cnc rotary table with stepper motor brands

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

The main part of the RollerDrive mechanism consists of an input shaft and an output turret in which roller followers are embedded. An integral cross-roller bearing supports the output turret with ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

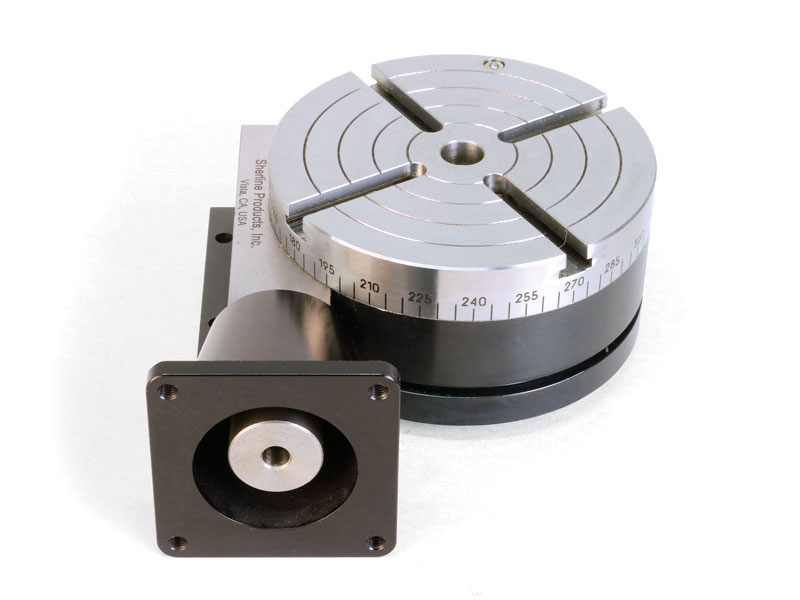

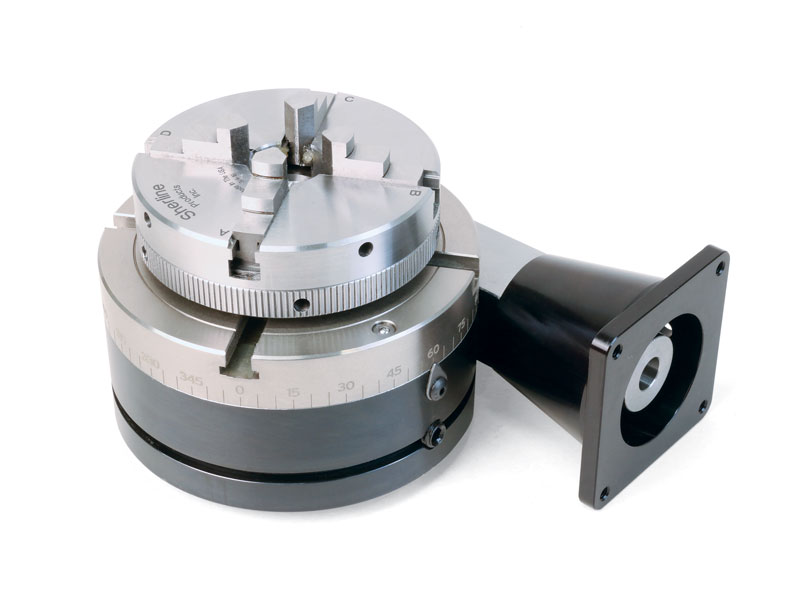

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

Control digital devices and make machinery more precise with a stepper motor from Alibaba.com"s wholesale equipment store. Our catalogue is the place to come when you need a replacement stepper motor rotary table or any other motor related products. You"ll find a huge array of wholesale motors, including step motors with high torque ratings that can offer incredibly precise control. Whether you"re constructing an astronomical telescope or a digital network for broadcasting, these motors will do the job.

Stepper motors are used in situations where devices need to be calibrated to extremely high levels of precision. They aren"t always the most powerful motors, but they do have very high torque levels, and this allows them to control devices in ways that other motors cannot. And they also tend to work well with digital devices due to their "step" mechanism. For instance, you can find step motors in many hard drives, handling millions of operations every minute. They have also become a go-to motor style for robotics installations. So you might need one for an advanced production line. When you need a stepper motor rotary table, finding the right motor is easy. Just search Alibaba.com"s catalogue and you"ll easily find what"s required.

Our stepper motor collection covers every base. Browse motors for use with mini computers like the Raspberry Pi or models designed for use with Arduino components. Look for permanent magnet motors, variable reluctance steppers, or hybrid syncronous steppers, and models with micro step, half step, and full step modes. Our listings include everything you need to control the most complex systems. So find a stepper motor rotary table and order what you need today. Everything can be handled with a couple of clicks, putting specialist stepper motor components within easy reach.

