haas 5 axis rotary table free sample

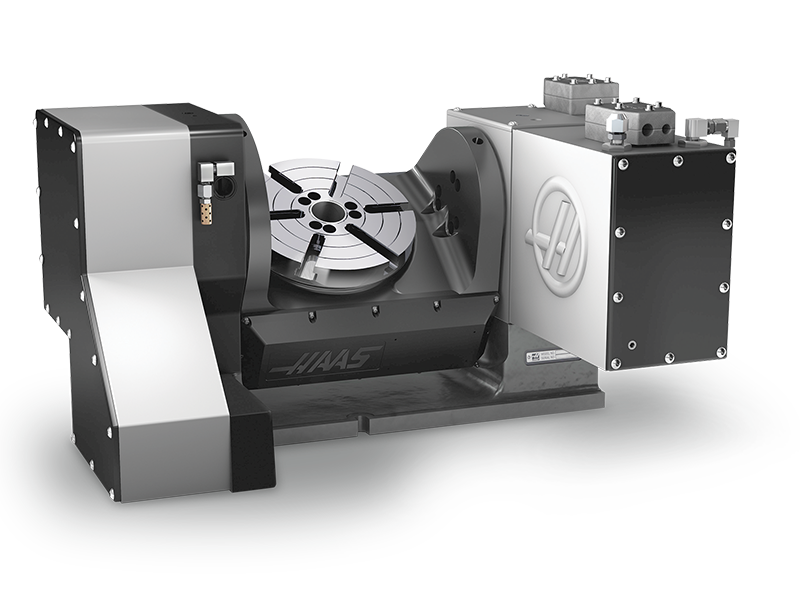

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Going from 3-axis machining to 4-axis and 5-axis machining can be intimidating. This short video shows how easy it is to transition from basic 3-axis milling to full 5-axis design and production.

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

Are you considering the purchase of a CNC machine and want to know whether to chooseHaasorMazak? Both are popular manufacturers and have their own loyal followers. As you will see, we compare the companies, machines construction, CNC controls, service and training. Both companies have their own strengths and serve their markets very well. In the end, you’ll have to evaluate each machine company’s strengths as compared with your needs. We encourage you to keep in mind your needs for machine service and training, types of materials that you’ll be machining, tolerances that you’ll need and part complexity requirements as you read through this guide. We also recommend that you call your local support technicians for both Mazak and Haas to evaluate the kind of local support that is available before you make your final decision.

Mazak is an international manufacturer of machining centers with a diverse product line including multi-tasking, 5-axis, turning, vertical and horizontal machining centers as well as an exclusive parts-moving cell system and automation software. They manufacture many CNC machines in their expansive Kentucky plant and machine even their largest cast-iron CNC equipment parts on their very own equipment. Because of their extensive capabilities, Mazak even sells CNC’s to competitors for making their machines. Mazak is known for their quality construction, service and innovative technology. They support Mazak CNC’s of any age with service and parts with factory-trained technicians.

Haas is a manufacturer of four main product lines: vertical machining centers (VMCs), horizontal machining centers (HMCs),CNC lathesand rotary tables as well as 5-axis CNC’s and other specialty machines. All products are made in Oxnard, California in a large modern machine tool shop with most of their machines being made on their own equipment. They have been known for making economical and reliable machine tools since 1988, when they introduced their first VMC, called the VF-1. This machine was introduced for a price under $50,000 and solidified their position as CNC manufacturer for the small job shop. Today they have an extensive line of machines of all sizes and applications.

Haas CNC are made with cast-iron construction which provides ten times more damping capacity as compared to steel. The castings are analyzed for flaws in reinforced with numerous heavy ribs to resist flex and damp vibration. They add bulk and ribbing to the headstock and tailstock of the Haas lathes for stability, repeatability and cutting accuracy. Haas machines are built to be economical but still solid. However, they are not considered the most heavy-duty. For applications machining aluminum and softer materials or lower production job shops, the Haas is often the CNC of choice.

