horizontal spindle rotary table surface grinder factory

Most other rotary table surface grinder manufacturers use conventional thrust roller bearings for their rotary table slide. Thrust roller bearings deliver inferior precision, as well as shorter service life due to their low resistance against wear and tear from prolonged use. As a result, grinders that use thrust roller bearings also require frequent repairs and replacements of the bearings.

As a superior alternative, our table slides use metal rings that are processed with our scraping techniques and fabricated with grooves for the lubricant oil. This technique delivers table surface rigidity against vibration to nearly 0 mm with sustained performance for an extended period, which reduces the need for regular maintenance.

Scraping technique is also applied to our box way of x-axis transfer slide to achieve superior parallelism and flatness of table surface. This differs from the LM-guide way for the x-axis that is widely used by other manufacturers. LM-guide ways have a transfer precision of roughly 0.005mm to 0.01mm on the grinder’s wheels and table and are unable to deliver high precision level. Moreover, the LM-guide requires frequent maintenance to adjust for the LM-guide’s loosened balls. By using our scraping techniques, LPR Global’s box way overcomes these shortcoming to deliver a <3㎛transfer precision of table and wheel and maintain high precision levels for an extended service life.

PERFECT PFG-R Rotary Surface grinders are equipped with a Horizontal Spindle to ensure the most precise and accurate grinding operations are undertaken. With rotary tables allowing a ground capacity from 200mm to 400mm across four models. The PFG-R Series utilise the established saddle type construction used within the current product range.

PGI Steel maintains several vertical and horizontal spindle reciprocating grinders that can handle extremely long parts or many parts at a time. These grinding machines can handle extremely long parts, up to 220″ long. They can also handle many parts at a time, which allows us to provide excellent pricing for large quantity runs. All of these machines produce high accuracy and are especially suited for grinding long steel bars – , , HR steel bar, and tool steel bar.

Our 36″ x 168″ Mattison grinder 400-S has the capacity to produce ground parts up to 24″ tall. Our second, unique, 48″ x 200″ Mattison 400-S reciprocating grinder has further been modified with a 415 HP motor and is fully capable of step grinding up to 240″, and in some cases 260″. This motor allows us to add pressure while slowing down the feed rate which increases the efficiencies while preventing heat buildup and plate burning.

We produce surface ground parts to incredibly close tolerances. Many times we can reach ± .001 parallelism, ± .002 per foot flatness, and as normally requested, to within ± .001-.005 thickness. Our production grinders along with our qualified machine operators allow us to grind these surfaces for you right the first time.

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.Visit Site

Since May 2020, the brand ISOG belongs to the globally active Precision Surfacing Solutions Group. With the addition of ISOG to the already existing strong brands within the Group, PSS further strengthens its position as a leading supplier of high quality, best in class technologies in the market of surface quality enhancement solutions.Visit Site

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".Visit Site

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.Visit Site

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.Visit Site

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.Visit Site

Since May 2020, the brand ISOG belongs to the globally active Precision Surfacing Solutions Group. With the addition of ISOG to the already existing strong brands within the Group, PSS further strengthens its position as a leading supplier of high quality, best in class technologies in the market of surface quality enhancement solutions.Visit Site

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".Visit Site

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.Visit Site

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.Visit Site

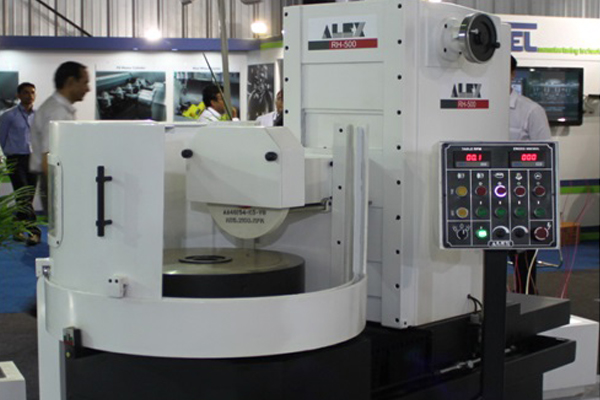

PINNACLE-make PHRC series Horizontal Spindle Rotary table surface grinding machines are 2 Axes CNC-Controlled High Precision surface grinding machines which has different table size of 500 mm, 800 mm, 1100 mm & 1500 mm.