Sherline 28,800 Max RPM Table/400 Max RPM Motor, 4" Table Diam, Horiz, CNC Rotary Indexing Table 1.963" Centerline Height, 4" Subtable OD, 0.316" Through Hole, 120.00 Voltage, 0.006" Positioning Accuracy, AC Stepper Motor

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

399.0US $ |Cnc 4th Axis Stepper Motor Rotary Table With 3-jaw Chuck For Cnc Router Lathe Milling Drilling Machine - Woodworking Machinery Parts - AliExpress

Shop stepper motor rotary table online with free shipping and fast delivery. Stepper motor rotary table is suitable for cnc lathes, milling machines and engraving machines.

MachineStation is keenly involved in the auction facilitation helping sellers capitalize on their surplus assets. Whether it be a Complete Plant or individual equipment. We work with nationally recognized auctioneers in finding the type of auction best suited for the seller’s unique situation.

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

When it comes to powered rotary table, it is the rotary tables widely used in CNC machining center which responsible for precisely locating the parts in the commanded angle in order to perform multi-face machining at one time.

For starters, we need to know what a rotary table is. Rotary table is a high precision positioning device which is widely used in machining and metalworking. With the rotation, the operators can perform drilling, milling, cutting and other applications at exact intervals around the horizontal or vertical axis. To achieve the high accuracy and efficiency, many rotary tables can incorporate with index plates or dividing plates. With the help of additional components, the rotary tables can be used for indexing application or even position the work piece at divisions on the dividing plates.

When it comes to powered rotary table, it is the rotary tables widely used in CNC machining center which responsible for precisely locating the parts in the commanded angle in order to perform multi-face machining at one time. Originally, in a 3-axis CNC machining center, there are only X, Y, Z working axes. The X, Y, Z axis are the linear lathe axes. Operating along the XYZ planes, the Z axis is the important axis that is aligned with the main axis of the machines. On the same plane, the Y axis works in horizontal direction while the X axis is the vertical operation direction.

In typical machining centers that have the 4th axis, the 4th axis is the 180° rotation axis around the X axis. With a CNC motors, the motorized rotary tables can play the role as the 4th axis in the machining centers to enhance the flexibility of metalworking applications. The arrangement of involving powered rotary table in 3-axis machining center is popular for cam machining, helical grooves producing, blade machining and other unique profile machining. Powered rotary tables have a wide range of applications, for example, utilizing in both manufacturing and inspection stage of essential components in aerospace industry, automobile manufacturing and other scientific industries.

The vital elements of a powered rotary table include a supporting disc where the work pieces are clamped for machining, a solid base for clamping onto another larger table, machine, or machining center, the CNC controller and motor. A through hole is machined into the CNC rotary table to fit the Morse taper center or fixture.

The precision-machined disc is the rotating surface where the work piece is positioned and fixed firmly. T slots are the typical parts to help clamping the work pieces. The chuck is used to hold the work piece with a dial indicator to ensure the chuck and product are centered. After installing the chuck with bolts and T-nuts then checking if the work piece is centered, the operator can position the job on the table. The disc can spin freely under the instructions from CNC controller and motor. It is also the components which the indexing plate or dividing plate can mount with. When CNC controller and the CNC motor provide inputs, the rotation of the worm gear is activated and the mating gear mounted beneath the table surface begins to spin, either. The worm gears perform the precise rotations of the rotary table and every parts of the disc are critically calibrated in degrees.

The computer numerical controller transport programmed commands to activate the powered rotary tables. The commands are conveyed in CAD files, which refers to Computer Aided Design files, and provide sequential instructions to ensure the smooth operation. Eliminating the human power, CNC provides reliable and precise high performance positioning for further machining applications.

The size and type of the CNC motors can determine the routers precision, the efficiency and also the accuracy. Following is the basic introduction of two classes of motors used in CNC rotary tables, which are the stepper motors and the servo motors. Within these 2 classes, there are more subtypes.

Servo motors use closed looping variable circuit which continuously run for maintaining smooth motor function. The brushes on this type of CNC motors should be replaced after two thousand hours of operation. The encoders may need to be checked and replaced, too. Servo motors feature the efficiency in power consumption. They perform with about 90 percent of efficiency when giving light loads.

Stepper motors only require the wires that connected with the motor driver, having simpler setup. The only wearing part in this type of CNC motors is the bearing mounted on the motor, which slightly reduce the equipment life. Compared to servo type, stepper motors consume a large amount of power to provide the output, and much of them is converted to heat. Depending on the stepper driver, the stepper motors are often seventy percent efficient.

8613371530291

8613371530291