hiwin rotary table pricelist

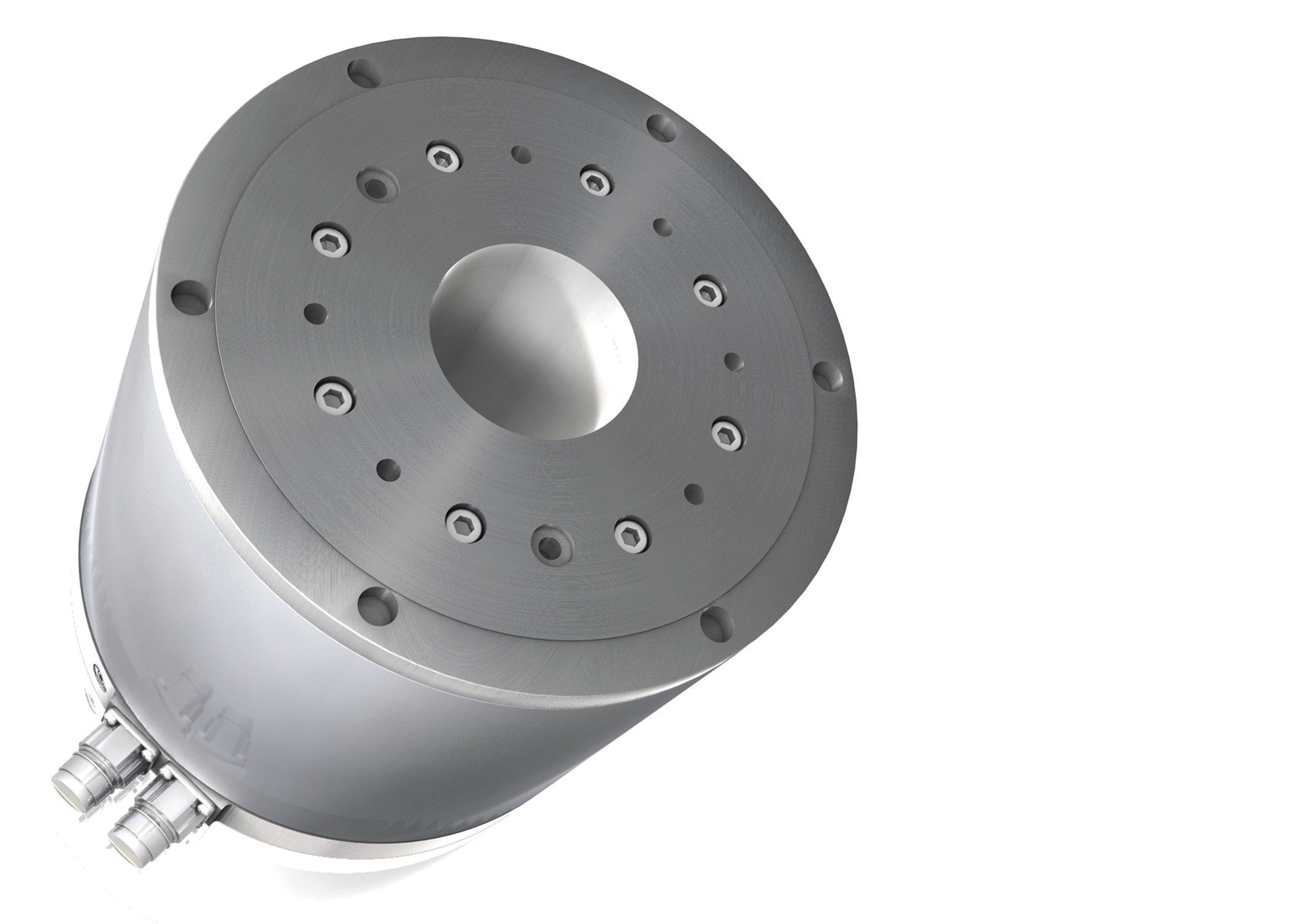

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

The vertical rotary tables of the RCV series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled torque motors, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the rotary tables achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller bearings, the tilt-resistant mechanical design is able to accommodate maximum loads.

