doosan rotary table brands

Are you looking for an accessory to boost the precision of your modern machining centers? CNC rotary tables provide a versatile tool in expanding the capabilities of your machines. They allow for precision positioning during 4 and even 5 axis cutting operations, thereby transforming 3-axis machinery into CNC machines with heightened accuracy. CNC rotary tables are a cost-effective solution to perform complicated machining tasks, with additional benefits such as increased productivity, efficient use of labor and materials, and better quality control.

Additionally, CNC rotary tables can be used independently to mount other components on a table, including trim attachments and chucks for drilling applications. CNC rotary tables offer considerable advantages that promote their usefulness in a variety of industrial settings.

Looking to sell your CNC Rotary Table? Simply fill out the sell your machine form and we will get back to you with a quote. Interested in one of our used machines for sale? Simply click the “Get Quote” button and a sales representative will contact you shortly.

Pre-owned DOOSAN DNM4500S 2019 Vertical Machining Center. This Vertical Machining Center has average cutting time and is equipped with a CNC control. This CNC Machine is currently located in USA. This DOOSAN Vertical Machining Center is available for a limited time. Get a quote today on this

You may have a bit of 5-axis experience from a previous job or it’s just as possible this is a brand new direction for you. Knowing where to start can be a bit confusing. Not to worry. No matter what your level of experience, Doosan"s lineup of 5-axis machines has enough variety to provide a perfect match between our equipment and your application.

Many machine shops are accustomed to cobbling together contraptions in an attempt to add a little boost in productivity. For example, retrofitting a 4th axis table with a tailstock onto a 3-axis mill, or putting a 4/5th axis trunnion table onto a 3-axis mill to give the operator access to more of the component faces. In this incremental approach to 5-axis capability, you likely experienced more than a few headaches such as maxing out your table weight, limited tool lengths because the retrofit table has eaten away your stroke, the accumulated error from stacked axes, etc. If you’re tired of dealing with improvised solutions, maybe it’s time to step up to the real deal. Let’s take a look.

The DNM 200/5AX Series is a step up from your standard C-frame, 3-axis vertical machining center with a factory-fitted 4/5th axis trunnion table. These machines are based off of the DNM platform, with the same reliability, stability and direct drive 12,000 r/min, 25hp spindle you might be familiar with. But included with the 5-axis model is a ø7.87" or trunnion table that has been specifically designed from the beginning to work with the machine. In addition, you have ample stroke to use the correct tool lengths for your operation. You"re not throwing away any table space on the sides of the trunnion table. The DNM/5AX Series comes with a FANUC 0iM control for 5-face or 5-axis work.

The VC630/5AX machine offers a more integrated solution. Equipped with a 24.8" trunnion style table, the spindle outputs 30HP at 12,000rpm to tackle all your complex machining requirements. The 81-tool magazine (optional 121) gives you more flexibility beyond the DNM 5AX machines.

The machine table is now an integrated cantilever style full 5-axis table allowing you to tackle your parts from angles you couldn"t on the DNM. We are presently offering a machine with a table diameter of 19.7" (DVF 5000); other table diameters slated for a Q3 launch will include 26” (DVF 6500) and 31.5" (DVF 8000).With this range of table diameters, you will be able to choose the size you need for your type of work. The DVF 5000 features a built-in 25/29.5hp (continual/short-term) 18,000 r/min spindle, allowing for high speed metal removal. It also comes standard with a 60-tool magazine, with options of up to 120 tools, to tackle your complex parts without having to re-tool your machine each time.

The VCF 850LSR is a large, multi-purpose, vertical machining center that is equipped with a 18,000 r/min CAT40 B-axis swiveling spindle head that has X-axis travel of 118". With this machine, you have two choices in the type of C-axis available: a mounted ø19.7” rotary table, or a built-in ø31.5” rotary table. With a 138”-long table, plus a standard center dividing partition (which can be easily removed for extra-long work pieces), you can create multiple work zones and keep the spindle removing metal in one zone, while the other is being loaded. For example, you can have an area equipped with the C-axis table for 5-axis work, and another area of the table dedicated to 3- or 4-axis work – maximizing the uptime potential. If flexibility is what you need in a 5-axis machine, this would be a great choice.

It"s not only verticals and 40 tapers that offer Doosan 5-axis technology. Built off of our NHP high performance horizontal machining center series is the DHF 8000, a 50 taper nodding spindle 5-axis machine. In addition to the full B-axis (360,000 positions) in the 800mm pallet, the A-axis in the spindle has a tilting range of +60 to -100 degrees, allowing 5-axis accessibility to your part. Dual ballscrews in the Y- and Z-axis in an already robust base give it even more rigidity, with a geared 6,000 r/min spindle, you can tackle all of your hard metal aerospace parts. Linear and rotary scales on all axes are standard!

