cnc milling machine rotary table quotation

I have represented Centroid Corp. for over 20 years now. This latest MPU11 hardware set is their most advanced controller ever produced. Centroid CNC controls are built to be flexable. We have integrated this controller onto Lathes, Mills, Waterjet, Routers, Gear hobb, Custom brush making machinery, Filiment winding machinery, Drilling machines, VTL, Large format machine tools and much more.Yes, we can update your machine too.

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

We provide exclusive range of Goizper make Turn tables (CAM based), rotary tables (indexers), Clutch-Brake units, Spares, Couplings, customized Gear boxes. Goizperread more... Brochure

The rotary table is an accessory for the CNC floor type boring and milling machine. It can be working together with the floor type boring milling machine for milling angle, reverse boring, polyhedral machining, and other complex machining processes. It could do five sides machining if the main machine equipped the angle milling head.

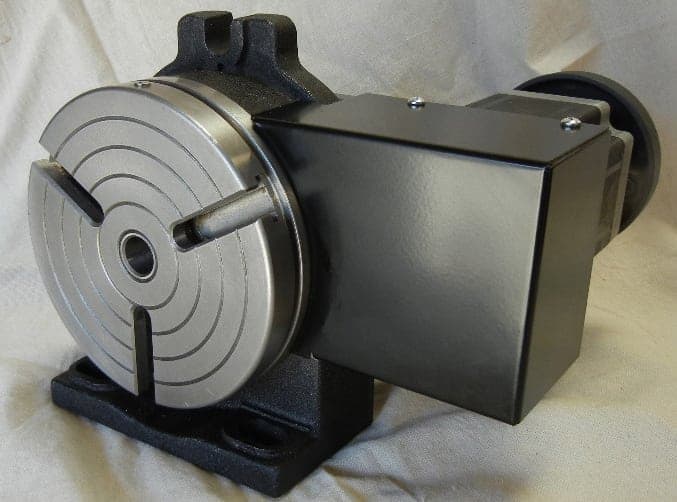

CNC rotary table is a common part of CNC milling machine, often used as a servo axis of CNC milling machine, namely C axis of vertical CNC milling machine and B axis of horizontal CNC milling machine. The CNC rotary table includes the foot of the turntable, a round turntable surface, four rolling bearing parts arranged on the upper surface of the foot of the turntable, and a center with a self-aligning bearing installed at the center of the upper surface of the foot of the turntable. Support, each rolling bearing component includes a rolling bearing and a support that supports the rolling bearing through the axle. The center of the lower surface of the turntable is provided with a vertical downward axle. The turntable is installed on the foot of the turntable. The inner ring of the self-aligning bearing is fixed, and the rotating surface of the rolling bearing is in rolling contact with the lower surface of the turntable surface.

The CNC rotary table has an inclinometer with two orthogonal test axes as the test tool. The inclinometer is set at the center of the turntable surface to be leveled, so that the two orthogonal test axes of the inclinometer are parallel to the turntable surface, by adjusting the milling machine turntable. The leveling mechanism under the base makes the tilt angle value output by the two test shafts of the inclinometer turntable in the leveling state.

CNC rotary table and swing head are the key components of multi-coordinate CNC machine tools. Traditional rotary tables and swing heads using high-precision worm gears and other transmissions are not only difficult to manufacture, costly, but also difficult to achieve the speed and accuracy required for high-speed machining. Therefore, it is necessary to develop a new electromagnetic drive system for the CNC milling machine turntable and swing head in a different way to realize the zero-drive drive of the rotational motion coordinates of the CNC machine tool.

1. The CNC turntable uses modular design technology. The PAN turntable and TILT turntable are independent components, which are easy to disassemble and can be controlled by linkage or individually.

Lagun’s BM RT is a bed type mill with C-Axis rotation and equipped with a rotary table. With a compact and robust design, this milling machine is ideal for machining bulky workpieces on all 5 sides.

Lagun’s BM RT mill is built with a modular configuration, which means all models in this spectacular line have interchangeable slides, rams and columns. This design method endows each machine with enhanced rigidity, precision and ergonomic working comfort for the operator.

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The hardy table, measuring at 63” x 47” (1600mm x 1200mm), column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges.

*Note: Interested in more bed type milling machines? Take a look at our BM-C and BM-BL bed mills. Or browse all machining centers offered by Lagun Engineering here.

Our 4C software and control system powers all models. Standard and optional equipment is the same across all models. The only differences between models are machine size, travels, spindle power, and part size capacity.

8613371530291

8613371530291