cnc rotary table with stepper motor pricelist

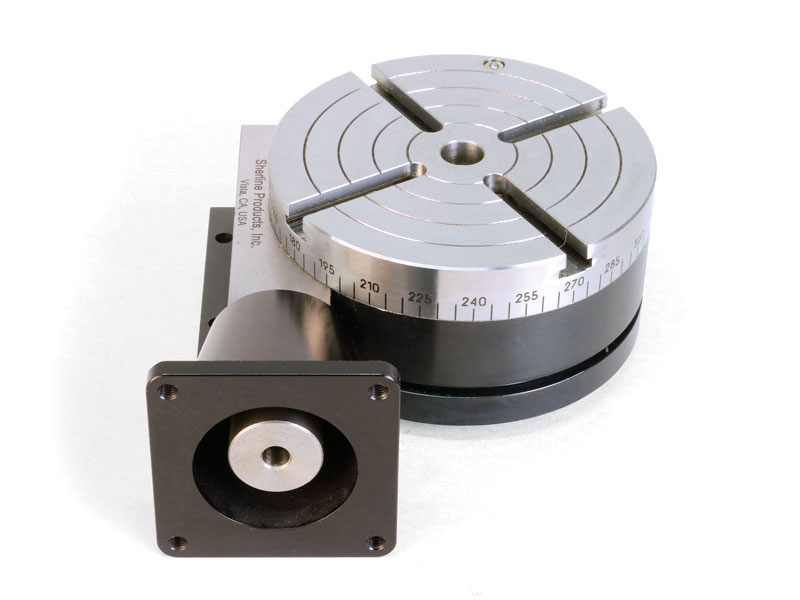

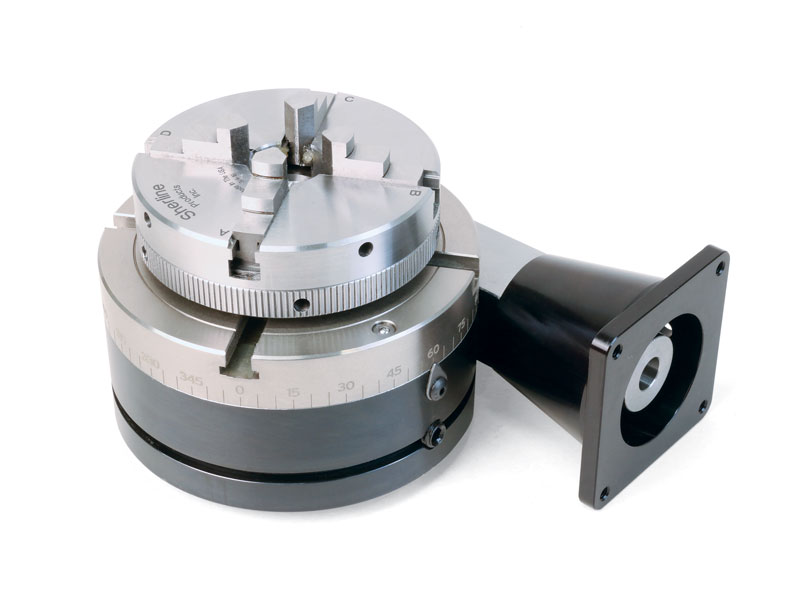

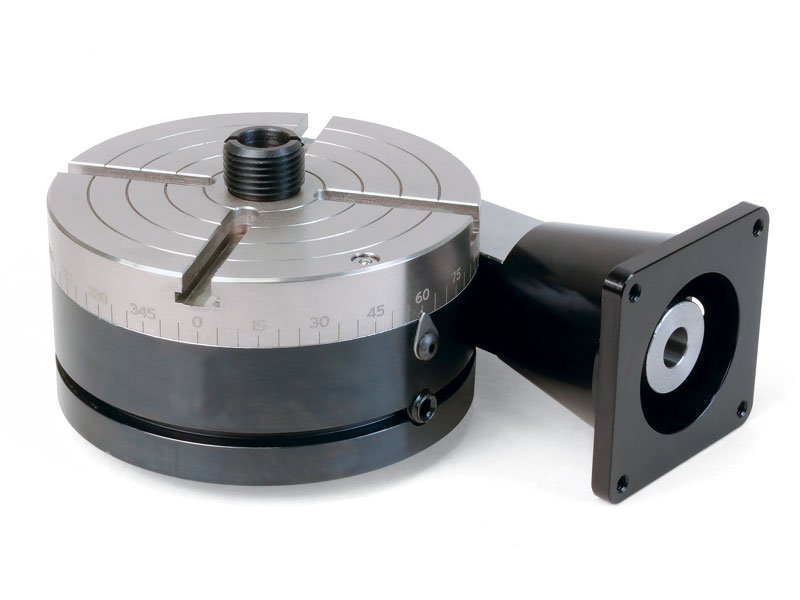

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. The 8730 rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external 8760 driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

