fadal vh65 rotary table free sample

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification.

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

As you"ll see below, we are the most qualified to repair your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. -Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of theses units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

The original Fadal rotary heads are still one of the best overall designed attachments for the Fadal machine. While there are many imported rotary heads that might "look good" on the outside, it"s the inside that really counts. The simple fact is the Fadal rotary tables were specifically designed to take a crash and keep on working.

Many different rotary heads were made throughout the years of production. A 4th or 5th rotary axis was one of the most popular machine options. In the early 90"s we started shipping all machines "4th axis ready" which means the machine has all the wiring necessary. You basically only needed an amplifier and a axis controller card with software. Contact us if you thinking of adding a 4th axis, we offer all the necessary components.

The very first rotary table sold that was sold on the VMC45 in 1981. It was designed and manufactured by Fadal for the VMC45, it never realized full production after production the VMC45 was stopped.

Troyke Mfg. Co. - Afterwards, with the introduction of the VMC40 in 1984, we began offering the TROYKE rotary products as a 4th axis option. The table had an interesting full contact bearing surface using Turcite between the faceplate and the casting with radial bearings support for the faceplate spindle. Few of these units still remain in the field today. If needed, we can provide complete service for these units.

Soon after 1987, we started adapting many of the popular Japanese rotary tables. Some customers would send us their tables and we adapt our motors and 4th axis interface to them. Eventually we started adding the Tsudakoma, Tecnara and Nikken rotary tables as a direct option to all machines.

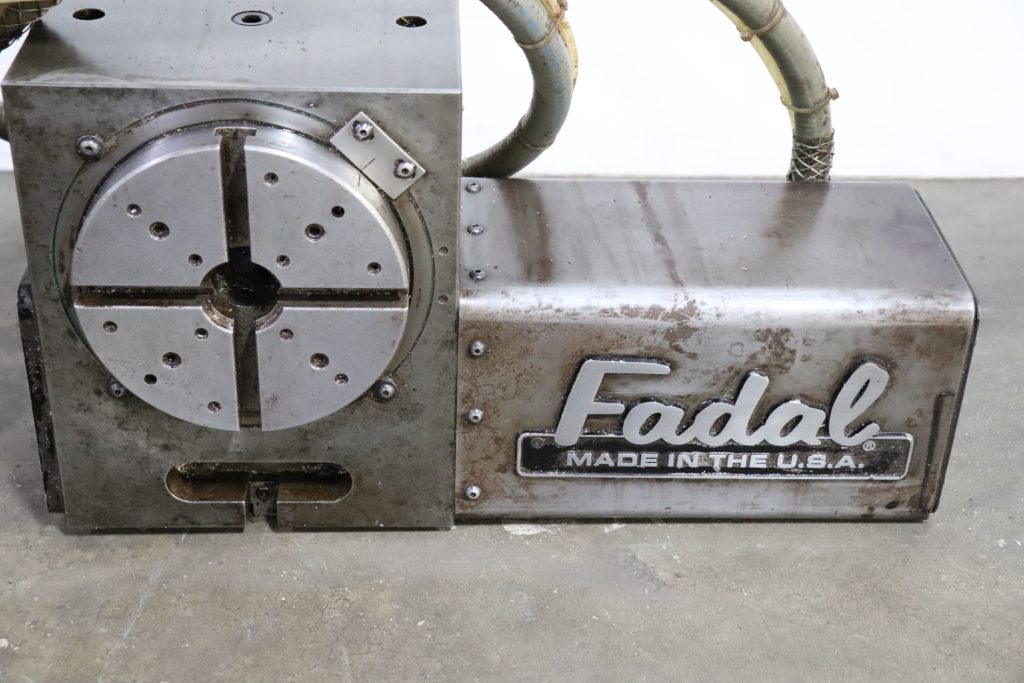

VH65 - After years of installing and also repairing the many various manufactures rotary tables we sold, we learned what different designs worked and didn"t work in the machines. The second rotary head Fadal designed was the VH65. The VH65 stands for Vertical or Horizontal mount and 6.5" diameter faceplate.

