golden sun rotary table manufacturer

GSA TECHNOLOGY CO., LTD. established in 1978, from time to time, our growing of devotion work stable, keeping in mind of honesty, faith, profession and innovation, nonstop communication and promotion of critical quality procedure, ensure every products could meet high quality of duration and precision.

GANRO makes every rotary table based on this concept from every single part to a complete rotary table. Even a small screw will decide if a machining center can achieve the most profitable function.

From 1978, Golden Sun Industrial Co., ltd. maintains quality and value in making rotary tables utilizing advanced technologies, GANRO Industrial Corp, was established in 2008 to meet the high standard and demands from our customers all over the world. The spirit of pursuing perfection of Golden Sun is fully passed on to GANRO.

GANRO is convinced that a perfect work isn’t made without a foundation. As everyone knows that German and Japanese manufacturers keep most strict standards to make rotary tables. Their standards and attitudes to make rotary tables are GANRO’s motive power that keeps GANRO walking forward.

- Using axial/radial bearings, they can allow heavy loads and are suitable for heavy cutting. The runout of axial and surface flatness is decreased, and higher accuracy is acquired.

For a wholesale golden sun rotary table, visit Alibaba.com. This online shopping platform works with various global wholesalers to offer you a wide range of evaporators. Go to the website at any time and place your order with a single button click.

When you look for a golden sun rotary table, you will also come across very specialist plastic welders. For instance, the Alibaba wholesale listings feature welding kits for car bumpers that can be used in home garages. These PVC repair guns actually have a wider range of uses than auto repairs and are handy additions to anyone"s tool kit. Our marketplace caters for home users and industry. You can source spot welders and welding units for production lines, and kits for running repairs. Everything is easy to find via our search engine, so look around and discover a welder that"s perfect for you.

Are you looking for wholesale golden sun rotary table? Look no more as Alibaba.com has all sorts of pile drivers that will ease your next pile driving process. A pile-driving machine is critical equipment in constructing structures and buildings as it helps in driving piles into the soil. These piles help in providing foundation support for a structure or building under construction. In that way, you can comfortably move a load of the structure to a difficult depth without a machine. Regarding your liking golden sun robotary table, available in different models and varieties, well-suited to both cars, trucks as well as motorcycles.

CNC Indexing & Feeding Technologies is proud to carry TJR Precision Technology rotary tables. All of TJR’s rotary tables incorporate a range of features that give them an edge over competitors, and the dual lead worm gear is at the top of the list. How Does A Dual Lead Worm Gear Work? With the dual […]

CNC Indexing & Feeding Technologies is proud to offer the best the industry has to offer in our complete line of Ganro Industrial Corp. rotary tables. While parts of a rotary table may seem the same no matter what brand you choose, the true test of quality lies in the equipment design. Ganro has been developing […]

Manufacturers across the globe are always looking for reliable workholding devices to accommodate their manufacturing indexing and rotating requirements. CNC Indexing & Feeding Technologies has been proud to represent the complete Ganro Industrial Corp. (Golden Sun) product line of workholding rotary tables and indexers. Ganro has been producing a wide variety of workholding products to accommodate manufacturers for over 30 years. To help a company decide which table is best for its applications, it is beneficial to understand the proper use and capability of each workholding device. CNC Indexing and Feeding Technologies offers various Ganro workholding products.

Standard Rotary Tables: The sizes range from 120mm (4.72") to 800mm (31.49") in faceplate diameter and can be used as a full rotating axis incorporated into a machine"s control or as indexers with Ganro"s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions and have large thru-holes to give manufacturers maximum flexibility.

Large rotary tables: The large rotary tables are available in a range of 1000mm (40") to 2500mm (98") in faceplate diameter. They can be used as a full rotating axis incorporated into a machine"s control or as indexers with Ganro"s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions.

Rear Motor Mount: Ganro manufactures two of the most popular sized rotary tables with a rear mounted motor for smaller vertical machining centers. The rear motor mount rotary table design is available in the standard 170mm (6.69") and 250mm (9.84") faceplate diameters. As with other Ganro rotary tables, they can be used as a full rotating axis incorporated into a machine"s control or as an indexer with Ganro"s M-Mate AC servo controller.

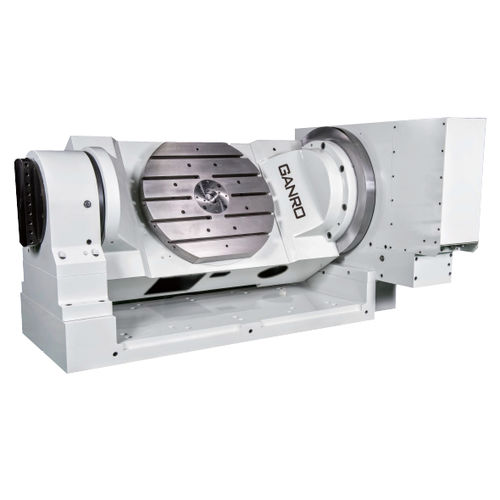

CNC Indexing offers three types of Ganro standard rotary tables to accommodate a wide range of 4- and 5-axis manufacturing requirements. The standard tilt rotary table is a trunnion design with faceplate diameters ranging from 320mm (12.59") to 800mm (31.49"). This style is created to give manufacturers ample room for workholding and workpiece while providing clearance for the machine"s spindle and tool.

Compact Tilt: The compact tilt rotary table design comes in faceplate sizes of 150mm (5.90"), 200mm (7.87") and 250mm (9.84") and is ideal for smaller machining centers and smaller workpieces.

Manual Tilt: The manual tilt table is designed with a full 4th axis (rotating axis) and a manual tilting axis. It is available in sizes from 200mm (7.87") to 630mm (24.80") and is ideal if a tilting axis is only occasionally required.

Horizontal Rotary Table: This rotary table design is available with table tops ranging from 400mm (15.74") to 2500mm (98.42") square. Ganro"s horizontal CNC rotary tables can be used in various areas of manufacturing but are ideal for horizontal boring mill applications.

Horizontal Index Tables: CNC Indexing offers two types of Ganro horizontal index tables for both manual and automated manufacturing processes. Both series of precision horizontal index tables use a two piece Hirth coupling design that provides superior indexing accuracy while maintaining high rigidity during heavy cutting.

CNC Index Table: The CNC Index Tables are clamped and unclamped with hydraulics and are designed to be incorporated into a machine"s CNC control or operated with Ganro"s M-Mate AC servo control system.

Manual Index Tables: The Manual Index Tables are clamped and unclamped pneumatically or hydraulically. Once unclamped the series is manually indexed to the desired degree and securely clamped into position.

Face Gear Rotary Tables: The Face Gear Rotary Tables are manufactured with a three piece Hirth coupling design to avoid lifting during rotation. The use of a Hirth coupling allows for the mounting of heavy loads while offering high rigidity and high accuracy. These tables are primarily used in applications incorporating a strong tailstock and a tombstone or fixture plate. It can be integrated into a machine"s control or operated through Ganro"s AC servo controller.

The index tables are available in four faceplate sizes (250mm, 320mm, 400mm and 500mm). Ganro rotary tables can provide a solution for rotating and indexing small workpieces to large workpieces, for vertical and horizontal applications, for 4-axis and 5-axis work and for manual and automated applications. Ganro products give manufacturers the capability of improving the manufacturing process by accessing multiple workpiece faces in one clamping. This improves workpiece accuracy and reduces manufacturing cycle times.

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

* With the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

8613371530291

8613371530291