The main part of the RollerDrive mechanism consists of an input shaft and an output turret in which roller followers are embedded. An integral cross-roller bearing supports the output turret with ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

This 4th axis rotary table system can be added to any of our machines, even if you already have your machine. Just send us the electronics panel and we can add the electronics for you. Includes all necessary electronics installed inside the machine with a plug on the front console. Wired, installed, and completely ready to run.

4th axis programming can be done with a 3 axis CAD program by converting the Y axis to A axis in the post processor. Just make the Y dimension of your drawing the same dimension as the cylindrical circumference of your work piece.

This item can be shipped with or without a shipping charge attached. The waiver of the shipping fee can only be applied when you purchase a CNC package along with this product. If you are purchasing this item by itself, the shipping charge will apply. All orders will be checked for accuracy.

Last Retail Price Increase: OCTOBER 1, 2015 Prices subject to change without notice, Updated 4/9/18

Mill Accessories, Books, and Videos Price ListP/N DESCRIPTION WT PRICE P/N DESCRIPTION WT PRICE1012 Sensitive Drilling Attachment 1.0 $115.50 3095 1/8" Mill Collet .05 17.001156 #1 Morse Taper Remover .1 26.25 3096 3/16" Mill Collet .05 17.001164 WW Collet Fixture—holds WW collets vertically on mill or rotary table 1.0 110.25 3097 1/4" Mill Collet .05 17.001165 8 mm Collet Fixture—Like 1164 but for 8 mm collets 1.0 120.75 3098 Mill Collet (Special Order .125" to .312") (Allow 3 wks.) .05 52.501187 Chuck-to-T-Slot Adapter .05 8.00 3200 Indexing Attachment 8.0 210.001296 Cutoff Tool Holder Riser Block .5 52.50 3217 Gear Tooth Cutter Holder & 1/4" HSS Tool Blank .5 36.751297 Mill Headstock Spacer .75 47.25 3230 Mill Arbor–7/8" Dia. (Short) .5 52.501299 Extended Mill Headstock Spacer Block 2.5 63.00 3231 Mill Arbor –7/8" Dia. (Long) .5 52.501300 Mill Column Spacer Block 1.50 42.00 3235 Mill Arbor –1" Dia. (Short) .5 52.502045 Index Block Set (Hexagon and Octagon) 2.0 63.00 3236 Mill Arbor –1" Dia. (Long) .5 52.502049 Spindle Handwheel 1.5 47.25 33050 DC Motor and Speed Control Units (headstock not included) 7.2 241.502100 3/4" Collet Pot Chuck .05 26.25 3306 Headstock, DC motor and speed control assembly 10.0 336.002101 1" Collet Pot Chuck .05 28.50 3307 Headstock, DC motor and speed control assembly with 10,000 RPM 10.0 420.00 pulley set (P/N 4335 installed)2102 1-1/4" Collet Pot Chuck .05 31.50 3308 Headstock and Motor Unit with ER-16 Spindle Nose 10.0 420.00 2118 Horological Mill Bushing and Depthing Attachment 1.0 90.00 3400 Oversize 2.5" Handwheel (Metric P/N 3410) .15 15.75 2128 Microscope Mount Only for Mill (Scope not included) 25.0 236.25 3420 2" Adjust. “Zero” Handwheel (Y-axis) (Met. P/N 3430) .25 36.7530100 Sherline Standard Headstock 2.5 107.50 3428 2" Adjust. “Zero” Handwheel (X or Z-axis) (Metric P/N 3429) .25 36.7530110 9/16" Headstock Assembly 2.5 178.50 3440 2.5" Adjust. “Zero” Handwheel (Y-axis) (Met. P/N 3450) .25 42.0030111 ER-16 Headstock 2.5 173.25 3455 2.5" Adj. “Zero” Handwheel (X or Z-axis) (Metric P/N 3459) .25 42.00 3012 Hold-Down Set .4 26.25 3013 Step Block Hold-Down Set 1.0 42.00 3460 2.5" Adjustable “Zero” Handwheel (W/Thrust and Bearing Set for “Z” .25 52.50 Axis) (Metric P/N 3465) 3015 Toggle Switch Dust Cover .05 9.00 3500 Rotary Column Attachment (Included on 2000 mill) 1.75 84.003020 Sherline 5/32" Hex “T” Driver .15 6.50 3551 Milling Vise 2.5 78.753021 Center Drill Set .05 17.00 3559 90° Angle Plate 4.0 105.003022 Multi-tool wrench (for nuts on Sherline lathe and mill) .5 26.25 3560 Mill Tooling Plate 2.5 63.003052 Fly Cutter .5 36.75 3561 Short 90° Angle Plate 1.0 63.003054 Boring Head (Metric P/N 3049) .75 73.50 3562 Mill Tooling Plate (7" X 13") 9.0 200.253055 #1 Morse Blank .5 17.00 3563 Mill Tooling Plate (7" X 18") 8.25 275.003056 T-Nuts, 10-32 (Set of 10) .15 8.50 3570 Rotating Mill Vise Base 1.0 105.003058 4-Jaw Hold-Down Set .15 6.50 3575 Mill Vise (P/N 3551) w/ Rot. Base (P/N 3570) 2.5 173.253060 Milling Collet Set (Inch, 1/8", 3/16", 1/4") .15 47.25 3580 Multi-Direction Vertical Milling Column (Metric P/N 3585) 10.0 393.753061 Boring Tool (Max. Depth .600, Min. Hole 1/4") Use with P/N 3054 .15 15.75 3700 4" Rotary Table 8.0 283.50 boring head 3700-OP 4" Reverse Rotary Table 8.0 343.503063 Boring Tool (Max. Depth 1", Min. Hole 5/16") Use with P/N 3054 .15 15.75 3700- 4" Rotary Table w/ stepper motor mount 9.0 336.00 boring head CNC3064 Boring Tool (Max. Depth 1.5", Min. Hole 5/16") Use with P/N 3054 .15 19.00 3700-OP 4" Reverse Rotary Table w/ stepper motor mount 9.0 396.00 boring head CNC3065 Slitting Saw Holder .25 42.00 3701 Right Angle Attachment (Use with P/N 3700) 3.0 78.753070 2.5" Dia. x 1-5/16" Steel Blank (Chuck body) w/ 3/4-16 thrd. 2.0 26.25 3702 Adjustable Right Angle Tailstock (For use with P/N 3700) 2.0 78.753074 Drill Chuck Tool Holder (for ¼" or 3/8" Jacobs Chuck) .5 36.75 37090 3/8-16 to 3/4 x 16 Rotary Table Chuck Adapter .06 7.003075 5/16" End Mill Holder .5 31.50 (For use with chucks 1041, 1040, 1040C, 1075, 1076, 1076C, 1076C-PIE, 1044, 1030)

3076 6.0mm End Mill Holder .5 31.50 37091 3/8-16 to 12 x 1mm Rotary Table Chuck Adapter .04 15.753077 8.0mm End Mill Holder .5 31.50 (For use with chucks 1068, 1077, 1071)

3078 10.0 mm End Mill Holder .5 31.50 37092 3/8-16 to 14 x 1mm Rotary Table Chuck Adapter .06 15.753079 3/8" End Mill Holder (for 1/4", 3/16" and 1/8" holders (See P/N .5 31.50 (For use with chucks 1031, 1079, 1034, 1035) 6079, 6080 and 6081) 37093 3/8-16 to 1/2-20 Rotary Table Chuck Adapter .06 15.753080 End Mill Set (1/4" Shank) (1/8", 3/16", 1/4") .05 31.50 (For use with chucks 1070, 1073)

3082 2" End Mill Holder Style Fixture, ¾-16 threaded long blank .05 19.00 37094 3/8-16 to 3/8-24 Rotary Table Chuck Adapter .04 15.753083 4" End Mill Holder Style Fixture, ¾-16 threaded long blank .10 21.00 (For use with chucks 1069, 1072, 3072, 3073)

3087 3/32" Mill Collet .05 21.00 37097 3/4-16 X 5/8-24 Rotary Table Chuck Adapter .06 27.003089 5/32" Mill Collet .05 21.00 (For use with chucks 1041, 1040, 1075, 1076, 1044, 1030)