Mazak has been building machines and innovating for over 100 years and has a reputation for designing and supplying high-quality, innovative and customer-friendly machines. No matter what your machining needs, there’s a good chance that there’s a used Mazak that will be a good fit for your application. Mazak builds heavy-duty CNC’s with solid cast iron bases that they machine in their own plants. They use heavy-gage external steel housing, which sets them apart from most of their competitors including Haas. Mazak CNC’s are known for solid construction and engineering – they are considered top quality CNC’s and new go for as much as 40% more than similar Haas machines. For tight-tolerance work, especially machining tougher materials, many prefer the Mazak.

The Haas control is considered one of the easiest to operate. Even models going to back to the year 2000 had Haas-only features like “Word Processor Editing” to help operators easily make changes. They carried features like one-touch, multi-function jog-handle and quick code programming even on early milling machines. Haas provides a robust dependable control that is integrated with the Haas CNC machine. They do not rely on third-party NC suppliers. Haas CNC’s have dedicated keypads with a full array of keys including a complete alphanumeric keypad with all common functions clearly labeled for operator use. Operators don’t need to remember any encrypted codes. As computer technology advances, Haas makes their controls even faster and smarter. Their goal is to keep the spindle turning which keeps the cash flowing into your pocket. Haas is known for their easy-to-learn controls.

The primary operating system for Mazak CNC’s is the Mazatrol, which was first introduced in 1981 and has since been developed into an advanced connected digital platform. In 2014 Mazak introduced the CNC Mazatrol Smooth controller and now offers five versions of their controllers for various applications. They are known for their technology which optimizes machining speed and accuracy with numerous advanced features. From position-controlled hobbing, to fast rotary axis speeds and variable acceleration controls as well other features to shorten cycle times, Mazaks are excellent for high-production shops and/or product lines with complex features in competitive markets. Mazak offers multiple software solutions and boasts the ability to connect and secure there CNC’s of all ages. This makes it possible for you to buy a used Mazak CNC machine and still take advantage of newer software solutions. For example, the Mazak SmartBox, developed in 2015 together with Cisco, provides security, analytics and machine monitoring which is backward compatible with older Mazak machines. Mazak also provides many automation accessories to CNC machining such as bar feeders, gantry loaders and articulating robots. Newer CNC’s are available with digital solutions including MTConnect, which is a key component ofMazak’s iSMART Factory conceptsince 2015.

Haas provides extensive online resources for training and support. They have troubleshooting guides, how-to procedures, mill operator manuals and lathe operator mills readily available on their website. You can watch videos for troubleshooting as well as service and maintenance and get regular tips on how to best operate and care for your Haas machines. In addition, operators can search from alarm codes for all kinds of resources. They also have an extensive network of service technicians at their Haas Factory Outlets and recommend that certain machine repairs be done only by authorized personnel.

Mazak customer service support is provided in the USA by over 350 factory-trained Mazak service representatives. You can find your support resource easily on their website or by calling them. Mazak offers free phone technical support – so you can directly call the company for help, not just your local support resource. For their software, Mazak machines are supported with free software upgrades for life as well as diagnostic software support direct from the company.

Be informed. When you buy a used Haas or Mazak machine, you’re going to need to do more research than when buying a used CNC. Start by making a list of your requirements. You should consider the:Types of materials you want to machine – Are the easy or hard to machine?

You may want to buy a similar CNC to a Haas or Mazak that you already have, or you may want to look for one that is newer, so you can begin to connect everything via ethernet or Wi-Fi to take advantage of software innovations.Ask for good photos. Zoom up in the photos and look for signs of damage and worn components.

Ask for the maintenance records of the specific Haas or Mazak that you are considering. Repair work isn’t a bad thing, in many cases, it will help you know what been replaced, what hasn’t and if it was done right. Ask for as much documentation as the seller can provide. This will help you in case you have problems at later date and provide you with details for buying parts. One advantage of buying a used Haas or Mazak is that since these machining centers are relatively common, finding parts shouldn’t be too difficult.

