hiwin rotary table manufacturer

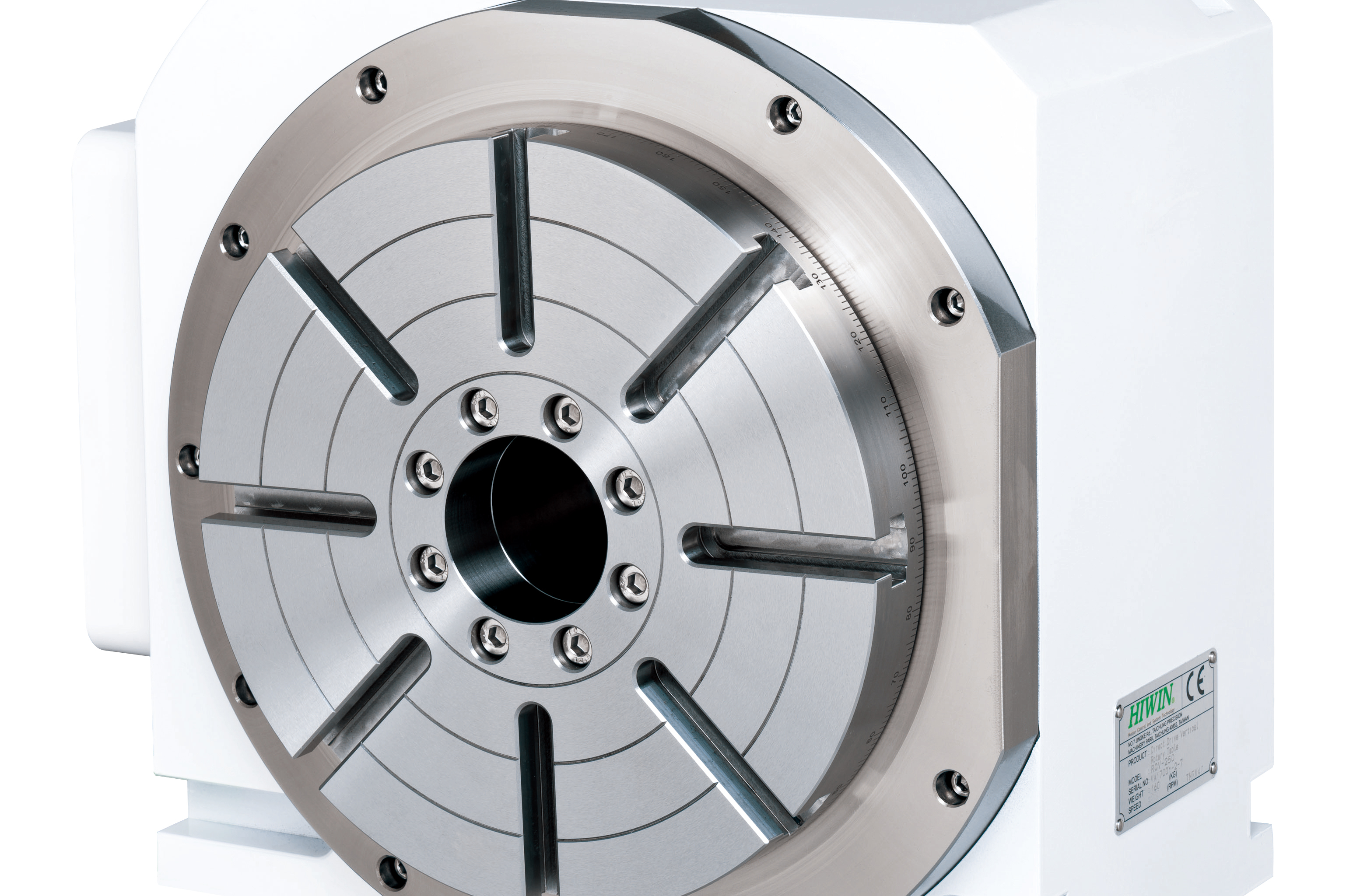

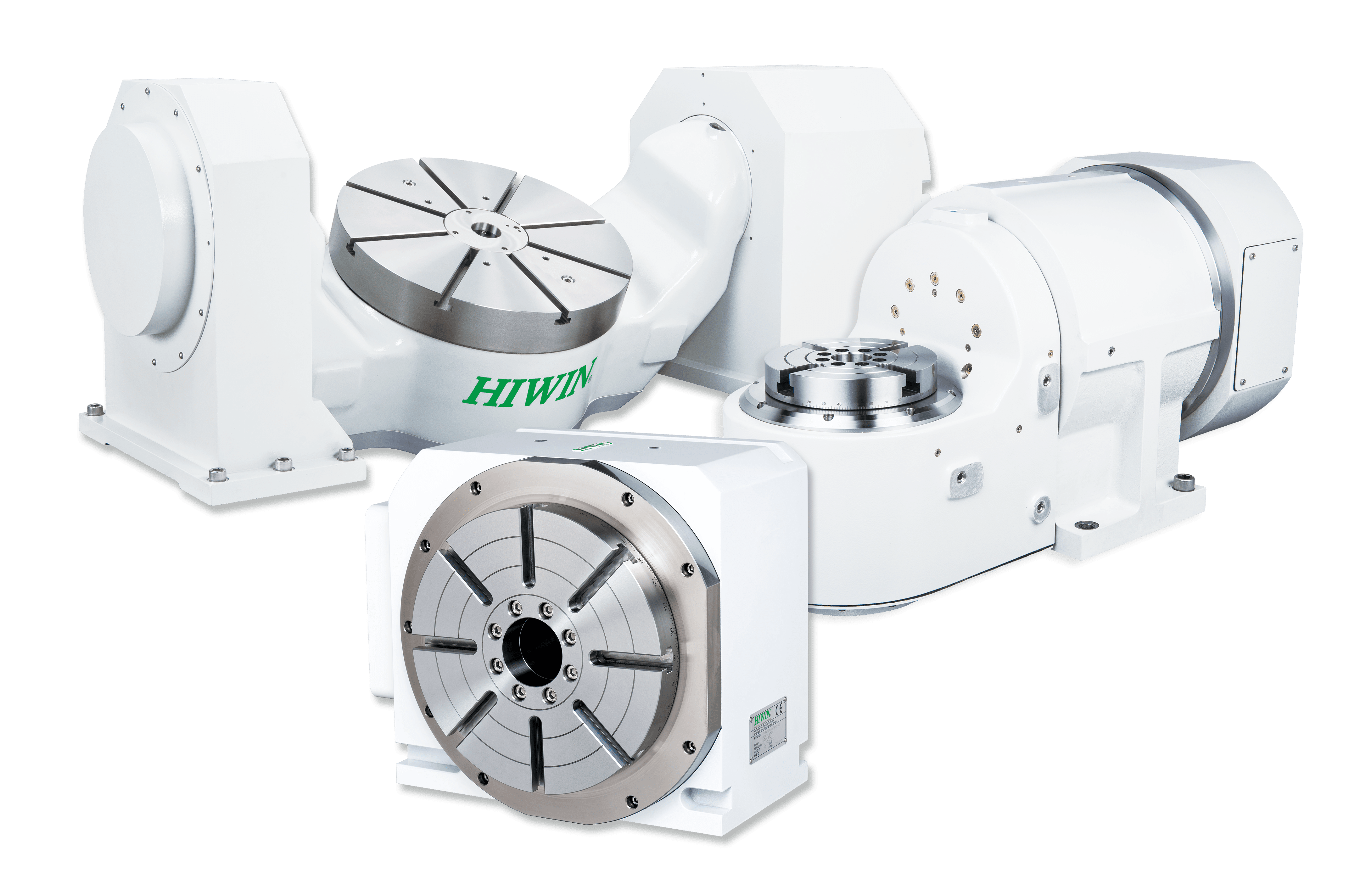

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

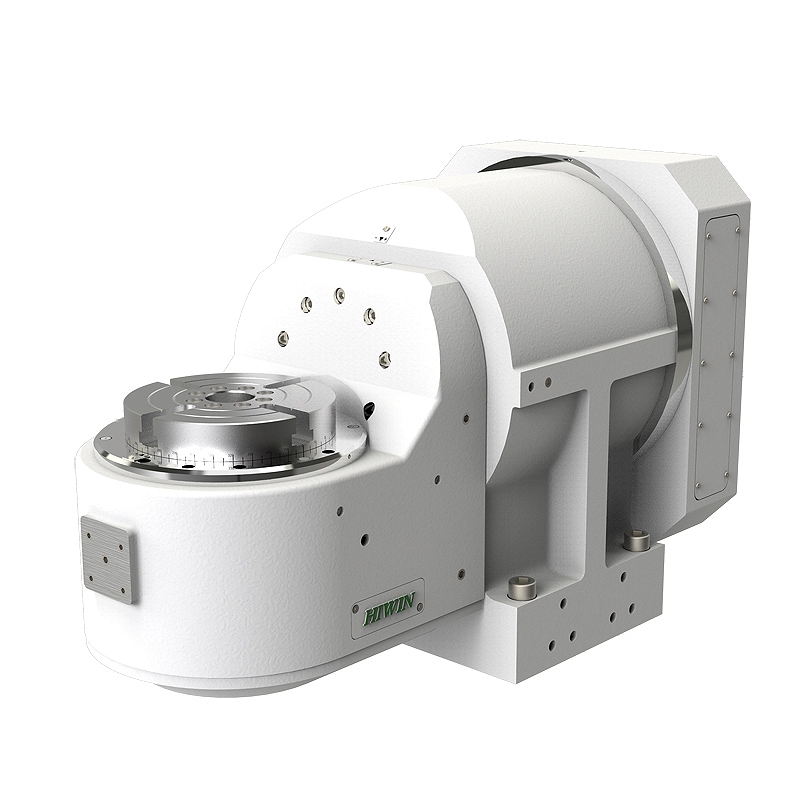

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

HIWIN Corporation torque motor and rotary tables ensure excellent acceleration capabilities and high precision uniform movements. Hiwin torque motor and rotary tables are backlash free, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. The rotary tables are play-free direct drives that are always used where classical motor/gear combinations come up against their limits. The fascinating features of these rotary tables are their unvarying torque, their rigid load coupling, and their maximised dynamic response, specifically under high load as well. Thanks to their high efficiencies and lack of gears, these rotary tables operate to great effect and are extremely quiet.

HIWIN Corp. will feature families of precision motion control components this year at IMTS, with their torque motor rotary tables as a highlight of their booth.

The TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates gear reducers, resulting in dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The series is compatible with most major CNC brands and uses HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

The particularly flat and lightweight DMN rotary tables are suitable for all applications in which high rigidity and accuracy are needed along with the smallest dimensions possible. Typical applications include the manufacture of LEDs, solar cells and semiconductors. The zero-maintenance DMN rotary tables use precision bearings and optical encoders to achieve high positioning accuracy. The rotary tables, which are designed as hollow shaft versions, allow media, cable systems or mechanics to pass through easily and thus facilitate installation.

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

HIWIN Corporation, a provider in motion control and system technology, will feature families of precision motion control components this year at IMTS, with their Torque Motor Rotary Tables, (TMRT), as a highlight of their booth. IMTS will be held September 12-17, 2022, in Chicago.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlashes enable tighter part tolerance. Direct drives provide smooth motion, resulting in an improved part surface finish.

