haas hrt 210 rotary table factory

For holding medium to large parts or fixtures, the HRT Series T-slotted rotary tables are the answer. The HRT210-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times parts must be loaded. Chucks and fixtures can easily be bolted to the platters using the six precision T-slots, and large through-holes allow for bar feeding and special fixture-locating requirements.

Note: Cannot be operated lying on its back. Requires a Haas mill with 4th-axis drive and NGC software version 100.19.000.1100 or later for full 4th-axis operation. Stand-alone operation requires a Haas rotary control box shipped afterNovember 10, 2021, with software version 26.32 or newer.

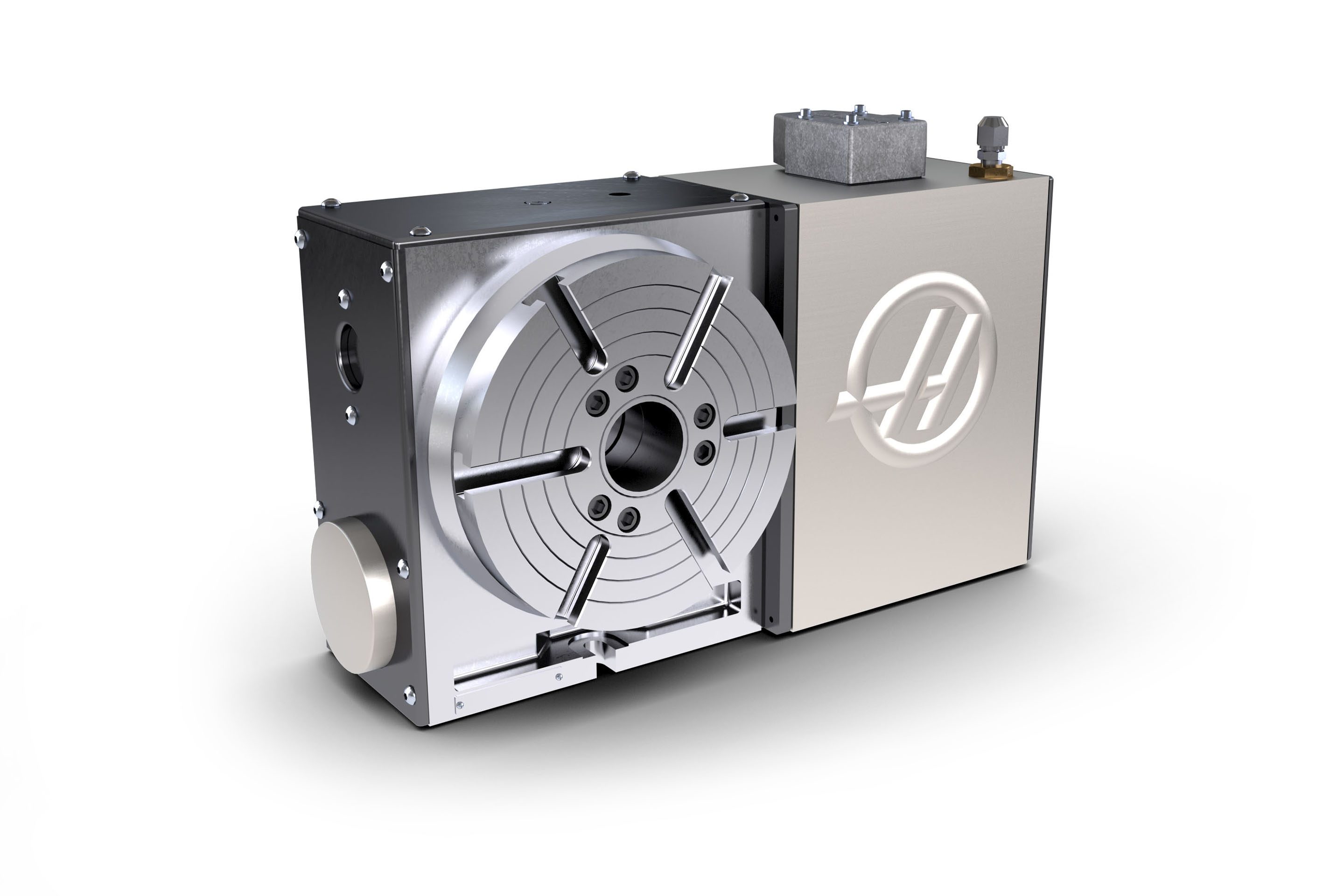

Motor is mounted to the right side on this device and leaves the total through hole capability should you want to machine long bar components that need to be mounted through the centre hole of the table. If this device style may be an issue due to width of the unit, such as collision with machine doors with Y axis travel forward, you should look at rear mounted motor versions. In selecting a side mount motor version you should consider the Y axis travel of the machine and if there would be any interference between the guard of the rotary table and the doors of the machine, particularly when referencing the machine as a lot of VMC machines reference with the Y axis travelling to the front of the machine, towards the operator. Additional equipment available for this device would be a 160mm or 200mm 3 jaw chuck and backplate and matching tailstock. Carrying capacity vertically unsupported 100kg or 200kg with matching tailstock. Net weight 75kgThrough bore 50mmMaximum speed 16. 6 rpmOne only in stock, strictly subject to prior sale – contact technical sales for any further assistance. ;The model number relates directly to the faceplate diameter. The Haas HRT models can be used in vertical and horizontal applications, the motor is mounted to the right side of the device and therefore can be laid on its back. The Haas HRT-210 is a full contouring 4th axis device. Can be controlled directly from the machine tool control or via a separate programmable box via M signal start (not included). All Haas products can be prepared to suit any machine interface and connection, regardless of machine make, model or control type. Please contact our technical sales team should you need further information. This product comes with a 6 month ;warranty covering parts and labour. Please note: ;This device ;can take 2 to 3 weeks to prepare for a specific interface.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

The Haas HRT-210 is an exclusive part of our Rotary Tables inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HRT160SS is a high-speed cycloidal drive rotary table that provides a maximum speed of 500° per second – nearly four times the speed of the standard HRT160. The compact size and high speed of the ...