3090 Mill Collet Set (Metric, 3.0, 4.0 & 6.0mm) .15 47.25 37098 ER-16 Rotary Table Chuck Adapter .10 14.003091 7/32" Mill Collet .05 $21.00 (For use with chucks 1042, 1078, 1032)

3092 3.0 mm Mill Collet .05 17.00 3710 4" Rotary Table Nickel-Teflon Coated with 15/32" Through-Hole 8.0 373.503093 4.0 mm Mill Collet .05 17.00 3710- 4" Table w/ stepper motor mount Nickel-Teflon Coated with 15/32" 9.0 426.003094 6.0 mm Mill Collet .05 17.00 CNC Through-HoleP/N DESCRIPTION WT PRICE P/N DESCRIPTION WT PRICE3725 5" Rotary Table Tooling Plate 1.0 47.25 7555 Super-Lube Dri-Film lube with PTFE, 11 oz. aerosol can 1.0 14.753750 Tilting Angle Table 2.5 115.50 7560 NIKX-STIKX metal cutting compound, 2.2 oz. stick .12 5.254058 Spindle Drawbar Rubber Gripper End Caps (Pair) .01 2.25 7620 Single Flute Insert Fly Cutter .5 $63.00 4059 Spindle Bar Set with Grips .05 3.25 7622 Replacement Carbide Tip (for P/N 7620) .05 16.504017OL Mill Z-axis Saddle Nut with Oiler (Metric P/N 4117OL) .5 31.00 8100 3-Axis Digital Readout, 120 VAC* (Mill) w/RPM Gauge (Metric P/N 3.0 393.75*4017U Mill Saddle Lock Lever Upgrade (Metric P/N 4117U) .5 26.25 8160) *For 240 VAC version, add $21.00 4017Z Mill CNC Z-axis Backlash Adjustment Upgrade (Metric P/N 4117Z) .75 36.75 8700 CNC Rotary Table w/ stepper motor and controller 17.0 761.25 4335 10,000 RPM pulley set (Replaces standard pulley set) 1.0 $84.00 8710 CNC Rotary Table Riser Plate 2.0 31.50 Chip Guard .5 15.75 8711 CNC Nickel-Teflon Coated Rotary Table w/ stepper motor and controller 17.0 851.254360 8730 CNC Rotary Table w/ stepper motor (w/ Sherline plug) 10.0 414.7550058 2" Rigid Column Spacer-Rectangular for 5400/5410 mill 1.5 40.00 8731 CNC Nickel-Teflon Coated Rotary Table with 15/32" Through Hole 10.0 504.755011U X and Y axis backlash upgrade (mills 1997 to 7/04) (Metric 5111U) .1 9.50 8760 CNC 4-axis Driver Box with cables, power supply, Linux and EMC2 7.0 630.00 5090 Mill Accordion Way Cover Set (compatible w/ 5000/5400/2000 mills) .5 52.50 software, parallel cable connects to computer 5150 Mill Vinyl Dust Cover, 5000 Series Mills .25 14.75 8770 Upgrade any Sherline CNC-ready mill to full CNC using your own 13.0 845.25 5151 Mill Vinyl Dust Cover, 2000 Series Mill .25 17.00 computer. Includes 3 stepper motors, P/N 8760 4-axis driver box and 5200 XY Base (10" base) (Metric P/N 5210) 19.0 273.00 Linux/EMC software on CD. (Installation and software support not5200- XY Base (10" base w/ oiler), CNC ready w/ stepper motor mounts 20.0 456.75 included.) CNC (Metric P/N 5210-CNC) 8800/ CNC Linear Controller w/ Stepper Motor (Use with Sherline CNC- 5.0 472.50 5201 XYZ Base (10" base) (Metric P/N 5211) 26.0 483.00 8810 ready lathes or mills, any axis5201- XYZ Base (10" base w/ oiler), CNC ready w/ stepper motor mounts 27.0 745.50 8850/ CNC Power Feed, Mill X- or Y-Axis (Inch only), includes controller, 6.0 525.00 CNC (Metric P/N 5211-CNC) 8851 stepper motor, mount and coupling (Also fits Lathe crosslide) 5220 XY Base w/ Adjustable Zero Handwheels (Metric P/N 5225) 19.0 351.75 8860/ CNC Mill Power Feed, Z-axis, 5000/5400 mills, includes Z-axis 7.0 535.50 5230 XYZ Base w/ Adjustable Zero Handwheels (Metric P/N 5235) 26.0 540.75 8861 leadscrew, controller, stepper motor and mount 5330 Safety Glasses .25 8.00 8865/ CNC Mill Power Feed, Z-axis, 2000 mills, includes Z-axis leadscrew, 7.0 535.50 5401 Deluxe XY Base (w/12" Base) (Metric P/N 5411) 20.0 425.25 8866 controller, stepper motor and mount5401- Deluxe XY Base (12" Base) CNC-ready w/ stepper motor mounts 21.0 540.75 8900 High speed engraving air spindle for CNC mill 3.5 257.25 CNC (Metric P/N 5411-CNC) BOOKS, VIDEOS, 3D CAD SOFTWARE 5420 Deluxe XYZ Base (w/ 12" Base) (Metric P/N 5430) 27.0 573.50 5300 Home Machinist"s Handbook, by Doug Briney, Softbound, black/ 2.0 $21.005420- Deluxe XYZ Base (12" Base) CNC-ready w/ stepper motor mounts 28.0 787.50 CNC (Metric P/N 5430-CNC) white, 275 pages, features Sherline tools 5600 8-Direction Mill XY Base (14" Base) (Metric P/N 5610) 22.0 446.25 5301 Tabletop Machining, by Joe Martin, Softbound, 8-1/2 x 11, 3.5 42.005600- 8-Direction Mill XY base (14" base) w/2 stepper motor mounts 23.0 603.75 color, 350 pages. The best book on miniature machining available., CNC (Metric P/N 5610-CNC) features Sherline tools 5605 Short round, rigid mill column base for 2000/2100 mill 3.0 94.00 5305 Machine Shop Essentials, by Frank Marlow, PE. Softbound, 7 x 10, 3.0 47.2556057 2" Rigid Column Spacer-Round for 2000/2100 mill 1.25 55.00 black and white, 518 pages, copiously illustrated, for all size machine 5606 Tall round, rigid mill column base for 2000/2100 mill 4.5 112.00 tools from Sherline on up 5625 8-Direction Mill XYZ Base (14" Base) (Metric P/N 5630) 34.0 866.25 5306 Machine Shop Trade Secrets, by James A. Harvey, Softbound, 8.5 3.0 42.005625- 8-Direction Mill XYZ Base (14" base) w/ 3 stepper motor mounts 35.0 1076.25 x 11, black and white, 312 pages, practical knowledge for all size CNC (Metric P/N 5630-CNC) machine tools from a shop pro 5640 Short, rigid-mill column base with 2000 ram (Metric P/N 5641) 9.0 285.50 5307 Machine Shop Know-How, by Frank Marlow, PE. Softbound, 7 x 3.0 52.50 5645 Tall, rigid-mill column base with 2000 ram (Metric P/N 5646) 10.5 299.75 10, black and white, 520 pages, more practical knowledge for all size 5650 Upgrade—Existing Mill Column to 8-direction capacity (Metric P/N 9.0 278.25 machine tools 5660) 5325 Sherline Tools and Accessories Catalog (8th Ed.), 48 pages, .5 2.25 5680 Upgrade—Existing Vertical Milling Column to 8-direction capacity 9.0 278.25 color (Free upon request with any order) (Metric P/N 5685) 5326 Sherline Assembly & Instruction Guide (6th Ed.) (Included w/ .5 2.25 5801 NexGen Mill XY Base (18" Base) (Metric P/N 5811) 26.0 1,445.00 each lathe and mill) 48 pages, color, 8-1/2 x 11 5816 Mill Accordion Way Cover Set (compatible w/ 5800 NexGen mills only) .5 104.00 5327 Sherline Accessories Shop Guide (6th Ed.) (Book of collected 3.0 10.50 5825 NexGen Mill XYZ Base (18" Base) (Metric P/N 5830) 39.0 1,865.00 Sherline accessory instructions) Softbound, 224 pages, black and 6079 1/4" End Mill Holder (See P/N 3075-3079 for other sizes available) .5 31.50 white, 8-1/2 x 11 6080 3/16" End Mill Holder .5 31.50 5328- Steam Engine Video w/ Plans, Rudy Kouhoupt (DVD, 3 Hrs) 1.5 76.75 6081 1/8" End Mill Holder .5 31.50 DVD Includes materials list, plans and instruction sheets 6100 Horizontal Milling Conversion 11.0 136.50 5329- Shop Secrets–Measuring, Video, Mike Rehmus (DVD, 2 hr) Covers 1.0 42.00 6700 CNC Upgrade Kit, 5000/5400 Mill (Metric P/N 6710) 2.5 262.50 DVD all common shop measuring tools, how to use them 6705 CNC Upgrade Kit, 2000 Mill (Metric P/N 6715) 2.5 262.50 5335 Sherline Lathe Basics—How to Set Up and Operate the .5 52.5067126 Hi-Torque Stepper Motor, 191oz-in, 2 amp, NEMA 23 frame, dual shaft 2.5 95.50 Sherline Lathe, Video, Mike Rehmus (DVD, 3.6 hr.) Also covers use (5-pin plug wired for use with Sherline CNC systems) of several important lathe accessories67127 Stepper Motor, 136 oz-in, 2 amp, 23 frame, dual shaft (5-pin plug 1.66 78.75 wired for use with Sherline CNC systems) Set screw flats ground on KITS shafts. J1000 Jack-in-a-Box Puzzle Kit 1.0 $80.0067130 Stepper Motor, 136 oz-in, 2-amp, 23 Frame, dual shaft (with six raw 1.5 68.25 T1000 Turner’s Cube Kit (without chuck) .5 82.00 wire leads for general use) Set screw flats T1076 Turner’s Cube Kit (with 4-jaw self-centering chuck) 3.0 255.256740 CNC Upgrade Kit, 5000-series Mills, Z-axis only (Metric 6745) 1.5 105.006750 CNC Upgrade Kit, 2000 Mill, Z-axis only (Metric P/N 6755) 1.5 105.00 For other accessories see:6760 CNC Upgrade Kit, all mills, X-axis only (Metric P/N 6765) 1.0 78.75 • Chucks and Collets Price List6770 CNC Upgrade Kit, all mills, Y-axis only (Metric P/N 6775) 1.0 78.75 • Lathe Accessories Price List7400 3/8" 6-piece Double-Ended End Mill Set (2-flute) 1.0 57.75 • Cutting Tools Price List • Replacement Parts Price List7401 3/8" 6-piece Double-Ended End Mill Set (4-flute) 1.0 57.757506 Parallel Set (Hardened and ground, sized for small mills) .5 52.50 CLICK HERE for links to all current Sherline price lists.7550 Super-Lube multi-purpose grease with PTFE, 3 oz. tube .25 8.50