Machining Overview5-sided vs. Simultaneous 5-axis There are pros and cons to both 5-sided machining and 5-axis machining. 5-sided (3+2) Simultaneous 5-axis (full 5-axis) Simple to program Cuts faster Fewer concerns about tool interference Excellent roughing strategy Better surface finish Longer tool life Allows tool to reach difficult places smoothly Impressive but slow – avoid if possible Basics of axis configuration http://www.youtube.com/watch?v=NAjuZnNKEnM To understand machine configurations, it’s important to understand the basic terminology of 5-axis machining centers. If you think in terms of a 3-axis machining center, it has an X-axis, Y-axis, and Z-axis. With a 5-axis machining center, the additional rotary axes will rotate about two of those three primary axes. The axis that rotates about the X-axis is called the A-axis. The axis that rotates about the Y-axis is called the B-axis. The axis that rotates about or under the Z-axis is called the C-axis.

Machine ConfigurationsDedicated 5-axis machining centers There are three types of machine configurations for 5-axis machining. Integrated trunnion table Swivel head with rotary table Traveling column Why / a swivel head with rotary table 5-axis machining center BC rotation axes configuration Heavier Parts: Because the table is stationary, the swivel head/rotary table machines are used with heavier parts. Versatility. You can add a vise for greater versatility because of the large table size. Use the extra space to finish the sixth side of the part or do 3-axis work. Minimizes tool interference Because the swivel head tilts the tool, you don’t need to worry about tool interference with the machine’s spindle head. Better chip control With the swivel head/rotary table configuration, you can run the machine horizontally and gain better chip control. Geographical preference The swivel head/tilting rotary table configuration continues to be more popular Germany and throughout Europe than the United States and Canada. Why / integrated trunnion table 5-axis machining center AC rotation axes configuration Better undercut capability The trunnion rotates +/-110 degrees versus the +/-92 degree rotation on a swivel head/rotary table design. Larger work volume compared to swivel head rotary table 5-axis machine because you don’t have to…

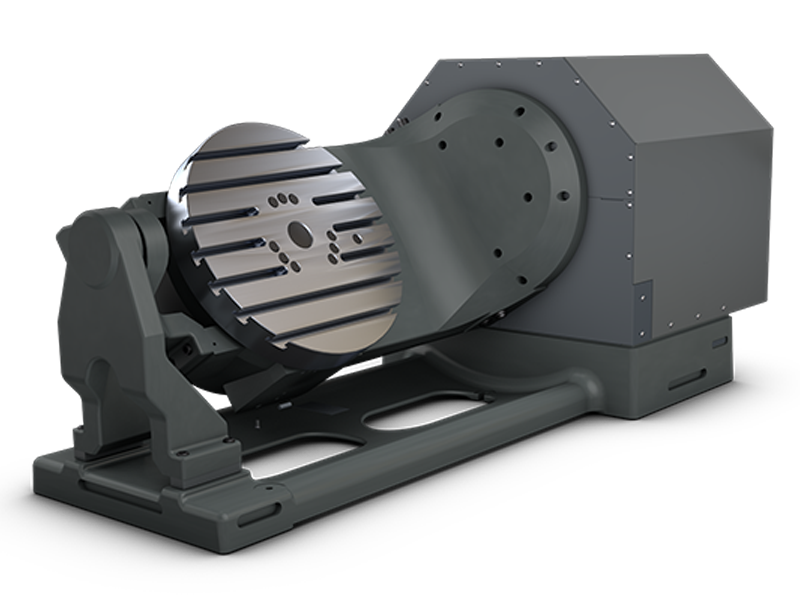

Tilt Rotary TablesTilt-Rotary Tables For some shops, adding a tilting rotary table to their 3-axis machining center is an economical solution to achieve 5-axis capabilities. There are some limitations to consider. Because the tilting-rotary tables are quite large, they monopolize most of the 3-axis machining center’s work envelope. The relatively small work surface means it should only be used for small parts (12 inches or less) and should not be used for heavy cutting operations. Additionally, you need to make sure the control of your 3-axis VMC is 5-axis capable.

HRT 210M only. 5 HRT A5 only. 6 HRT A6 only. 7 Not compatible with AC brushless models. All prices subject to change without prior notice. 15% restocking charge on all returns/exchanges.

8613371530291

8613371530291