how does a rotary table work quotation

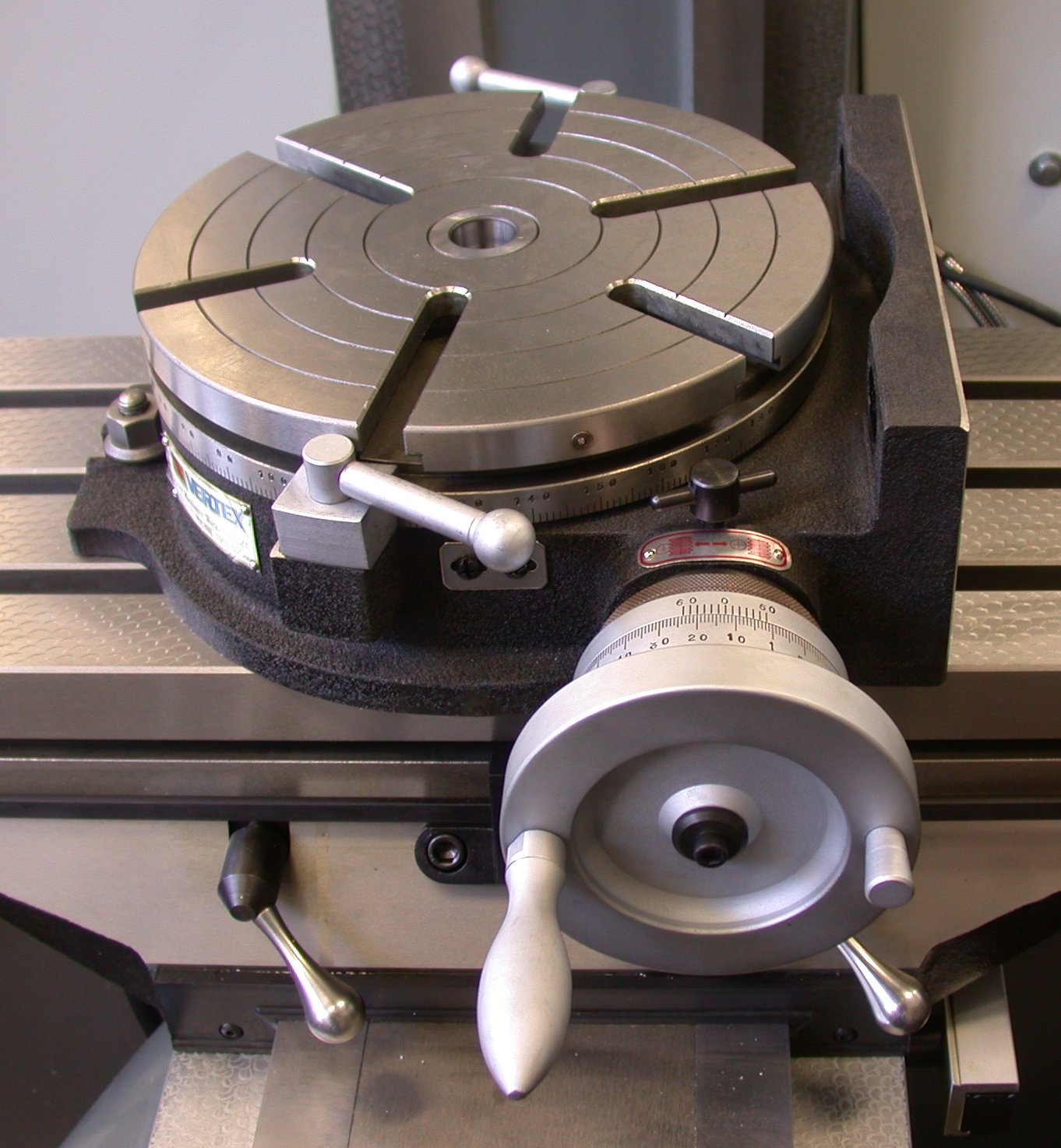

A rotary table is a precision device that is ideal for work positioning. Such table is used in metal works as it makes the job of drilling easier for the metal worker. Other than this, the metal worker can also cut the piece on fixed axes during specific interval with the help of a rotary table. Rotary Tables are available in varieties. Some of these tables use indexing plates for operations related to indexing whereas, others enables the user to fit dividing tables and leads to a better work positioning.

What make rotary tables important for metal industry are its numerous uses. Here is a list of few: Rotary tables are used for machining spanner flats on bolts. For cutting round pieces. For drilling holes at equal distance on circular flanges. A metal worker can also create large diameter holes on milling machines with these tables. Rotary tables are also used for cutting complex curves and mixing helixes.