DMS rotary tables are high-torque rotary axes that are ready to install. The extremely rigid coupling between the motor and load in conjunction with a quality servo drive controller provides for outstanding acceleration properties and an unvarying torque. DMS rotary tables are available in a range of sizes and with diverse options. Thanks to their hollow shafts, DMS rotary tables are ideal for applications in automation systems. Media, cable systems, and mechanisms can pass through with ease.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. The rotary tables are play-free direct drives that are always used where classical motor/gear combinations come up against their limits. The fascinating features of these rotary tables are their unvarying torque, their rigid load coupling, and their maximised dynamic response, specifically under high load as well. Thanks to their high efficiencies and lack of gears, these rotary tables operate to great effect and are extremely quiet.

HIWIN Corp. manufactures an extensive line of linear and rotary motion components, positioning systems and complete motion solutions, with superior quality at competitive prices. Mechanical components include a variety of precision ground and rolled ballscrews, linear guideways, ball splines, crossed roller bearings, and strain-wave gears. Mechatronic and robotic products include single ball screw stages and AC Servo motors, linear motors and stages, rotary tables, and the drives, controllers, and know-how to make multi-axis motion systems. Many of these items are in stock for on-site cutting, machining and fast shipment. Our robots include articulated, delta, SCARA and more.

Search in all categories Lubrication Arcanol CX80 Smary Hiwin Bearings spherical bearings barrel roller bearings spherical roller bearings for vibratory machinery ball bearings deep groove ball bearings single row double row angular contact ball bearings angular contact single row angular contact double row self-aligning ball bearings four point contact bearings radial insert ball bearings special bearings tapered roller bearings accessories for bearings cylindrical roller bearings single row double row crossed roller bearings spindle bearings spindle ball bearings spindle roller bearings axial bearings axial deep groove ball bearings axial cylindrical roller bearings axial needle roller bearings axial spherical roller bearings needle roller bearings needle roller bearings bearings roller clutches inner rings track & stud type track rollers rotary table bearings chain sprockets & belt tension pulleys spherical plain bearings rod ends plain bushes Tools measuring device for bearing diagnostics optibelt service tools mounting tools bearing assembly tools belt assembly tools bearing dismounting tools lubrication systems accessories Linear guidance systems monorail guidance systems guideways accessories for guideways carriages accessories for carriages shaft guidance systems shafts and support solid metric shafts solid metric shafts X46 sold metric shafts X90 metric solid shafts Cr solid inch shafts hollow metric shafts shafts with support linear bearings linear bearing units Ballscrews roller screws roller nuts bearings for screw drives Shaft rotary seals Snap rings Bearing housings housing units with shaft bearing housings accessories housing units Belts and pulleys belts wedge & V-belts wedge cogged kraftbands double sided V-belts variable speed ribbed timing endless open-ended special flat AGRO pulleys V-belt pulleys V-belt pulleys for taper bushing v-belt pulleys for plain boring timing belt pulleys HTD Pulley for Taper Bushing HTD Pulley for plain boring taper Lock bushings

2 HIWIN GmbH Brücklesbünd 1 D Offenburg Phone +49 () Telefax +49 () info@hiwin.de All rights reserved. Complete or partial reproduction is not permitted without our permission. Note: The technical data in this catalogue may be changed without prior notice.

3 Motors, Drives & Accessories Directly-driven rotary tables from HIWIN have a backlashfree and very rigid design, making them highly versatile. The compact design makes the tables easy to integrate and allows for a space-saving setup. Various diameters and heights simplify the process of selecting the right rotary table. On request, the rotary tables are also supplied as a complete system with drive. TM-6-2-EN-29-K 3

5 Contents 1 Product overview Sample applications HIWIN rotary tables optimise transport processes HIWIN rotary table in glass plate handling 8 3 HIWIN rotary tables DMS Characteristics of the DMS rotary tables Order code for DMS rotary tables Technical data for DMS Technical data for DMS Technical data for DMS Technical data for DMS Technical data for DMS HIWIN rotary tables DMN Characteristics of the DMN rotary tables Order code for DMN rotary tables Technical data for DMN Technical data for DMN Technical data for DMN Technical data for DMN93 23 TM-6-2-EN-29-K 5

