harmonic drive rotary table supplier

Harmonic Drive® rotary actuators are the easiest solution for your high precision motion control applications. Performance matched precision gearing, motors, and encoders are designed to provide a power dense, cost effective solution.

Gear Units are typically housed zero backlash Harmonic Drive® strain wave gears with a precision output bearing & flange. Offered in a variety of compact designs including hollow shaft configurations. A robust and easy-to-use gearhead/gearbox solution.

Zero backlash Harmonic Drive® gear component sets offer the ultimate in design flexibility and can be tightly integrated into your machine design. These are well suited for applications where high torque density is of paramount importance.

Zero backlash Harmonic Drive® and low backlash Harmonic Gearhead®Planetary Quick Connect® gearboxes easily mount to any servomotor to create a high precision actuator. Available in a wide range of gear ratios, sizes and output configurations.

Harmonic Drive Linear Actuators deliver both high force and outstanding positional accuracy. These actuators provide linear forces from 49N to 12,000N with sub-micron position resolution.

We offer a complete range of digital servo drives for brush or brushless actuators. Our drives support many command protocols including analog, stepper, CanOpen, DeviceNet and EtherCat.

As a Harmonic Drive distributor, Electromate proudly supplies Harmonic Drive systems & actuators. Harmonic Drive LLC designs and manufactures precision servo actuators, gearheads and gear component sets. We work with industry-leading customers and companies of all sizes to provide both standard product and custom-engineered solutions. Harmonic Drive LLC provides high precision, high performance products to meet customer’s mission critical application requirements.

Electromate is a Harmonic Drive distributor offering a wide selection of Harmonic Drive systems, actuators, & motors. We supply products throughout Canada in regions like British Columbia, Quebec, and Ontario. View our selection below!

Harmonic Drive is a strain wave gear which can improve certain characteristics compared to traditional gearing systems. Harmonic Drive is trademarked by the Harmonic Drive company. The strain wave gear was invented in 1957 by C.W. Musser.

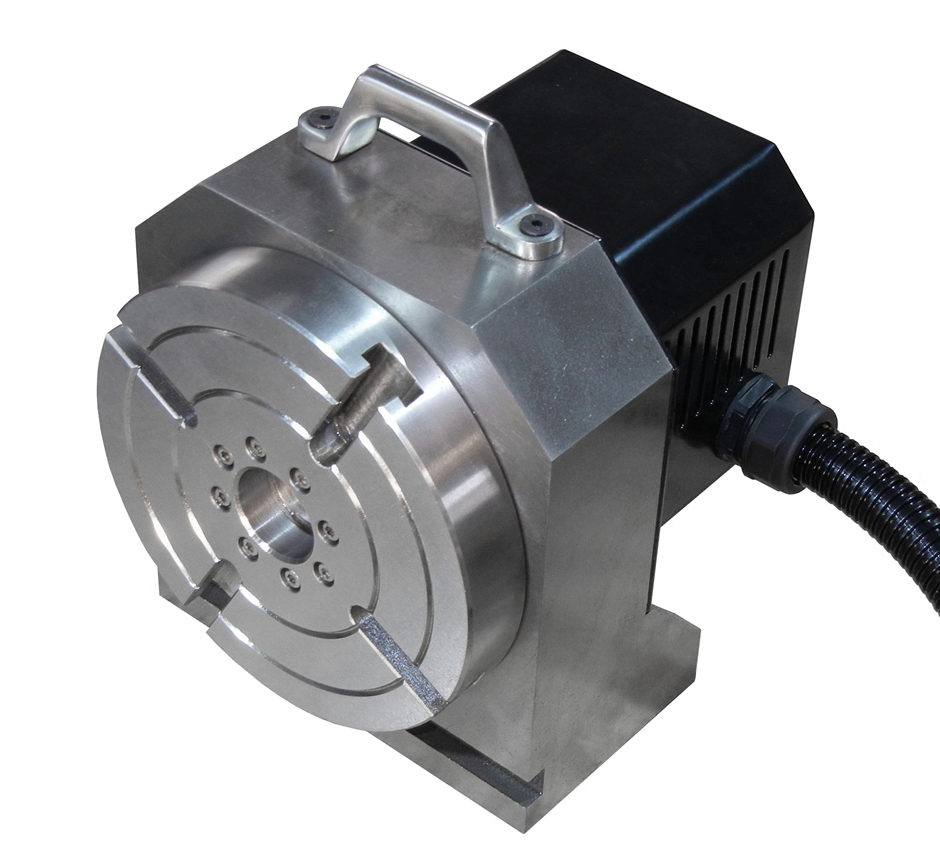

Based on the great features of harmonic drive, we developed this 4th axis set including 4", 6" and 8" units. The unit body is made of casted iron HT250, and the rotary table is made of harden C45 steel. The rotary table is set on a P5 class precision crossed roller bearing which only can be seen on high level 4/5 axis sets.