There are different parts and components in rotary tables and all have different functions. Work table is the most important part of the table. It has spherical working area with four t-slots, which are used for mounting work pieces. There is a clank handle on rotary tables that enables the user to rotate the tables in clockwise and anti-clockwise directions. Rotary tables also have two bases, one is meant for vertical rotation whereas the other one is meant for horizontal rotation. At times, rotary tables are also mounted flat on planes similar to the way cutters are placed on vertical milling machines. If we look closely, rotary tables play a crucial role in the metal industry. Because they are used to perform different jobs, there is a specialized variety of rotary table to meet industry specific needs.

Located at the entrance of a conveyor belt, or directly to the machine that has to feed, performs the function of “station of accumulation and distribution”. The products can be loaded manually or by conveyor belt. The adjustable deflectors allow you to sort and align products to the food evenly and without interruption the machine that receives them. Positioned at the exhaust of a conveyor belt or in the output of a packaging machine, filling machine, labeling etc., Performs the collection and accumulation of products function. The rotary tables are equipped with a speed variator to adapt to the various needs. The rotating disc may be provided in a slippery plastic material or stainless steel.

Methods & Equipment works with several manufacturers of rotary tables: Tsudakoma, Nikken, Yuasa and more. Give us a call or fill out the RFQ if you would like a quote on any of the high speed rotary tables, direct drive rotary table, or the new ball drive rotary table with zero backlash.

RT industrial rotary indexing table was designed to be fixed to your work table so it can be used for various shop applications such as drilling, milling, grinding and locating angles applications.

Keeping replacement parts on the shelf is import to keep your equipment going. We recommend have a few replacement parts for this indexing fixture click here to be take to it’s online store.

Like the rest of the equipment that Kalamazoo Industries manufacturers this indexing fixture with 6 inch chuck is manufacturer right here in Kalamazoo, MI 49048.

A rotary table is a mechanical device on a drilling rig that provides clockwise (as viewed from above) rotational force to the drill string to facilitate the process of drilling a borehole. Rotary speed is the number of times the rotary table makes one full revolution in one minute (rpm).

Quote from video: I"m gonna use the spindle with a dial indicator to Center it up once I"m on center I"m gonna clamp down and then. I can offset the milling machines table by the proper.

A rotary engine is an internal combustion engine that separates an engine’s four jobs — intake, compression, combustion, and exhaust — into four individual parts within the overall engine housing. The rotor moves from chamber to chamber, expanding and contracting gas.

There are two groups of big rotary drilling: (1) rotary crushing by high-point loading to the rock from three cones, as shown in Fig. 7.7a, and (2) rotary cutting by shear force from drag bits, as shown in Fig.

A conventional rotary rig or rotary table rig or kelly drive rig is a drilling rig where the rotation of the drill string and bit is applied from a rotary table on the rig floor.

A rotary table is a disc-shaped metalworking device used to obtain precise workpiece positioning. It enables a metalworker to cut or drill a workpiece at precise intervals around a vertically or horizontally fixed axis.

Quote from video: That"s how it"s much better so just install it in a collet. Okay then run run your tool down until it goes into the bore of the rotary. Table. All the way down until it starts to Snug.

A rotary steerable system (RSS) is a form of drilling technology used in directional drilling. It employs the use of specialized downhole equipment to replace conventional directional tools such as mud motors.

A rotary joint, also referred to as a rotary union or rotating union, is a rotary sealing device that connects rotating equipment to fixed piping for the transfer of steam, water, thermal oil, coolant, hydraulic oil, air, and other media.

BALL DRIVE TABLE. Unlike the worm drive, these tables have zero backlash and maintenance, higher speed indexing, higher accuracy, and higher rigidity. …

A rotary indexing table is specifically designed to make repetitive moves around a platform. Essentially, they are highly precise work-positioning devices that index parts to be worked or machined in multiple operations.

With the face horizontal, it has been used to mill curved slots, and could be used equally well to put a radius on the end of a workpiece. If you want to choose between one or the other, the rotary table can be set at any angle, but a dividing head cannot.

A milling table is a part of a standard milling machine. The table is an important part of the machine’s function and is featured on every complete milling machine. The milling table is where a worker sets his work piece in order to mill it with the attached milling head.

Indexing is an operation of dividing a periphery of a cylindrical workpiece into equal number of divisions by the help of index crank and index plate. A manual indexing head includes a hand crank. Rotating the hand crank in turn rotates the spindle and therefore the workpiece.