TR65 - The TR65 (Tilt/Rotate, 6.5" dia. faceplate) had a unique clutch system build into the trunion for the B-axis. One of the biggest problems with 5-axis programming was that is was easier to crash than to program. And a B-axis crash usually resulted in the customer having to return the unit for repair. With this unique design, if the Z-axis crashed into the part, instead of damaging the gears it would simply slip the trunion clutch. The CNC knows the exact position of the B-axis because of the rotary scale feedback that is directly attached to the trunion and not the motor. The addition of the trunion clutch was so important because it virtually eliminated the disruption of operation for a service call.

You will receive an estimate of repair 5-10 days (depending on workload) after receiving rotary unit. Repairs take an average of 10 to 30 working days after receiving approval. Evaluation charge of $500.00 will apply if you do not get it done.

Your rotary unit is repaired, reassembled and run in for 10 hours. It is then re-inspected, all final adjustments and calibrations are performed to the original manufactures specification. We warranty our complete Rebuilds for 1 year.

As you can see we are the most qualified to tune-up or rebuild your rotary table. Having been there from the beginning, we know exactly what your table needs to bring it up to original specifications. Simply call Toll Free 1-800-342-3475 for any questions.

We have that machine 15XT 1996. We actually (Very carefully) drilled and line bored alignment pin holes through a one in. steel ground 4140 plate and into the table. The plate moved the 4th axis assembly to the right over the chip guard... on the x axis until the limit was about the same as the back edge of the 4th rotary face plate... but not so far out that it was beyond the chip guard edge, or you might hit the sheet metal. Also, when centering on the Y we had to pick the best position to accommodate that travel to keep from hitting the door and in the y +, the Z chip guard.

The 4th mounted to the mounting plate is mounted so that it can be adjusted on the mounting plate... if necessary. Though we have never needed to adjust it since the first mounting to the plate. With removal from the table and replacement the assembly repeat has been always in the 5 tenths.

as a first pass you need to understand that the fadal will output a DC motor drive, and will be looking for a resolver feedback, not an encoder assuming that your 1997 has DC motors. otherwise it could be AC and would be looking for encoder. if your machine is AC but rotary table is DC you will need to install a DC power supply chassis, overloads, and probably other gear.

to add a 4th you need an amp, 1010 with AB no limit eeprom, hopefully your machine is pre-wired up thru the sheet metal to the big military style connector. you need the dummy plug for that when the 4th is off the table.

alternately you can use just the indexer in indexer mode with m30 codes to where the machine wiill say "index" then wait for the signal from your indexer box that says "i am done indexing" to accomplish this you need the extra m-codes option board, which i think lots of machines had. tell tale sign is a long cable with 4 pin connector near the bottom of your ctrl cab. you should only need that m-code board 1050-3A (PCB-0008). read the fadal manuals to find out how to hook up the indexer line - it needs to just close a relay when the indexing is done. I used my rotary as an indexer for a while, it is plenty useful / mostly i dont need to do full 4th. although managing the indexer code was a pain as my cam doesn"t output for it / had to manually make it happen. i used relative coords to make my life easier in that situation. i bet you could get cam to do it somehow / depends on a lot.

i have experience with this to an extent. i have a VH-65 which was an indexer using the fadal indexer box, and a DC motor with an encoder on it. to get it to be a "full" 4th, i had to add the 1010 card, and a DC amp. my machine is a 1992 DC drives machine. I had to put a different motor into my VH-65 which has a resolver assembly on it, and rewire it to hook up correctly to the 4th axis pre-wire.

to get the haas table to work you"ll need to know all details of motor currents, feedback type, and so on. its not a job for someone without a lot of engineering experience... best of luck man...

VH5C ROTARY TABLE ........................................................................................................................................................ 13

VH65 ROTARY TABLE ........................................................................................................................................................ 16

TR65 ROTARY TABLE ........................................................................................................................................................ 19

DUAL VH65 ASSEMBLY ..................................................................................................................................................... 25

ROTARY ACCESSORIES ..................................................................................................................................................... 27

300/400 ROTARY TABLE BOX ......................................................................................................................................... 33

