haas rotary table accessories supplier

The Third-Party Rotary provision provides access to the rotary parameters in the Haas control, allowing you to use a third-party single- or two-axis rotary table on your Haas machine. The option supports full simultaneous machining up to 5 axes, and is compatible with Dynamic Work Offsets and Tool Center Point Control. It is the responsibility of the customer and the third-party manufacturer to troubleshoot and fine tune the different parameters. Requires the purchase of the 4th-Axis Drive option to operate a single-axis rotary, or the purchase of both 4th- and 5th-Axis Drive options to operate a two-axis rotary.

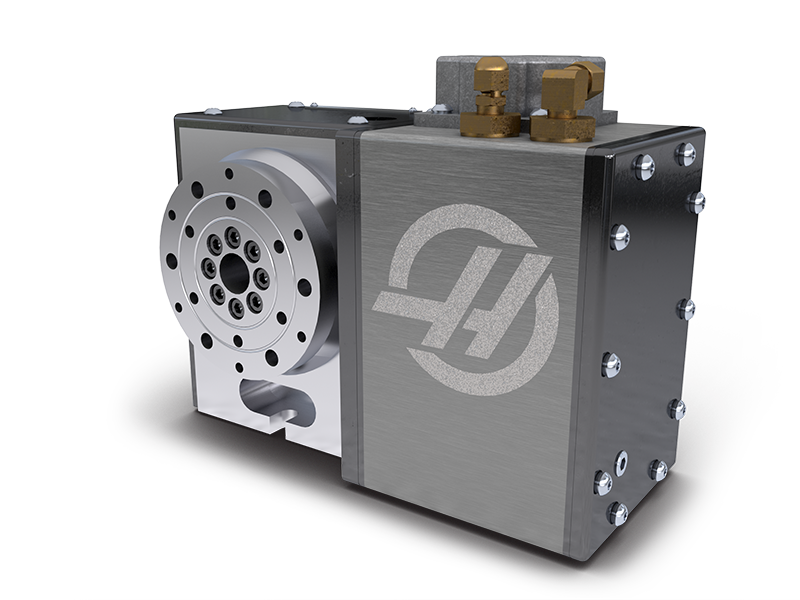

... heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive to deliver a true 4th-axis ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary control box for ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HRT160SS is a high-speed cycloidal drive rotary table that provides a maximum speed of 500° per second – nearly four times the speed of the standard HRT160. The compact size and high speed of the ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

... fixtures, the HRT series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... features and benefits as the standard HRT Series, but the motor is wrapped behind the table to provide a substantially shorter overall length, and help you fit a lot of table into a small work envelope. ...

HAAS TH240 Rotary Table features a Compact Footprint with versatile mounting options. 100 degrees per second max rpm with a 9.45” T-slotted faceplate, 2” thru-hole and 200 ft-lb of Brake Torque. Optional A1-6 Platters available. Requires a Haas mill with 4th-axis drive and NGC control for full 4th-axis operation. For use on a Classic Haas control, or standalone operation please contact us.

