haas rotary table installation made in china

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Haas Automation, Inc is an American machine tool builder headquartered in Oxnard, California. The company designs and manufactures lower cost machine tools and specialized accessory tooling, mostly computer numerically controlled (CNC) equipment, such as vertical machining centers and horizontal machining centers, lathes/turning centers, and rotary tables and indexers. Most of its products are manufactured at the company"s main facility in Oxnard.Haas F1 Team and in NASCAR the Stewart-Haas Racing Team.

Gene Haas founded Haas Automation in 1983machine tool accessory tooling. The company entered the machine tool industry with the first fully automatic, programmable collet indexer.

In 1987, Haas Automation began developing its first vertical machining center (VMC), the VF-1, a machine designed to perform operations such as milling, drilling, tapping, and boring. The first VF-1 prototypes were completed in 1988,Chicago, Illinois.

2019: Haas purchases 279 acres of land in Henderson, Nevada for $27.4 million to expand its business, planning to build 4.3 million square feet of commercial space with 2.3 million square feet intended for a $327 million manufacturing facility

The VF in the name stands for "Very First" as the first machine Haas produced was the VF-1 ("Very First One"). One of these machines was restored by an employee, gifted to Gene Haas, and now resides in Haas"s demo room in Oxnard, CA.

The Haas DT series was originally introduced as a 30 taper high-speed machine, ideal for operations where high speed and small footprint are required, but the ability to handle large axial cutting loads is not needed. Eventually, the DM series was introduced as a 40 taper variant of the DT machine, but does not offer the 20,000 RPM spindle option.

The CM is focused on machining small parts where high accuracy is required. The CM is a 20 taper machine, with spindles from 30,000 to 50,000 RPM. Haas only offers one machine in this series, the CM-1.

Haas Automation is an ISO 9001 certified company. All machine tools carry the ETL Listed mark, certifying that they conform to the NFPA 79 electrical standard for industrial machinery and the Canadian equivalent, CAN/CSA C22.2 No. 73.CE mark to its products.

Products are distributed worldwide through a network of independently owned franchised local "factory outlet" businesses that provide sales, service, and applications support for Haas machine tools. Introduced in 1999, with the first outlet established in Torrance, California, it was applied to the company"s existing worldwide network,Europe.