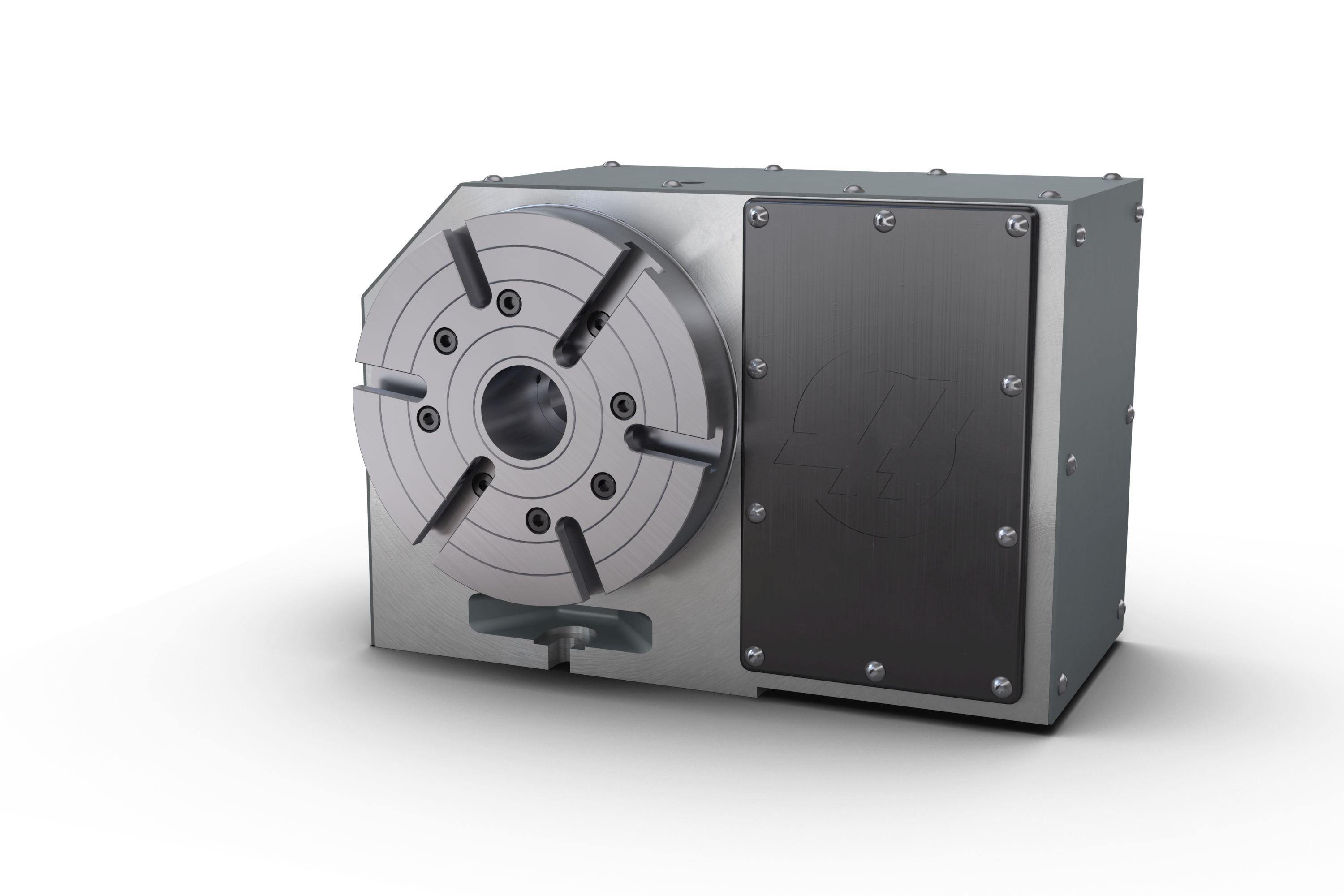

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

... fixtures, the HRT series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

For Example: When a rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. We have labeled this particular rotary and mill combination with a yellow caution

You can design and build your own sub-plate using the dimensions of your Haas mill and the dimensions of the rotary you"d like to use on that mill. Product dimensions are available for every machine and rotary on this website.

While the Stallion Trunnion Table can be designed and manufactured for any CNC rotary table on the market, we have more experience making fixtures for HAAS rotary tables than any other brand. We are often faced with limitations due to machine table size, machine travel and rotary table capabilities. In this post we are running through potential 4th axis applications specifically for your HAAS rotary tables and how they resolved certain limitations.

In our first workholding solution, we are featuring the HRT-210 and the Stallion 9/23. In this case, we were faced with a job that included many parts at many different sizes. With that said, we knew we needed to use a modular workholding system that would allow us to machine parts at many different lengths. The solution: Triag International Workholding. This vise system features a base rail that allows for the clamping modules to be moved to different positions, which creates immense setup flexibility as the Triag product can be used for a wide variety of parts. The deck of the trunnion table has a two inch grid pattern with hardened bushings in every other hole, which works seamlessly with the triag rail and power clamps. On the support end of the fixture resides our TS400PNU braking system. At over 400 ft. lbs of clamping torque, this pneumatic brake keeps the trunnion table extremely rigid when making heavy, off center cuts to the workpiece. While this animation instead features a KOMA Precision Rotary Table, it displays this concept perfectly:

