection by User Level • Data Protection Key • Drip Feed Through RS232, USB, SD...

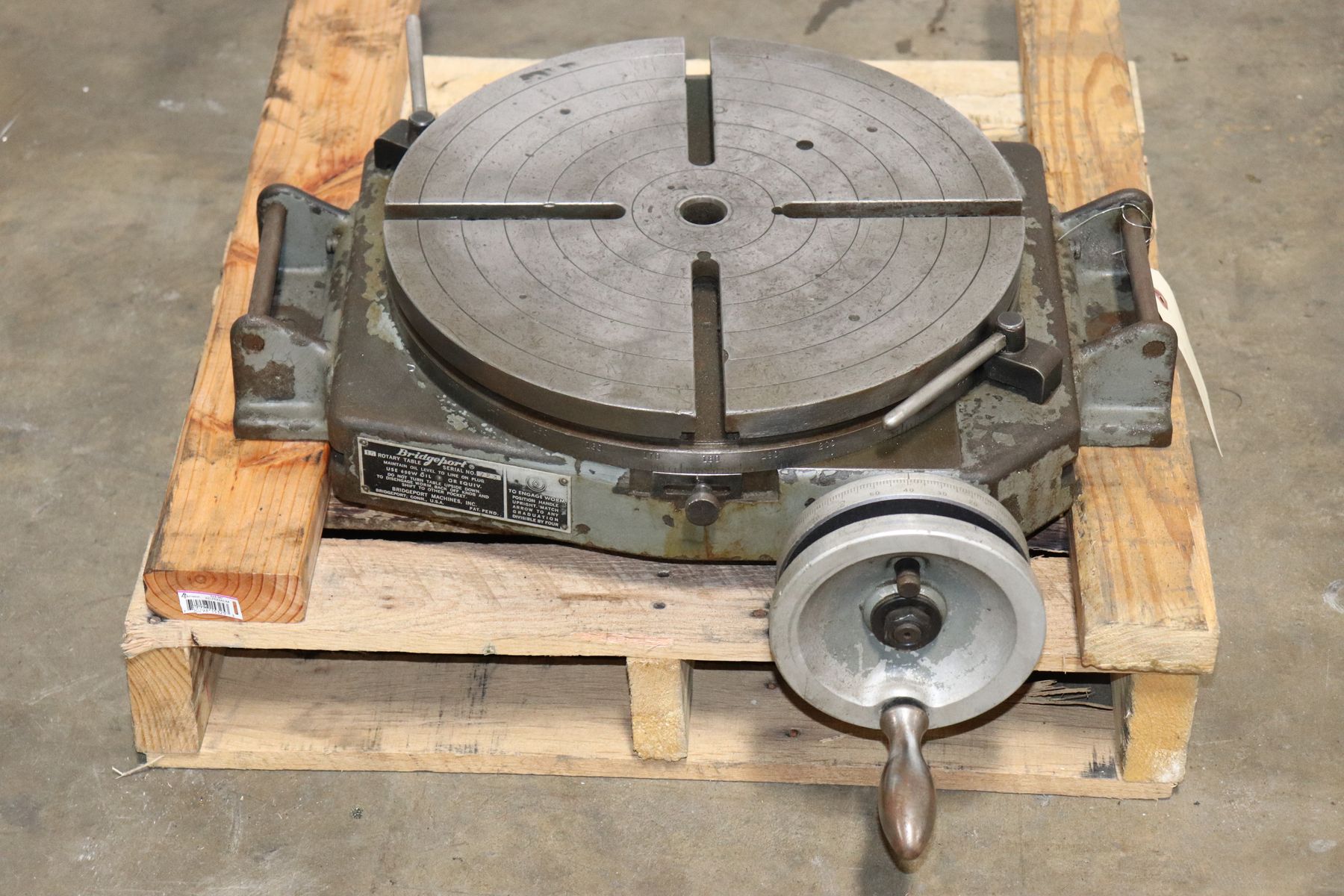

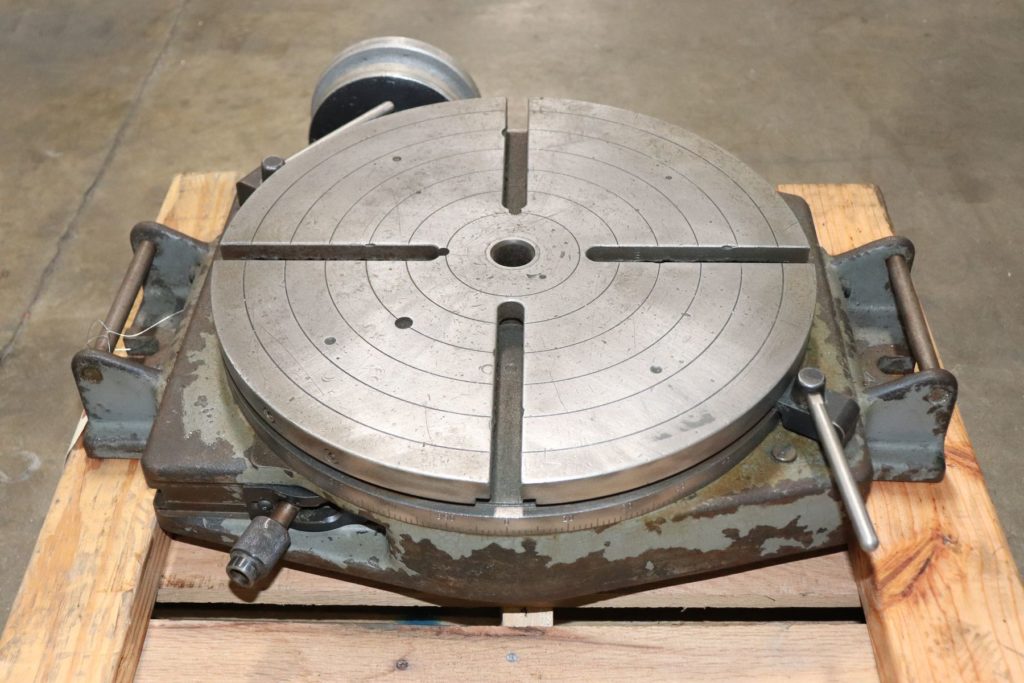

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

bridgeport milling machine are milling machines which are controlled directly by human operators, instead of being reliant on automation systems. As with all milling machines, they use various shapes of cutting implement to remove material from items being processed, and are particularly useful when creating flat metal surfaces. In fact, a bridgeport milling machine will be a versatile addition to almost any metal working factory or workshop, and various types can be purchased wholesale from the Alibaba store.

Manual mills can be horizontal or vertical, and they both have their strengths. If you need precision, a vertical bridgeport milling machine will be a good call. The vertical blade orientation means that operators can create more intricate shapes with more control over the direction of cuts. However, a horizontal manual mill has benefits as well. These mills are more suited to cutting heavier materials and for making deep cuts. In practice, many factories prefer to have both types of bridgeport milling machine in reserve, and it"s easy to add both to your portfolio via Alibaba"s wholesale partners.

There are other styles of bridgeport milling machine to consider as well, and some have very specific applications. For instance, some mills are designed to work with iron or steel rods while others combine drilling and milling functions to create multi-purpose work stations. These stations are often a good choice for small workshops, as they double up on useful functions and aren"t generally bulky. Browse the listings and find manual mills that work for you. Large and small, specialized and universal, our mills catalog covers everyone"s material processing requirements.