The harmonic drive is directly driven by closed-loop stepper motor system to prevent loosing steps. It can make the rotary table rotate at max >30rpm speed. A tiny home senser is also integrated into the 4th axis unit so users can use this 4th set at high accuracy required applications.

Zhejiang Laifual Drive Co., Ltd is a national high-tech enterprise, mainly engaged in research and manufacture of high-precision harmonic reducers and planetary gear reducers. Total factory is 30,000 square meters. About 300 employees, including around 30 R&D Personnel, with more than 10 years experience in research and development.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Harmonic Drive Rotary Table with motor, 300°/sec, spindle torque of 65 ft-lb. Smaller than a 7" cube. Requires a Haas mill with 4th-axis drive and software version 18.13 or later. Not available for stand-alone operation

Hollow Rotary Table is also called Hollow Rotary Actuator, Programmable Servo Rotary Table and Hollow Shaft Rotary Indexer, which can be equipped with any brand of stepper motor or servo motor in the market with support of Sango flange warehouse. With the most featured central hollow structure and its precision positioning control, Hollow Rotary Table becomes one of the popular rotary components in Automation Industry.

As a professional Hollow Rotary Actuator manufacturer in China, Sango Automation provides full range of Precision Rotary Table product which covers from frame size 60, 85, 130, 200 to 280, as well as reinforced, heavy-duty version to maximum meet the requirement for different industrial application.

These hollow rotary tables can meet the requirement on arc seconds level of positioning precision accuracy for automatic rotation motion for the well-known system integrators and reputable factories from China and worldwide.

BacklashNo backlash (adjustable structure)No backlash (adjustable structure)No backlash (adjustable structure)No backlash (adjustable structure)No backlash (adjustable structure)

As one type of industry precision reducers, the most advantage of hollow rotary platform is the large aperture hollow structure which allows easy wiring and piping when the rotary motion executed.

Sango Automation provides multiple options of rotary tables, from ouput surface size 62, 85, 130, 200 to 280, as well as reinforced, heavy duty version to maximum meet the requirement for different industrial application. On motor connection direction, we provide side connection and right angle type connection method, which gives more flexibility and space for automation engineers and designers.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

The main part of the RollerDrive mechanism consists of an input shaft and an output turret in which roller followers are embedded. An integral cross-roller bearing supports the output turret with ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

The aerospace transmission devices require a simple structure that can adapt to harsh space environments. In this regard, the structure of strain wave gear harmonic reducers for aerospace is simple. After special treatment, standard gear models can be applied to the driving of satellite wing solar panel arrays, tracking devices with various pan-tilt motions, and the driving of unmanned vehicles.. . Leaderdrive"s research-driven development of strain wave gear and rotary actuator technology means that we are uniquely placed to provide solutions for ambitious gearing projects. For more information about aerospatial gear development, contact our technical team today.

The transmission gears of automated packaging equipment require high precision and a fast pace. Handling robots, sealing machines, and other equipment need to be synchronized and indirectly driven.. . There are strict requirements on the accuracy of the drive system. A high-precision strain wave gear harmonic reducer will greatly improve the transmission system"s accuracy and improve the equipment"s production efficiency.. . Leaderdrive is a world-renowned manufacturer of high-precision strain wave gear harmonic reducers. We are glad to assist in the design and assembly of automated packaging equipment, so do not hesitate to contact our technical team today.

Industrial laser cutting equipment needs an integrated module with high precision and high speed. The high-quality required by customers seeking laser cutting services means that material surfaces should be smooth and burr-free. In addition, service providers want increased efficiency, low consumption, energy-saving operation, and environmental protection.. . At present, the main equipment in industrial laser cutting is laser marking machines, laser welding machines, and laser cutting machines. The high-precision gearing harmonic reducer has high precision, small size, and high torque and is widely used in this equipment.. . Leaderdrive is a leading manufacturer of strain wave gear harmonic reducers. Please contact us to learn more about how you can use our solutions for industrial laser cutting technology.

