dmg mori rotary table supplier

Chuck packages offer a convenient and productive turn-key bundle providing the Set-Tru Chuck for increased precision and rigidity, adapter for interface between the DMG Mori Seiki Rotary Table and the chuck and all necessary T-nuts and bolts. HVH offers DDRT200 and DDRT260 types of chucks packages for DMG Mori Seiki Rotary Tables, Indexers and Trunnions.

Machine tool maker DMG MORI improved this coolant delivery adapter by making the part through additive manufacturing instead of machining. One of the viewer-chosen winners of The Cool Parts Showcase.

DMG MORI Boston, located in Somerville, Mass., is intended to serve as a hub for research and development of digitization solutions, and situated next to technology partner Tulip.

During a three-day celebration, DMG MORI live-tested four machines for customers: the NLX 2500 SY universal turning center, the NTX 2500 turn & mill center, the DMU 65 FD monoBLOCK milling & turning machine and the CMX 50 U five-axis machining center.

On October 9, DMG MORI will present the U.S. portion of its digital event, which will cover automation, digitization, and product and service solutions, among other topics.

During a recent open house event at DMG MORI’s factory in Pfronten, Germany, the company highlighted advances in digitalization as well as automation and additive manufacturing.

DMG MORI’s two XXL machines, the DMU 200 gantry and DMU 340 gantry, are pulling the crowds at its booth, not just due to their large size and five-axis simultaneous machining capabilities, but also because of the new stealth design.

IMTS 2018: DMG MORI will be displaying a range of automation products, including the second-generation Robo2Go mobile robotic automation system for turning machines.

IMTS 2018: DMG MORI’s Lasertec 30 SLM selective laser melting system enables the use of different powder materials, while an intelligent powder module concept speeds up changes of material.

Taiyo Koki, a DMG MORI company, provides vertical grinding machines for aerospace, automotive, heavy equipment and tooling manufacturers, including its super-high production vertical grinding machine featuring a two-place (PGV-2) or three-place (PGV-3) automatic chuck changer.

Among other highlights, this year’s iteration of DMG MORI’s annual open house event showcased the company’s latest efforts to connect traditionally disparate machining operations, both in the physical sense and the virtual sense.

The LaserTec 45 Shape from DMG MORI combines five-axis precision machining with 3D laser ablation and texturing to produce high-quality fine contours and filigree cavities.

DMG MORI’s NLX 3000 | 3000 lathe provides a distance between centers of 3,000 mm, accommodating long workpieces such as shafts and hydraulic cylinders.

DMG MORI has extended the high-precision machining centers in its Dixi series to include the smaller Dixi 125 for workpieces with diameters ranging to 1,250 mm.

DMG MORI’s Lasertec 4300 3D hybrid machine incorporates additive-directed energy deposition (blown powder) into a five-axis turn-mill machining center with a working area of 600 × 1,500 mm.

DMG MORI has announced important changes in how it goes to market here by transitioning to a direct service and sales model for the United States. The company is also evolving its leadership in the states.

DMG MORI’s NLX 6000|2000, which is the successor of DMG MORI’s SL series, is designed for applications in the energy and oil industries as well as hydraulic and mechanical engineering.

DMG MORI presents its extended Sprint series of turning centers, including the 32|5 and 32|8, designed for turning workpieces as long as 600 mm and ranging to 32 mm in diameter.

During DMG MORI"s “Innovation Days” event in Japan, the company showcased 58 machine tools in its newly renovated Iga Global Solution Center, which boasts 3,500 m2 (37,674 ft.2) of floor space.

DMG MORI has played a role in the success of Porsche’s Hybrid 919 LMP1 car that won both first and second place at this year’s Le Mans endurance race.

DMG MORI’s EcoTurn 450 and EcoTurn 650 turning centers, part of its Ecoline series, feature stable construction to enable accurate machining, even with difficult metal-removing conditions, the company says.