The workpiece is held on a worktable of the machine. The table movement controls the feed of the workpiece against the rotating cutter. This cutter is fixed on a spindle or arbor which revolves at desired speed.

There are five roll systems in a flour mill: break, sizing, midds (for middlings), low grade, and residue. In the break system, the kernel is opened, the bran flattened and the endosperm broken into large chunks.

The F1300N provides a simple and efficient method of dispensing a circular pattern on areas that can sometimes be difficult to access. The Z-axis tilt is easily and quickly adjusted for controlled rotary dispensing at a fixed angle, onto a vertical wall within a cylindrical part or on an outside wall or top surface.

Alternatively, the machine can be configured into an index mode, whereby multiple parts can be positioned equally dispensed apart from each other in a single circular pattern. When initiated, the machine will dispense onto a component in a fixed position, and when complete will rotate at a fixed indexing angle in order to dispense onto the next part.

The fully programmable intuitive touchscreen user display allows dispense parameters (i.e. dispense angle, pre and post dispense time and rotation speed) and machine settings to be quickly changed and simultaneously viewed on the home screen.

Technitron has been integrating rotary tables and accessories on machine tools since 1992. Over the past 30 years Technitron has pioneered new technology and techniques to allow us to set the industry standard for rotary table and accessory integrations. By utilizing our vast experience, we have been able to meet and exceed our customers’ expectations. No other company has our experience on a variety of machines and controls.

Technitron is dedicated to supplying high quality Integration Services to the Machine Tool Industry. Our Turn-Key Integration Services are designed to enhance the productivity from both new and existing machine tools. We have installed more than 3500 rotary tables to date.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Dimensions and openings on rotary tables vary greatly from manufacturer to manufacturer. To assist you in measuring, we have provided drawings to guide you. Click on the type of rotary below. A new window will open displaying the rotary as well as the standard measurements for each size of that rotary. If your rotary is not a standard size, print out the drawing and fill in all necessary dimensions. Once completed, email us the drawing and we will work up a price quote for you. If you have any questions, please give us a call at 281-482-8668, and we would be happy to help you.

Lagun’s BM RT is a bed type mill with C-Axis rotation and equipped with a rotary table. With a compact and robust design, this milling machine is ideal for machining bulky workpieces on all 5 sides.

Lagun’s BM RT mill is built with a modular configuration, which means all models in this spectacular line have interchangeable slides, rams and columns. This design method endows each machine with enhanced rigidity, precision and ergonomic working comfort for the operator.

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The hardy table, measuring at 63” x 47” (1600mm x 1200mm), column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges.

*Note: Interested in more bed type milling machines? Take a look at our BM-C and BM-BL bed mills. Or browse all machining centers offered by Lagun Engineering here.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

Smaller versions can be used to power joints in robots for automation, powering pick-and-place applications, material handling, packaging and handling as well as servomechanism applications

ABTech’s line of precision mechanical rotary tables address the motion needs for a full range of part sizes and weights. High precision angular contact bearings are incorporated into stages that are designed and manufactured in-house to extremely tight geometric tolerances. The result is superior performance in radial, axial, and angular (tilt/coning) error motions.

Mechanical rotary tables are used in a wide range of applications and are ideal as stand-alone units and/or multi-axis assemblies, cylindrical part staging, TIR Inspection, for assembly and alignment tools, position measurements, optical scanning, light machining and grinding, and more.

Precision motion comes in many forms and applications, each with its own set of pertinent specifications. Diversity in today’s applications creates unique requirements, we provide configuration flexibility as an integral part of our design philosophy. All rotary tables can be customized with a variety of options and accessories. This includes motor drives, vacuum worktables, high-resolution optical encoders, digital readout (DRO) displays, inspection-grade granite surface plates, and more.

In addition to the options and accessories, material selection is a key focus of our applications engineers. For harsher environments, best accuracy, precision, and stability we use 440 hardened stainless-steel components. Focused on cost, ABTech will utilize the efficiencies of hard-coated aluminum construction. Our precision motion experts will work closely with you to configure a rotary motion solution that will meet your exact needs.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

600 mm (23.6") Servo Rotary Table. Requires Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. Requires a Haas mill with software version 18.00 or later.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item so that we can evaluate the issue and make it right.

Certain types of items cannot be returned, like custom products (such as special orders or personalized items), and personal care goods (such as beauty products). We also do not accept returns for hazardous materials, flammable liquids, or gases. Please get in touch if you have questions or concerns about your specific item.

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

8613371530291

8613371530291