7 1. Product overview HIWIN rotary tables DMS Page 9 Standard series Torques up to 45 Nm Integrated rotary encoder Outer diameter 11 3 mm With pneumatic clamping as an option HIWIN rotary tables DMN Page 18 Extremely flat design Torques up to 39.6 Nm Outer diameter mm Integrated rotary encoder TM-6-2-EN-29-K 7

8 Sample applications 2. Sample applications 2.1 HIWIN rotary tables optimise transport processes The specification Rapid positioning when transporting the work-pieces between the interlinked system parts on a vertical circular path = special requirements apply to acceleration and braking due to the short distances travelled Flexible solution, allowing changes or additions to be made during commissioning It should be possible for the system to be stopped in any position in order to inspect the parts Our solution Swivel drive minimises the cycle times = saves time and money Centrifugal forces are reduced = transport components swiftly and gently to the next station with the gripper arm Precision bearing and optical distance measuring system = maximum reproducibility Design with hollow shaft = pass cables or mechanisms through with ease Direct drive = no gearbox backlash or gearbox mechanisms prone to wear 2.2 HIWIN rotary table in glass plate handling The specification Lay-up station in which the finished strings are drawn in with special vacuum suckers after welding. The strings are then swivelled and deposited either in string boxes or on glass plates The current method of holding the Z-axis for the cross bar above toothed belt and servo motor is to be replaced because it takes up too much room and is too heavy A high level of torque and a compact design are needed due to the long swivel arm and high inherent weight of the arm High speed is needed because of the short cycle times required Our solution Rotary indexing table = high torque and compact design = high throughput, space and cost savings Design with hollow shaft = pneumatic hoses and cables can pass through Direct drive = no gearbox clearance or gearbox mechanisms prone to wear Adaptation to existing control 8

9 3. HIWIN rotary tables DMS 3.1 Characteristics of the DMS rotary tables DMS rotary tables are directly driven rotary tables and do not therefore have a gearbox. The extremely rigid connection between the motor and load, coupled with a high-quality servo drive controller, ensures outstanding acceleration capabilities and movement with good uniformity. Due to the hollow shaft design, DMS rotary tables are especially well suited to automation tasks. Media, cable systems or mechanisms can pass through with ease. Key features: Backlash-free and extremely dynamic Brush-less and high-torque Integrated optical rotary encoder Typical applications: Automation technology Pick-and-place machines 3.2 Order code for DMS rotary tables DM S 3 4 L A Torque motor Type: S: Rotary table complete with crossed roller bearing Outer diameter [mm]: : 11 1: 15 3: 2 7: 3 Rotor height [mm]: 2: 2 3: 3 4: 4 6: 6 7: 7 8: 8 C: 12 Special equipment: : None Protection class: : IP4 Clamping element: : None Distance measuring system: A: Optical, incremental (DMS, DMS1, DMS3) D: Optical, incremental (DMS7) Winding variant: None: standard winding L: For high rotary speed TM-6-2-EN-29-K 9

10 HIWIN rotary tables DMS 3.3 Technical data for DMS Technical data for DMS Torque-speed curve (DC bus voltage: 56 VDC) Torque [Nm] 12 1 DMS3 Tp Tc , Speed [rpm] Table 3.1 Technical data for DMS HIWIN rotary tables Technical data of rotary table Symbol Unit DMS3 Peak torque (for 1 sec.) T p Nm 9.3 Continuous torque T c Nm 3.1 Stall torque T s Nm 2.17 Inertia of rotating parts J kgm 2.3 Weight M m kg 4 Max. axial load F a N 3,7 Max. radial load F r N 82 Max. moment of tilt M k Nm 4 Nominal speed (at 4 VAC, 3 % duty cycle) n 1/min 7 Position accuracy arcsec ± 45/± 1 2) Repeatability arcsec ± 3 Radial run-out mm.3 Axial run-out mm.3 Protection class Technical data of motor Peak current (for 1 sec.) I p A eff 6. Continuous current I c A eff 2. Motor constant K m Nm/ W.5 Resistance 1) R 25 Ω 7.1 IP4 Inductance 1) L mh 15.2 Electrical time constant T e ms 2.1 Torque constant K t Nm/A eff 1.55 Back emf constant K u V eff /(rad/s).82 Number of poles 2p 1 Thermal resistance R th C/W 1.76 Thermal time constant T th s 1,93 Thermal sensor PTC SNM 1 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line 2) With error mapping Encoder type A specifications (optical, incremental) 2,48 lines/cycle Index mark Signal output sin/cos 1 V PP 1