For multi-axis machining, a good workholding fixture gets the part away from the worktable surface, yet holds the part securely for aggressive machining. This video shows a dovetail pedestal doing this job in a 3+2 application.

DMG MORI hosted its 20th open house earlier this month in Pfronten, Germany. The event featured 76 machine tool exhibits, including four world premieres, and nearly 8,800 attendees had the opportunity to tour the recently renovated and expanded facility to see its latest machine tool technologies. Here are some observations from the event:

DMG MORI’s NVX 5100 vertical machining center is designed to promote machining efficiency with high spindle speeds, and increased stability and vibration damping through the use of slideways.

DMG MORI’s NHX 4000 2nd Generation and NHX 5000 2nd Generation horizontal machining centers are said to be suitable for single-part manufacturing ranging to serial production.

The HSC 30 Linear and HSC 70 Linear precision milling machines from DMG Mori are said to provide quality surface finish for tool and moldmaking applications.

To machine helical gears at 45-degree angles, Gurecky installed a customized multifunctional machine from DMG Mori Ellison Technologies with a hobbing tool from Heimatec.

DMG Mori Seiki’s Manufacturing Days 2013 event in Davis, California, gave customers, press and other guests a close look at the company’s Digital Technology Laboratory and Manufacturing Factory, plus presentations on many facets of today’s advanced manufacturing.

The Sprint 65 automatic turning machine from DMG Mori Seiki is equipped with direct-drive technology and three turrets, including a bottom turret with a B axis.

The CTV 315 linear vertical turning center from DMG/Mori Seiki accommodates workpieces measuring 300 mm in diameter and 210 mm in height, and weighing as much as 25 kg.

Efforts at energy efficiency in manufacturing can have a big impact. In fact, DMG/Mori Seiki says its heat-treat alternative, grind-hardening, has the potential to reduce the carbon footprint of surface hardening by 85 percent.

DMG / Mori Seiki USA will demonstrate a range of gear machining capabilities, highlighting gearMill software and Sandvik Coromant’s InvoMilling process.

The recent DMG/Mori Seiki USA Innovation Days event highlighted 45 machines—five new to the U.S. market—and attendance was up 45 percent compared to last year’s edition.

A ribbon-cutting ceremony marked the opening of Mori Seiki Manufacturing, a recently completed machine tool factory in Davis, California. The factory, described as a $50-million state-of-the-art manufacturing facility, is producing Mori Seiki NHX4000, NHX5000 and NHX5500 machines. The plant will also serve as a showplace of advanced manufacturing and automation.

By enhancing milling capability in a compact, high-speed vertical machining center, DMG/Mori Seiki has redefined the role of the 30-taper machine in high-production applications.

Featuring stable construction and a swivel-type indexing table, the compact DMU 65 monoBLOCK universal milling center from DMG/Mori Seiki offers a large work area that can accommodate oversized workpieces as large as 840 mm in diameter and weights ranging to 1,800 kg.

As construction continues on its new factory in Davis, California, machine tool builder Mori Seiki USA has announced a career fair at the at location on October 5 from 11 a.m. to 2 p.m. The company is seeking the following employee candidates: procurement specialists, trade compliance professionals, assembly professionals, machinists and administration.

Machine tool builders DMG and Mori Seiki say their joint appearance at EMO 2011 symbolizes their cooperation as they prepare to pool sales and services in Europe.

The space-saving DMU 60 eVo five-axis machine from DMG/Mori Seiki is designed to manufacture complex workpieces in the aircraft and medical industries.

At the inaugural imX (interactive manufacturing experience) industry event, DMG/Mori Seiki USA will present a learning lab about enhancing production management through information flow to and from the shop floor.

Last week, Mori Seiki celebrated a ceremonial groundbreaking of the machine tool factory to be built in northern California, right next door to its Digital Technology Laboratory in Davis.

