haas hrt 210 rotary table pricelist

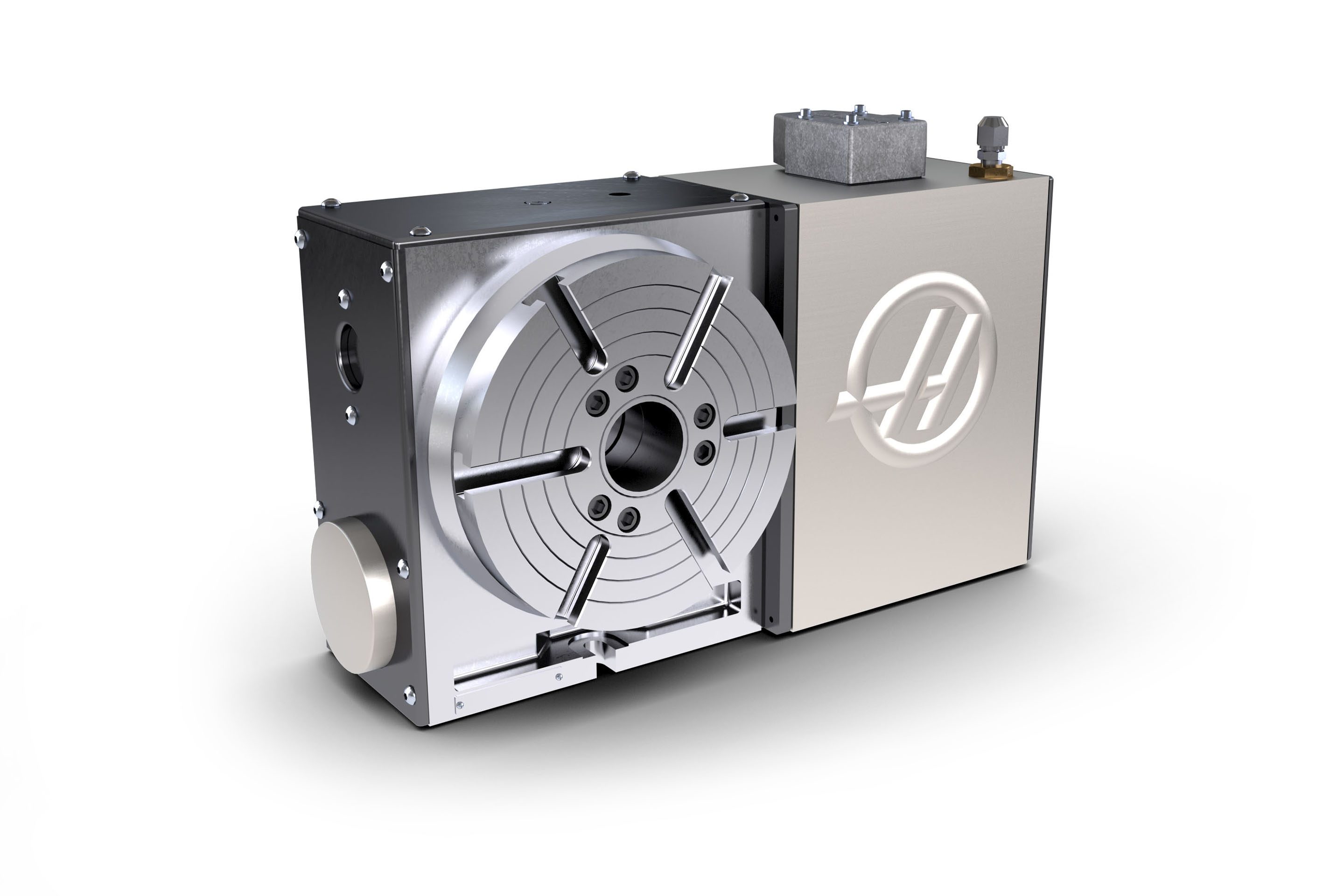

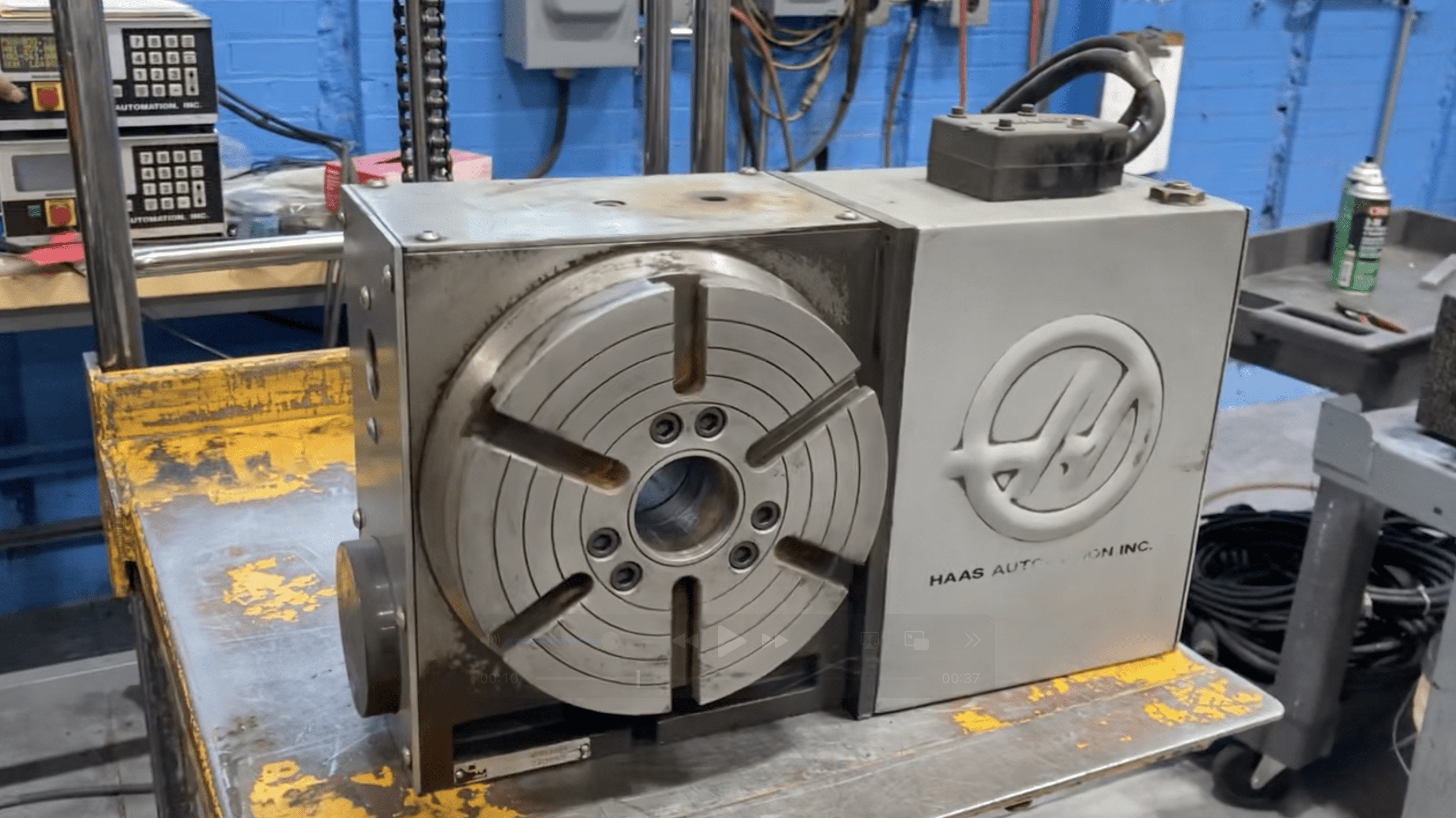

For holding medium to large parts or fixtures, the HRT Series T-slotted rotary tables are the answer. The HRT210-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times parts must be loaded. Chucks and fixtures can easily be bolted to the platters using the six precision T-slots, and large through-holes allow for bar feeding and special fixture-locating requirements.

Note: Cannot be operated lying on its back. Requires a Haas mill with 4th-axis drive and NGC software version 100.19.000.1100 or later for full 4th-axis operation. Stand-alone operation requires a Haas rotary control box shipped afterNovember 10, 2021, with software version 26.32 or newer.

