craigslist rotary table made in china

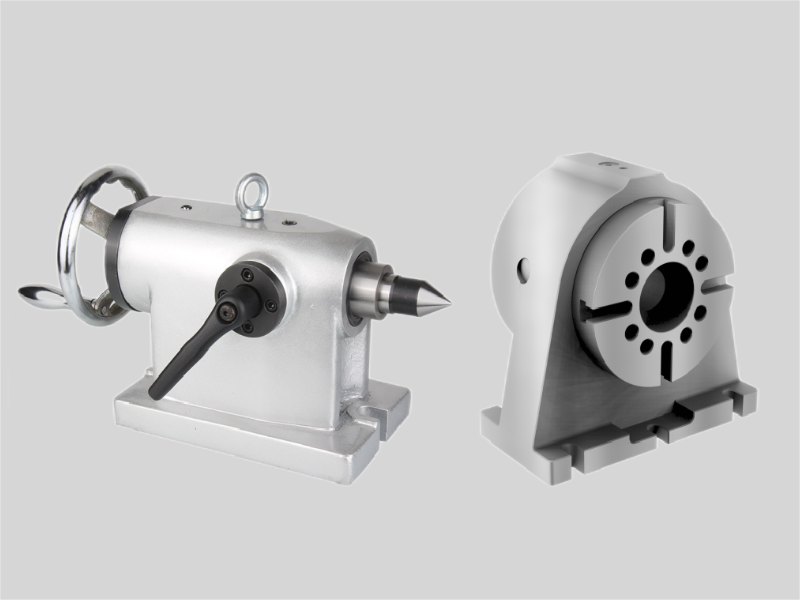

Rotary table horizontal. Of the brand china but also a vertical height -> 4 inch · A center bore qualified as 1 inch and this is also a setting position represented by horizontalvertical and also an operation equivalent to cnc. U...

I own a Sherline 4" rotab and it is quite good. However, it is also somewhat limited in that it does not accept dividing wheels and it does not have a table release; you have to crank it around to get to your next location. It is quite well made, reliable and accurate. It will mount to a milling table as well as a tilting angle table without eating up that much room in Z.

I also own a Japan-made 6" Yuasa that is pretty much fully tooled up. This is a really fine, fully featured rotab that is probably the most cloned rotary table out there. Vertex makes a clone that is quite close. Smooth, accurate and no longer made.

The only other import I have heard of that might meet your needs is the Warco HV-4: https://www.warco.co.uk/rotary-tables-engineering-tools/124-hv4-rotary-table.html. At that price, I"m pretty sure it will be a Warco design but Chinese made. Cannot attest to how good it is but Warco sells some nice small stuff so you might inquire.

I"m considering getting a rotary table for my V10 Maximat. I"ve seen the array of stuff on eBay and from the various suppliers. I don"t feel much like paying the asking price for an original Emco, which is only 4" anyway.

As to the milling base: The same friend has an Emco-Maier tabletop milling machine (I forget the model designation), which has the same head and column as on my V10, but has a much longer/deeper table than is possible on the V10. He showed me some old literature (from American Edelstaal) that listed the base unit as an accessory, allowing you to convert the V10 (or I suppose the V7) to two machines.

I don"t have your experience or expertise to modify/re-machine the "Out of the East" stuff, so I don"t think I"ll try to make one of the Chinese-junk tables work.

I"ll keep looking for an original (or maybe East-European, they"re still good) rotary table. I may have to budget kind of tight for a few months, but good tools are worth it.

PeteH wrote:I"m considering getting a rotary table for my V10 Maximat. I"ve seen the array of stuff on eBay and from the various suppliers. I don"t feel much like paying the asking price for an original Emco, which is only 4" anyway.

As to the milling base: The same friend has an Emco-Maier tabletop milling machine (I forget the model designation), which has the same head and column as on my V10, but has a much longer/deeper table than is possible on the V10. He showed me some old literature (from American Edelstaal) that listed the base unit as an accessory, allowing you to convert the V10 (or I suppose the V7) to two machines.

My main interest in the rotary table was originally making gears... which I since found out is a messy business - and with some research, usually unnecessary. But the idea of being able to mill an O-ring groove (or a carburetor spacer) is very appealing.

I bought it from a posting in craigslist and I thought that I could have replacement gears and a motor. Came to find out that nothing would fit my Maximat, not even the motor.

I found out recently that Emco used to sell the base only, so you could remove the milling column and have it transported it this larger, more stable base.

Adding a larger table would be a solution but then the clearance distance to the spindle would be so reduced specially if a chuck is being used, that will render the milling head almost useless.

1. In the horizontal position, the left (top in the vertical position) hold-down notch has a rounded and painted surface on the top. This means the clamp bolt"s washer doesn"t sit parallel to the table. This means it has a tendency to slide around as it is tightened. I will probably mill it flat, shortly.

3. There is a fair amount of backlash in the worm gear, but I haven"t even looked for an adjustment yet. There are 2 clamps on the side of the table and these can be locked in place to deal with the backlash.

6. There are 2 clamps, 4 bolts, and 4 t-slot nuts supplied. On a 6" table, it doesn"t take a big part to run out of clamping room. I have already made a simple ring to bolt down a part that I was making.

7. In the vertical position, the base is too wide to allow both slots to be used to clamp it down to the table. This is a concern for me. I found this out today and used a couple of 123 blocks to wedge it in position. There isn"t much room to use a clamp block as the clamps that are on the rotary table swing down very close to the mill"s table as it is rotated.

9. Remember to lock the mill"s table in place or you can get some very puzzling movement due to backlash in the mill"s table. It isn"t much but it can be a headscratcher!

8613371530291

8613371530291