Approximately 1,600 people attended the recent Innovation Days event at DMG/Mori Seiki, which featured more than 30 milling, turning and multitasking machines.

The Mori Seiki Digital Technologies Laboratory (DTL) will demonstrate software, networking and machining solutions at the annual Interconnect Showcase, which is scheduled for April 7 and 8 in Davis, California. The two-day event will include technical seminars presented by industry specialists nad spanning several topics.

Machine tool builder Mori Seiki (Chicago, Illinois) and distributor Ellison Technologies (Santa Fe Springs, California) will host a grand opening event for a new joint Technical Center in Mississauga, Ontario on April 27 and 28. Event attendees will be the first to see Mori’s NVX5080 VMC from the new X-Class, as well as the NMV5000DCG five-axis VMC, the NT1000/SZM turn-mill and the NL2500SY lathe.

Through a new business collaboration, the Mexican divisions of machine tool builders DMG and Mori Seiki are offering comprehensive sales, engineering and customer service for both product lines.

Machine tool builder DMG/Mori Seiki USA (Chicago, Illinois) and distributor Ellison Technologies will open a new joint technical center in Houston that will showcase machine tools and technology for the energy and oil field industries.

DMG/Mori Seiki invited me to visited Andretti Autosport in Indianapolis. Here’s a slideshow of some of the neat machining- and racing-related things I saw there.

Machine tool builder Mori Seiki (Hoffman Estates, Illinois) has announced that Ellison Technologies (Santa Fe Springs, California) is now its exclusive distributor in Canada.

DMG / Mori Seiki USA has announced that this year’s Innovation Days will take place at the company’s headquarters and Chicago Technical Center May 24-26.Innovation Days 2010 marks the first joint event organized by DMG / Mori Seiki USA under the partnership that began last month.

Machine tool builder Mori Seiki (Hoffman Estates, Illinois) has announced a call for entries for the 2010 Innovation of the Americas contest, the third edition of the biennial competition.

The DMF 260 linear from DMG now offers a 3,150-ipm rapid traverse, 15. 7" longer Y path and 7.9" more space in the Z direction, compared to the smaller machine. All of the moving-column machining centers in the series are suited for aerospace applications and machine construction as well as tool making and mold production.

Mori Seiki’s Digital Technology Laboratory (DTL), a 71,000-square-foot laboratory and technical center in Davis, California, has achieved LEED Gold certification for sustainable design.

Machine tool builder Mori Seiki says its new Mori360º service package was created to go beyond standard service and provide more comprehensive customer support from every angle.

Sauer’s Ultrasonic 10 from DMG is a compact, five-axis machine designed for dental indications in soft plastics, demanding metals and high-strength zircon oxide materials.

Mori Seiki’s Digital Technology Laboratory (DTL), a 71,000-square-foot laboratory and technical center in Davis, California, has achieved LEED Gold certification for sustainable design.

Integrating Lyndex-Nikken rotary tables into three-axis Mori Seiki VMCs provided this shop with five-axis capability at a fraction of the cost of a new five-axis machine.

Machine tool builder Mori Seiki says the grand opening event for its new American headquarters was a “resounding success,” attracting more than 2,200 visitors for four days of machining demonstrations, seminars and facility tours. A showroom, quality control room and workroom comprise 40,000 square feet—roughly 40 percent—of the new facility, which is located just north of Chicago in Hoffman Estates.

Japanese machine tool builder Mori Seiki has signed a distributorship agreement with German machine tool manufacturer Gildemeister AG (DMG) for sales and service activities in Japan. Under the agreement, Mori Seiki will take responsibility for sales and service of all Mori and DMG products in Japan.

