edm rotary table price

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

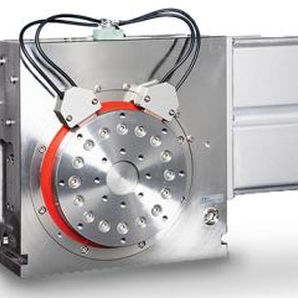

MK250RAV00 Rotary Table (includes Quinte Controller) with compact design, high performance nd improved mounting. The innovative triple disc brake system & friction welded construction gives substantially ...

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or ...

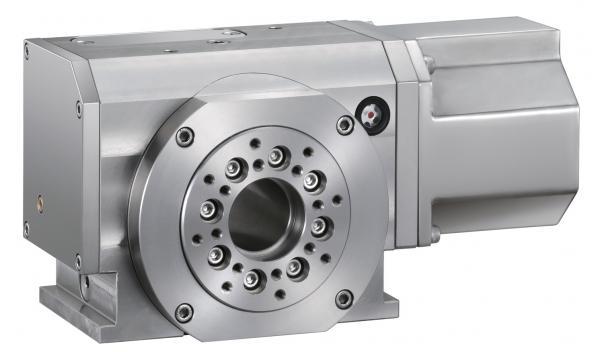

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

This control unit can be connected to any make or model of machine control and is started via M signal command. Programmable directly in either direction to any specified angle directly. The unit can be mounted vertically or horizontally at will. Motor is mounted to the left side on this device, through hole capability is closed due to the style and application of the device. Hofmann products are a high quality unit, this is no different being pre-owned is incredible value for money and come with a 1 year warranty. General dimensions are attached to this listing, however for clarity in vertical, the centre height is 160mm, the overall height is 250mm, in the horizontal plane, the height is 160mm. Carrying capacity vertically unsupported 120kg or 250kg with matching tailstock. Horizontal ;plane carrying capacity Is a very impressive 600kg. Net weight 60kg (Table and motor) This is a one only offer and cannot be repeated and is therefore subject to prior sale – contact technical sales for further information. The model number relates directly to the spindle and height, there is no faceplate with this unit.

To select the right rotary table for you is our aim, not just by the cost-effectiveness but by the most appropriate, so let us work together to find you the optimum solution from a wide variety of manufacturers from all around the world.

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

Anyway, to answer your questions, I looked up the Hirschmann table you referenced and it looks to me like it"s a spinner and indexer, not a turn while burn table.

Hirschmann must have a similar provision to integrate their turn while burn capable tables to whatever machines they are going to be run on...I don"t think you can just buy one and bolt it to a machine without the interface kit to mate it to the control.

Turn while burn requires that the controller governs the rotary motion; this is because the rate of rotation has to be driven by the spark gap conditions in conjunction with the axis motion of the rest of the machine whether it"s X or Y or U or V.

It was faked by tilting the wire to an angle other than the thread helix angle with the U axis, then driving a fine pitch helix with B and X (B is the rotary axis on my machine).

You can imagine just how many passes that would take (a LOT), and you will always have a 0.005" radius at the junction of each flank and the root, which may or may not be acceptable depending on the application.

The manual rotary tables of the EXPERT-TÜNKERS EDM-series are a cost-efficient solution for simple automation applications up to a total mass of 1.000kg. Although the automation solutions and applications of our customers are continuously increasing in complexity, there is still a solid demand for safe and reliable manual human-machine-interface solutions.

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

Lyndex Nikken – Hydraulic Chucks & Toolholders, 3 Jaw Chucks and Angle Heads, Rotary Tables, Live Tools for Turning Cneters, Shrink Fit Machines & Holders, Precision Collets

Where wire EDM is concerned, accuracy has traditionally come at the cost of speed. That’s why FANUC has developed a next generation ROBOCUT wire-cutting machine. The α-CiB series comprises three versatile all-around machines, including the first model with an 800 mm table. With incredibly long mean times between failures, low maintenance, longevity and excellent uptimes, these future-proof spark erosion machines are designed to save time and drive down unit costs while ensuring outstanding accuracy and cutting efficiency.

ROBOCUT’s Smart Positioning function gets you started faster by cutting the time it takes the wire EDM machine to measure geometrical references on the workpiece.

ROBOCUT is available with a CCR rotary table. This lightweight universal rotary table comes with high-resolution glass scales and, for maximum concentricity, provides optimum travel between the U and V axes.

Depending on the model, ROBOCUT’s U and V axes can be traversed 90 mm beyond the table. This enables smaller workpieces to be machined without the need for expensive clamping devices.

8613371530291

8613371530291