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HRT160SS is a high-speed cycloidal drive rotary table that provides a maximum speed of 500° per second – nearly four times the speed of the standard HRT160. The compact size and high speed of the ...

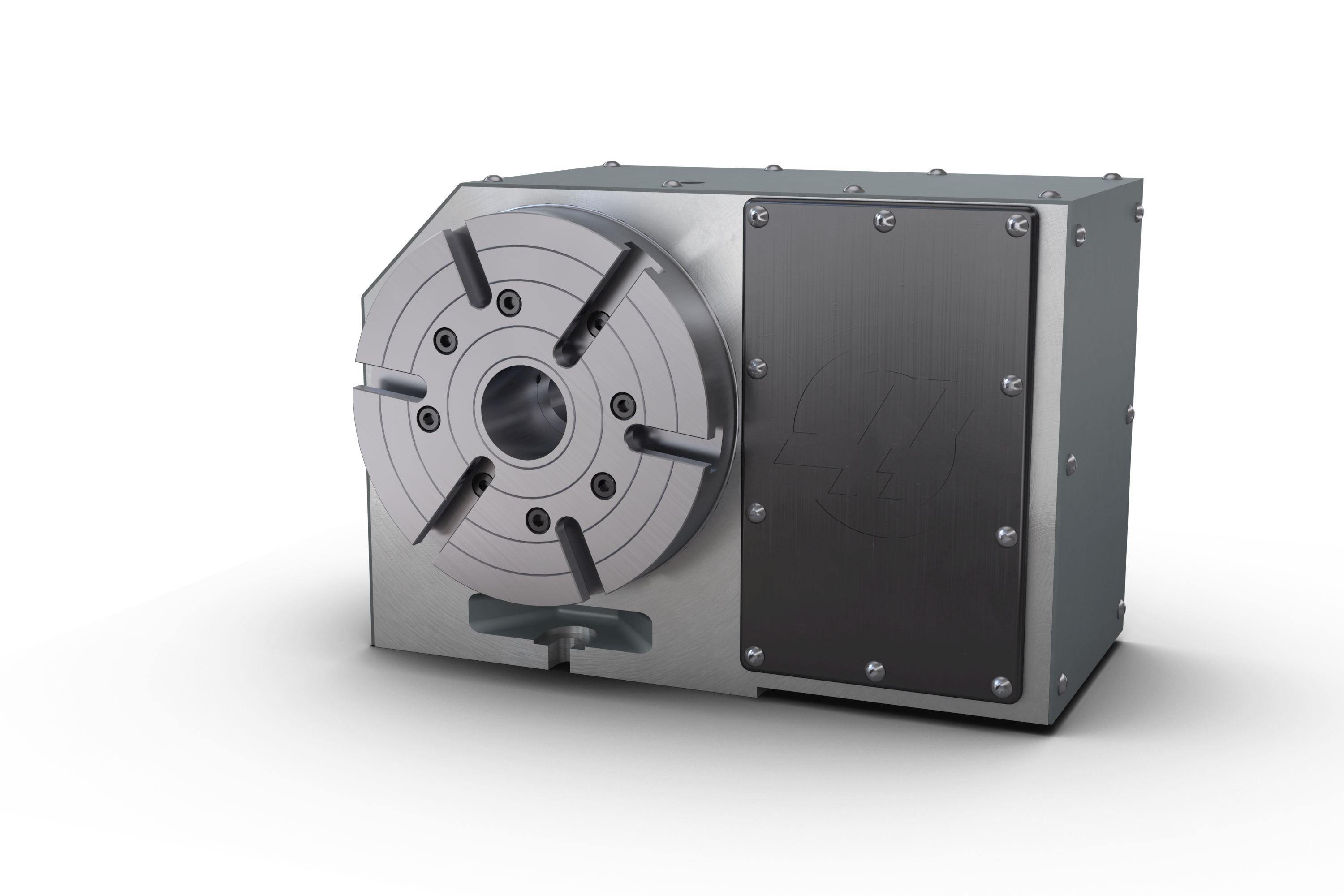

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

... fixtures, the HRT series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

Haas Automation is the largest machine tool manufacturer in North America, building a full line of CNC vertical and horizontal machining centers, CNC lathes, rotary tables and 5c indexers. Haas machine tools and rotary products are built to deliver higher accuracy, repeatability and durability than any other machine tools on the market.

