horizontal boring mill with rotary table pricelist

The PowerTec horizontal milling machine is a modern floor-type boring mill. It is a "full hydrostatic machine" including all linear and rotating axes and the extendable hydrostatic boring ...

The HBW series from KAAST is a collection of CNC horizontal boring mills that feature either a fixed or moving column design paired with hardened and ground guideways. These machines are made of strongly ...

Boring Machine with the most unique technological innovations of any other, in order to meet the ever-growing need of precision. The INVAR s level of accuracy is unmatched by any machine of comparable size today.

Lymco CBA T-type HBM is configured with moving column and rotary table for efficient multi face machining of large size workpieces. With the stack effect of different axis, the CBA-TR column moving HBM can provide a more ...

The new high-performing machine WHT 130 is a horizontal boring machining centre suitable for the most demanding operations that require precise boring, threading, vertical lathing and/or milling. The ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

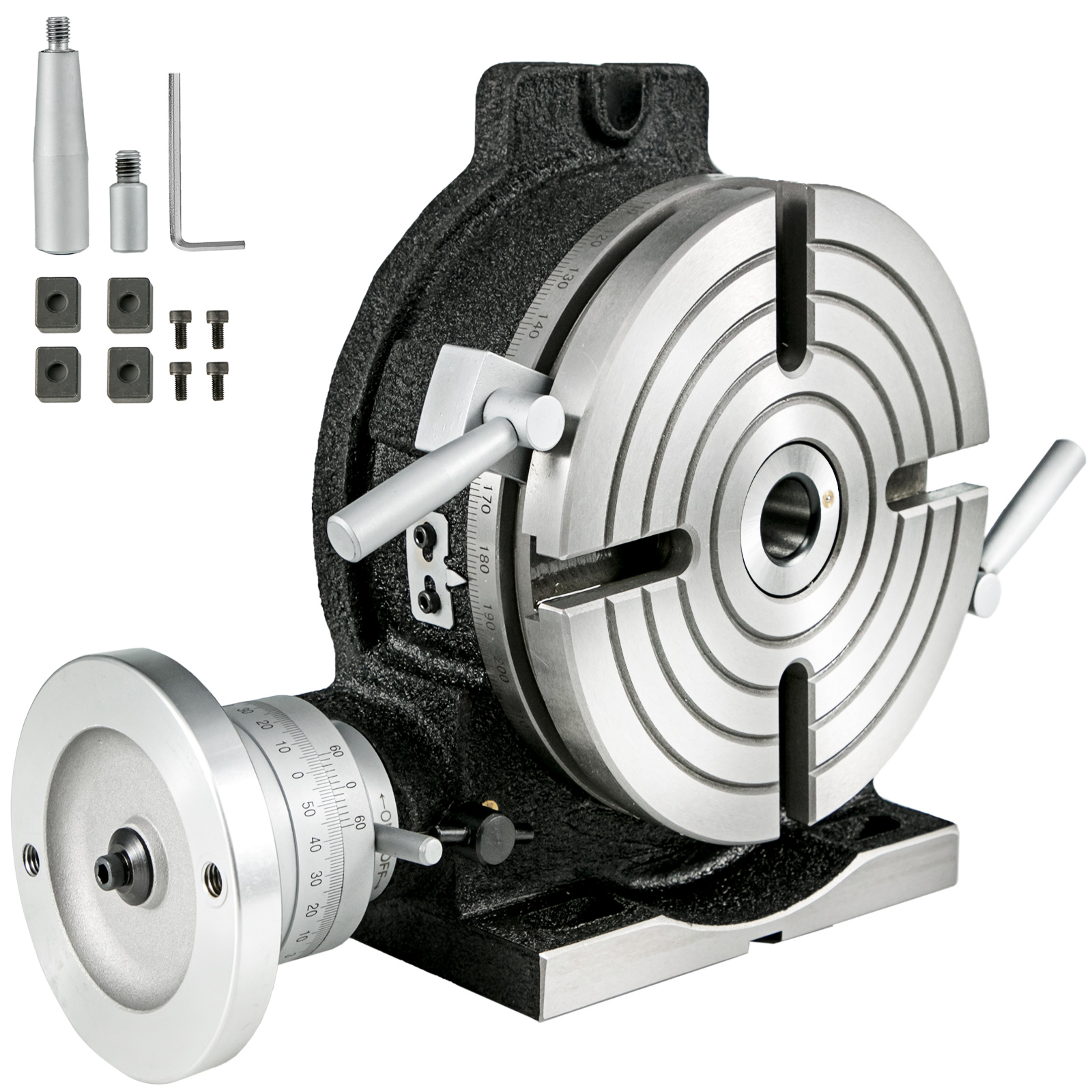

The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on.

Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice!

Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work.

It"s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial.

If you purchase our product, we are going to give you a free wrench, 2 positioning keys and screws. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences.

This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

Our dealer and auctioneer members offer the most extensive selection of used machinery in the world, with thousands of machines available in warehouses and plants across the globe.

Nomura Model B-85BT-2 Horizontal Boring Mill Table Type.3.35" Spindle Dia. 40" Vert, 20" spdl Travel, 40" Cross Travel, Rapid Traverse, 35.5" x 39" Rotary T Slot Table, Pendant Control, DRO

USED GIDDINGS AND LEWIS MODEL MC 50 TWIN PALLET HORIZONTAL MACHINING CENTRE WITH LIVE SPINDLE, 60 ATC AND G&L 8000A CONTROL SYSTEM. Serial # 445-1052.YEAR OF MANUFACTURE: 1987

X-travel: 2965mm, y-travel: 2000mm, z-travel: 1500mm, spindle diameter: 110mm, table dimensions: 1800x1500mm, max. load: 10t, controls: HEIDENHAIN TNC 355, with chip conveyor.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

This HBMs were numerous in Europe, and C&E mills are sturdy rigid machines, not known for many mechanical problems. They are a lot of heavy cast iron, in many aspects superior to many actual machinery.