One thing that is sorta misleading about the CNC tables unless you"re seen one first hand is just how big they are. I"ve got a Tsudakoma THNC-301, which is a 320mm (12"+) table thats rotary powered and manually tiltable from horizontal to a bit past vertical. It weighs somewhere between 400 and 450 lbs, and I guess the new cost now is somewhere north of $16,000. They have positioning accuracy within a few arc seconds, and are capable of holding accuracies like this with a part that weighs a couple hundred pounds and cutting forces that can generate several hundred ft-lbs of torque.

Pricewise, assuming my 16K current estimate is accurate, that would work out to a bit less than $40/lb, because it definitely weighs over 400#. For comparison, a 10" Kitagawa power chuck for a lathe retails now for about $4000, and although I"ve never weighed one, I guess they weigh less than a hundred lbs from picking one up a "few" times. So that puts the chuck at over $40/lb. If you ever have cause to take one of these chucks apart, they are surprisingly simple. They"re accurate and repeatable, and everything is hardened and ground, but they"re still simple, especially when compared to a rotary table. A good sized collet chuck from Royal to fit an A-8 spindle nose on a lathe weighs barely over 40 lbs and costs close to $2500. Once again, its all hardened and ground, but this is the price of a pullback type chuck which is just one single piece of steel with no moving parts whatsoever, yet it sells for over $60/lb. When you compare the rotary tables and their size and complexity to other machine tool parts of similar complexity and quality, the price begins to look not so far out of line, even though its still not cheap by a long shot.

The robust geared rotary tables of the 500 series are extremely flexible to use and, thanks to the combiFLEX® modular system, can be converted or extended at any time to meet new machining tasks. The rotary tables are not only suitable for positioning operation, but can also be used for short simultaneous machining operations. The preloaded gear and the powerful bearings allow high long-term accuracies as well as large spindle loads. The maximum clamping force of up to 7,000 Nm leaves hardly anything to be desired.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

8613371530291

8613371530291