From its beginnings in 1983, Haas Automation has always produced top-quality products at affordable prices. Haas produces all critical components in-house, using dedicated state-of-the-art cnc machine tools. the company"s 1 million-square-foot facility makes extensive use of automated lights-out flexible manufacturing systems (FMS) and robotic loaders to streamline production capabilities and reduce costs. This, combined with highly trained electronics and mechanical assembly teams, allows Haas to control quality, cost, reliability and availability. Haas delivers more standard features, high-tech innovations and rock-solid engineering than perhaps any other CNC manufacturer in the world and at better prices.

DESCRIPTION:30” X 16” X 20” CNC Vertical Machining Center with Haas CNC Controller, HRT 210 Rotary table with Tail Stock, 24 Position Side Mount Tool Changer, 7500 RPM, 2 Speed Gear Box Driven Cat 40 20HP Spindle, Probing and 300 PSI Thru-Spindle Coolant.

INCLUDES: HRT 210 Rotary table with Tail Stock, 24 Position Side Mount Tool Changer, 7500 RPM, 2 Speed Gear Box Driven Cat 40 20HP Spindle, and 300 PSI Thru-Spindle Coolant, Tool and Part Probing, High Intensity Lighting, Remote Jog Handle, Chip Auger, Rigid Tapping and 1 MB Program Memory

HRT 210M only. 5 HRT A5 only. 6 HRT A6 only. 7 Not compatible with AC brushless models. All prices subject to change without prior notice. 15% restocking charge on all returns/exchanges.

For holding small to large parts or fixtures, the HRT series of horizontal/vertical rotary tables is the answer. Available in sizes from 110 mm to 600 mm, these rugged, heavy-duty rotary tables can accomadate parts and fixtures weighing up to 1,475 lb. Chucks and fixtures can easily be bolted to the table using the six precision T-slots. Large through-holes allow bar feeding and special fixture locating.

Super High-Speed, High-Speed, High-Accuracy, Compact-Housing and Dual-Platter versions are available. A1 Spindle Nose versions are also available. Contact us for more information on the HRT series rotary table best suited for your application. (***) 718-6734

The Haas HRT210SHS is a compact, super high-speed horizontal rotary table for light-duty machining of small to medium parts. Nearly six times faster than the standard HRT210, the super high-speed version greatly increases productivity with rapids to 360°/sec and feedrates to 270°/sec. This version features a wrap-around motor, like the compact SP series, making it ideal for applications requiring several indexes within limited workspace.

There are two ways to order Haas rotary products: with a servo control unit (see stand alone), or without. Every Haas rotary product can be used on both Haas CNC machines and other brands using a Haas servo control unit. When ordering a Haas rotary product for use on a Haas machining center with built-in 4th and/or 5th-axis drive, it is not necessary to purchase the configuration that includes a servo control unit. However, it is suggested you purchase the servo control unit with your rotary unit so you can use your rotary unit on other machines or independently.

Haas rotary products with model numbers ending in "-B" include a brushless servo control unit. This rotary option, referred to as "Stand Alone" configuration, can be used on any make of machine as a semi-4th axis, or independently, using the included servo control unit. The rotary unit will also plug directly into Haas CNC machines with brushless AC drive(s).

Haas rotary products with model numbers ending in "-CNCB" do not include a servo control unit if it is a single-axis rotary product. A servo control unit is included with dual-axis rotary products. This rotary option, referred to as "CNC Configuration", is designed to be used on Haas CNC machines with brushless AC 4th-axis drive. The rotary unit is programmed through the Haas machining center"s control, providing true 4th-axis capabilities. Dual-axis rotary units use the included servo control unit to program the secondary axis. CNC Configuration rotary products can be used on a Haas CNC machine with brush DC 4th-axis drive by installing a brush-to-brushless conversion kit. Contact us for more info.