I do this for a living as most of you know and have since 1981. I have had 2 mills, my 1st was a Kent mill, wore out piece of **** with no parts available, made in 1980, I used that thing for 8 years and made lots of money. Didn"t sell it I took it to the scrap yard when I was finished. I now have a Bridgeport clone made by Willis, heavier frame than a Bridgeport, just as accurate and will take a heavier cut. Bridgeport used to be an industry standard for this type of mill, not anymore, to costly when compared to other mills.

Stick with R8 collets, way cheaper than NMT taper holders. A 30 or 40 taper is as big as will go into a Bridgeport size head, sturdier than collets but cost prohibitive in the long run, unless you get a bunch with the machine.

My picks would be Acer, Acra, Lagun, Willis, Birmingham, Millport, Newport. Or newer Kent from say 1988 up to present. All are as good as a Bridgeport, I have run them all over the years. The Lagun would be my top pick.

I do agree stay away from the M model Bridgeports with the round ram, horrible beasts. If you can find a Bridgeport in good shape under $1500-1600 go for it. I paid $800 for my current machine. Digital readouts will help a lot on a used machine especially for a newby and make doing things more accurate and faster.

We offer Bridgeport Milling Machines that have been serviced by our TAS IRON LTD facility in Berea, Ohio. Some of the best pricing around. Your need to have your Bridgeport serviced and brought back to a good service. Send it to us, we will send it back ready to work. We have serveral in stock machines available as well as we take orders, if you want one unit or ten units, we will build them for you.

We offer crating service and free loading and packaging. Don"t take a chance on buying a used machine tool until you give us a chance. If you need glass scales installed, Table feed drives, what ever it may be, we do it here. So when your mill breaks down, send it in to get repaired, a lot of times its more cost effective.

8613371530291

8613371530291