hofmann rotary table factory

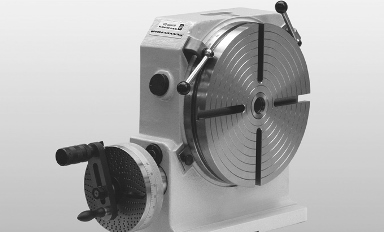

Manual precision rotary table with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications.

Additional direct indexing plate for the indexing plate device for all divisions up to 100 and higher ones, many up to 400, with included adjusting table.

Angled Rotary Table WR is a manual precision angled rotary tables in a compact, space-saving design with high rigidity have been designed for use with horizontal or vertical turning axis on machine tools or for measuring tasks. Its available in the types WR, WRI, WRD und WRDI .Rotary Tables RH are Manual Precision Rotary Tables with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications. Table plate has 200 mm diameter. The table is available in the types RH and RHI.

Hofmann Rotary Tables has developed a solid reputation for high-quality and affordable indexing devices, rotary tables, and tailstocks. Superior Spindle is proud to be a factory service partner for all, including the HPRS, HTH, R, and WR series.

When you experience issues with your Hofmann products, you can count on our ISO-certified and factory-trained technicians at Superior Spindle. We can repair all types of NC and manual indexing devices, tailstocks, and chuck stands.Our average turnaround time is usually between 10 and 14 business days.

Our Repair ProcessDisassembly & Free Evaluation: When you send your Hofmann rotary table to us, our team will fully disassemble it in our HEPA Class 10,000 cleanroom and evaluate all components for signs of wear and tear or damage.

Testing & Inspection: After repairs are complete, our team tests the rotary table to ensure optimal performance. Before your table is shipped back to you, our Quality Assurance team will perform a final inspection.

Shipping: All shipping and handling is covered by Superior Spindle. When you receive your newly refurbished table, we will provide you with a list of all components that were repaired/replaced as well as recommended maintenance.

Ourcutting-edge facility allows us to offer a wide array of additional services. Beyond our standard and expedited Hofmann rotary table repairs, we also provide vibration analysis, engineering recommendations, and retrofitting. Superior Spindle understands precision and is able to hold tolerances to 1 micron.

Superior Spindle has been a trusted provider of Hofmann rotary table repairs for over a decade and provides services to manufacturers throughout North America. If you’re experiencing issues with your rotary table, or are looking for design upgrade recommendations, call (734) 224-4778 orfill out our online formtoday.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

I am looking for a Soba 6" rotary table and a chuck adapter plate. Everywhere seem to be out of stock. Does anyone have a secret source or can offer advise on a suitable alternate that is in stock?

I"d look for second hand, sadly there are loads of engineering companies out there selling off top quality equipment at knock down prices. I don"t have a Soba rotary table but their products are, in my opinion at best average. Good luck with your quest though.

If you can afford the Vertex, it is made to a higher standard than Soba. I have a 6" Soba, bought privately, but in new condition, and the first thing I had to do was ditch the central needle roller bearing and turn up an aluminium bush. This was because I noticed a large ammount of radial play when the table was unlocked. I did not think 0.010" movement was reasonable, and who needs a needle roller bearing for the speeds at which a rotary table achieves. Now it works ok. As the table has four tee slots, a four jaw independent with front mounting is easy to fit. I have drilled and tapped holes for a 5" front mount Pratt Burnerd three jaw scroll chuck. This requires some thought, I made the mistake of drilling one of the holes into the drilling for lubrication, and had to re align all three. Now the holes are in the right place, fitting the chuck is easy, and with a test bar in the central Morse taper, and the chuck jaws lightly clamped on it before the screws are tightened, the chuck is centralised to about 0.002" tir which is good enough for my purposes. Having some short grub screws to put in the holes when the chuck is not fitted keeps the muck out of the works.

ps. I note that RDG Tools show a 6" "no brand" 3 tee slot rotary table here Apart from the 3 rather than 4 tee slots, it looks superficially like my Vertex unit.

On the assumption that the graduation lines are of equal width on both machines, an error in rotating the handwheel, of, just for the sake of argument, 1 degree will result in an error of 0.01111111 degrees in the table position.

A sip rotary table used in jig boring will have optical scales, but our scales are good enough for most jobs. The downside of a 90:1 worm ratio is the number of turns required to get anywhere. I prefer not to disengage the worm.

Handwheel markings and Verniers or Division Plates are merely different forms of graduation. What matters in terms of precision is the error, or lack of it, in the position of the Table. So the higher ratio results in less error (greater precision ) in Table position for a given error in the input.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

8613371530291

8613371530291