craftsman rotary table made in china

I purchased a craftsman rotary table at an estate sale about a year ago. It is an older USA made RT that I thought would be OK for my skill level. Yesterday I was making some carbide insert tool holders and was using the rotary table. The inserts are a cm style with 80* offset. I had a palmgran vise mounted to the craftsman RT and it was a nightmare. I was depending on the RT for 0* & 10* only but there was an obvious lack of rigidity while using a 3/8" end mill to cut the pocket. I tightened everything I could and things went slightly better while milling the corner with an 1/8" end mill. Then I needed to mill the end and side with some relief and the RT started moving A LOT! Turns out that the screws for the gibs had vibrated out. I rrtightrned them and all three are frigging stripped. This thing seriously reminds me of chinesium. I know it is not a professional type RT but Cmon! THREE STRIPPED GIB SCREWS?

AriensCo began in 1933 when Henry Ariens and his three sons developed the first American-made rotary tiller. They did this at a time when other manufacturers were experimenting with imported tillers. Since then, the company has been passed down, son to son, for four generations. Over the course of nearly 90 years, the company’s zip code, along with their CEOs’ last names have remained the same.

Stanley Black and Decker (or SBD) includes almost too many brands to count. Most are familiar with the DeWalt, Craftsman, Stanley, Black + Decker, Bostitch, Irwin, Porter-Cable, Mac Tools, Proto, and Lenox brands—to name just a handful.

Founded in 1959, Generac was the first company to engineer affordable home standby generators. They also claim the first engine developed specifically for the rigors of generator use. Currently, Generac claims to be the largest portable generator manufacturer in North America.

Ron Meyer and Si Kraft established the Kraft Tool Co. in 1981. Thirty years later, Kraft Tool continues to manufacture Made-in-the-USA tools for the professional cement finisher, brick mason, asphalt paver, tile setter, plasterer, and drywall craftsman. The Kraft Tool Co acquired several companies and brands over the past 39 years including W. Rose, Sands Level and Tool, Superior Tile Cutter, Inc, and Hi-Craft.

They assemble all of their belt-driven models, including both portable and stationary air compressors, as well as some of their direct drives, at Rolair’s facility in Hustisford, WI. The company assembles over 90% of its compressors in the USA.

Ever wonder who owns Craftsman tools? How about Milwaukee, Mac Tools, or Skilsaw? It may surprise you to know that only a handful of power tool companies own your favorite tools. That’s right, most tool brands fall under a parent company that also controls additional power tool manufacturers and brands. We break it down for you…with charts!

Stanley Black & Decker (SBD) turned heads when it bought Craftsman Tools in 2017 after Sears closed 235 stores in 2015. The company owns many brands, however. Dating back to 1843 with a man named Frederick Stanley, the company quickly formed its roots. In 2010, it merged with another company that started in 1910—Black and Decker. As of 2017, the company maintains a $7.5 billion business in tools & storage alone. SBD brands include:

First off, Bosch Tools only represents part of the Bosch Group which includes Robert Bosch GmbH and over 350 subsidiaries across 60+ countries. In 2003 Robert Bosch GmbH combined its North American power tool and power tool accessory divisions into one organization, forming Robert Bosch Tool Corporation in North America. The company designs, manufactures, and sells power tools, rotary and oscillating tools, power tool accessories, laser and optical leveling devices, and range finding tools all over the globe. Bosch also manufactures the following tools:

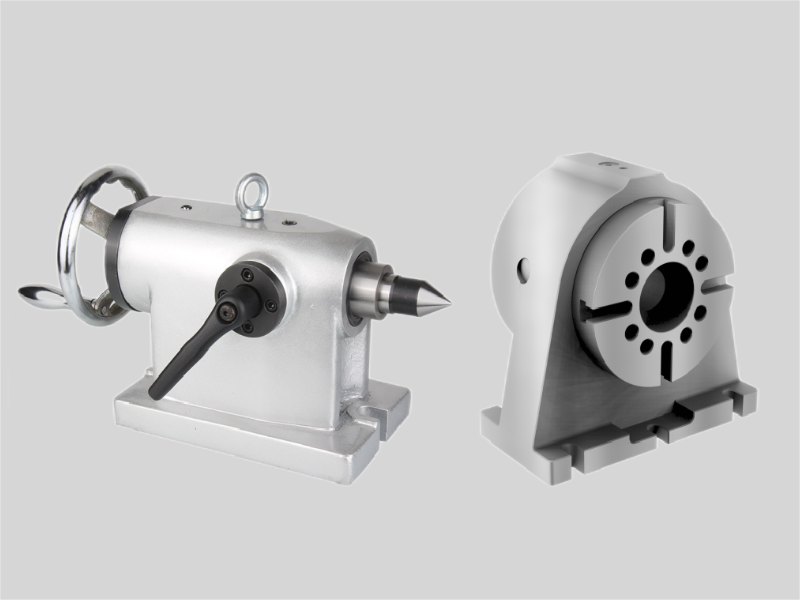

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

Craftsman’s Bolt-On system is a new modular power tool system where you swap tool heads for different functionality. This allows DIYers to have the versatility of many tool types without having to budget for separate full-size tools.

Since the base handle is to be used with all of the various tool heads, it should be comfortable, and it is. The balance is good, the handle is ergonomically shaped, and the grip texture is soft and comfortable.

While not as comfortable or versatile as the Craftsman Nextec cordless jig saw, the Bolt-On jig saw attachment works well for light duty cutting tasks. We used it to cut aluminum sheet metal, plywood, and thin plastic sheets without trouble. The handle configuration looks awkward but seems to work well enough.

After having used and tested the various Bolt-On attachments, we are convinced that Craftsman has indeed put together a very versatile modular tool system.

Most homeowners and DIYers should consider purchasing an additional battery and the impact driver attachment with the starter kit. While the extra battery isn’t essential, it’s a good idea seeing as how some of these tool attachments are very power-hungry. The impact driver holds its own against many full-size tools and we wouldn’t be surprised if Craftsman decided to offer a new starter set that comes with it.

Thank you to Craftsman for providing the review sample unconditionally. Review samples are typically given away, donated, or retained for benchmark and comparison purposes.

Ever wonder who owns Craftsman tools? How about Milwaukee, Mac Tools, or Skilsaw? It may surprise you to know that only a handful of power tool companies own your favorite tools. That’s right, most tool brands fall under a parent company that also controls additional power tool manufacturers and brands. We break it down for you…with charts!

Stanley Black & Decker (SBD) turned heads when it bought Craftsman Tools in 2017 after Sears closed 235 stores in 2015. The company owns many brands, however. Dating back to 1843 with a man named Frederick Stanley, the company quickly formed its roots. In 2010, it merged with another company that started in 1910—Black and Decker. As of 2017, the company maintains a $7.5 billion business in tools & storage alone. SBD brands include:

First off, Bosch Tools only represents part of the Bosch Group which includes Robert Bosch GmbH and over 350 subsidiaries across 60+ countries. In 2003 Robert Bosch GmbH combined its North American power tool and power tool accessory divisions into one organization, forming Robert Bosch Tool Corporation in North America. The company designs, manufactures, and sells power tools, rotary and oscillating tools, power tool accessories, laser and optical leveling devices, and range finding tools all over the globe. Bosch also manufactures the following tools:

This is a Genuine replacement part designed for Dremel Rotary Tool. It helps to lock the the Spindle Shaft. It is Made out of Metal and it is Sold Individually. This Assembly includes a Collar and a Pin.

This is an original replacement part sourced directly from the manufacturer. The screw is commonly found in yard equipment from Craftsman, such as lawn tractors, snow blowers, and edgers. This part is made of metal, and may be found in various locations in the machine, depending on model. Please be aware that there are different screws used in the machine. Refer to the parts diagram to be sure of ordering the correct part. You will require a wrench when replacing this item. The screw is sold as an individual replacement part.

This is a replacement part that is sourced directly from the original parts manufacturer for use with Craftsman Rotary Tools. The metal cap driver is used to connect the flex shaft to the motor and has a square hole for this to fit properly. This cap driver is sold as an individual replacement part.

This is a Genuine Manufacturer Sourced replacement part used on some of the Craftsman Multi-Tools. This part is made from Clear Plastic Material and it is Sold Individually. It is used to connect the armature and drive shaft. It will also strip to safeguard the motor from burning up if the drive shaft becomes bound up. If the tool is not used for a long period of time it can become brittle and break.