PHR CNC series machines are suitable for grinding High precision thin & circular parts. In case where High Production of parts are required with high quality, precision & good surface finish in much lesser time, these machines are the perfect alternate to Horizontal Spindle Reciprocating table Surface grinding machines.

Rotary Movement i.e. X-Axis is Hydrodynamically lubricated table with heavy load capacity, neglecting the wear & tear of guide ways and inaccuracy caused by rotary wobble.

Grinding Spindle-Cartridge is assembled with Imported SUPER PRECISION BEARINGS grease packed with Imported Grease filled for Life for long trouble-free service.

We always insisted on the management concept of"Customer first,quality first,service first".Ample supply of the company can ensure the long term and excessive supply,and stable quality,reasonable price.We sincerely welcome you to visit our company and contact us for cooperation.

Alibaba.com offers 88 rotary table surface grinder machine products. About 42% % of these are surface grinding machine, 38%% are other grinding machine.

A wide variety of rotary table surface grinder machine options are available to you, such as manufacturing plant, machinery repair shops and construction works .You can also choose from 1 year, unavailable rotary table surface grinder machine,As well as from provided, {2}, and {3}. and whether rotary table surface grinder machine is russia, mexico, or indonesia.

A wide variety of rotary table surface grinder options are available to you, such as manufacturing plant, machinery repair shops and construction works .You can also choose from 1 year, unavailable rotary table surface grinder,As well as from provided, {2}, and {3}. and whether rotary table surface grinder is russia, mexico, or indonesia.

Grinding area 1000 x 450 mm, rotary table diameter 1000 mm, grinding wheel 400 x 100 x 127 mm, spindle power 11 KW, magnetic clamping plate diameter 1000 mm, coolant system with paper belt filter, user-friendly operation with Mitsubishi SPS control, alternatively SIEMENS 828 CNC control, new machine, approx. 30 weeks delivery time.

Kehren RIW9 CNC rotary table surface grinding machine Max workpiece diameter 900mm x 500mm height complete with internal grinding spindle it can be inspected in our warehouse in Gussago BS Italy Mimu Machine Tools

Table Diameter 36″ (915mm). Segmental Wheel Dia. 22″ (559mm) Max. Height Capacity 11″ (280mm). Grinding Spindle Speed 700rpm. Table Speed 8 & 24rpm. Auto Feed 0.004-0.04 ins/min 0.1-1.0 mm/min. Spindle Motor 40HP (30Kw)

The Double Disc Grinder YHDM580B/5 can process high efficiency and precision grinding of the upper and lower parallel discs of all kinds of metal and non-metal thin parts (bearings, valves, aluminum alloy plates, seals, oil pump blades, piston rings, etc.) with irregular shape and round shape.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

•Access to work table is unique, in that a greater proportion of the work table is opened for easier and safer work handling. Being a fixed centre table the initial accuracies are maintained for the entire life of the machine.

This series features the well proven program of surface grinders with rotary tables. These machines are particularly suitable for High precision surface grinding on thin parts of accuracy and circular parts where one piece is to be ground at a time flat or with a radial taper. Besides, in applications where batches of small parts are to be ground with a high degree of parallelism and high surface finish this type of machines is a better alternative to a reciprocating machine as production time will be much less. This is because the grinding wheel is in constant touch with the grinding pieces are higher and the work pieces work constantly in one direction only.

Rotary Surface GrinderOur product range includes a wide range of ailpa rotary surface grinder, rotary surface grinder machine, mc 1100 rotary surface grinder, rotary surface grinder delta, blohm rotary surface grinder and horizontal spindle rotary surface grinder favretto.

Since its establishment in 1996, Dowell surface grinder manufacturer has held the company philosophy of "Keep & Improving". We always listen to customers" demands and devoted to R&D to build better Grinders. Dowell produces a wide range of grinding machines including manual, semi-auto, auto, NC and CNC, double column grinding machineand rotary surface grinder. Furthermore, we also develop precision rack grinder and high precision multi-function (vertical and horizontal) grinding machine. Dowell is committed to providing customers the highly sophisticated products and services. Learn more details, please come and visit Dowell right away!

8613371530291

8613371530291