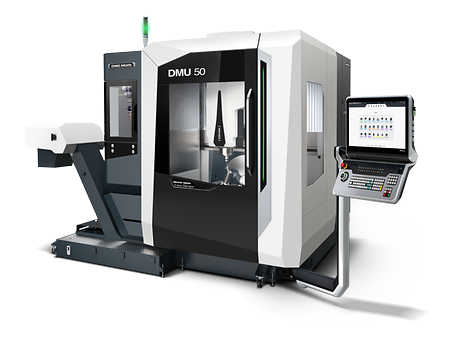

The DMU 50 and DMU 70 CNC five-axis milling machines from DMG are suited for milling single parts and small series—from simple to highly complex workpieces. Highlights include digital drives in all axes, a rapid traverse rate ranging to 944.9 ipm and a motor spindle with speeds ranging to 18,000 rpm.

Machine tool builder Mori Seiki will host a grand opening ceremony and open house from November 3-5 to celebrate the completion of its 102,000-square-foot North American corporate headquarters northwest of Chicago in Hoffman Estates, Illinois. The three-day event will showcase more than 25 machine and cutting demonstrations, technologies in development and technical presentations from the Mori Seiki engineers and guest speakers.

DMG’s CNC universal milling machine, the DMU 50 eco, is designed for high precision and reliability in workshop, training and laboratory settings, as well as for tool, fixture and mold construction applications. With its sturdy cross-slide construction and large, easily accessible machining compartment, the machine is suited for both one-off production and efficient manufacture of small lots, the company says.

DMG offers the Microset VIO Linear, the company’s first series of tool presetting units with linear drives for presetting of drilling, milling and turning tools. The direct drives in the X and Z axes provide repeatable accuracy of about ±1 micron, the company says.

A change in focus to lower-volume jobs led this manufacturer to sell its multi-axis screw machine and seek a new, flexible process to avoid tying up its traditional mills and lathes. DMG’s CTX 310ECO V3 turn-mill has helped the shop improve productivity and part quality while reducing labor costs.

Machine tool builder Mori Seiki has been selected to serve as an official supplier to the WorldSkills Calgary 2009 competition. Scheduled for September 1-7 in Calgary, Alberta, Canada, the biennial competition was created to promote increased technical proficiency within participating countries.

Mori Seiki’s MV-1003L VMC uses cast iron columns and beds to achieve the high rigidity needed for heavy-duty cutting in the aircraft, shipping and energy industries. The machine’s four types of spindles enable a range of processing options—from high speed machining to heavy-duty cutting.

Machine tool builder Mori Seiki will host an opening ceremony and open house to celebrate the expansion of its Digital Technology Laboratory (DTL) in Davis, California. The three-day event, scheduled for May 20-22, will introduce media and guests to the new 70,000-square foot DTL headquarters and research and development center. According to the company, the facility is both environmentally and technologically friendly.

Machine tool builders Mori Seiki (Nagoya, Japan) and Gildemeister AG (Bielefeld, Germany) have signed a cooperation agreement to promote global business activities. The agreement covers production, purchasing, machine development, and sales and services in selected markets. In particular, the companies plan to control costs by leveraging their joint procurement and purchasing power on a global basis.

DMG America will conduct a 4-day open house from April 21 to 24 at its Chicago Technology Center in Itasca, Illinois, located just west of the city near O’Hare airport. The center is the company’s North American headquarters and houses an 11,500-square-foot showroom as well as 130 sales, customer service, application engineering, technical support and corporate management personnel. From 9 a.

DMG’s CTX beta TC and CTX gamma TC series turn/mill centers feature an integrated, moving column with a turning/milling spindle and an interpolating B axis. The machines are capable of turning workpieces ranging from 49. 2" to 78.

Machine tool builder Mori Seiki announces that it has become a member of the AMT-The Association For Manufacturing Technology. Founded in 1902, AMT represents and promotes the interests of American providers of manufacturing machinery and equipment. Its goal is to promote technological advancements and to act as an industry advocate on trade matters to governments and trade organizations throughout the world.

Mori Seiki has developed a text-engraving function that allows companies to engrave company or product names onto workpieces. The function is included on all its machines with Mapps III, a high-performance operating system with improved processing capacity and conversational functions. This system is said to improve tool management and facilitate short programming and setup times.