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

Does anyone know of such a gadget for sale anywhere? With Essential Tremors getting worse by the year, the odds against me striking anything with a hammer the same two times in a row are approaching 1:1.Robert DownsFrom: atlas-craftsman@groups.io [mailto:atlas-craftsman@groups.io] On Behalf OfJohn FrySent: Saturday, June 22, 2019 22:12To: atlas-craftsman@groups.ioSubject: Re: [atlas-craftsman IO] Thrust bearing mod for 10F crossfeed screw assy

Thank you Bill. I have a rotary indexer. Making the lines in no problem on my milling machine. My main problem is getting the numbers in there. I have used number punches but getting them to line up and getting a good clean result has been to put it mildly, challenging. Right now I’m just using my tired old eyes to see the faint lines and numbers. One of these days I will do something.

John in TexasFrom: atlas-craftsman@groups.io [mailto:atlas-craftsman@groups.io] On Behalf OfBill WilliamsSent: Saturday, June 22, 2019 9:35 PMTo: atlas-craftsman@groups.ioSubject: Re: [atlas-craftsman IO] Thrust bearing mod for 10F crossfeed screw assyOn 6/16/19 11:42 PM, Bill Williams wrote:John, I am going to jump in here and suggest that you look up an article in HSM by Glenn Wilson on building a device to doing this. It combines a horizontal indexer with an adaptation of the automatic center punch that mounts in your drill press. The part is mounted on the indexer, rotation is set, and the spindle fed down until the punch strikes. I have seen the results last Saturday and they are professional!Bill in Boulder CO USAHere are some pictures of the indexer from last week"s meeting.Bill,

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

Thank you Bill. I have a rotary indexer. Making the lines in no problem on my milling machine. My main problem is getting the numbers in there. I have used number punches but getting them to line up and getting a good clean result has been to put it mildly, challenging. Right now I’m just using my tired old eyes to see the faint lines and numbers. One of these days I will do something.

Thank you Bill. I have a rotary indexer. Making the lines in no problem on my milling machine. My main problem is getting the numbers in there. I have used number punches but getting them to line up and getting a good clean result has been to put it mildly, challenging. Right now I’m just using my tired old eyes to see the faint lines and numbers. One of these days I will do something.

I think that what Bill was talking about was a gadget that would presumably hold the number punch in a drill press spindle (and I presume that one would have to be able to lock the spindle to prevent the punch from rotating) that operated like an automatic center punch to deliver a consistent or repeatable blow to the number or letter stamp.

Thank you Bill. I have a rotary indexer. Making the lines in no problem on my milling machine. My main problem is getting the numbers in there. I have used number punches but getting them to line up and getting a good clean result has been to put it mildly, challenging. Right now I’m just using my tired old eyes to see the faint lines and numbers. One of these days I will do something.

Thank you Bill. I have a rotary indexer. Making the lines in no problem on my milling machine. My main problem is getting the numbers in there. I have used number punches but getting them to line up and getting a good clean result has been to put it mildly, challenging. Right now I’m just using my tired old eyes to see the faint lines and numbers. One of these days I will do something.

Paul, I have a milling machine and rotary table that can index the 100 lines, but how do you make the numbers? I would really like the indications on the dials to pop out more.

MyMachineShop.Net offers machinist tools and tooling with a specialty in Atlas Craftsman Lathes ans Milling Machines. Starrett, Mitutoyo and other fine tools. Atlas lathe parts and Accessories especially for the Home Shop Machinist and industry. Many parts not listed from my large inventory. Please contact us with any of your parts needs.

The historical region now known as China experienced a history involving mechanics, hydraulics and mathematics applied to horology, metallurgy, astronomy, agriculture, engineering, music theory, craftsmanship, naval architecture and warfare. Use of the plow during the Neolithic period Longshan culture (c. 3000–c. 2000 BC) allowed for high agricultural production yields and rise of Chinese civilization during the Shang Dynasty (c. 1600–c. 1050 BC).multiple-tube seed drill and the heavy moldboard iron plow enabled China to sustain a much larger population through improvements in agricultural output.