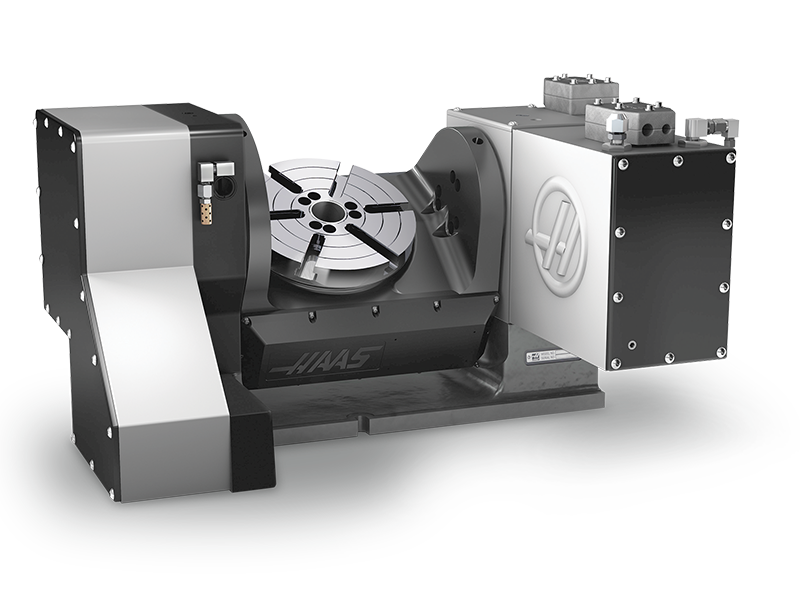

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

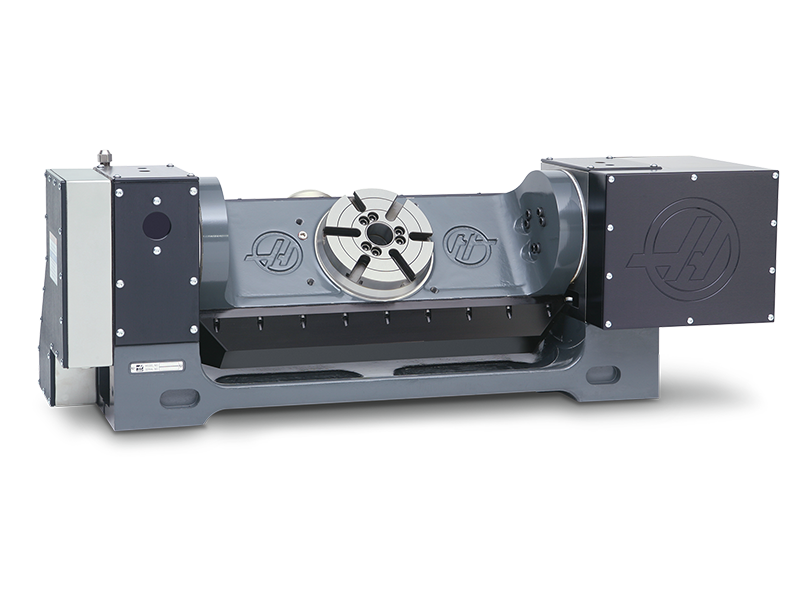

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

Gene Haas founded Haas Automation, Inc., in 1983 to manufacture economical and reliable machine tools. The company entered the machine tool industry with the first-ever, fully automatic, programmable collet indexer – a device used to position parts for machining with very high accuracy. The patented Haas 5C collet indexer was a huge success, and over the next four years, the company expanded its product line to include a wide selection of fully programmable rotary tables, rotary indexers, and machine tool accessories.

In 1987, Haas Automation began developing its first vertical machining center (VMC), a machine designed to perform such machining operations as milling, drilling, tapping, and boring. This machine, the VF-1, was introduced at a cost that was competitive with machine tools from offshore manufacturers. Employing the latest equipment and procedures for close-tolerance manufacturing, the first VF-1 prototypes were completed in 1988 and introduced at the International Machine Tool Show (IMTS 88) in Chicago, Illinois.

At that time, industry scholars and members of the trade press were skeptical that an American-made machining center could be sold for less than $50,000. Haas not only delivered on the price, but delivered the product, as well, something other manufacturers often were unable to do. Today, the Haas VF-1 still sells for less than $50,000, and in most instances, a customer’s machine can be delivered within just a few weeks of the initial order.

To ensure accuracy, Haas manufactures all critical components in-house using dedicated state-of-the-art CNC machine tools. The company’s 1.1-million-square-foot facility makes extensive use the latest lean manufacturing methods and just-in-time production practices to streamline production capabilities and reduce costs. This, combined with highly trained teams for electronics and mechanical assembly, allows Haas to control quality, cost, reliability, and availability. The resulting savings and increased quality are passed on to the customer in the form of lower prices and better products.

Of the nearly 300 chip-making machine tools in the Haas machine shop, more than two-thirds are Haas machines – proof positive that the company believes in its own products. To increase production capacity and capability, new manufacturing equipment is added constantly, allowing Haas to produce more parts more efficiently, and further reduce the cost of Haas products to the end user.

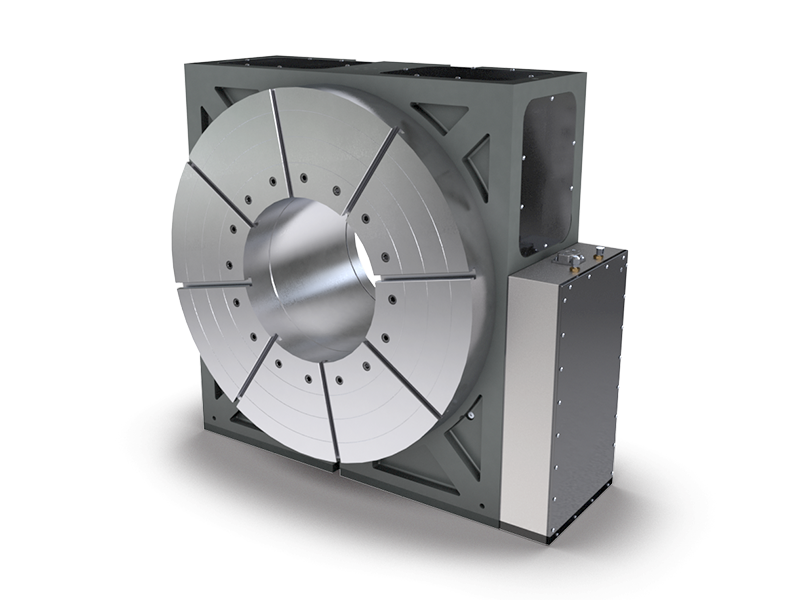

Today, Haas manufactures four major product lines: vertical machining centers (VMCs), horizontal machining centers (HMCs), CNC lathes, and rotary tables, as well as a number of large five-axis and specialty machines. All Haas products are manufactured at the company’s expansive facility in Oxnard, California – the largest, most modern machine tool manufacturing operation in the United States.

Haas Automation is the largest machine tool manufacturer in North America, building a full line of CNC vertical and horizontal machining centers, CNC lathes, rotary tables and 5c indexers. Haas machine tools and rotary products are built to deliver higher accuracy, repeatability and durability than any other machine tools on the market.

From its beginnings in 1983, Haas Automation has always produced top-quality products at affordable prices. Haas produces all critical components in-house, using dedicated state-of-the-art cnc machine tools. the company"s 1 million-square-foot facility makes extensive use of automated lights-out flexible manufacturing systems (FMS) and robotic loaders to streamline production capabilities and reduce costs. This, combined with highly trained electronics and mechanical assembly teams, allows Haas to control quality, cost, reliability and availability. Haas delivers more standard features, high-tech innovations and rock-solid engineering than perhaps any other CNC manufacturer in the world and at better prices.

8613371530291

8613371530291