haas rotary table installation free sample

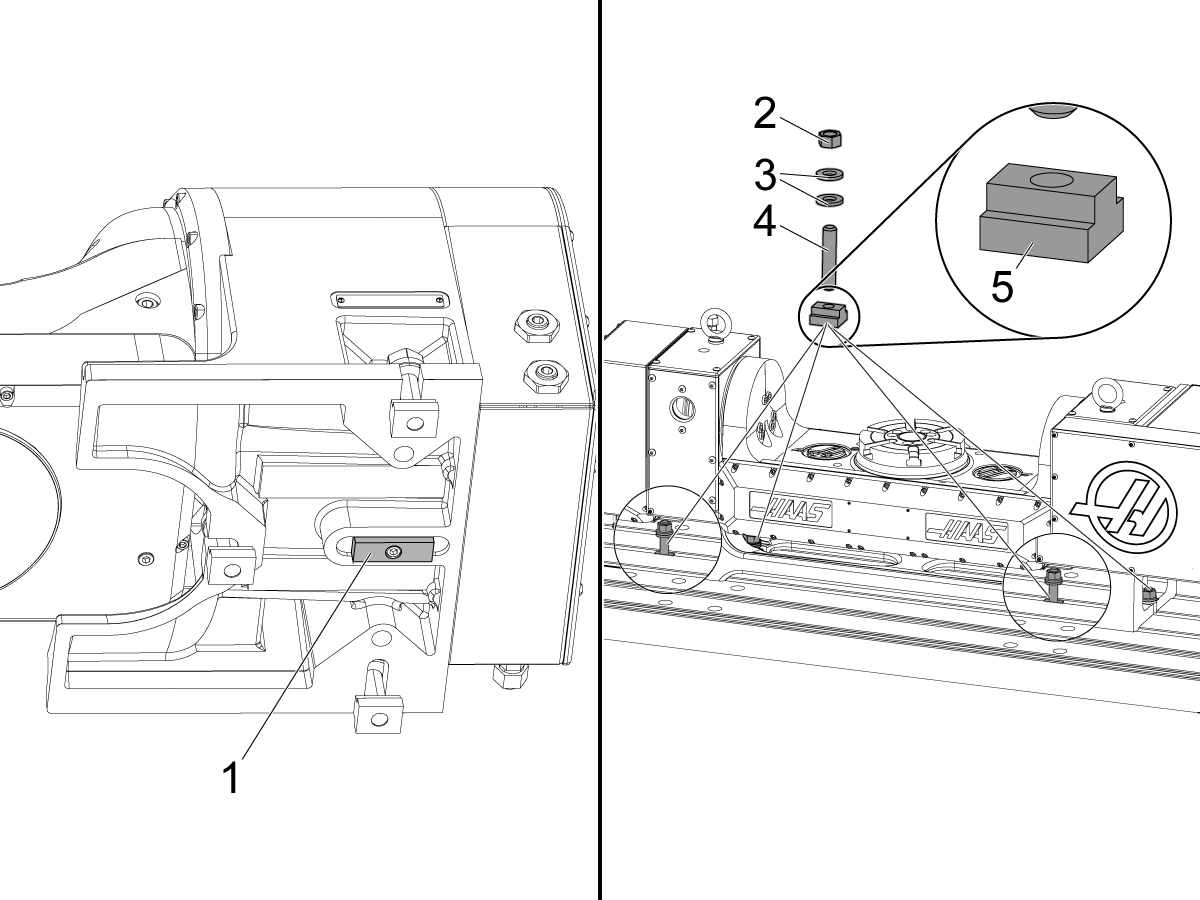

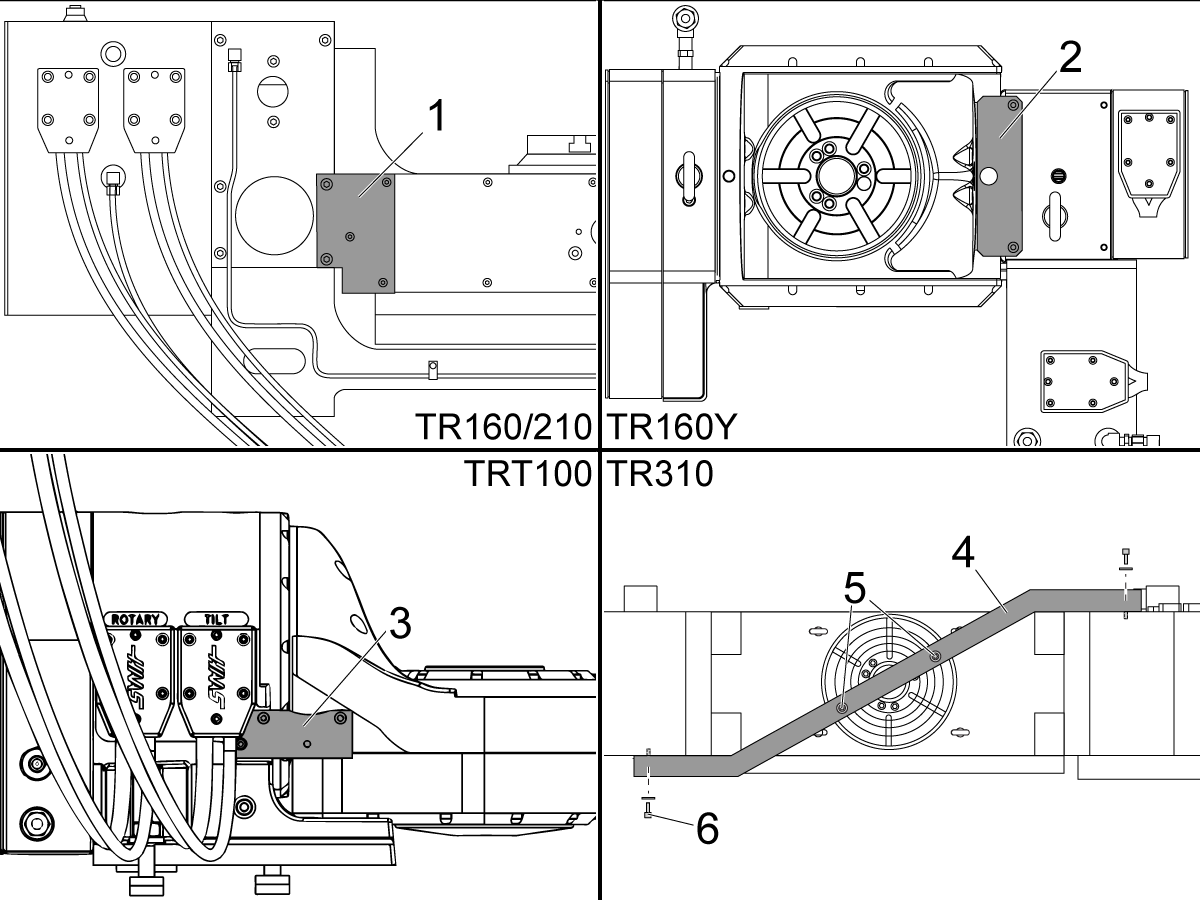

The first part is the model number of the rotary unit [1]. This can be found on the serial plate of the unit. Some Rotary units have a dash in there name, that dash may or may not be in the included in the file name.

The first part is the model number of the rotary unit [1]. This can be found on the serial plate of the unit. Some Rotary units have a dash in there name, that dash may or may not be in the included in the file name.

4. The feedback cables tell the mill that the rotary unit has finished. The relay can be used to FEED HOLD NC machine movements, or can be used to cancel an M function. If the machine is not equipped with this option, an alternative may be to dwell (pause) longer than it takes to move the rotary unit. The relay triggers for all CYCLE START closures, except G97.

This procedure tells you how to set up a custom rotary configuration. Do this procedure to set up a non-Haas rotary in a Haas machine that has the Next Generation Control (NGC).

The Custom Rotary Generator generates a spreadsheet where you input the specific parameters that apply to your rotary. It then generates a custom rotary configuration file. You can then load the rotary configuration file into the machine.

The first part is the model number of the rotary unit [1]. This can be found on the serial plate of the unit. Some Rotary units have a dash in there name, that dash may or may not be in the included in the file name.

