hofmann rotary table free sample

I have the 8” with plates. Don’t use the plates often but easy to fit, otherwise they normally they get in the way but ok when used. I would have liked it to work in vertical mode, but I have a good vertex dividing head so no problem here. it’s certainly is a brilliant bit of kit. The thrust bearing under the table is huge. It’s smooth and accurate. Best bit of kit I have. Same t slots as a myford, but parallel 20 mm bore centre. So no mounting stubby morse tapers but I now have a range of dedicated centres..

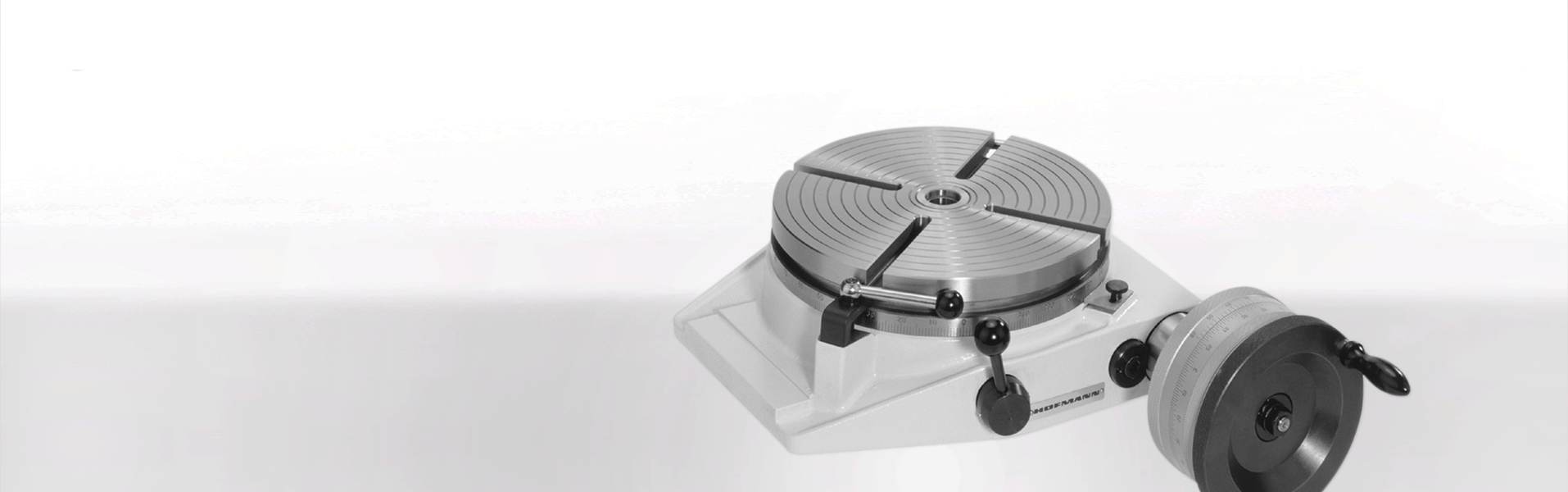

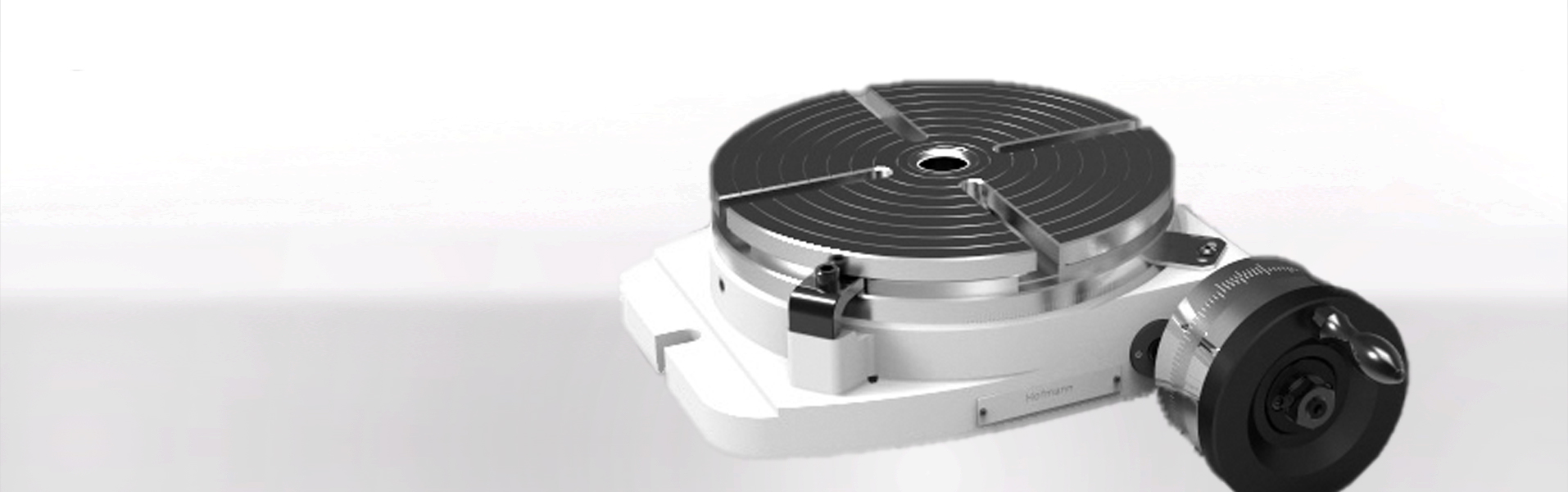

Angled Rotary Table WR is a manual precision angled rotary tables in a compact, space-saving design with high rigidity have been designed for use with horizontal or vertical turning axis on machine tools or for measuring tasks. Its available in the types WR, WRI, WRD und WRDI .Rotary Tables RH are Manual Precision Rotary Tables with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications. Table plate has 200 mm diameter. The table is available in the types RH and RHI.

Manual precision rotary table with compact and space saving design. The high rigidity allows the use for machine tools as well as for measuring applications.

Additional direct indexing plate for the indexing plate device for all divisions up to 100 and higher ones, many up to 400, with included adjusting table.

Some are confused by thinking that a table with control unit should be called an indexer, it is in fact exactly the same as a rotary table, it will do all the same things in the same way, it is simply controlled from outside of the machine cabinet, but is connected to it by an interface cable.

Hofmann Rotary Tables has developed a solid reputation for high-quality and affordable indexing devices, rotary tables, and tailstocks. Superior Spindle is proud to be a factory service partner for all, including the HPRS, HTH, R, and WR series.