11 Dimensions of the DMS HIWIN rotary table (For values, see Table 3.1) M k F r F a Ø8 Ø11 (27) 6-M5.8P 1DP P.C.D Ø6 (Rotor fixation) ±.3 1 X 6 6 = 36 Ø24H7 Rotating hollow shaft Home position Marker 2-Ø9H7 2.1DP for centering bush 6-M6 1P 9DP P.C.D Ø9 (Stator fixation) 6 6 = 36 Motor connection (built-in socket M17) Encoder connection (built-in socket M17) X View TM-6-2-EN-29-K 11

12 HIWIN rotary tables DMS Technical data for DMS1 Torque-speed curves (DC bus voltage: 56 VDC) Torque [Nm] 4 35 Tp 3 Tc DMS Speed [rpm] Torque [Nm] 8 7 Tp 6 Tc DMS Speed [rpm] Table 3.2 Technical data for DMS1 HIWIN rotary tables Technical data of rotary table Symbol Unit DMS14 DMS18 Peak torque (for 1 sec.) T p Nm 3 6 Continuous torque T c Nm 1 2 Stall torque T s Nm 7 14 Inertia of rotating parts J kgm Weight M m kg Max. axial load F a N 3,7 Max. radial load F r N 1,7 Max. moment of tilt M k Nm 6 Nominal speed (at 4 VAC, 3 % duty cycle) n 1/min 6 5 Position accuracy arcsec ± 45/± 1 2) Repeatability arcsec ± 3 Radial run-out mm.3 Axial run-out mm.3 Height H mm Protection class Technical data of motor Peak current (for 1 sec.) I p A eff 12 Continuous current I c A eff 4 Motor constant K m Nm/ W Resistance 1) R 25 Ω Inductance 1) L mh Electrical time constant T e ms Torque constant K t Nm/A eff Back emf constant K u V eff /(rad/s) Number of poles 2p 22 Thermal resistance R th C/W.8.48 Thermal time constant T th s 2,29 2,52 Thermal sensor PTC SNM 1 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line 2) With error mapping IP4 Encoder type A specifications (optical, incremental) 3,6 lines/cycle Index mark Signal output sin/cos 1 V PP 12

13 Dimensions of the DMS1 HIWIN rotary table (For values, see Table 3.2) M k F r F a Ø99 H±.3 1 Ø15 X 6 6 =36 Ø35 H7 Rotating hollow shaft (27) 6-M6 1P 9DP P.C.D Ø6 (Rotor fixation) 45.5 Home position Marker 2-Ø9H7 2.1DP for centering bush 2-Ø5H7 7DP P.C.D Ø48 8-M6 1P 12DP P.C.D Ø142 (Stator fixation) 8 45 =36 2-Ø5H7 7DP P.C.D Ø142 Motor connection (built-in socket M17) Encoder connection (built-in socket M17) 35 X View TM-6-2-EN-29-K 13

14 HIWIN rotary tables DMS Technical data for DMS3 Torque-speed curves (DC bus voltage: 56 VDC) Torque [Nm] 1 Tp 8 Tc 6 DMS , Speed [rpm] Torque [Nm] DMS38 6 Tp Tc Speed [rpm] Torque [Nm] 2 Tp 16 Tc 12 DMS3C Speed [rpm] Table 3.3 Technical data for HIWIN rotary tables DMS3 Technical data of rotary table Symbol Unit DMS34 DMS38 DMS3C Peak torque (for 1 sec.) T p Nm Continuous torque T c Nm Stall torque T s Nm Inertia of rotating parts J kgm Weight M m kg Max. axial load F a N 8, Max. radial load F r N 6,5 Max. moment of tilt M k Nm 24 Nominal speed (at 4 VAC, 3 % duty cycle) n 1/min Position accuracy arcsec ± 25/± 1 2) Repeatability arcsec ± 2.5 Radial run-out mm.5 Axial run-out mm.5 Height H mm Protection class Technical data of motor IP4 Peak current (for 1 sec.) I p A eff 1.2 Continuous current I c A eff 3.4 Motor constant K m Nm/ W Resistance 1) R 25 Ω Inductance 1) L mh Electrical time constant T e ms Torque constant K t Nm/A eff Back emf constant K u V eff /(rad/s) Number of poles 2p 22 Thermal resistance R th C/W Thermal time constant T th s 2,2 2,13 2,17 Thermal sensor PTC SNM 12 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line 2) With error mapping Encoder type A specifications (optical, incremental) 3,6 lines/cycle Index mark Signal output sin/cos 1 V PP 14