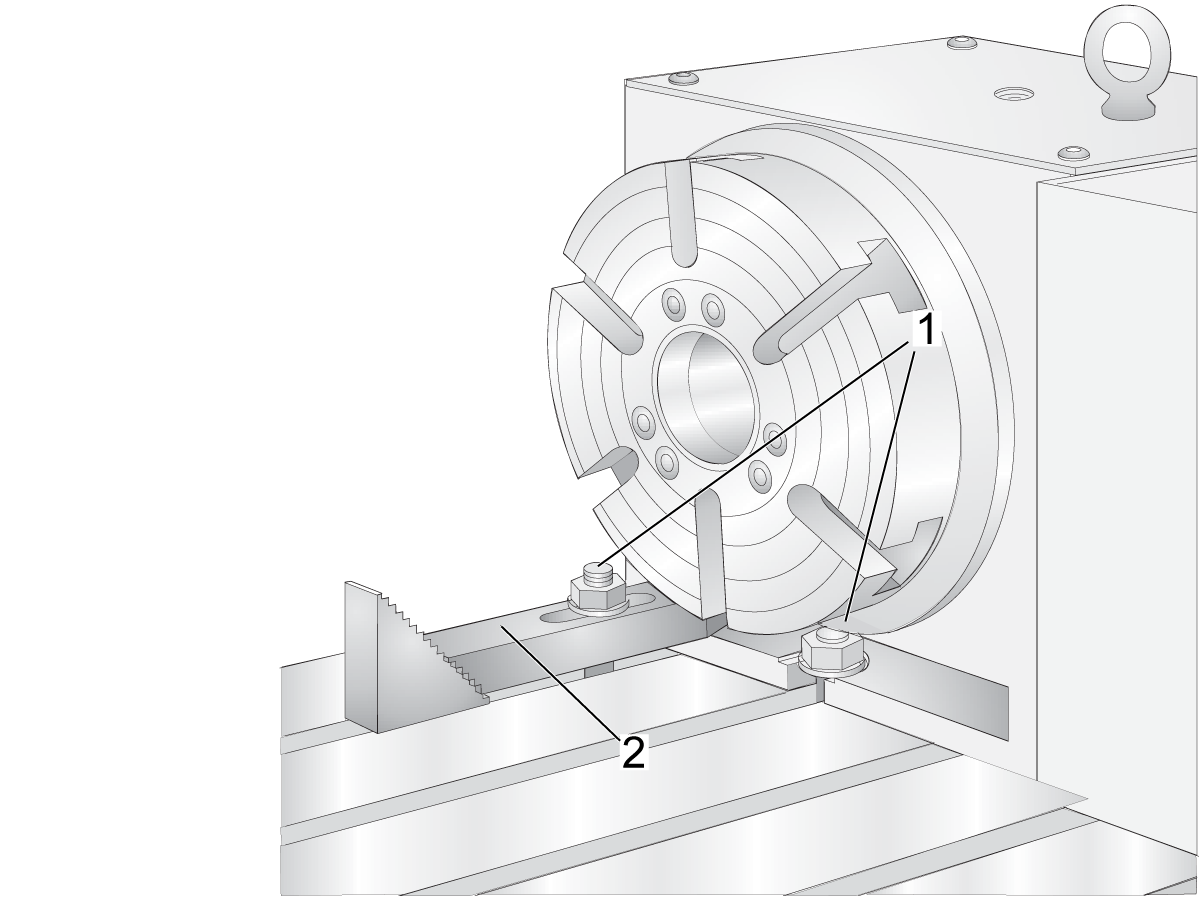

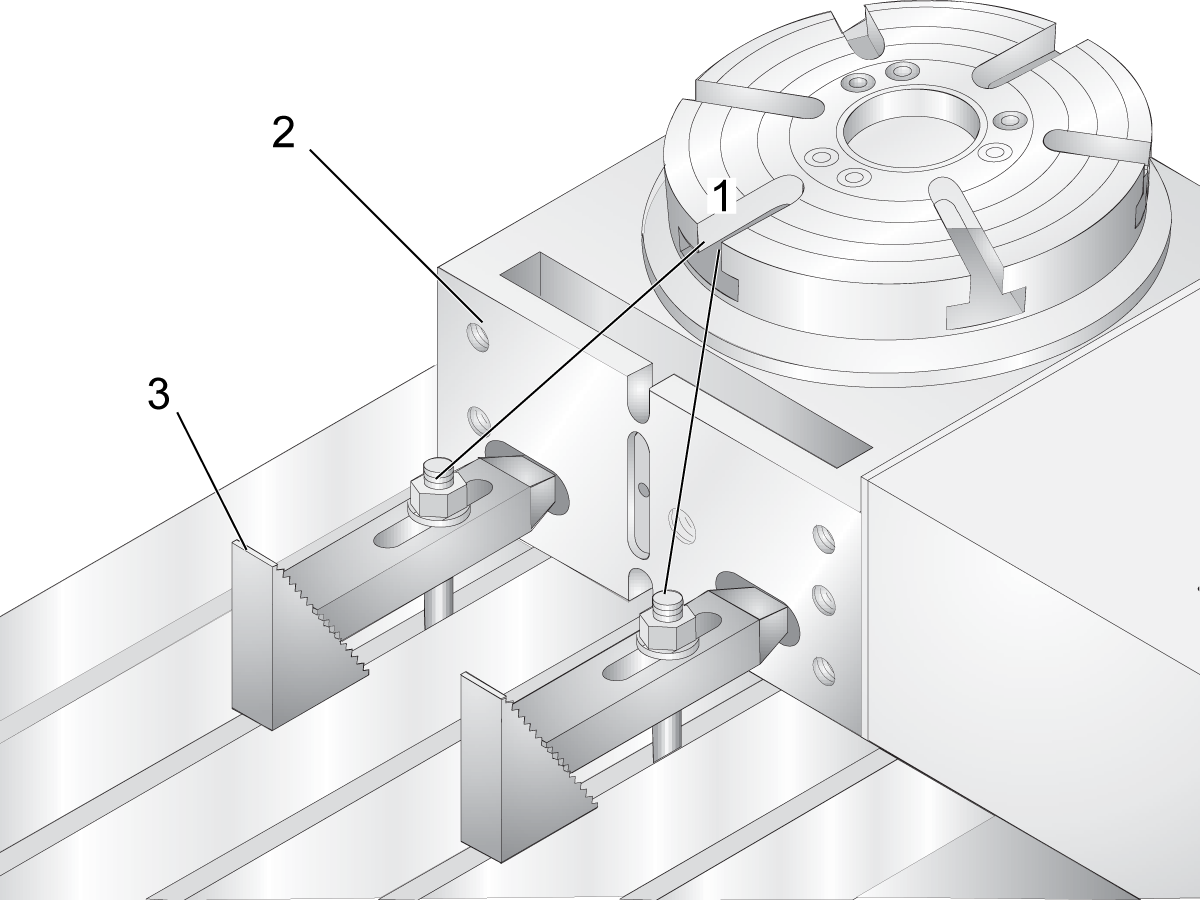

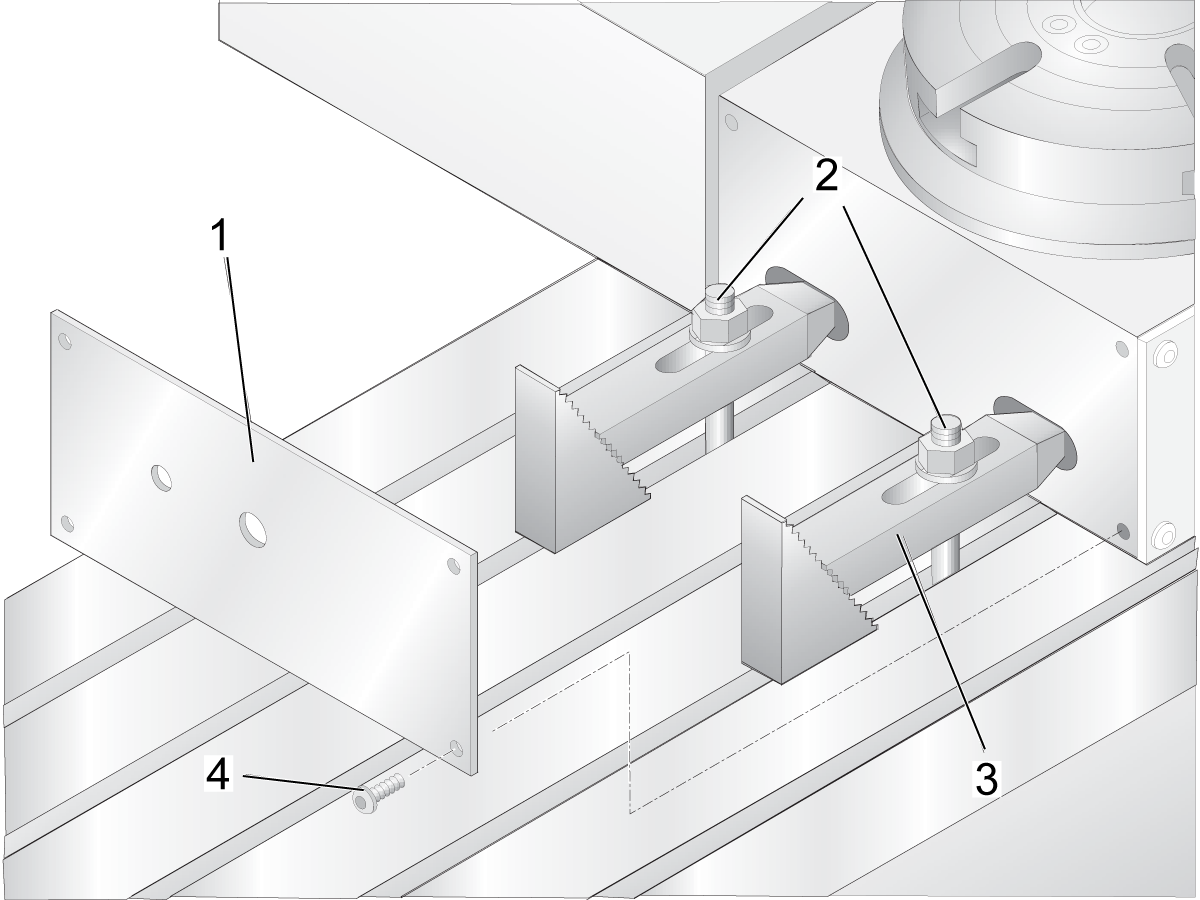

For Example: When a rotary fits with alternative fixturing, it may fit in that particular Haas mill, but will require a