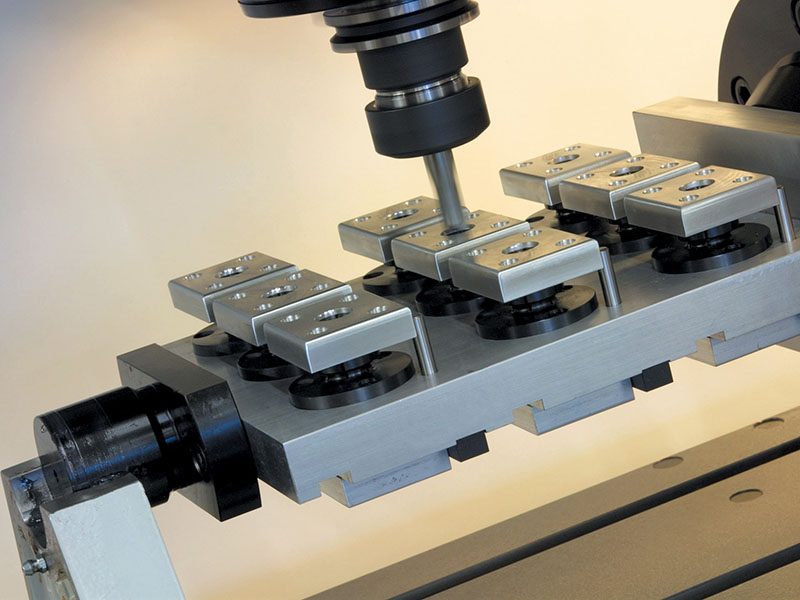

The TBS-210 Haas Tooling Block System is made from 6061-T6 aluminum alloy, and can be machined to meet your requirements. The system includes the aluminum tooling block (tombstone), an outboard A-frame support, and a steel mounting plate. The tooling block measures 12" (305 mm) long x 4.5" (102 mm) square, and is designed for use with HRT210 Series rotaries. The operator can be setting up parts on one tooling block, while parts are being machined on another.

The rotary table have successfully installed and used on various machine tools and CNC systems. such as Fanuc robodrill, Brother, Haas, DMG, Mazak, Makino, Doosan, Hurco, Mikron and so on. its performance can comparable to Nikken and Haas.

Haas Automation is the largest machine tool builder in the western world, manufacturing a complete line of CNC vertical machining centers, horizontal machining centers, CNC lathes and rotary products. The company also builds a variety of specialty machines, including 5-axis machining centers, mold making machining centers, toolroom machines, and gantry routers. Haas machine tools and rotary products are built to the exacting specifications of Gene Haas to deliver higher accuracy, repeatability, and durability than any other machine tools on the market.

Gene Haas founded Haas Automation, Inc., in 1983 to manufacture economical and reliable machine tools. The company entered the machine tool industry with the first-ever, fully automatic, programmable collet indexer – a device used to position parts for machining with very high accuracy. The Haas 5C collet indexer was a huge success, and over the next four years, the company expanded its product line to include a wide selection of fully programmable rotary tables, rotary indexers, and machine tool accessories.

In 1987, Haas Automation began developing its first vertical machining center (VMC), a machine designed to perform such machining operations as milling, drilling, tapping, and boring. This machine, the VF-1, was introduced at a cost that was competitive with machine tools from offshore manufacturers. Employing the latest equipment and procedures for close-tolerance manufacturing, the first VF-1 prototypes were completed in 1988 and introduced at the International Machine Tool Show (IMTS ’88) in Chicago, Illinois.

At that time, industry scholars and members of the trade press were skeptical that an American-made machining center could be sold for less than $50,000. Haas not only delivered on the price, but delivered the product as well, something other manufacturers often were unable to do. Today, the Haas VF-1 still sells for less than $50,000, and in most instances, a customer’s machine can be delivered within just a few weeks of the initial order.

To ensure accuracy, Haas produces all critical components in-house using dedicated state-of-the-art CNC machine tools. The company’s 1-million-square-foot facility makes extensive use the latest lean manufacturing methods and just-in-time production practices to streamline production capabilities and reduce costs. This, combined with highly trained teams for electronics and mechanical assembly, allows Haas to control quality, cost, reliability, and availability. The resulting savings and increased quality are passed on to the customer in the form of lower prices and better products.

Of the nearly 300 chip-making machine tools in the Haas machine shop, more than two-thirds are Haas machines – proof positive that the company believes in its own products. To increase production capacity and capability, new manufacturing equipment is added constantly, allowing Haas to produce more parts more efficiently, and further reduce the cost of Haas products to the end user.

Today, Haas manufactures four major product lines: vertical machining centers (VMCs), horizontal machining centers (HMCs), CNC lathes and rotary tables, as well as a number of large five-axis and specialty machines. All Haas products are manufactured at the company’s expansive facility in Oxnard, California – the largest, most modern machine tool manufacturing operation in the United States.

The largest tool builder in the world, Haas Automation, is an evolving line of American made, accurate and durable machining products, puts us in the position to offer our customers reliability, technology and value. Our alliance with Haas Automation is defined not only by its machining centers but by its outstanding service and applications. As a factory direct distributor, we carry replacement parts for next day delivery and a fleet of fully stocked service trucks providing installation and ongoing service. Our Application Engineers have the experience to help you select the best Haas product for your application provide turnkey solutions and training.

8613371530291

8613371530291