Machine tool builder DMG American has opened a new Technology Center in Cypress, California, in the greater Los Angeles area. According to the company, the new facility is a demonstration of its commitment to better serve the West Coast aerospace, medical and general machining market at all levels and with more equipment diversity. Hundreds of visitors from local job shops and OEMs attended the grand opening ceremony in late October.

Mori Seiki USA has announced the winners of the 2008 Innovation of the Americas machining competition, which is designed to recognize talented machinists in the metalworking industry. Four professionals from reputable industry organizations and universities, led by Professor Kazuo Yamazaki of the University of California, Davis, judged more than 130 entries in four categories. The entries represented a wide range of materials, sizes and shapes, and were of such high quality that selecting winners was challenging for the judges.

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

Mori Seiki’s NT series of integrated mill-turn centers fully combines a lathe with a machining center. The NT5400 DCG/1800S employs both driven at the center of gravity (DCG) technology and the box-in-box construction of the NH series HMCs. The center also employs a turret with a built-in milling motor from the NL series CNC lathes.

CAM developer DP Technology recently performed a successful test cut of a new cutting tool for turning applications that is designed to reduce vibration and heat buildup. The company"s CAM software package, Esprit, now contains an add-on for programming the new tool. Developed jointly by machine tool builder Mori

Machine tool builder Mori Seiki has announced that it will move its U.S. headquarters to a larger facility this year. The expansion will accommodate the growth of the company"s Chicago office since becoming the national headquarters in 2005. The new facility is currently in the planning stages and will be located

DMG America recently opened an 11,500-square-foot technical center and showroom in Itasca, Illinois. The facility offers a chance for visitors to see the company"s various milling, turning, ultrasonic and laser machining equipment in action. Featuring 15 machines, the facility offers demonstrations of the company"

Mori Seiki"s Innovation Days event for 2008 will coincide with the company"s 25th anniversary celebration. Scheduled from May 14-16 at the company"s Chicago Technical Center, the event will feature presentations on topics including the latest machine innovations, new technologies and workforce developments. Attend

As revealed at EMO 2007, DMG’s line of machine tools has a new look which strengthens the corporate identity of the product line while giving each brand distinctive design elements that differentiate it. The look is part of a “New Design” concept that the company says is based on the interaction among functionality, ergonomics and form. Significantly, a number of elements in the new design reflect attention to the role of the operator, thus indicating that the operator’s role is very important in overall machine tool productivity.

In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead. This configuration can improve roundness, facilitate single-setup processing and prolong the life of the machine. Loading and unloading may gets easier, too. Workpieces with relatively large diameters and short lengths benefit the most from vertical grinding.

Much of machine tool development is based on an incremental approach to design. In such cases, each "new" design is more a refinement of the previous generation of proven technology than a reinvention of the machine type and its purpose. With Mori Seiki"s new NL series of turning centers, however, the builder was

Walk into Mori Seiki"s Digital Technology Laboratory (DTL) in Sacramento, California, and you might think you"ve instead wandered into a West Coast extension of the United Nations. The facility is dedicated to software development and engineering for the machine tool builder worldwide, and the makeup of the staff certainly speaks to diverse needs of a global market.

The DML 40 and the DMU 60L, sister 100W YAG laser cutting machines made by DMG America Inc., could be the first shot in a battle between lasers and ram-type EDM machines for die and mold machining applications.

The names Deckel and Maho have long ranked among Europe"s principal players in milling machines and machining centers. Those names have been put together to form a single company, which in America is known as DMG America.

DMG is a sales brand of DMG Mori AG, one of the largest manufacturers of CNC turning and milling machines in the world. Its extensive product range includes universal, vertical, production and automatic lathes, machining centers, laser cutting systems and ultrasonic milling machines. In particular, DMG was instrumental in the development of the innovative ultrasonic cutting technology.