sub-plate or alternate T-slot for proper positioning. We have labeled this particular rotary and mill combination with a yellow caution

You can design and build your own sub-plate using the dimensions of your Haas mill and the dimensions of the rotary you"d like to use on that mill. Product dimensions are available for every machine and rotary on this website.

.png)

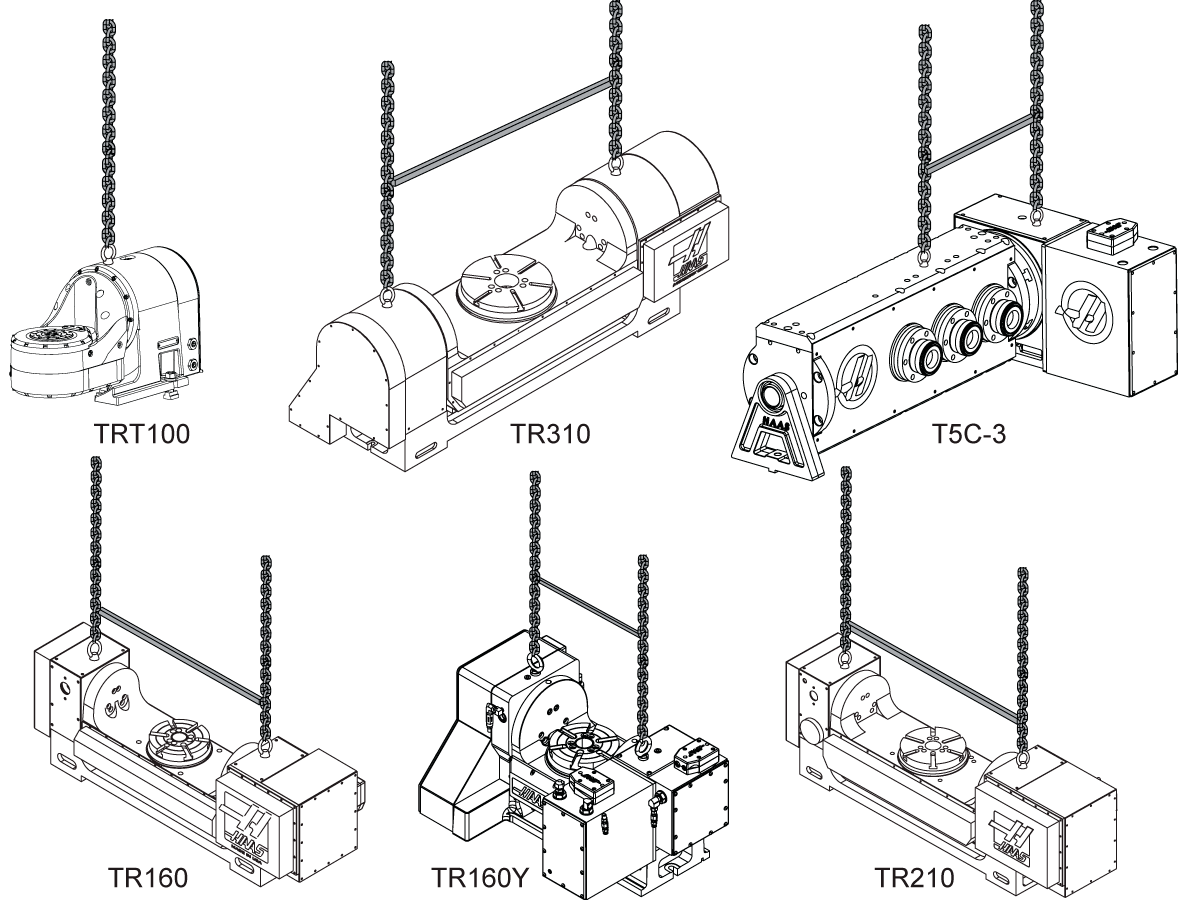

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

8613371530291

8613371530291