Although it is recorded that the Han Dynasty (202 BC – AD 220) court eunuch Cai Lun (50 AD – AD 121) invented the pulp papermaking process and established the use of new materials used in making paper, ancient padding and wrapping paper artifacts dating to the 2nd century BC have been found in China, the oldest example of pulp papermaking being a map from Fangmatan, Tianshui;was in widespread use, replacing traditional but more expensive writing mediums such as strips of bamboo rolled into threaded scrolls, strips of silk, wet clay tablets hardened later in a furnace, and wooden tablets.Alxa League, where Han Dynasty troops had deserted their position in AD 110 following a Xiongnu attack.mulberry tree bark, hemp, old linens and fish nets created a pulp that was pounded into paste and stirred with water; a wooden frame sieve with a mat of sewn reeds was then dunked into the mixture, which was then shaken and then dried into sheets of paper that were bleached under the exposure of sunlight; K.S. Tom says this process was gradually improved through leaching, polishing and glazing to produce a smooth, strong paper.

An illustration published in Wang Zhen"s (fl. 1290–1333) book of AD 1313 showing movable type characters arranged by rhyme scheme in round table compartments

Shen Kuo (1031–1095) of the Song dynasty (960–1279) was the first to describe the process of movable type printing in his Bi Sheng (990–1051).Wang Zhen (fl. 1290–1333) of the Yuan dynasty (1271–1368), who also arranged written characters by rhyme scheme on the surface of round table compartments.Hua Sui (1439–1513) of the Ming dynasty (1368–1644) that the Chinese perfected metal movable type characters, namely bronze.Qing dynasty (1644–1912) scholar Xu Zhiding of Tai"an, Shandong developed vitreous enamel movable type printing in 1718.

Du Shi (d. 38 AD) applied the use of rotating waterwheels to power the bellows of his blast furnace smelting iron, a method which continued in use in China thereafter, as evidenced by subsequent records; it is a significant invention in that iron production yields were increased and it employed all the necessary components for converting rotary motion into reciprocating motion.

Han Dynasty (202 BC – 220 AD) green-glazed pottery tomb model of a farmyard, complete with a rotary grain mill, a man operating a foot tilt hammer for pounding grain, and to his left a winnowing machine with a crank handle used to operate the fan.bellows, the water well windlass, and other devices.

Gerolamo Cardano (1501–1576), yet it was known long before him.Joseph Needham writes that the earliest confirmed use of gimbals in Europe is the 9th century recipe book Little Key of Painting and English antiquary and book collector Thomas Phillipps"s Mappae clavicula, which mentioned a vase surrounded by rings which allowed it to be undisturbed when in a rolling motion.George Sarton both write that an Arabic translation—dated to roughly the era of Al-Ma"mun (r. 813–833)—of an ancient Greek work now lost (i.e. Pneumatica) by 3rd-century BC Greek engineer, physicist, and writer Philo of Byzantium (c. 280 – c. 220 BC) contains a description of gimbals used to support an inkpot that could wet a pen on any of its sides, yet Needham suspects Arabic interpolation and doubts total authenticity, while Belgian-born American chemist and historian of science George Sarton asserts that for the most part the Arabic translation is faithful to Philo"s lost original, hence Philo should be credited with the invention of the gimbal.Ding Huan (丁緩) — who also created a rotary fan and zoetrope lamp—invented a "Perfume Burner for use among Cushions", or "Bedclothes Censer".incense burner had a series of metal rings which could be moved in any direction while the burner in the middle remained constantly level.Sima Xiangru (179–117 BC) that this device existed in the 2nd century BC (i.e., "the metal rings burning perfume").Liang Dynasty (502–557) there is mention of gimbals used in hinges for doors and windows, while an unnamed artisan presented a warming stove to Empress Wu Zetian (r. 690–705) in 692 which employed gimbals to keep it constantly balanced.

An illustration of a handheld portable multiple rocket launcher as depicted in the 11th century book Song Dynasty. The launcher is constructed using basketry.

air conditioning, the Han Dynasty craftsman and mechanical engineer Ding Huan (fl. 180 AD) invented a manually operated rotary fan with seven wheels that measured 3 m (10 ft) in diameter; in the 8th century, during the Tang Dynasty (618–907), the Chinese applied hydraulic power to rotate the fan wheels for air conditioning, while the rotary fan became even more common during the Song Dynasty (960–1279).Georg Agricola (1494–1555).

Ding Huan (fl. 180 AD) is a pottery tomb model of a crank-operated rotary winnowing fan from the Han Dynasty, used for separating chaff from grain.Yan Shigu (581–645), in his commentary on the Book of Agriculture published in 1313 by Yuan dynasty inventor and politician Wang Zhen (fl. 1290–1333).

8613371530291

8613371530291