diy cnc rotary table quotation

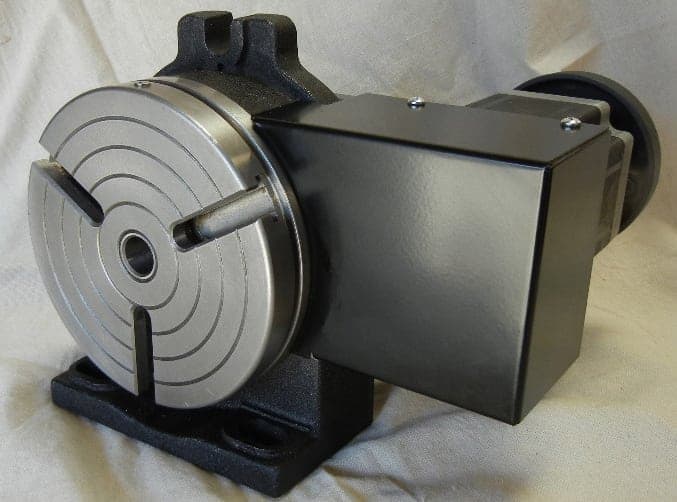

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

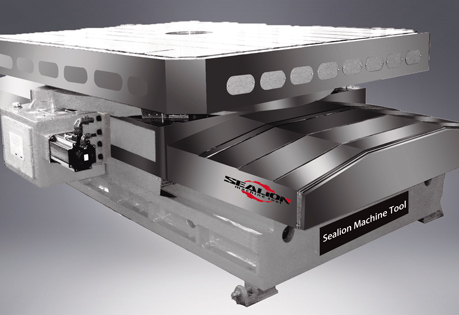

5TH Axis rotary table:The following chart shows specifications of two-axis rotary tilt tables with worm gear drives as well as in the table and trunnion axis.

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

We provide exclusive range of Goizper make Turn tables (CAM based), rotary tables (indexers), Clutch-Brake units, Spares, Couplings, customized Gear boxes. Goizperread more... Brochure

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

This forum looked a bit empty so I"ve posted this here. Whilst not a 3 axis machine it is technically CNC. I have posted this design elsewhere so apologies if you"ve already seen it.

It"s a device intended to drive a rotary table, lathe head or any form of indexing device. It"s cheap - the electronics running around �30 and (for a small 4-8" table at least) can use some of the appallingly cheap steppers and drivers we see around these days...

I made it after purchasing a set of division plates for my 6" vertex table, I played with them and then decided they were tedious and error prone. So I designed this.

Basically the controller connects to a stepper which you"ve coupled to your rotary table / lathe head / dividing head etc. Then with a couple of button presses it"ll divide, move by an angle, move continuously for machining or if you"re feeling adventurous you can program complex sequences of moves which can be driven automatically or with operator intervention etc.

For example to divide a circle into 171 parts - turn on, press [2] (division) enter the number "0171" and press [G]. Each press of left or right will now move the table 1/171 of a circle anticlockwise or clockwise. Backlash compensation is automatically applied.

Attached (should be) Rotary V2.0.zip - unzip this into a folder somewhere and double click on "Documentation.htm", this file has links to other files including a manual, partslist, circuit diagram etc. Most of it should be self explanatory. Since the device is based around a microcontroller (18F452) I"ve also included the firmware for it (I notice elsewhere on the forums someone has very kindly offered to program these for free...)

I"ve also attached some photos of the completed unit and one of it in use (hooked to a 4" rotary table which is in turn bolted to my lathe head for a spot of gear cutting).

I have represented Centroid Corp. for over 20 years now. This latest MPU11 hardware set is their most advanced controller ever produced. Centroid CNC controls are built to be flexable. We have integrated this controller onto Lathes, Mills, Waterjet, Routers, Gear hobb, Custom brush making machinery, Filiment winding machinery, Drilling machines, VTL, Large format machine tools and much more.Yes, we can update your machine too.

8613371530291

8613371530291