DMG Mori AG emerged from the cooperation between the German manufacturer Deckel-Maho-Gildemeister and the Japanese company Mori Seiki and unites the traditional brands DMG, Gildemeister, Mori Seiki, Sauer and Wasino under the worldwide sales brand DMG MORI as a "Global One Company." With a total of 14 production sites worldwide, DMG MORI is now one of the most important international manufacturers of machine tools.

Due to its broadly based product portfolio and wide range of applications, machine tools from DMG MORI are used in almost all areas of industry, from vehicle and shipbuilding to mechanical and plant engineering and aerospace. DMG high-tech machines can process a remarkable amount of materials, from stainless steel, steel and metal to various plastics, glass and diamond. The efficiency and precision of DMG grinding machines, DMG milling machines and CNC-controlled lathes from DMG are outstanding features of the successful manufacturer..

To meet the diverse needs of its customers, DMG MORI operates a global network with over 150 sales and service locations in 79 countries. With wide-ranging services such as maintenance, repair, spare parts service as well as special training courses, the company offers its customers comprehensive and reliable support..

Due to their widespread use, DMG machine tools can often be found on the used market at favorable conditions. To ensure that you are on the safe side when buying a used DMG machine tool, Stenzel offers you a full all-round service from the joint inspection of the machine at the seller"s premises to insured transport and commissioning. In this way, you receive a reliable used machine from DMG at an attractive price and with full service.

Digitization is changing our world both quickly and radically. DMG MORI continues to develop positively – technologically, structurally and culturally. Our business is marked by Dynamic and Excellence.

Digitization is changing our world both quickly and radically. DMG MORI continues to develop positively – technologically, structurally and culturally. Our business is marked by Dynamic and Excellence.

In Booth S-9092, CNC Indexing & Feeding Technologies (Mason, OH) proudly announces their new partnership with TJR (or Tan Jia) Precision Technology Company, Ltd. (TJR; Taichung City, Taiwan), a well-established supplier of rotary tables to machine tool OEMs such as Okuma, Doosan, DMG Mori, Mazak, and Tongtai. “The new partnership allows us to supply the most technically advanced rotary tables in the industry, with special emphasis on direct drive and 5C collet 4th-axis series units,” explained Steve Smith, the president of CNC Indexing & Feeding Technologies.

The company originated as a rotary table sales and service agent prior to establishing TJR as an OEM in 2009. After much success, they grew to having the largest market share of machine tool accessories in China. Today, TJR is a top OEM with offices all around the world. Their rotary tables are built with high quality features, such as an anti-wearing worm gear and shaft made of high tensile brass for durability. Their encircling braking systems use a large clamping range to prevent displacement during heavy-duty cutting. For tilt rotary tables, TJR offers a 2+1 independent braking system and large diameter radial and axial preloaded bearings for rigid support during 4th- and 5th-axis cutting on both single and dual arm rotary tables. A three-year parts warranty is standard for all new TJR rotary tables.

TJR, or Tan Jia Precision Technology, is a well-established supplier of rotary tables to machine tool OEMs such as Doosan, DMG Mori, Mazak, Hardinge, YCM, Feeler, Leadwell, Bulova and Tongtai.

The company originated as a rotary table sales and service agent prior to establishing TJR as an OEM in 2009. After much success, the company grew to having the largest market share of machine tool accessories in China. Today TJR is a top OEM with offices all around the world. Their rotary tables are built with high quality features such as an anti-wearing worm gear and shaft made of high tensile brass for durability. Further, encircling braking systems use a large clamping range to prevent displacement during heavy-duty cutting. For tilt rotary tables, TJR offers a 2+1 independent braking system and large diameter radial and axial preloaded bearings for rigid support during 4th and 5th axis cutting on both single and dual arm rotary tables. A 3-year parts warranty is standard for all new TJR rotary tables.

8613371530291

8613371530291