HIWIN Torque Motor Rotary Tables utilize HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Since 1992, HIWIN Corporation has focused on components, systems, and expertise in the motion control industry. HIWIN will be celebrating its 3oth anniversary in America at IMTS

Hiwin (Booth 134514) will feature families of precision motion control components this year at IMTS, with the company"s Torque Motor Rotary Tables (TMRTs) as a highlight.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

A rotary table is the revolving plate on the rig"s drill floor that turns the drill string in a clockwise path. The rotary desk surrounds the 4 or six-sided kelly bushing and kelly drive to which the drill string is attached, transferring the power from the rig"s drive machine to the drill string and bit.

The rotary table hyperlinks the rig"s electricity supply to the drill string, it may be defined as a seize. maximum rigs have a rotary table because the top mover for the drill string, however, pinnacle power systems that permit continuous rotation of the drill string have changed the rotary table, the kelly bushing and the kelly pressure in some rigs, because of adjustments in trenchless construction requirements.

The rotary drive desk is prevalent in pinnacle-force rigs, that is, those that have their drive motor on the pinnacle of the rig. Drill string sections are first connected to the lowest hollow assembly. As drill string sections pass into the bore, extra sections of drill string are attached to the top pressure motor and to sections inside the bore, building the drill string from the pinnacle. those sections of drill string screw together using a clockwise movement. The rotary table -- which turns clockwise -- is used to tighten the segments of the drill string.

Widely used in machining center main axis and working table SKU: HIWIN-TRT-RCVCategory: Torque Motor Rotary TableTags: hiwin RCV Series Torque Motor Rotary Table, Hiwin Torque Motor Rotary Table, Rotary Table, Torque Motor Rotary Table

In the past, Taiwan has to purchase “Torque Motor Rotary Table” from European and Japanese suppliers. The high import cost, long delivery time and no timely after services affects competitiveness of Taiwan machine makers. HIWIN is the only supplier in Taiwan which can mass produce torque motor. RAS-170 is made of HIWIN self-developed key components.

HIWIN Technologies Corp. is the world leading brand of motion control and system manufacturer. With its core technologies, HIWIN focuses on creating innovative products with high speed, high precision, eco-friendly, and energy-saving. Our products, from components to sub system and system, include Ballscrew, Guideway, Bearing, Robot Reducer, Industrial Robot, Medical Robot, Torque Motor Rotary Table. HIWIN products are widely applied by the Automation, Semi-Conductor, Electronics, Medical, Precision Machine, and Transportation Industries etc. HIWIN commits to be a manufacturing service company by creating innovative intelligent products and providing mechatronic total solution to serve customers and build a great work environment and well-being to improve human’s life. With company motto “Professional Excellence, Working Enthusiasm, and Ethics & Responsibility”, HIWIN has the vision to develop a sustainable company.

Through perseverance HIWIN became well-known overseas with high quality. After receiving global acknowledge, HIWIN finally won domestic recognition under the contempt of Taiwan brand.

HIWIN is now top tier in motion control and system with 14 subsidiaries and over 300 distributors. HIWIN believes “Manufacturing is not a purpose, it is a means to satisfy human needs”, which leads to innovation for better life! Nikkei Business 2017 “ASIA 300 Market Growth”, HIWIN is ranked No.1! HIWIN, a MIT company, being the No.1 above the Asia public companies is a honor for Taiwan! HIWIN proves branding is difficult but rewarding.

HIWIN Corp. manufactures an extensive line of linear and rotary motion components, positioning systems and complete motion solutions, with superior quality at competitive prices. Mechanical components include a variety of precision ground and rolled ballscrews, linear guideways, ball splines, crossed roller bearings, and strain-wave gears. Mechatronic and robotic products include single ball screw stages and AC Servo motors, linear motors and stages, rotary tables, and the drives, controllers, and know-how to make multi-axis motion systems. Many of these items are in stock for on-site cutting, machining and fast shipment. Our robots include articulated, delta, SCARA and more.

8613371530291

8613371530291