In order to participate in the auction, all BIDDERS must provide AUCTIONEER a 25% deposit in cash, cashier’s check, or company check accompanied by a bank letter of guarantee of unqualified payment to AUCTIONEER, or a wire transfer (with a wire transfer fee included) of BIDDER’S maximum expected spending inclusive of taxes and fees. Credit cards are not acceptable form of payment and will not be accepted.The final payment in full of BIDDER’S invoice must be received by AUCTIONEER within the first banking day 24 hours after the auction or BIDDER will be in default of AGREEMENT. AUCTIONEER will charge BIDDERS a taxable surcharge BUYERS PREMIUM on AUCTIONEER’S invoice to BIDDER. BIDDER shall provide proof satisfactory to AUCTIONEER of BIDDER’Sentitlement to claim exemption from sales tax. BIDDER’S proof of any claimed tax exemption must be representative of the same industry as the LOTS purchased. In the absence of proof satisfactory to AUCTIONEER, BIDDER shall pay all taxes. AUCTIONEER is not responsible for any Department of Motor Vehicle fees, taxes, registration, licensing, penalties, smog certificate, or any other fees. Certain vehicles as announced and/or noted in the auction catalog or on BIDDER’S invoice will be sold “AS IS” with a Bill of Sale only. Each titled item will be charged a $75 title transfer fee. If available to AUCTIONEER, titles will be sent to BIDDER approximately 7-30 business days after receipt of payment from BIDDER to AUCTIONEER. Sales tax on Motor Vehicles is the responsibility of BIDDER to be remitted to BIDDER’S appropriate state Department of Motor Vehicles. All vehicles are sold “AS IS, WHERE IS, WITH NO WARRANTIES EXPRESSED OR IMPLIED”. It is the BIDDER’S responsibility to inspect the vehicle to verify accurate description, model, year, mileage, condition and any and all details pertaining to the vehicle. AUCTIONEER is not responsible for any inaccuracies regarding LOTS of any kind INCLUDING THE DESCRIPTIONS ON THE FINAL INVOICE.

Should any pits, floor bolts or hazards of any type exist after removal of equipment, it is BIDDER’Sresponsibility, at BIDDER’S cost, to reasonably safe guard these areas using generally accepted safety practices, such as safety tapes, pipes or bars welded in place or suitable safety barriers acceptable to AUCTIONEER. All floor bolts and/or anchoring fasteners are to be cut flush to the floor and the area left broom clean and all debris removed. It is the responsibility of BIDDER to be sure that power to the LOTSis off and then to safely disconnect all electrical wiring and utility piping from the LOTSand to cap at the first electrical or air junction of the LOTS.

