how to use a rotary table and dividing plates manufacturer

One of the programs included with the DIVHEAD archive on my webpage allows you to calculate the hole plates required for any number of divisions up to an input maximum. Below are the results of that program for rotary table gear ratios of 40, 80 and 90 assuming one wants the ability to make all divisions up to 50.

These solutions are minimum hole drilling solutions so it"s possible that some of the lower number divisions could be accomplished with a single circle of holes at the expense of drilling more holes. For example, the 4 and 6 hole circles in the 40:1 solution could be accomplished with a single hole circle of 12 holes or some integer multiple of 12 holes.

This plate can be used either directly, or through a geared dividing mechanism. In direct indexing the workpiece and plate rotate in a 1-to-1 ratio, and holes are used directly. That is, a plate with 12 holes can divide the workpiece into 2, 3, 4, 6, or 12 equal segments. A dividing head incorporates an internal gear ratio (usually 40:1, 60:1, or 90:1) with the same plates. In doing so, the dividing head enables many more combinations than just direct indexing.

For example, imagine a plate with 15 equally-spaced holes and a dividing head with a 40:1 gear reduction. In direct indexing, a workpiece could be divided into 3, 5, or 15 equal segments. Using the dividing head, the same workpiece could be divided into 2, 3, 4, 5, 6, 8, 10, 12, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200, 300, or 600 segments. Essentially, the dividing head acts as if it’s a direct indexer with 600 holes; 15 holes in the actual plate * 40:1 gear ratio. Let’s look at how some of these combinations are possible.

I have an 8" Rutland horizontal/vertical RT made in Taiwan that is about all I want to carry around without mechanical help. It has done all I ask of it, and a larger fixture plate mounted to the top of the table could be up to any diameter I care to make it. It is a high quality RT, and I am happy with it. Just went out and weighed it on a bathroom scale, said ~55 pounds. I also recently picked up a beautiful old adjustable height tailstock for it. It is also very heavy and solid, maybe 25 pounds.

I also have a 6" swing dividing head (no maker"s mark, WWII?) with two sets of three dividing plates, two D.E. Whiton 1-3/4" 8 tpi mount chucks (3 and 4 jaw, also marked Rivett!}, and #9 B&S spindle tooling for it as well, and a mill mounting table adapter plate that holds the dividing head and the tailstock to it for quick mounting to the mill table. Throw it on the mill, tighten 4 bolts, and it is ready to use, with less than .001" tolerance fit everywhere.

Given the choice between dividing head and rotary table, I vote for both! The jobs they do are mostly quite different, and one does not work for the other very well. In a pinch, yes, it can be done.

A rotary table can be divided automatically, according to the size of the table. Secondly, a kitchens can benefit from longevity and convenience. It is easy to use, a spice rack can help to organize items andlyize accordingly.

A server rotary plate can be used as an alternative to a standard rotary plate. It is easy to operate as a server rotary plate, it can be easily moved to the objects by rotating on them. The kitchenware can benefit from the different benefit of a rotary table dividing plate as it is easier to operate. It is environmentally friendly, dishwasher safe and drying, and can benefit from the advantage of a rotary table dividing.