15 Dimensions of the DMS3 HIWIN rotary table (For values, see Table 3.3) M k F r F a H X Connecting thread 8 M6 9DP Ø12 H7 2.1DP for centering bush Marker Home position Ø 6 H7 Ø 12 Ø (= 36 ) Ø12 H7 2.1DP for centering bush Rotating hollow shaft Ø12H7 2.1DP for centering bush Ø18 Encoder connection (built-in socket M17) Motor connection (built-in socket M17) Connecting thread 1 M6 9DP Ø12H7 2.1DP for centering bush 9 3 (=27 ) X View TM-6-2-EN-29-K 15

16 HIWIN rotary tables DMS Technical data for DMS7 Torque-speed curves (DC bus voltage: 56 VDC) Torque [Nm] Tp Tc DMS Speed [rpm] Torque [Nm] 3 24 Tp Tc 18 DMS76L Speed [rpm] Torque [Nm] 5 4 Tp Tc 3 DMS7C Speed [rpm] Table 3.4 Technical data for DMS7 HIWIN rotary tables Technical data of rotary table Symbol Unit DMS74 DMS76L DMS7C Peak torque (for 1 sec.) T p Nm Continuous torque T c Nm Stall torque T s Nm Inertia of rotating parts J kgm Weight M m kg Max. axial load F a N 8, Max. radial load F r N 6,5 Max. moment of tilt M k Nm 36 Nominal speed (at 4 VAC, 3 % duty cycle) n 1/min Position accuracy arcsec ± 25/± 1 2) Repeatability arcsec ± 2.5 Radial run-out mm.5 Axial run-out mm.5 Height H mm Protection class Technical data of motor Peak current (for 1 sec.) I p A eff Continuous current I c A eff Motor constant K m Nm/ W Resistance 1) R 25 Ω Inductance 1) L mh Electrical time constant T e ms Torque constant K t Nm/A eff Back emf constant K u V eff /(rad/s) Number of poles 2p 44 Thermal resistance R th C/W Thermal time constant T th s 2,23 2,33 2,35 Thermal sensor PTC SNM 12 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line 2) With error mapping IP4 Encoder type D specifications (optical, incremental) 11,152 lines/cycle Index mark Signal output sin/cos 1 V PP 16

17 Dimensions of the DMS7 HIWIN rotary table (For values, see Table 3.4) M k F r F a H X Ø12H7 2.6DP for centering bush Connecting thread 8 M8 16DP Marker Home position Ø3 Ø19 ±.1 Ø14H7 16DP 5 1 ± Ø12H7 2.6DP for centering bush (= 36 ) Ø12H7 2.6DP for centering bush Rotating hollow shaft 2 16 Ø28 Encoder connection (built-in socket M17) Motor connection (built-in socket M17) Connecting thread 9 M8 16DP Ø12H7 2.6DP for centering bush (= 36 ) X View TM-6-2-EN-29-K 17

18 HIWIN rotary tables DMN 4. HIWIN rotary tables DMN 4.1 Characteristics of the DMN rotary tables The particularly flat and light precision rotary tables of the DMN series are suited to all applications in which high rigidity and accuracy are needed along with the smallest dimensions possible. Typical areas of use include the manufacture of LEDs, solar cells and semiconductors. The zero-maintenance DMN rotary tables use precision bearings and optical encoders to achieve very high positioning and repeat accuracy. Key features: Backlash-free and extremely dynamic Extremely flat design Integrated rotary encoder Typical applications: LED manufacture and testing Production of solar cells Manufacture of semiconductor components 4.2 Order code for DMN rotary tables DM N 7 1 E Torque motor Type: N: Rotary table complete, flat design Outer diameter [mm]: 4: 118 7: 18 9: 23 Distance measuring system: E: Encoder Rotor height [mm]: 1: 1 2: 2 3: 3 18