It has a travelling colum, that makes for a large cross travel of the table. And it also has a large vertical travel, making it fit for machining large workpieces.

In the case of this machine, however, its important, because the machine has no rotary table. HBMs are often used for machining gearboxes or similar box type workpieces with holes on opposite sites which have to be aligned. With a precies rotary table and measurement equipment, You can manufacture this without outboard support. Its much faster and usually as accurate as with support and a long boring bar. In fact, I just once in my live used a long boring bar when I had to machine a spherical bore with a shopbulit tool on a wotan boring mill.

But it remains a big disadvantage of this machine that it has neither an outboard support nor an rotary table. So with those typical gearboxes you will get in trouble.

I dont think that to be a critical point. Many moden cnc type boring mills dont have fixed boring slides. You can attach a separate facing slide, ok, its a bit worse than a built-in one.

But, there are not many machining jobs that need one! Axial surfaces are today milled instead of turned, so the use of a facing slide is more or less limited to very large boring. If you have to bore 1ft or more in diameter, you could use it well; else it is an unused surplus.

I dont know the quality of DeVlieg machines, though I often had red about that brand. But Collet&Engelhardt are one of the top boring mill manufacturers in Germany - probably no better and no worse than US top machines.

One thing to remember, it"s probably a metric machine. Some conventional boring mills have a threading attachment as an option. If this machine has it, its questionable whether you can machine all the standard inch threads with it; the gear options on boring mills are usually limited compared to a good lathe.

3.TIME OF PAYMENT – All invoices must be paid in full within 48 hours of the sales conclusion. Any other arrangements must be made with auctioneer prior to bidding. If not, the merchandise will be deemed abandoned and Buyer will lose any right, title or interest Buyer may have acquired and the merchandise shall revert and repossess to Auctioneer without further notice to Buyer and the transaction shall be null and void as to Buyer.

4.REMOVAL - All purchases must be removed not later than the date specified in the Auction Catalogue and/or announced on the website. In any case, No later than 14 days after the close of the sale. . All goods are sold “Where Is”. Removal shall be at the expense, risk and liability of the Buyer. Purchases will be delivered only on presentation of paid bill. Auctioneer shall not be responsible for goods not removed within the time allowed, but shall have the option to remove and store at the expense and risk of the Buyer any article purchased, but not paid for and removed within the time aforesaid.

5.MANNER OF PAYMENT –All payments must be made by cash, cashier’s check or company check with a bank letter of authorization guaranteeing funds to Cincinnati Industrial Auctioneers, Inc. All checks for deposits and balances due shall be payable to the order of “Cincinnati Industrial Auctioneers, Inc." All invoices must be paid to the Auctioneer at the office address 2020 Dunlap St. Cincinnati, Ohio 45214 unless otherwise announced. The full purchase price on all lots sold to the same Buyer must be paid within the time fixed and before removal of any goods. The Auctioneer does not accept any form of credit card for payment.

6.CONDITION OF ARTICLES SOLD – The auctioneer shall not be responsible for the correct description, genuineness, authenticity of, or defect in any lot, and makes no warranty in connection therewith. No sale will be set aside nor allowance made on account of any incorrectness, error in commentary, cataloging, or any imperfection not noted. No deduction allowed on damaged articles, all goods being exposed for public exhibition, are purchased and accepted by Buyer “AS IS”, “WHERE IS” and “WITH ALL FAULTS”. Auctioneer makes no warranties or guarantees whatsoever whether written, oral or implied as to quality, quantity, condition, usability, salability, weight, measurement, year, model, mechanical condition, performance or other specifications and without recourse.

9.COMPLIANCE WITH TERMS OF SALE– In default of payment of bills in full within the time therein specified, the auctioneer in addition to all other remedies allowed by law, may retain all monies received as deposit or otherwise, as liquidated damages. Lots not paid for and removed within the time allowed herein may be resold at public or private sale without further notice, and any deficiency, together with all expenses and charges of re-sale, will be charged to the defaulting purchaser.

11.ADDITION TO OR WITHDRAWAL FROM SALE– The auctioneer reserves the right to alter the order of the sale, withdrawal from the sale any of the property listed or to sell at this sale property not listed, and also reserves the right to group one or more lots into one or more selling lots or to subdivide into two or more selling lots. Whenever the best interest of the Seller will be served, the Auctioneer reserves the right to sell property listed, in bulk.

19.SHIPPING – All coolants, oil and fluids must be drained from all machinery and equipment prior to removal. All of the above must be shipped in compliance with state and federal regulations.

20.INSURANCE – All buyers, or the buyer’s riggers must provide the auctioneer, owner and landlord a certificate of insurance in amounts acceptable to the above parties prior to removal of any machinery and equipment.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Technical data: - center distance 1500 mm- center height 400 mm- max. machining diameter FI 400 mm- motor power 4,0 kW- voltage 400 V / 50 Hz- spindle speed 3000 rpm- number of controlled axes 3- guide linear guides and ball screw- control MACH3 + software- pneumatic workpiece clamping- V-shape steel- milling spindle for flat engraving- compressed air supply 6 bar- dimensions L=2700, W=1400, H=1750 mm- net weight 1800 kg

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

8613371530291

8613371530291