Our latest offering is the HFP 1540, a horizontal 5-axis profiler made for the high-speed machining of aerospace structural components like ribs and wings. The integrated unibody frame structure houses all XYZ axes, optimizing synchronicity at rapids as fast as 2,362ipm. The profiler is equipped with a large 157.5" x 59" table with a servo driven pallet changer for added productivity. The 30,000 r/min HSK63A universal spindle gives this machine the A and C axes to make it a game-changing 5-axis machine.

That’s our 5-axis lineup. It’s kind of like the menu at your favorite restaurant. Everything looks so good, it’s hard to choose. That’s okay. Just give your local Doosan distributor a call. We’ll be happy to serve up the model that’s the best match for your machine tool appetite.

Fanuc 0iMB CNC Control, 4-th Axis Control, SMW Accu-Rock RT 160 8" Programmable Rotary Table and Tailstock, 24 Station Twin-Arm Automatic Tool Changer, 12,000 Max Spindle RPM, Cat 40 Spindle Taper, Remote Jog Handwheel, Coolant System, Thru Spindle Coolant (290 PSI), Chiller

"description": "We have a wide range of used Doosan machines for sale including vertical machining centers, horizontal machining centers and Puma and Lynx lathes. \nBrowse our inventory of machines or contact us if you need something that you don"t see.",

"twitter:description": "We have a wide range of used Doosan machines for sale including vertical machining centers, horizontal machining centers and Puma and Lynx lathes. \nBrowse our inventory of machines or contact us if you need something that you don"t see.",

"og:description": "We have a wide range of used Doosan machines for sale including vertical machining centers, horizontal machining centers and Puma and Lynx lathes. \nBrowse our inventory of machines or contact us if you need something that you don"t see.",

Full 4th Axis, through spindle coolant, 60 ATC tool changer, LNS chip conveyor. This Doosan HP-6300 horizontal machining center also has Renishaw part probes and tool presetter.

"Like New" Doosan Lynx 2100LSYA with Y-axis, Sub-spindle. LNS Alpha SL65-S Bar Feeder, live tool holders and quick change collets. Machine has seen very little use and is available immediately.

4th Axis Ready, 24" Rotary Table, TSC, Probe, 6,000 RPM. This originally owned single shift 2007 Doosan MV 8035 CNC vertical mill has been well maintained and includes the 24" Tsudakoma rotary ta...

Y-Axis, Live Milling, Sub Spindle, 10" chuck (main), 6" chuck (sub), Royal Collet, 3" Bar Capacity, (4) Live Tool Holders, Very Low Hours. This 2009 Doosan Puma 2500LSY cnc lathe is in plant, under...

Fanuc 21i-TB Control, 30" Swing, 18” chuck, 6.5" Bar Capacity, Tailstock, Tool Presetter, Chip Conveyor, Gear Box, Box Way. This 2007 Doosan Puma 400C cnc lathe is in plant, under power and availab...

Extraordinary large capacity CNC Lathe with tailstock, chip conveyor and 24" 3-Jaw Hydraulic Samuchully Chuck. Doosan Puma 480XL is one of the more powerful CNC lathes to hit the market.

Twin Turrets, Twin Spindles, Y-Axis, Live Milling, LNS Bar Feeder, Royal Collet Chucks, Like-New, only 160 Hours. This 2022 Doosan Puma TT1800SY cnc lathe is in plant, under power and available imm...

Available Immediately - Unique, "like new" Doosan Puma TT1800SY with bar loader under 200 cutting hours, new in December 2020, installed January 2021. Dual Turrets, Dual Spindles with 2.6" Bar C...

Doosan CNC Machine Tools have high quality, heavy duty turning and machining centers along with boring mills and double column machining centers available. Daewoo started making machine tools in the 1970s and was purchased by Doosan in the 2000s. Machines can still be found available with both manufacturing names. The majority of Doosan machines come with Fanuc CNC controls.

In the Doosan turning line there are Doosan Lynx, Doosan Puma, Doosan Puma TT and Doosan Puma MX series lathes. The newest Doosan Puma lathes are Puma GT lathes. Lathes come in a variety of bar capacities, chuck sizes and bed lengths. They come with live milling, y-axis, sub spindle, dual turrets and many other value added options.