When you experience issues with your Hofmann products, you can count on our ISO-certified and factory-trained technicians at Superior Spindle. We can repair all types of NC and manual indexing devices, tailstocks, and chuck stands.Our average turnaround time is usually between 10 and 14 business days.

Our Repair ProcessDisassembly & Free Evaluation: When you send your Hofmann rotary table to us, our team will fully disassemble it in our HEPA Class 10,000 cleanroom and evaluate all components for signs of wear and tear or damage.

Testing & Inspection: After repairs are complete, our team tests the rotary table to ensure optimal performance. Before your table is shipped back to you, our Quality Assurance team will perform a final inspection.

Shipping: All shipping and handling is covered by Superior Spindle. When you receive your newly refurbished table, we will provide you with a list of all components that were repaired/replaced as well as recommended maintenance.

Ourcutting-edge facility allows us to offer a wide array of additional services. Beyond our standard and expedited Hofmann rotary table repairs, we also provide vibration analysis, engineering recommendations, and retrofitting. Superior Spindle understands precision and is able to hold tolerances to 1 micron.

Superior Spindle has been a trusted provider of Hofmann rotary table repairs for over a decade and provides services to manufacturers throughout North America. If you’re experiencing issues with your rotary table, or are looking for design upgrade recommendations, call (734) 224-4778 orfill out our online formtoday.

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

with the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Rotary tables have many applications, including being used in the manufacture and inspection process of important elements in aerospace, automation and scientific industries. The use of rotary tables stretches as far as the film and animation industry, being used to obtain accuracy and precision in filming and photography.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

8613371530291

8613371530291