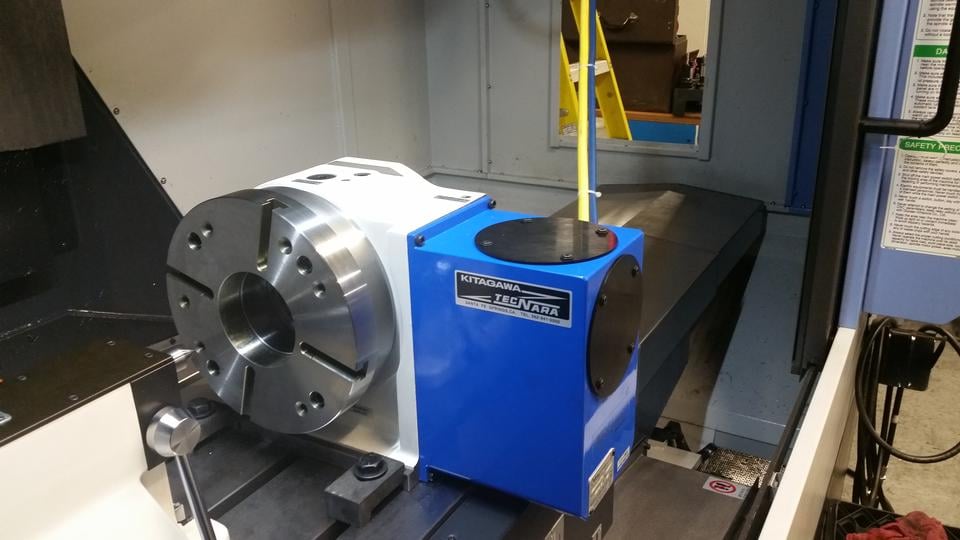

doosan rotary table factory

In 2022, it is likely you are considering either completely automating your machine tending or looking for avenues to reduce setup time and increase throughput. Our complete workholding packages for DNM series mills are perfect for achieving just that. When purchasing a complete solution from Martin Trunnion Tables, you will be provided with a rotary table, baseplate, trunnion solution, and workholding preassembled and ready to cut chips. Scroll down for more information and package options.

Our standard DNM6700 manual workholding package is ideal for 250mm and 320mm rotary tables and can be outfitted with a variety of workholding products from 5th axis and others. Featuring our Stallion Tombstone, this 4th axis trunnion is made from rigid, class #35 cast iron with multiple machined surfaces for higher productivity. Riser blocks can be provided at a variety of heights based on your configuration.

The PUMA VTR with adjustable W-axis comes with some of the largest vertical turning center specs in the industry. Give it your higher profile parts, then sit back and watch the show.

Goodbye wasted time, wasted space and wasted money. Hello NHP Series: unbeatable linear roller guide horizontal machining centers in a compact layout. Built for massive metal removal, these machines can single-handedly change your business.

DN Solutions’ Rotary Pallet System (RPS)—available on NHP, NHM and HC horizontal machining centers—is a one-, two- or three-story standout that grants you productivity your competition can’t touch.

The DVF 5000 comes standard with an 18,000 r/min integral Big Plus 40 taper spindle. A FANUC 31iB5 CNC controller makes full 5-axis simultaneous control possible, giving complete contouring capabilities. It also features a 500mm diameter (630mm option) built-in rotary table. Standard table with outboard support allows a maximum weight of 882 lbs. and minimizes any table deflection. The rotary table is designed for ease of use and consummate work efficiency, minimizing interference as the part is machined.

The DVF 8000 shares many of the features of the DVF 5000, but is far bigger and has a much different structure, incorporating dual ballscrews and motors on the Y axis and dual motors driving the A axis along with a direct drive C axis. It has a larger (800mm diameter) rotary table that supports a maximum weight of 3,086 lbs. The twin-drive table rotates at 60 r/min so you can make parts faster.

A: These VMCs offer a diverse range of tailored options and automation that make them ideal for unmanned machining. They come automation-ready and supplied with an optional/retrofittable AWC (Auto Work piece Changer) that provides additional productivity by offering up pallets to feed the machine for unattended machining. The 5000 will hold 8 pallets.

A: Doosan"s standard thermal compensation system features multiple sensors placed across critical structures such as the bed, column and spindle head assembly to minimize any thermal growth effects. The DVF Series also incorporates roller LM guideways for speed and added rigidity.

Tsudakoma rotary tables are standard on Doosan’s high-power DNM400-31iA5 vertical machining center with a 36.2" x 17.1" loading area, as well as the DNM500-31iA5 vertical turning centers with a 47.2" x 21.2" capacity. Both models are powered by a 30hp spindle motor capable of driving CAT 40 tools at speeds up to 15,000rpm, and generate up to 1,655 lb thrust along the X and Y axis, and 3,611 lb along the Z axis.

The bed is constructed of fine-grain Meehanite for its exceptional dampening and heat dissipating characteristics. The table is supported by the saddle in all positions, with no table overhang. All axes have precise linear motion guideways.

8613371530291

8613371530291