The second setup features the HRT-160 and the Stallion 9/20 Trunnion Table. One of our most often faced obstacles in fixture design is making sure that the customer"s parts can be rotated 360 degrees. The HRT-160 has a center height of just 5 inches, which prompted us to provide a 1" riser block for this customer"s rotary table while simultaneously adjusting our outboard support center height to match this 6 inch mark. This adjustment allowed for our customer"s parts, along with the 5th Axis V552 vises, to be rotated 360 degrees. This design also features our TS1200 Hydraulic braking system, which has 500 ft. lbs of clamping torque at 100 PSI. Similarly to the TS400PNU from the previous setup, this feature is designed to allow for heavy, off center milling and drilling of the customer"s workpiece.

Our last fixture highlighted in this post features a HAAS HRT-310 with a Stallion Triangle Trunnion Table attached. This design again features the Triag International Rail and Power Clamps. The triangle configuration offers the immense benefit of tool clearance. Because the trunnion table features three sides on 60 degree angles as opposed to four sides on 90 degree angles, there becomes less concern about investing in longer tools. The bolt-hole pattern on the end plate of the fixture is customized for the HRT-310, allowing the manufacturer to easily insert and remove the trunnion when necessary, Additionally, the entire assembly resides on a baseplate, which results in a very short and simple setup time.

8613371530291

8613371530291