19 4.3 Technical data for DMN Technical data for DMN42 Torque-speed curve (DC bus voltage: 32/56 VDC) Torque [Nm] 5. Tp 4. Tc 3. DMN , Speed [rpm] Table 4.1 Technical data for DMN42 HIWIN rotary tables Technical data of rotary table Symbol Unit DMN42 Peak torque (for 1 sec.) T p Nm 4.2 Continuous torque T c Nm 1.4 Stall torque T s Nm.98 Inertia of rotating parts J kgm 2.3 Weight M m kg 2 Max. axial load F a N 6 Max. radial load F r N 6 Max. moment of tilt M k Nm 3 Nominal speed (at 4 VAC) n 1/min 7 Position accuracy arcsec ± 45 Repeatability arcsec ± 2.5 Radial run-out mm.3 Axial run-out mm.3 Height H mm 45 Protection class Technical data of motor Peak current (for 1 sec.) I p A eff 4.5 Continuous current I c A eff 1.5 Motor constant K m Nm/ W.4 IP4 Resistance 1) R 25 Ω 4.59 Inductance 1) L mh 8.18 Electrical time constant T e ms 1.8 Torque constant K t Nm/A eff.97 Back emf constant K u V eff /(rad/s).56 Number of poles 2p 16 Thermal resistance R th C/W 4.84 Thermal time constant T th s 1,17 Thermal sensor PTC SNM 1 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line Encoder specifications (optical, incremental) 2,48 lines/cycle Index mark Signal output sin/cos 1 V PP TM-6-2-EN-29-K 19

20 HIWIN rotary tables DMN Dimensions of the DMN42 HIWIN rotary table (For values, see Table 4.1) M k F r F a (145.5) Ø86h7.3 A Ø12 thru ±.3 A 4-Ø6.6 thru; Ø11 11DP (Stator fixation) 2-Ø5 H7 thru Ø5H7 7DP; PCD 75 Encoder connection 92 Motor connection Marker Home position 6-M5.8P 8DP; PCD 75 (Rotor fixation) 2

21 4.3.2 Technical data for DMN71 Torque-speed curve (DC bus voltage: 32/56 VDC) Torque [Nm] 12 Tp 1 Tc 8 6 DMN , Speed [rpm] Table 4.2 Technical data for DMN71 HIWIN rotary tables Technical data of rotary table Symbol Unit DMN71 Peak torque (for 1 sec.) T p Nm 11.1 Continuous torque T c Nm 3.7 Stall torque T s Nm 2.59 Inertia of rotating parts J kgm 2.8 Weight M m kg 3.5 Max. axial load F a N 1, Max. radial load F r N 1, Max. moment of tilt M k Nm 5 Nominal speed (at 4 VAC) n 1/min 6 Position accuracy arcsec ± 45 Repeatability arcsec ± 2.5 Radial run-out mm.3 Axial run-out mm.3 Height H mm 5 Protection class Technical data of motor IP4 Peak current (for 1 sec.) I p A eff 1.2 Continuous current I c A eff 3.4 Motor constant K m Nm/ W.6 Resistance 1) R 25 Ω 2.55 Inductance 1) L mh 9.2 Electrical time constant T e ms 3.5 Torque constant K t Nm/A eff 1.9 Back emf constant K u V eff /(rad/s).63 Number of poles 2p 16 Thermal resistance R th C/W 1.7 Thermal time constant T th s 1,42 Thermal sensor PTC SNM 1 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line Encoder specifications (optical, incremental) 2,48 lines/cycle Index mark Signal output sin/cos 1 V PP TM-6-2-EN-29-K 21

22 HIWIN rotary tables DMN Dimensions of the DMN71 HIWIN rotary table (For values, see Table 4.2) M k F r F a (212) (Ø18) Ø15 h7.3 A ±.3 A 14 4-Ø6.6 thru; Ø11 7DP (Stator fixation) Ø35 thru 2-Ø6 H7 thru Ø5 H7 7DP; PCD 16 Encoder connection 14 Motor connection Marker Home position 6-M5.8P 8DP; PCD 16 (Rotor fixation) 22