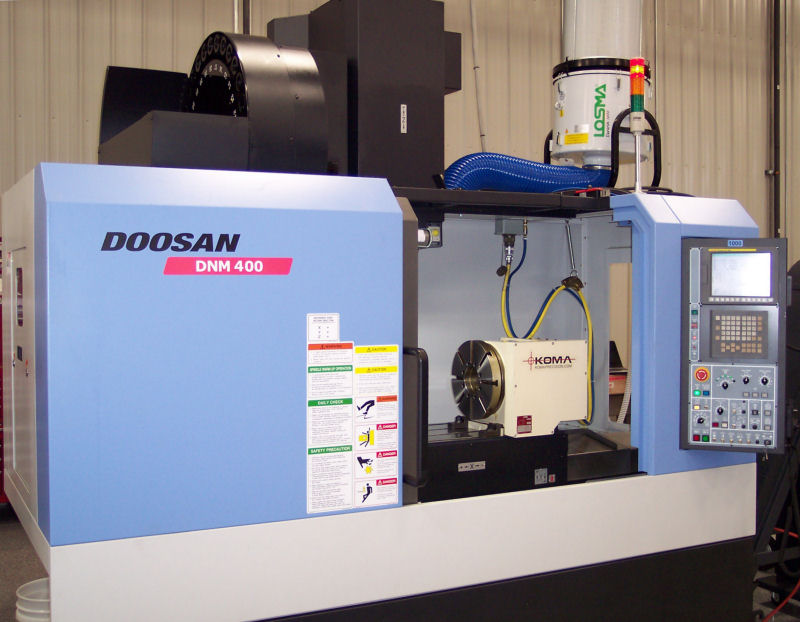

Doosan has a line of vertical machining centers (DNM series) and horizontal machining centers (HM or NHM or NHP series). These range in sizes and have a wide variety of options including 4th axis, through spindle coolant, probing and more to meet all of your machining needs.

F1RST PLACE REPORTS SUMMER 2005 CNC rotary tables C N C R O T A R Y T A B L E S - A R E V O L U T I O N A R Y G U I D E F O R B U Y E R S Don’t just go round in circles… Check out who’s in first place… and why!

CNC rotary tables - features comparison Features The contenders ±20 4 Sec Carbide Ion Nitrided HV930 Solid one piece spindle/faceplate 940Nm Hollow tube roller Yes No ±20 ±2 Sec Steel Bronze Bolt on face plate 650Nm Solid type No Yes ±20 ±10 Sec Steel Bronze Bolt on faceplate 400Nm Solid type No Yes 45 8 Sec Steel Bronze Bolt on faceplate 450Nm Solid type No No 50 4 Sec Steel Bronze Bolt on faceplate 354Nm Solid type No Yes 60 10 Sec Steel Bronze Solid type 350m Turcite slide face Yes Yes ±20 10 Sec Steel Bronze Bolt on faceplate 620Nm Solid type Yes Yes Indexing accuracy sec Repeatability...

Nikken CNC rotary tables - are in First Place Nikken Kosakusho UK Limited, Precision House, Barbot Hall Industrial Estate, Rotherham, South Yorkshire, England, S61 4RL TEL: +44 (0)1709 366306 FAX: +44 (0)1709 376683 info@nikken-world.com www.nikken-world.com 4. AFTER-SALES Rotary tables are expensive high precision pieces of equipment. They enable manufacturers to increase productivity levels by achieving one hit operations and reducing time spent on multiple fixturing operations when integrated with a machine tool - milling machine, grinding machine, EDM machine etc. Critical to the...

"description": "Automatics & Machinery has a large selection of used machining centers available from brands like Haas, Fadal, Brother, Mori Seiki, Doosan and more.",

"twitter:description": "Automatics & Machinery has a large selection of used machining centers available from brands like Haas, Fadal, Brother, Mori Seiki, Doosan and more.",

"og:description": "Automatics & Machinery has a large selection of used machining centers available from brands like Haas, Fadal, Brother, Mori Seiki, Doosan and more.",

Pre-owned DOOSAN DNM400-II 2014 Vertical Machining Center. This Vertical Machining Center has average cutting time and is equipped with a Fanuc control. This CNC Machine is currently located in USA. This DOOSAN Vertical Machining Center is available for a limited time. Get a quote today on this DNM400-II before it"s gone.

IMTS 2016 was the premier of the new partnership between CNC Indexing & Feeding Technologies and TJR rotary tables from TJR Precision Technology. TJR is the rotary table and direct drive unit OEM for brands such as Hardinge, Doosan, DMG Mori, Mazak, Feeler, Leadwell and Tongtai. These direct drive tables were also a hit at the show!

All models come with a pneumatically operated gripper driven by a rotary cylinder. The gripper’s rotating angle is 180° (without a B-axis). For safety, the loading area is guarded with either a light curtain or safety door. AUTOLOAD’s gantry systems are available in stocker or pallet style loading and unloading with optional inbound/outbound conveyor and flip over station.

8613371530291

8613371530291