FADAL VH-65 Rotary Table (6.5" Diameter) AC Motor, with Tailstock. ebay template Fadal FADAL VH-65 Fourth Axis Rotary Table with Tailstock Good working condition. Sold as pictured. The Fadal VH-65 Rotary Table is a compact, rugged unit that allows vertical/horizontal operation. Lets you work on four sides of a workpiece with only one set up. SPECIFICATIONS Faceplate Diameter 6.5" Center Height 6.5" Swing Clearance 12.95" Thru Hole Diameter 1.37" Load Capacity 180 lbs *Specifications subject to verification Shipping Shipping is the responsibility of the buyer; however, Machinery Exchange has a large network of freight carriers to help you find the best price. If you would like a freight quote for this item please click "Contact Seller" or “Ask Question” at the bottom of the listing and provide us with your city, state and zip code. Or contact us via telephone at (818) 718-6734 Machines are attached to a skid for and covered in protective cosmoline coating for shipment. A forklift may be required to remove the machine from its skid. The cosmoline can be removed using a light kerosene/water mixture. Tooling: Below are directions on how you can calculate shipping for items under 150lbs. That does not qualify for USPS Flat Rate. Pick up/Will Call: All our items are available for pick up Monday thru Friday from 9am to 4:30. Arrangements can be made for Saturday pick up. We do not charge loading fees for loading machines or tooling unless we have to bring in special equipment or call a mover. Note: Most of our listings are marked Freight shipping. We ship via FEDEX and USPS for item(s) 150lbs or lighter. The cost of shipping will be sent via invoice. We encourage all customers to log into the FedEx website to calculate shipping. Listed on every item are the directions and information needed to do so. ENCLOSED FREIGHT- Items over 100 lbs. less than 1000 lbs. will be sent via LTL Freight via enclosed truck. For an enclosed freight quote please email us with: item #, name, zip code, and destination type [commercial or residential]. We forward your emails to a freight broker who networks with all the major freight companies to find you the best rate. We can act on your behalf for shipping quotation but shipping arrangement and charges are your responsibility. We will send you the freight broker"s contact info to schedule pick up. Enclosed shipments require an item to be palletized and protected. The cost labor and materials to prepare an item for enclosed shipment is generally $50. This charge will be passed on to you as a packaging fee. We will load the item at no additional charge. In some cases, we will send an item under 1000 lbs. via open-bed freight if we feel enclosed shipment is not a suitable means of shipment. MACHINE DIMENSIONS: 30" x 20"pallet, x 15"H (inches) approximate. MACHINE WEIGHT: 100 lbs. approximate. Payment We accept Check, Credit Card, or PayPal. We accept all major credit cards except American Express. Payment is due within 5 days of purchase. Orders are not processed until they’re paid in full. Our invoice will include a subtotal of item(s) purchased, sales tax for in-state purchases [CA], and a rigging/packaging charge if applicable. Please wait for a complete invoice with estimated shipping price before sending payment. Machinery Exchange reserves the right to open an Unpaid Dispute against buyers who do not pay or contact us in regards to payment. Machinery Exchange reserves the right to re-list or re-sell a purchased item if we do not receive payment. Terms Listed Items- Items listed on eBay are available for immediate purchase through our showroom as they are advertised through various trade publications. This item is subject to prior sale. We reserve the right to end a listing early if the item sells through another outlet. WARRANTY: The goods described herein are pre-owned used goods and are offered "as is", "where is" unless otherwise noted herein, SELLER MAKES NO WARRANTIES OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, OR MERCHANT-ABILITY AND FITNESS FOR A PARTICULAR PURPOSE. All specifications and description of said goods are approximate only. It is the Buyers responsibility to inspect the goods and ascertain if the specifications, description and condition of the goods conform to Buyer"s requirements. MACHINE USE AND SAFETY: Buyer acknowledges that the goods described herein are preowned used GOODS WHICH WERE NEITHER DESIGNED NOR MANUFACTURED BY THE seller, nor has the Seller knowledge of, or control over the prior use or misuse of said goods, nor does the Seller have knowledge or control over the future application of these goods by the Buyer. It is the Buyer"s (user"s) responsibility to provide proper safety devices, equipment and instructions for any particular use and to take all necessary steps to conform to all federal, state or local government safety standards including OSHA. INDEMNIFICATION: Buyer agrees to indemnify, hold harmless and defend Seller of and from any and all claims, liabilities and damages from any accidents or other incidents involving the goods described herein. Machinery Turn-around Time - Your order is processed after it is paid for in full. Average turn-around time varies depending on the item you have purchased. Many factors come in to play when purchasing industrial equipment. Machines must be "blocked" for shipment before they can be removed from our showroom and loaded on to a freight truck. We hire an outside technician to prepare the machine for shipment. Machinery movers may also be contracted to remove the machine from our showroom and load it on to a freight truck. Our turn-around time depends on the schedules of these outside sources. Generally an item can be ready to ship within five business days of purchase. Please contact us if you need detailed information on this items availability. We will do our best to expedite an order if you make the request prior to purchase. Damages- We go above and beyond to assure your item arrives safely but there have been cases when an item still gets damaged during transit. We will not be held accountable for an item damaged during transit unless it was packaged improperly. Always insure your shipment when making shipping arrangements. This allows you to make a claim against the shipping company for the amount of loss. If an issue arises during transit we will do our best to represent you as our customer and resolve the issue. Ultimately shipping is a contract between you and another company. Machinery Exchange cannot be held responsible for freight costs, transit times, etc. Feedback - eBay has advised sellers to use the feedback system as a tool to know customers are completely satisfied with their purchase. The final step of the transaction is leaving you positive feedback. Machinery Exchange goes to great lengths to make sure our customers are satisfied. If you feel we have earned anything less than a positive remark please contact us and we will resolve your issue as best we can. You are buying from a MDNA professional. We specialize in reliability, quality, and we back our equipment with a thirty day return privilege to assure your satisfaction. So, Bid With Confidence! Contact Info- Feel free to contact us for more information regarding any of our eBay listings. You can contact us directly by phone or email. Call us Monday through Friday 9am-5pm PST [phone removed by eBay] Our address is 20933 Plummer Street Chatsworth, CA 91311 NEED FINANCING? GET APPROVED INSTANTLY ONLINE ! DIRECT CAPITAL provides equipment financing for our customers across the U.S. for both new and used equipment. Click the Direct Capital logo on the left to be redirected to the Equipment Financing Center. Casey Goodell (603) 766-9365

Quantronix has been able to reduce cycle times by using a Fadal 6030 VMC with a TR 165 fourth/fifth axis tilting rotary table to machine the frames and housings for its lasers.