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

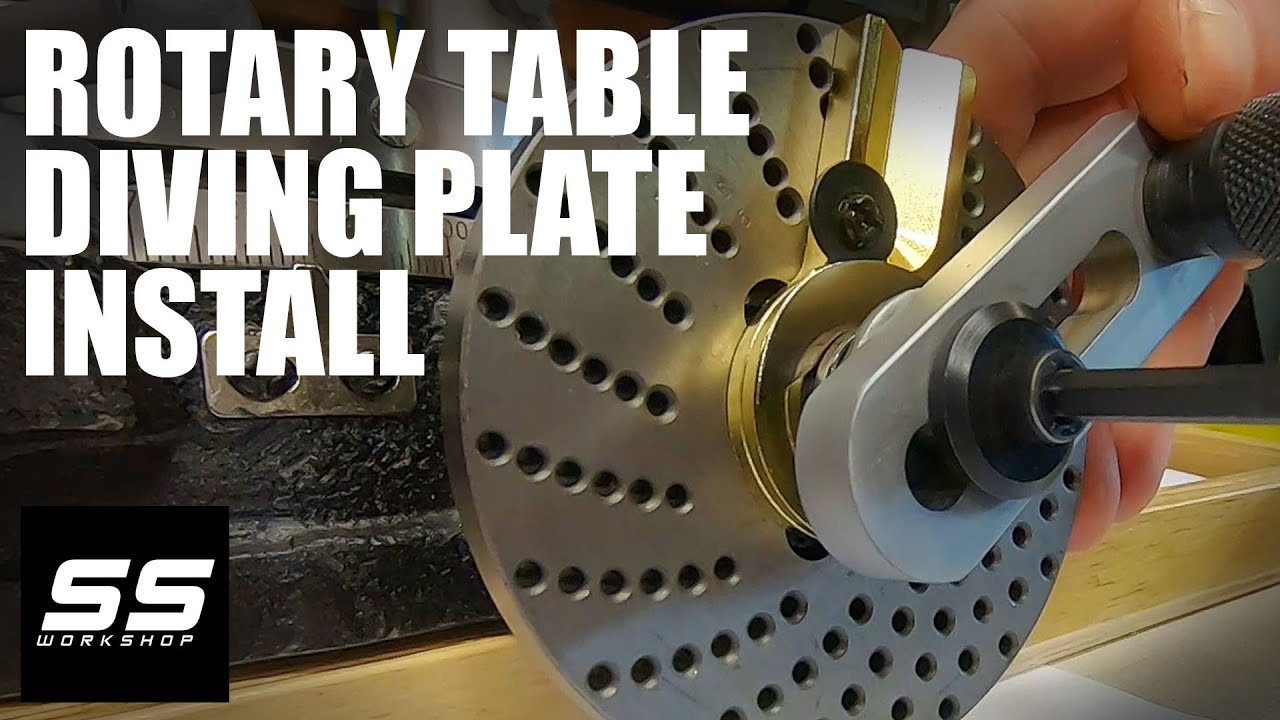

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

To create large-diameter holes, via milling in a circular toolpath, on small milling machines that don"t have the power to drive large twist drills (>0.500"/>13 mm)

with the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Rotary tables have many applications, including being used in the manufacture and inspection process of important elements in aerospace, automation and scientific industries. The use of rotary tables stretches as far as the film and animation industry, being used to obtain accuracy and precision in filming and photography.

Cut gears with your rotary table by using dividing plates (index plates) to get the exact divisions. You can also precisely divide a circle into a number of divisions or degrees, cut bolt hole circles, or mill polygons with the use of these dividing plates. 33-101 is a 3-piece set that fits on your 6" rotary table, 33-100. 33-106 is a 2-piece set that fits on your 8" rotary table, 33-105.

This item is backordered from our supplier. We will ship as soon as it is received. Your credit card will not be charged until shipped. Please Note: For shipments to locations outside the USA, backordered items must be placed on separate orders.Remove From Cart

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

PO Box, APO/FPO, Africa, Alaska/Hawaii, American Samoa, Armenia, Azerbaijan Republic, Bangladesh, Bhutan, Bosnia and Herzegovina, Brunei Darussalam, Cambodia, China, Cook Islands, Ecuador, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Greenland, Guam, Guernsey, Jersey, Jordan, Kazakhstan, Kiribati, Kyrgyzstan, Marshall Islands, Micronesia, Moldova, Mongolia, Montenegro, Nauru, Nepal, New Caledonia, Niue, Pakistan, Palau, Papua New Guinea, Republic of Croatia, Russian Federation, San Marino, Solomon Islands, Svalbard and Jan Mayen, Taiwan, Tajikistan, Tonga, Turkmenistan, Tuvalu, US Protectorates, Ukraine, Uzbekistan, Vanuatu, Venezuela, Vietnam, Wallis and Futuna, Western Samoa

8613371530291

8613371530291