Haas rotary products with model numbers ending in "-5XB" are dual-axis rotary products that do not include a servo control unit. This rotary option, refered to as "Five Axis Configuration", is designed to be used on Haas CNC machines with, both, a brushless AC 4th-axis amplifier and brushless AC 5th-axis amplifier. The dual-axis rotary product is programmed through the Haas machining center"s control, providing true 4th and 5th-axis capabilities. Five Axis Configuration rotary products can be used on a Haas CNC machine with brush DC 4-axis and/or brush DC 5th-axis drive(s) using a brush-to-brushless conversion kit(s).

All warranty work is provided at Haas Automation, Inc. in Oxnard, California. The user is responsible for first obtaining an RMA number, and then returning the unit directly to Haas Automation"s factory. When warranty work is complete they will return the unit, freight pre-paid, via ground service. Allow 10 working days for repairs. Faster turn-around is available at additional cost.

Haas Rotary Products are built-to-order. Average lead time on Haas rotary units is 4-6 weeks. Average lead time on Haas rotary accessories is 1-2 weeks. Actual turn-around time varies depending on the item ordered. Please contact us for availability prior to placing your order.

You are encouraged to contact us prior to placing an order. We are here to help you choose the best Haas rotary solution for your needs. Please note that any suggestion to set up your application is based on the information you provide to us; we can not truly know your application. The user is solely responsible for properly sizing the rotary product to the work required and ordering the correct rotary product.

With 20 years in business, we understand some times machine shops must prepare for those just-in-case jobs. Whether you are tooling-up to take advantage of a tool budget or preparing for a possible contract, its safe to place your order with us. Machinery Exchange, Inc. offers an exclusive 30-day return privilege on all Haas rotary products. You have 30-days from the date of receipt to return or exchange the new, unused item in its original packaging. Returned items showing any signs of use will not be accepted.

Haas Automation, Inc. has set the industry standard in precision and performance. We are proud to offer their complete line of rotary products and back them as the best in the industry. The accuracy of Haas Rotary products is measured in an unloaded condition, without any attachments. It is important to note that your indexing accuracy results can be affected by a number of things, including the fixtures used, the size and weight of the part, off-center parts, outboard supports, tailstock pressure, off-axis drilling and milling, inadequate or uneven fixture mounting surfaces, out of alignment (TIR) tailstocks or supports.

SOLUTION FOR EVERY PART Haas high-precision rotary products provide powerful 4th- and 5th-axis capabilities for every shop – boosting productivity through affordable, plug-and-play simplicity. MEDIUM TO LARGE PARTS When you need to hold medium to large parts for multi-side machining or complex contouring, the Haas HRT Series rotary tables are the perfect solution. These rugged, heavy-duty rotary tables can be mounted vertically or horizontally, and they feature precision T-slots and large through-holes for versaltile fixturing AVAILABLE ROTARY TABLE MODELS SMALL MEDIUM LARGE HRT100 HRT210...

REDUCE SETUPS AND INCREASE ACCURACY Five-axis machining is the fastest way to reduce setups, boost throughput, and increase accuracy on complex PLATTER SIZE parts. And Haas plug-and-play dual-axis rotary tables and indexers make 5-axis machining easier than ever, allowing you to reduce or totally eliminate multiple setups, and easily handle multi-sided parts. POWERFUL 5-AXIS SOLUTIONS FOR 3-AXIS MILLS AVAILABLE DUAL-AXIS MODELS TRUNNION TILTING ROTARY TILTING INDEXER Haas dual-axis rotary tables and indexers are the perfect bolt-on solutions for machining complex parts. These dual-axis...

ROTARY CONTROL All Hass rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4- or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy of understand. For standalone rotary operation, we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable. ROTARY FIXTURING CHOICES Haas offers a wide selection of workholding...

In 1988 Haas introduced the VF-1, a machine designed by machinists for machinists Since the VF1 Haas has continued to provide CNC mills for numerous applications. Today Haas Automation is the leader in North American CNC machine sales. In the world of CNC, Haas is so popular that "Haas CNC For Sale" is the most searched for CNC-related term in search engines today.

Haas CNC are made in Oxnard, California, USA, and has become the most trusted brand in the industry. As of 2018, they continue to sell thousands of machines each month and even have backlogs in their delivery because of the demand and momentum in the United States. One of the most popular models made by Haas is the Haas VF2. The Haas VF2 on haascnc.com. The VF2 has remained so popular, that they"ve made the same model for over 10 years. Haas is a great brand for companies looking for economical machines that they would like to support themselves. Haas supports its customers with online resources to encourage shops to maintain and repair their own Haas CNC as much as is reasonable.