23 4.3.3 Technical data for DMN93 Torque-speed curve (DC bus voltage: 32/56 VDC) Torque [Nm] 45 4 Tp 35 Tc 3 25 DMN Speed [rpm] Table 4.3 Technical data for DMN93 HIWIN rotary tables Technical data of rotary table Symbol Unit DMN93 Peak torque (for 1 sec.) T p Nm 39.6 Continuous torque T c Nm 13.2 Stall torque T s Nm 9.24 Inertia of rotating parts J kgm 2.12 Weight M m kg 7.5 Max. axial load F a N 1, Max. radial load F r N 1, Max. moment of tilt M k Nm 5 Nominal speed (at 4 VAC) n 1/min 5 Position accuracy arcsec ± 45 Repeatability arcsec ± 2.5 Radial run-out mm.3 Axial run-out mm.3 Height H mm 55 Protection class Technical data of motor IP4 Peak current (for 1 sec.) I p A eff 1.2 Continuous current I c A eff 3.4 Motor constant K m Nm/ W 1.5 Resistance 1) R 25 Ω 4.3 Inductance 1) L mh 23.2 Electrical time constant T e ms 5.4 Torque constant K t Nm/A eff 3.9 Back emf constant K u V eff /(rad/s) 2.25 Number of poles 2p 22 Thermal resistance R th C/W 1.1 Thermal time constant T th s 1,7 Thermal sensor PTC SNM 1 Max. DC Bus V 6 All the specifications in the table (except dimensions) are in ± 1 % of tolerance at 25 C ambient temperature 1) Line-to-line Encoder specifications (optical, incremental) 3,6 lines/cycle Index mark Signal output sin/cos 1 V PP TM-6-2-EN-29-K 23

24 HIWIN rotary tables DMN Dimensions of the DMN93 HIWIN rotary table (For values, see Table 4.3) M k F r F a.3 B.3 A (Ø23) Ø16h7 (.4) Ø35 Marker Home position 2 ±.5 18 ±.1 2-Ø8H7 ( ) thru Encoder connection (47.6) 15 ±.5 18 ±.1 ( 212) ± A 8-M5.8P 1DP; PCD 15 ±.1 (Rotor fixation) 4-Ø15 14DP; Ø9 thru (Stator fixation) +.15 Motor connection 45 TYP (142.5) ±.5 Ø5H7 ( +.12 ) 7DP 24

28 We live motion. Linear Guideways Ballscrews Linear Axes Linear Axis Systems Torque Motors Robots Linear Motor Components Drives & Servo Motors Germany HIWIN GmbH Brücklesbünd 1 D Offenburg Phone +49 () Fax +49 () info@hiwin.de Taiwan Headquarters HIWIN Technologies Corp. No. 7, Jingke Road Taichung Precision Machinery Park Taichung 4852, Taiwan Phone Fax business@hiwin.tw Taiwan Headquarters HIWIN Mikrosystem Corp. No. 6, Jingke Central Road Taichung Precision Machinery Park Taichung 4852, Taiwan Phone Fax business@hiwinmikro.tw France HIWIN GmbH 4, Impasse Joffre F-6722 Wolfisheim Phone +33 () info@hiwin.fr Italy HIWIN Srl Via Pitagora 4 I-2861 Brugherio (MB) Phone Fax info@hiwin.it Poland HIWIN GmbH ul. Puławska 45a PL-2-81 Warszawa Phone Fax info@hiwin.pl Switzerland HIWIN Schweiz GmbH Eichwiesstrasse 2 CH-8645 Jona Phone +41 () Fax +41 () info@hiwin.ch Slovakia HIWIN s.r.o., o.z.z.o. Mládežnicka 211 SK-171 Považská Bystrica Phone Fax info@hiwin.sk Czech Republic HIWIN s.r.o. Medkova 888/11 CZ-627 Brno Phone Fax info@hiwin.cz Austria HIWIN GmbH info@hiwin.at Netherlands HIWIN GmbH info@hiwin.nl Romania HIWIN GmbH info@hiwin.ro Slovenia HIWIN GmbH info@hiwin.si Hungary HIWIN GmbH info@hiwin.hu China HIWIN Corp. Japan HIWIN Corp. mail@hiwin.co.jp USA HIWIN Corp. info@hiwin.com Korea HIWIN Corp. Singapore HIWIN Corp. TM-6-2-EN-29-K

8613371530291

8613371530291