Quantronix uses a Fadal 6030, a large box way VMC with a 60-inch X-axis travel; 30-inch Y-axis travel; a 10,000 rpm spindle; 88HS control and a 21-tool changer.

Five-axis machining tends to conjure up images of pricey VMCs machining aerospace components with complex curves and undercuts. However, manufacturers and commercial job shops are finding a VMC and tilting rotary table with fourth- and fifth-axis motion can significantly reduce setup, handling and cycle times on a variety of commercial components and parts. These rotary tables can deliver higher accuracy and provide more rigidity for heavy cutting routine operations, such as facing, pocketing, drilling holes and tapping.

The basic concept is to machine parts with only one setup per part. The operator loads the part just once, pushes the cycle start button, and the rotary table moves the part in the required position. This is repeated until all sides/surfaces of the part have been machined and the cycle is finished. Or, the operator can load several parts onto the rotary table and start the machining. As one part is finished, the rotary table brings the next one into the proper position, machining begins, and so on. The advantage is that the VMC can be left unattended for longer periods of time, and less time is spent handling the part.

The company decided to use a Fadal 6030, a large box way VMC with 60-inch X-axis travel, 30-inch Y-axis travel, a 10,000 rpm spindle, 88HS control and a 21-tool changer from Fadal (Chatsworth, California). The 6030 features Cool Power, Fadal’s refrigerant system that maintains the temperature of positioning elements to ±1 degree of the machine’s ambient temperature by recirculating a high performance heat-transfer agent through the spindle nose, around the spindle cartridge and headstock, and through the center of the Y-axis ballscrews. The heat transfer agent flows through the gun-drilled ballscrews and dissipates heat before it causes thermal expansion. This ensures pinpoint positioning and repeatability by minimizing thermal expansion throughout the day.

Whether machining one part at a time, or loading several parts on the same rotary table, the most tangible benefit is the time savings. For example, the machinists at Quantronix load a 6- by 6- by 4-inch aluminum block onto the rotary table and machine the main pocket on the part, which becomes the optical housing. Four different surfaces can be machined with only one setup—the aluminum block is held in place on two sides, so the remaining four sides can be machined—then, machined using the fifth axis starts. The part has angled compound holes with milled surfaces. Drilling these angled holes on the fifth axis eliminates four separate handlings and leads to machining individual housings in 17 minutes, instead of 1 hour. Tool changes are reduced because all of the operations for a tool are completed before the next tool is loaded.

It is important to recognize that each time a part is moved, it is impossible to position it exactly the same as before, which will affect the specified tolerances. But by handling the part once and letting the rotary table rotate the part into position, the part will be positioned within the tolerance capability of the rotary table.

The optical housings must be parallel within 0.001 inch. This parallelism is achieved with the rotary table, and housings are manufactured with tolerances of 0.0005 inch or better. Accuracy and repeatability on the rotary table are ensured with hardened and precision ground faceplates, pre-loaded bearings and CNC ground-worm shafts.

An important factor in this situation is how the rotary table and VMC work together. Knowing the rotational speed of the table and its torque is essential. The rotary table should also be able to keep up with the tolerances of the VMC. The control needs to accept the rotary table without rewiring. Many of today’s controls can be ordered prewired for rotary tables. For example, the Fadal 88HS Fanuc-compatible control on Quantronix’s 6030 can be ordered so that it can connect to four- and five-axis rotary tables for indexing and true simultaneous machining operations.

Having reduced part cycle times by more than two-thirds, Quantronix reports a revenue increase. “We’ve had phenomenal results with our 6030 and the rotary table,” says Steve Worner, Quantronix’s job shop manager. “Our Fadal 6030 has helped us grow our business beyond what we had expected, and our productivity has shot up.”

8613371530291

8613371530291