cutting gears with a rotary table for sale

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

SteveEx30 cutting the teeth in plastic goes pretty quick,probably a couple hrs.I got 3 gears out of that blank after the teeth were cut.That Nyloil MDX was a pain in the ass to part off.You nave to use plenty of coolant.The stringers will not chip and make a much stronger stringer than Delrin.If you stop before you part off completely it wraps tightly in the groove and takes a while to pull out before you proceed.I have found,with plastic and brass that when cutting multiple gears that it is quicker to cut the teeth first first then part off the blanks.It is easier to finish the blanks and then cut the teeth but you have to make a more complicated mandril and have to change blanks one at a time.I was able to stay on cutting the teeth to completion,but had to wait a day after I set up before I could start,then several days before I could finish because of breakdowns,other priorities.So it is hard to figure exact time but maybe 3 hrs per gear.Since these types of jobs are added value of my own initiative the time factor is not as critical as it would be in a job shop with a customer waiting.One good thing about this place is that I am allowed to tackle any job that I think I can do.I am 70 years old and when I think about retiring,my hobby would be dicking around in my shop doing basically the same thing as I do at work,without the insurance,pay and benefits!

Prop 65 Warning(s)Many metalworking products contain chemicals or metals included in the latest Prop 65 warning. Exposure may cause cancer and reproductive harm. KBC is currently gathering required California Prop 65 warnings for our customers. For more information go to www.P65Warnings.ca.gov

Gotta keep track of those partial degrees and add them up and move the dial accurately. One mistake in your math or turning the knob and you have scrap.

Cut gears with your rotary table by using dividing plates (index plates) to get the exact divisions. You can also precisely divide a circle into a number of divisions or degrees, cut bolt hole circles, or mill polygons with the use of these dividing plates. 33-101 is a 3-piece set that fits on your 6" rotary table, 33-100. 33-106 is a 2-piece set that fits on your 8" rotary table, 33-105.

This product can expose you to materials and/or chemicals including arsenic, lead, and other materials and/or chemicals which are known to the state of California to cause cancer and/or reproductive harm.

After entering the number of steps per revolution (or the number of degrees per step) on a simple numeric keypad, the table advances quickly and precisely to the next position at the touch of a single advance key. If an error is made, previous positions can be accurately recalled by hitting another button. Basic resolution is 28,800 steps per revolution, ±0.006° per step. This allows the accurate machining of items like gears with odd numbers of teeth. Computations are made internally to a high degree of accuracy to avoid cumulative errors.

The CNC rotary indexer is a stand-alone unit. You get everything you need to make complex indexing jobs easy. In addition, the unit can be connected to an existing CNC control to act in conjunction with that system. An input signal triggers the programmed function. When it is complete, it signals back to continue the program. The unit can also be “daisy chained” with other units to trigger sequential actions. As with all Sherline accessories, complete instructions are included.

The rotary table can also be “daisy chained” with Sherline’s linear controller (P/N 8800) to achieve combinations of rotary and linear movement in sequence. This makes it easy to set up for relatively sophisticated operations like cutting gears without having to know anything about CNC programming beyond what is entered from these simple keypads.

The rotary tables can hold more weight when they are not under a continual load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

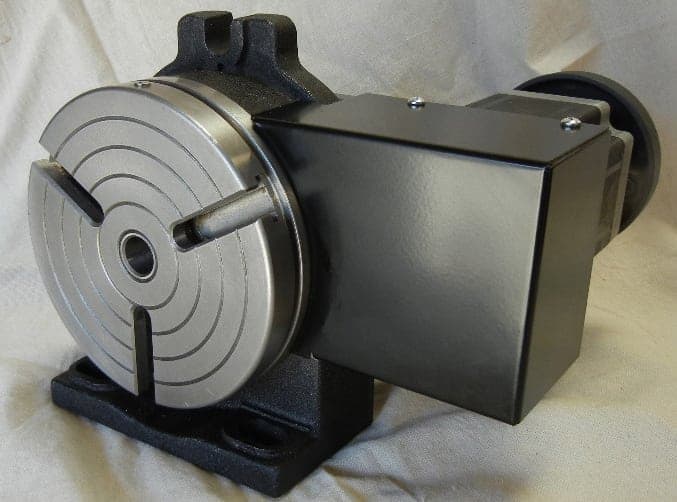

TSL vertical&horizontalrotary table is one of the main accessories of milling machine, it is used for index boring, milling, circle cutting, spot facing and boring hole etc on the milling machine. The rotary table in vertical with working together can be used on complex work for circle index boring and milling.

RDG Tools was started up by Richard Dickinson in 1992. We started exhibiting at model engineering exhibitions in 1994 and realised from the shows that people wanted quite specialised tooling for their machines and also a wide range of tooling which they could adapt to suit their needs.

Tailstocks are adjusted & matched to the centre height of the rotary table, ideally when machining shafts & spindles. Indexing heads are preferred for gear cutting & similar as the shaft can be set on an angle as the indexing head tilts thru 90’. Rotary tables are a lot more versatile, robust and common for general engineering. Mostly rotary tables can be used in horizontal or vertical position, when bolted to the machine table.

Kitagawa NC Rotary table series is designed to flexibly respond to a variety of machining needs. The strong spindle-clamping system, allows very high positioning accuracy, and large thru-hole sizes will accept the big shaft works.

Models can be configured with their own controller, to be driven by “M Codes” from the machine tool or as full 4th and 5th axis controlled directly from the CNC of the machine tool.

A rotary table will vary in diameter depending what you require to hold. Generally rotary tables can rotate thru. 360’ at 90:1 ratio. Using a manual rotary table, winding a handle around drives the worm gear to index the rotary table and can be clamped at designated position. Most rotary tables have a Morse Taper thru the centre spindle; also a 3 or 4 jaw chuck can be mounted to the rotary table for work holding.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new gear rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement gear rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new gear rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

8613371530291

8613371530291