The Haas control makes Haas CNC easy to operate. Even models going back to the year 2000 had Haas-only features like Word Processor Editing to help operators easily make changes. On their milling machines, they had features like one-touch, multi-function jog-handle and quick code programming even on machines made 18 years ago. They provide a robust dependable control that is integrated with the Haas CNC machine. They do not rely on third-party CNC suppliers. Haas machines have dedicated keypads with a full array of keys including a complete alphanumeric keypad with all common functions clearly labeled for operator use. Operators do not need to remember any encrypted codes. Keep in mind, if you are buying an older Haas, its very likely that the control can be updated. Haas supports their equipment no matter what the age and provides updates to all Haas CNC machine owners.

As computer technology advances, Haas makes itscontrols even faster and smarter. Their goal is to keep the spindle turning which keeps the cash flowing into your pocket. Contact your local Haas distributor or visit the Haas website for information on updating an older Haas machine. Newer models have: HaasConnect Remote Monitoring, Ethernet connectivity, DWO/TCPC (Dynamic Work Offsets and Tool Center Point Control), User-Definable Macros, WiFi Connectivity, and Expandable Memory.

You will find the used Haas mills are sold as VF Series, as universal machines (UMC), Haas mini mills (MINI MILL) and drill/tap/mill (DT & DM). There are also machine series designed for specific applications, like the mold machines (VM) and tool room mills (TM). For small parts in tight spots, the compact CNC vertical mill (CM) may fit the bill. For the largest applications, cutting plate and sheet Haas offers the Gantry series (GR). The Haas VR Series ended in 2013 but is still widely available used.

Haas VF Vertical Mill VF1, VF1YT, VF2, VF2TR, VF2YT, VF2SS, VF2SSYT, VF3, VF3SS, VF3SSYT, VF3YT/50, VF4, VF4SS, VF5, VF5/50, VF5XT VF5SS, VF6, VF6/50, VF6SS, VF7, VF9, VF10, VF11, VF12 1990 - 2019

Horizontal mills have the spindle on the horizontal axis and are used for making much larger parts than the vertical milling machines. Differentiators between various Haas horizontal machines are similar to those of vertical milling machines. Size, spindle speed, horsepower and the design of the tool changing system all make an impact on the speed and complexity of part that can be made on horizontal milling machines. Haas offers the EC series which can make parts up to 10,000 lbs. Haas offers two basic sizes of horizontal milling machines, 64 x 50 x 32 and 64 x 50 x 40. The additional 8 is on the ZT variation of their EC. Look for EC-1600, EC-1600ZT or for both 5 Axis and the extra size, the EC-1600ZT-5AX.

Haas makes a full line of Used Haas lathe turning centers (CNC lathes) including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis models and Y-axis capabilities.

Hass offers rotary products that add 4th and 5th axis capabilities to many of their machines. T-slotted rotary tables allow for flexible fixturing for machining round parts and odd-shaped parts. Model numbers for these rotary tables usually begin with HRT. Their 5-axis rotary tables and add a 3+2 position or full 5-axis motion. The models of tilting indexers include the T5C, T5C2, T5C3, and T5C4. The TR70, TRT100, TRT160, and TRT210 are models of tilting rotaries. Prices for these begin around $20,000 for new. Indexers have model numbers like HA5C, HA5C-T, HA5CS, HA5C2, HA5C3 and more. They can be single-spindle or multi-spindle and have new prices ranging from $8,000 to $13,000. When buying used Haas CNC, sometimes you"ll find that rotary table and/or indexers included. If one of these accessories is included, then the price will be proportionately higher in most cases.

Haas provides extensive online resources for training and support. They have troubleshooting guides, how-to procedures, mill operator manuals and lathe operator mills readily available on their website. You can watch videos for troubleshooting as well as service and maintenance and get regular tips on how to best operate and care for your Haas machines. In addition, operators can search from alarm codes for all kinds of resources. They also have an extensive network of service technicians at their Haas Factory Outlets and recommend that certain machine repairs be done only by authorized personnel.

8613371530291

8613371530291