At the beginning of the 20th century, industrial robots became popular in factories worldwide, especially in the automotive industry. With the continuous development of the robot industry, light-duty robots have gradually moved to every industry"s factory floor. However, the original RV gear reducers used by traditional large robots have gradually become inadequate because they cannot meet the needs of modern lightweight robots. New generation components made by companies like Leaderdrive have started to supplant the old RV gears. . . Machine assembly parts such as strain wave gears, rotary actuators, and frameless motors make up industrial robots" core components. These parts help production engineers to realize ideal motion functions without experiencing difficulties such as backlash and mechanical wear. The precision offered by strain wave gears and rotary actuators means that modern industrial robots can perform increasingly accurate micro-level actions.. . Leaderdrive"s product range meets the challenges of modern industrial robotics. High-precision strain wave gear reducers and rotary actuators can be widely used in multi-joint robots, SCARA, collaborative robots, and parallel robots. Contact us to learn more about our industrial robot solutions.

Intelligent robotic medical equipment is a revolutionary field that integrates modern high-tech means into standard medical practices. Such devices have incredibly demanding precision requirements for gearing components like strain wave gear harmonic reducers.. . Leaderdrive contributes to intelligent medical devices such as surgical robots, rehabilitation robots, and wearable robots. These devices have high flexibility, high safety, and precise control requirements. Our precision harmonic reducers are compact, lightweight, and highly precise and can fully meet the needs of smart medical devices.

With the continuous development of processing, production, and manufacturing, the requirements for the analysis and inspection of production products have improved, and the requirements for the accuracy of measurement, analysis, and test equipment have also continuously improved. Naturally, the quality of measurement, analysis, and test equipment is only as good as the accuracy of components such as strain wave gear harmonic reducers, rotary actuators, and frameless drive motors.. . Leaderdrive harmonic reducers are compact, light in weight, and high in accuracy; they are widely used in delicate analysis and testing equipment. The main applications are the driving of optical analysis devices, three-coordinate measuring instruments, and metal tensile testing machines. Other parts such as indexing turntable and plate turning machine transmission also adopt these components.. . Contact Leaderdrive to find out more about how our products can be used in measurement, analysis, and test equipment.

When we think about actuators, we typically think about linear actuators — devices that move loads in a straight line, driven by a screw, belt, or other mechanical power transmission device. But there also exists a class of actuators that provide rotary motion for positioning a load radially around a fixed axis. While these rotary actuators can be driven by pneumatic, hydraulic, or electromechanical power, we’ll focus here on electromechanical versions.

Electromechanical rotary actuators are designed to move loads in angular increments with very high positioning accuracy and repeatability. Although all rotary actuators can provide up to 360 degrees of rotation, many designs can provide continuous rotation through multiples of 360 degrees.

There are two main design principles for rotary actuators: those that incorporate a mechanical drivetrain — such as a belt or gear — to transfer motion from the motor output to a rotating table, and those in which the motor is directly coupled to the rotating table. In either case, an absolute or incremental rotary encoder is often integrated into the actuator assembly, and brakes are typically offered as standard options. To support the rotating load, most designs use either a rotary ball bearing or a radial (ring-style) crossed-roller bearing.

The first type — those that use a mechanical drivetrain — most often use a belt, worm gear, or pinion gear coupled to a servo or stepper motor. In the case of belt-driven versions, gearing (torque multiplication and speed reduction) can be achieved through additional gear components or by using different diameters for the motor and table pulleys.

Direct-drive rotary actuators use a style of rotary servo motor that has a flat construction principle, known as a torque motor, or a pancake motor. The actuator’s table top, where the load is attached, is directly mounted to the motor, so components that would introduce compliance and backlash — such as couplings, screws, or belts — are eliminated. This gives direct-drive versions very high positioning accuracy, repeatability, and stiffness.

Rotary actuators — particularly direct-drive versions — are often used as the rotary axis in multi-axis systems such as Cartesian and gantry robots. And because electrical rotary actuators provide tight control over speed and positioning accuracy, they’re often chosen over pneumatic and hydraulic designs in printing, machining, assembly, and inspection applications.

Another permutation of the rotary actuator is the rotary indexing table. In general, rotary actuators are used for moving loads at any angle, while rotary indexing tables are designed to move loads to pre-set, fixed positions, where the load dwells for some time and then moves to the next position. For example, an indexing table would be used for a part that required a machining operation to be performed around its circumference at 90 degree intervals.

As in the linear world, in the world of rotary motion, a distinction is often made between rotary actuators and a rotary stages. Rotary stages are commonly used in applications that require a very high flatness of travel during rotation — in other words, there should be no (or very little) “tilt” or “wobble” as the stage rotates. This is typically achieved by using highly-machined base and table structures with stringent requirements for flatness, along with high-precision radial bearings or crossed roller bearings. However, the distinction between rotary actuators, rotary stages, and even rotary tables is not strictly followed, so it’s not uncommon to see these terms used interchangeably.

8613371530291

8613371530291